Page | 9

6.0 Maintenance

The PermaSEAL Basement Sump and Pump System requires minimal maintenance, however it is strongly

recommended that the unit is serviced quarterly during the first year. It is essential that the unit is serviced at least

annually thereafter. To clean out the unit you must first turn off the power supply and ensure that it cannot be

inadvertently turned back on (i.e. remove the fuse). Now remove the access cover to gain access to the pump. Next

you must remove the pump from the tank by disconnecting the pipe work and lifting the pump out. It is advisable to

check the underside of the pump to ensure there is no build up of debris around the pump and the float switch as

this can often lead to poor pump performance or damage to the pump itself. You must also clean out the tank

ensuring that there is no debris in the bottom of the tank. Now that the tank is clean you must reconnect the pump

to the pipe work and check the function of the pump prior to replacing the access cover.

Please note that we recommend that the Alarm is tested monthly as per a fire alarm and the battery be replaced

every 2 years.

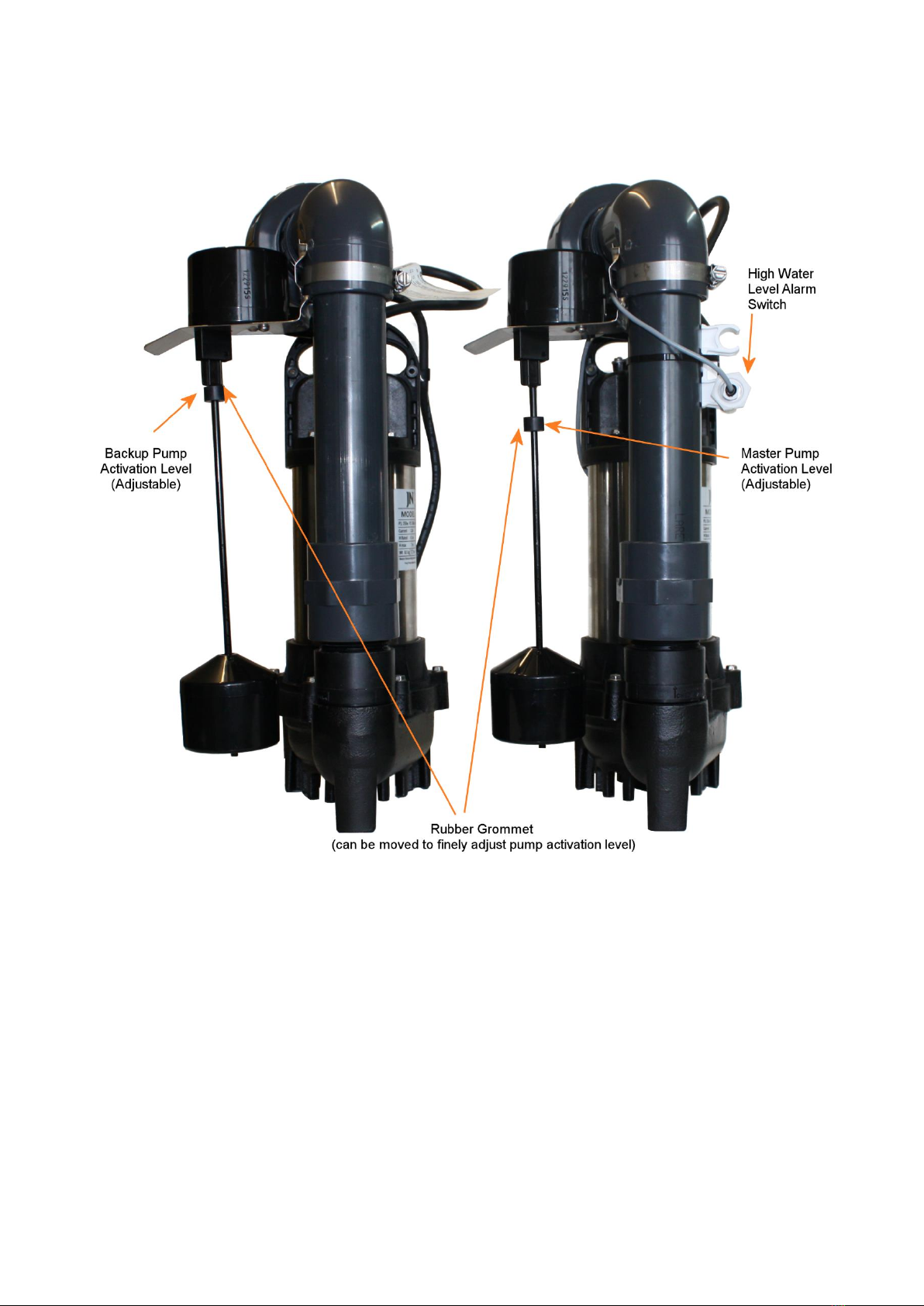

With dual pump systems it is recommended that the master and back up pump are alternated when the system is

serviced and the backup pump tested.

7.0 Health and Safety

In order to minimise the risk of accidents in connection with the service and installation work, the following rules

should be followed.

•Do not ignore health hazards.

•Observe strict cleanliness.

•Bear in mind the risk of electrical accidents.

•Use a safety helmet, safety goggles and protective shoes.

•All personnel who work with sewage systems must be vaccinated against diseases to which they may be

exposed.

•A first aid kit must be close to hand.

•Note that special rules apply to installations in an explosive atmosphere.

•Special note should be taken to site health and safety warnings.

Electrical Connections

•The following works should only be done by qualified and authorised electricians.

•Permagard disclaim all responsibility for work done by untrained and/or unauthorised personnel.

•Heed operating voltage (see name plate and additional labels).

•Take out the main fuses to isolate the mains supply from the control unit before repairs or any other

works and ensure it cannot to energized again.

•As the pump is equipped with an automatic level control, there is a risk of sudden restart.

•Before starting check the efficiency of the protective arrangements of the pump and the monitoring

equipment. Failure to heed this warning may cause a lethal accident.

•Do not put the lead ends into water! Irruption of water may cause malfunctions.

•If persons are likely to come into physical contact with the pump or pumped media, the earthed (grounded)

socket must have an additional connection to an earth (ground) fault protection device (GFI).

•Use the pump only in accordance to the date stated on the pump’s plate.

•Connection only to mains supply installed in accordance to the local regulations. For fusing of D.O.L.

•Starting pumps use only appropriate slow fuses or automatic circuit breakers with D characteristics. This is

because the motor’s nominal voltage is measured at the terminal board of the pump; please consider the

voltage drop of long supply cables.

•Replace the cable if the cable jacket is damaged. Do not pinch the cable or pull it around sharp bends.

•Always install the control unit in a dry and well ventilated room. Never install the control unit within the

tank.