Contents

Contents ...............................................................................Chapter - Page

8.03 Switching the machine on/off .................................................................................... 8 - 5

9Setting up ................................................................................................................. 9 - 1

9.01 Inserting the needle ................................................................................................... 9 - 1

9.02 Winding the bobbin thread, regulating the winder tension ........................................ 9 - 2

9.03 Removing and inserting the bobbin case ................................................................... 9 - 3

9.04 Threading the bobbin case and adjusting the bobbin thread tension ......................... 9 - 3

9.05 Threading needle threads and regulating tensions..................................................... 9 - 4

10 Care and maintenance........................................................................................... 10 - 1

10.01 Cleaning the hook areas and the hooks ................................................................... 10 - 1

10.02 Oiling the hook......................................................................................................... 10 - 2

10.03 Checking/adjusting the air pressure ......................................................................... 10 - 3

10.04 Cleaning the air filter of the air-filter/lubricator ......................................................... 10 - 3

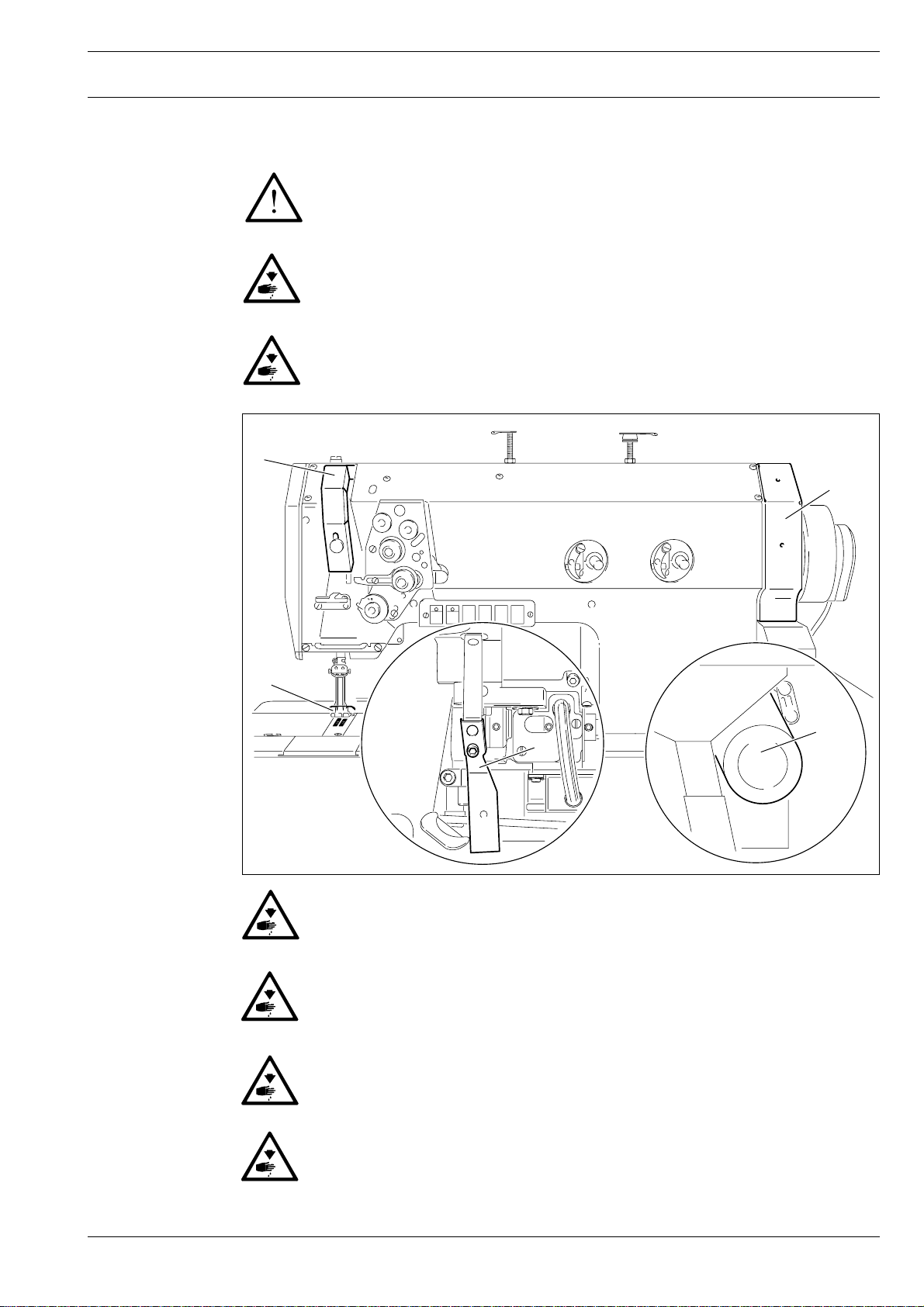

11 Adjustment ............................................................................................................. 11 - 1

11.01 Notes on adjustment ............................................................................................... 11 - 1

11.02 Tools, gauges and other equipment......................................................................... 11 - 1

11.03 Abbreviations ........................................................................................................... 11 - 1

11.04 Adjusting the basic machine................................................................................. 11 - 2

11.04.01 Adjusting the synchronizer....................................................................................... 11 - 2

11.04.02 Balance weight ........................................................................................................ 11 - 3

11.04.03 Positioning the feed dog in the needle plate cutout................................................. 11 - 4

11.04.04 Neutral position of the feed dog .............................................................................. 11 - 5

11.04.05 Feeding stroke of feed dog...................................................................................... 11 - 6

11.04.06 Lifting stroke of feed dog......................................................................................... 11 - 7

11.04.07 Feed dog height ....................................................................................................... 11 - 8

11.04.08 Needles in needle-hole centre ................................................................................. 11 - 9

11.04.09 Needle height (preliminary adjustment) ................................................................... 11 -10

11.04.10 Needle rise, hook-to-needle clearance, needle height (final adjustment)

and needle guard ..................................................................................................... 11 - 11

11.04.11 Bobbin case opener stroke ...................................................................................... 11 - 13

11.04.12 Re-engaging the slip-clutch...................................................................................... 11 -14

11.04.13 Clearance between presser foot and needle plate................................................... 11 -15

11.04.14 Knee lever................................................................................................................11-16

11.04.15 Needle thread tension release (on machines without Subclass -900/81)................. 11 -17

11.04.16 Needle thread tension release (on machines with Subclass -900/81) ...................... 11 -18

11.04.17 Bobbin winder.......................................................................................................... 11 -19

11.04.18 Presser foot pressure .............................................................................................. 11 - 20

11.04.19 Thread check spring and thread regulator................................................................ 11 - 21

11.05 Adjusting the thread trimmer 900/81.................................................................... 11 -22

11.05.01 Resting position of roller lever/radial position of control cam................................... 11 - 22

11.05.02 Thread-catcher height .............................................................................................. 11 - 23

11.05.03 Thread catcher position............................................................................................ 11 - 24