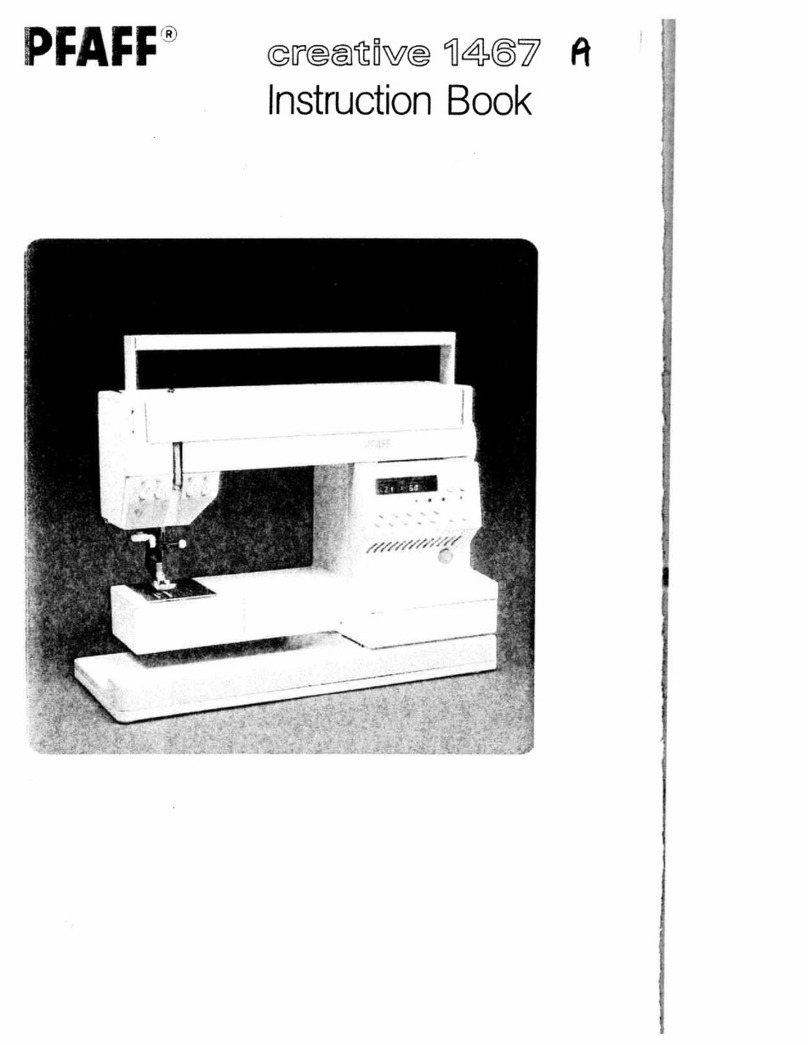

Pfaff 238 User manual

Other Pfaff Sewing Machine manuals

Pfaff

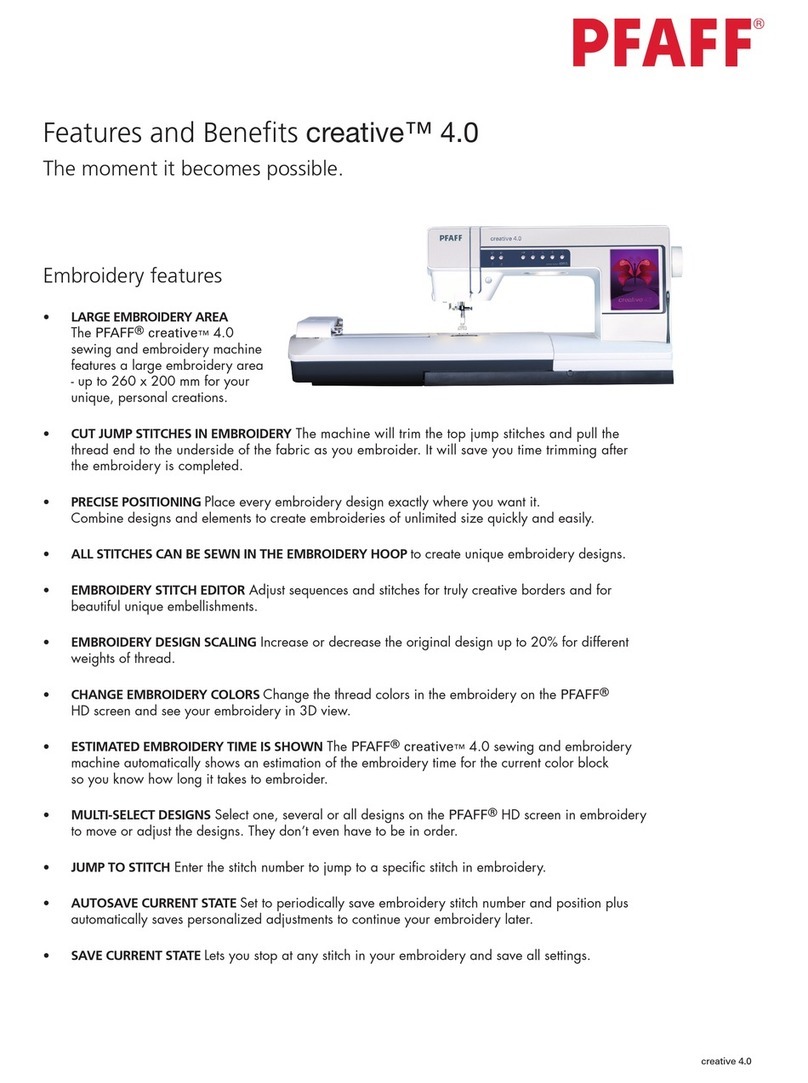

Pfaff CREATIVE 4.0 - User manual

Pfaff

Pfaff 145 User manual

Pfaff

Pfaff creative sensation pro User manual

Pfaff

Pfaff CALANDA 132 User manual

Pfaff

Pfaff hobby GrandQuilter 1200 User manual

Pfaff

Pfaff 1245 User manual

Pfaff

Pfaff 339 User manual

Pfaff

Pfaff creative 4874 User manual

Pfaff

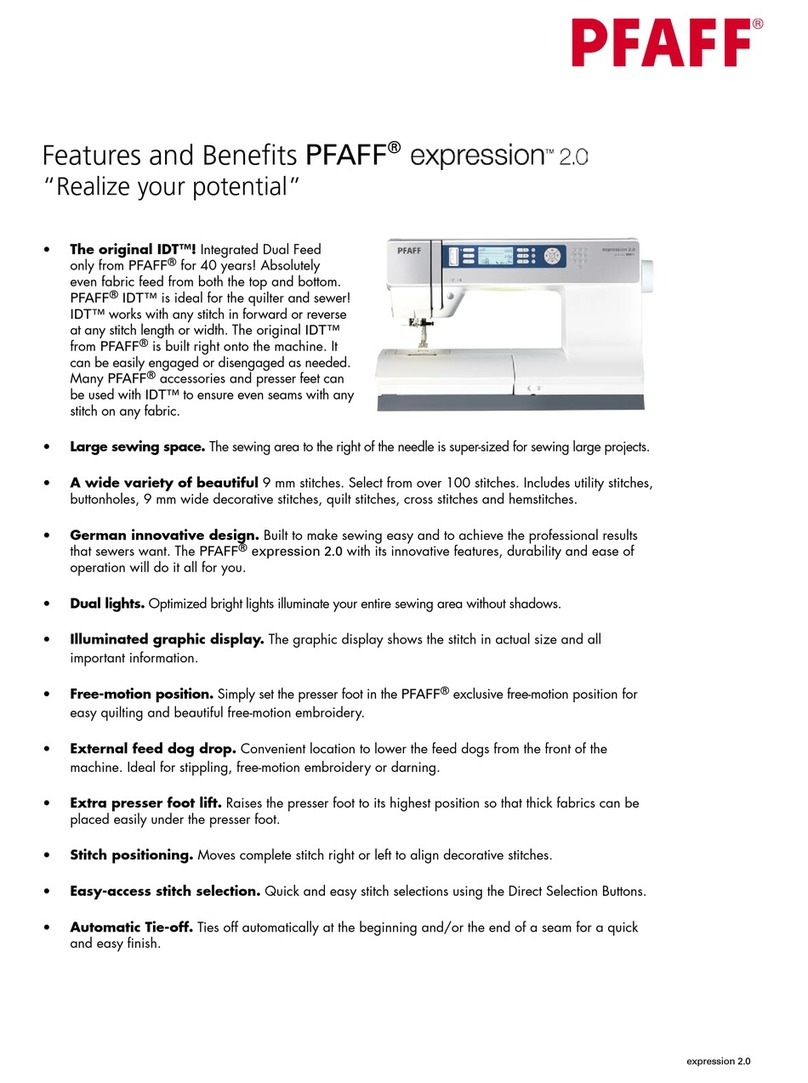

Pfaff expression 2.0 User manual

Pfaff

Pfaff creative 7570 User manual

Pfaff

Pfaff Powerline 2545 User manual

Pfaff

Pfaff CREATIVE VISION - V13598 UPDATE CREATIVE VSION SEWING AND EMBROIDERY... Technical manual

Pfaff

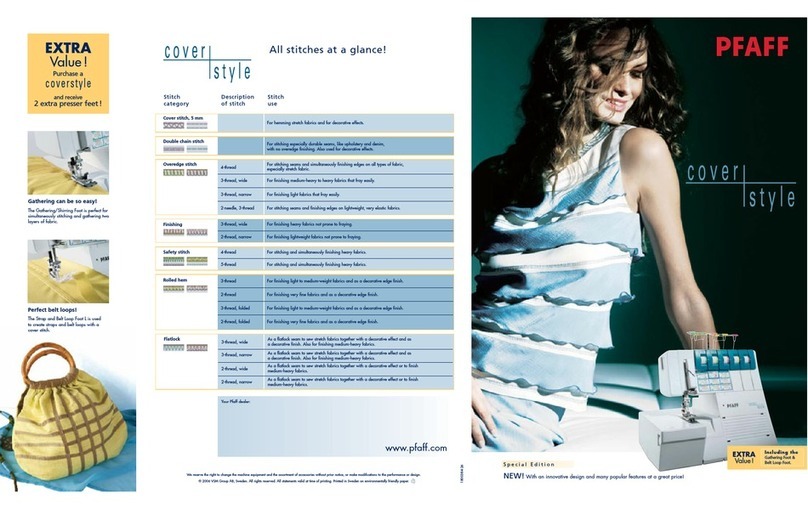

Pfaff Coverstyle User manual

Pfaff

Pfaff 480 Series User manual

Pfaff

Pfaff 2081 User manual

Pfaff

Pfaff coverlock 4872 User manual

Pfaff

Pfaff 2144 User manual

Pfaff

Pfaff 3801-3/07 User manual

Pfaff

Pfaff expression 2026 User manual

Pfaff

Pfaff Creative Vision Technical manual