e1nmdlCsm-rev0512

WWW.VERSAMATIC.COM 2

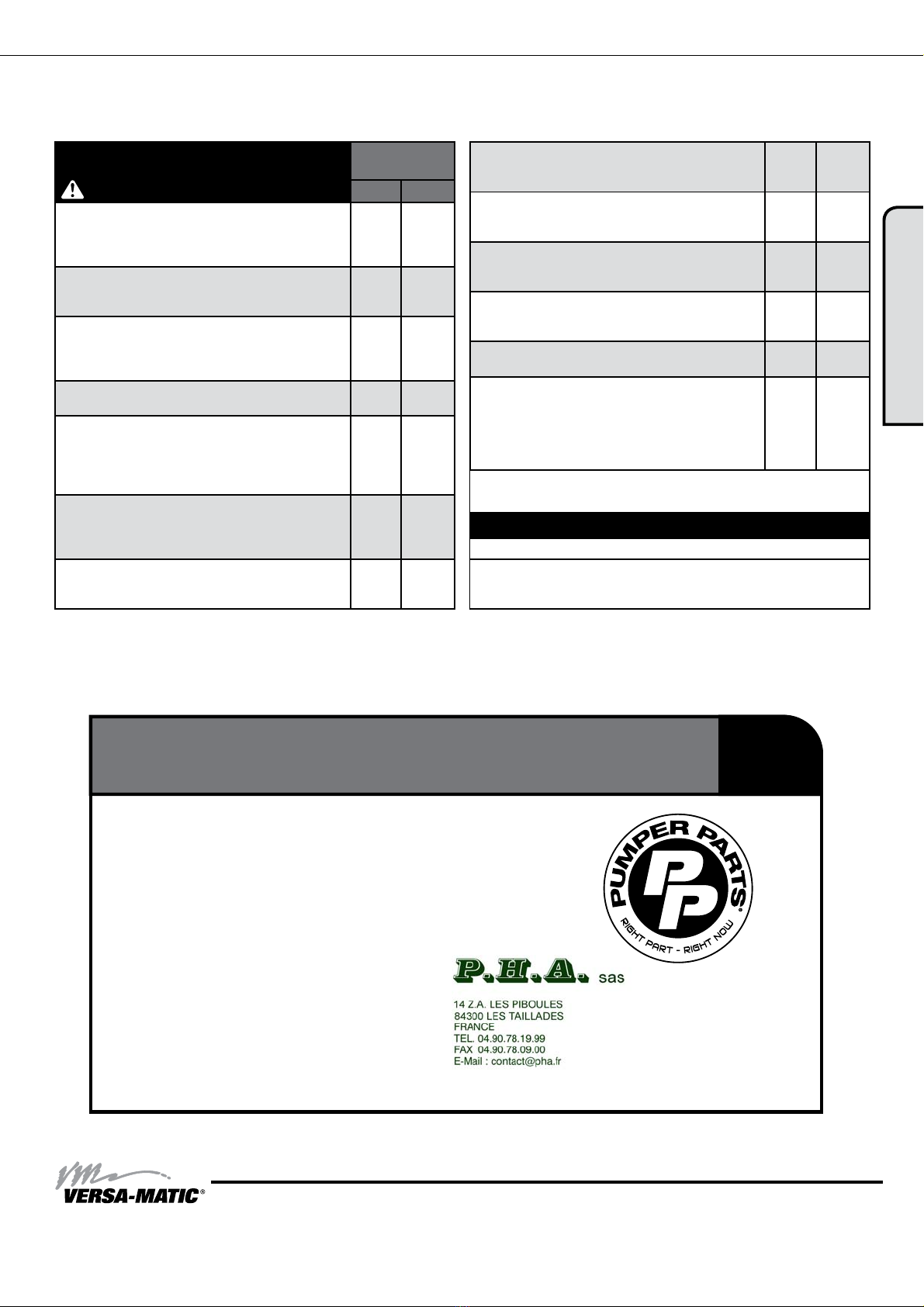

Materials

Operating

Temperatures:

Max. Min.

Tough, impact resistant, ductile. Good

agents.

190°F

88°C

°F

°C

poor resistance to oils and solvents, but is fair in ketones and

alcohols.

280°F

138°C

°F

°C

FKM:

of oils and sovents; especially all aliphatic, aromatic and

halogenated hydrocarbons, acids, animal and vegetable oils.

°

350°F

°C

°F

°C

Hytrel®: Good on acids, bases, amines and glycols at room

temperatures only.

220°F

104°C

°F

°C

Neoprene: All purpose. Resistance to vegetable oils. Generally

not affected by moderate chemicals, fats, greases and many

ketones, esters and nitro hydrocarbons and chlorinated aromatic

hydrocarbons.

200°F

93°C

°F

°C

Nitrile:

hydrocarbons and nitro hydrocarbons.

190°F

88°C

°F

°C

Nylon:

and chemicals.

180°F

82°C

32°F

0°C

Polypropylene:

180°F

82°C

32°F

0°C

High tensile strength and impact resistance.

250°F

121°C

0°F

°C

Santoprene®:

resistance.

°F

135°C

°F

°C

UHMW PE: A thermoplastic that is highly resistant to a broad

180°F

82°C

°F

°C

Urethane:

resistance to most solvents and oils.

150°F

66°C

32°F

0°C

Virgin PTFE:

temperatures.

220°F

104°C

°F

°C

Metals:

Alloy C:

Stainless Steel:

resistant iron chromium, iron chromium nickel and nickel based alloy castings for

general applicaitons. Commonly referred to as 316 Stainless Steel in the pump industry.

CAUTION! Operating temperature limitations are as follows:

AFTERMARKET PARTS

Pumper Parts

®

®

®

RIGHT PART, RIGHT NOW

Designed to perform equal to or greater

than original equipment manufacture.

www.pumperparts.com

! "###

®$%&'(!)#)Yamada®is a registered trademark of

Yamada Corporation. ARO®is a registered trade name of Ingersoll-Rand Company. *®*&(#%+(

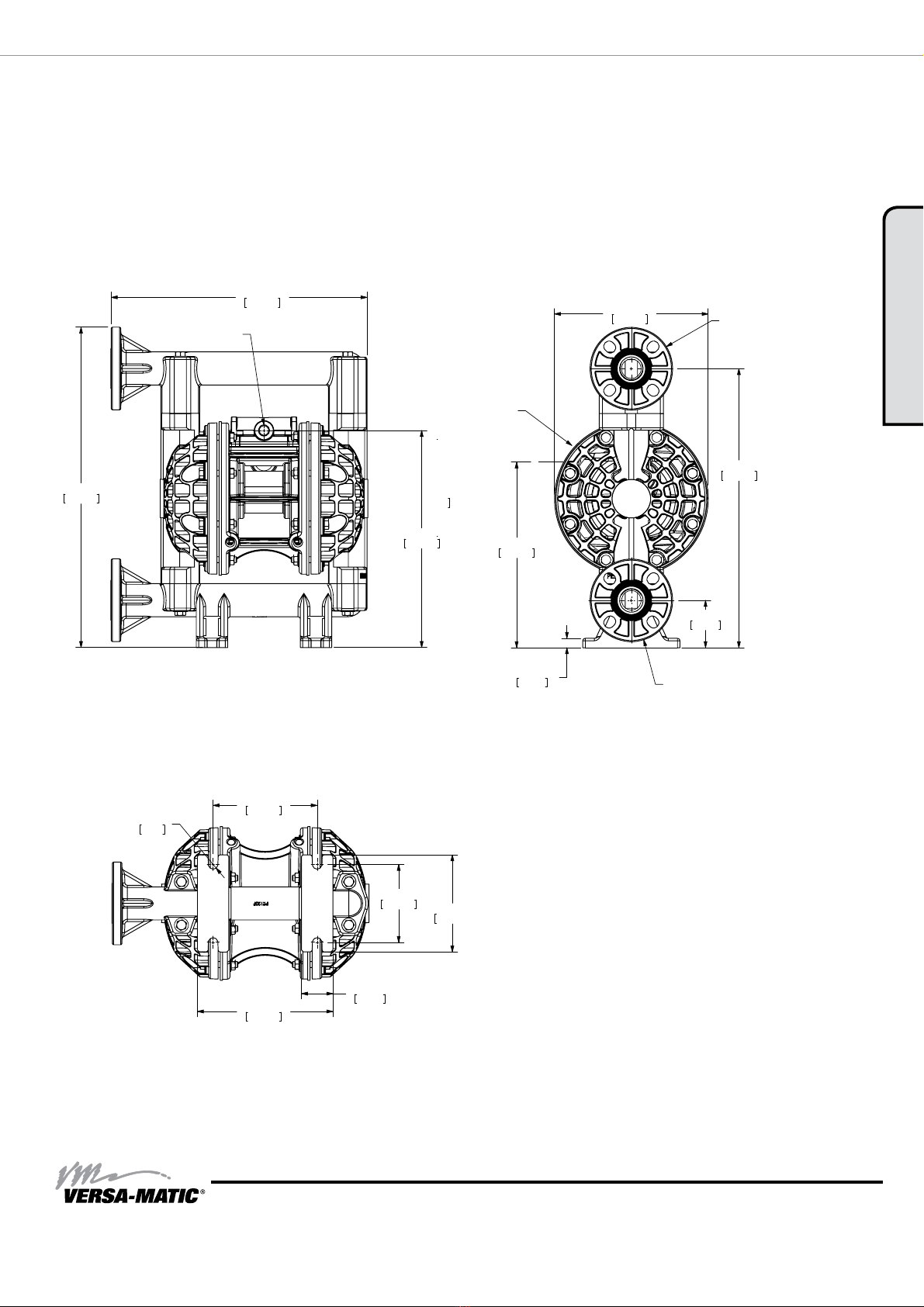

1: PUMP SPECS