Phase Technologies DV Series User manual

ii | Page

2022 © Copyright.V0.0 All rights reserved. All contents are property of Phase Technologies, LLC.

No portion of this publication or its contents may be duplicated by any means, electronic or otherwise, without the

express written consent of Phase Technologies, LLC.

V0.0_09012022

222 Disk Drive

Rapid City, SD 57701

Phone: 605-343-7934

Fax: 605-343-7943

Toll Free: 866-250-7934

www.phasetechnologies.com

iii | Page

SAFETY MESSAGES AND WARNINGS

To ensure safe and reliable operation of output filters, it is important to carefully read

this manual and to observe all warning labels attached to the unit before installing.

Please follow all instructions exactly and keep this manual with the unit for quick and

easy reference.

Definitions of Warning Signs and Symbols

CAUTION: Indicates a potentially hazardous situation that could result in injury or

damage to the product.

WARNING: Indicates a potentially hazardous situation that could result in serious

injury or death.

HIGH VOLTAGE: The voltage associated with the procedures referenced could

result in serious injury or death. Use caution and follow instructions carefully.

READ THESE WARNINGS BEFORE INSTALLING

OR OPERATING EQUIPMENT!

WARNING: Risk of electric shock. More than one disconnect switch may be

required to de-energize the equipment before servicing.

WARNING: Risk of electric shock. Before servicing the equipment, de-energize

the filter by disconnecting all incoming sources of power, wait 10 minutes for internal

charges to dissipate, and verify with a voltmeter that all power sources are off and

capacitors are discharged. Failure to do so may result in severe injury or death.

HIGH VOLTAGE: This equipment is connected to line voltages that can create a

potentially hazardous situation. Electric shock could result in serious injury or death.

This device should be installed only by trained, licensed, and qualified personnel. Follow

instructions carefully and observe all warnings.

WARNING: This equipment should be installed and serviced by qualified personnel

familiar with the type of equipment and experienced in working with dangerous voltages.

WARNING: Installation of this equipment must comply with the National Electrical

Code (NEC) and all applicable local codes. Failure to observe and comply with these

codes could result in risk of electric shock, fire, or damage to the equipment.

CAUTION: Circuit breakers, fuses, proper ground circuits, and other safety

equipment and their proper installation are not provided by Phase Technologies, LLC,

and are the responsibility of the end user.

iv | Page

CAUTION: Failure to maintain adequate clearance may lead to overheating of the

unit and cause damage or fire.

WARNING: Input power connections should be made by a qualified electrician into

circuit with adequate voltage and current carrying capacity for the model.

CAUTION: Use 600 V vinyl-sheathed wire or equivalent. The voltage drop of the

leads needs to be considered in determining wire size. Voltage drop is dependent on

wire length and gauge. Use only copper conductors.

CAUTION: Wires fastened to the terminal blocks shall be secured by tightening

the terminal screws to a torque value listed in Table 4.

CAUTION: The maximum wire gauge for the input terminals is listed in Table 4.

CAUTION: Never allow bare wire to contact metal surfaces.

CAUTION: For SW filters with internally powered fans, ensure that the variable

frequency drive (VFD) is set to V/f (Volts per Hz) mode. Failure to properly configure

the VFD could result in failure of the VFD or filter components.

CAUTION: Before installation, visually inspect the filter and secure any loose

electrical connections before applying power. Failure to do so may result in damage to

the filter or diminished performance.

v | Page

TABLE OF CONTENTS

INTRODUCTION..................................................................................................... 1

1.1 RECEIVING INSTRUCTIONS .................................................................................. 2

1.2 MODELS AND RATINGS ....................................................................................... 3

RATINGS ................................................................................................................ 5

2.1 PRODUCT SPECIFICATIONS ................................................................................. 5

INSTALLATION...................................................................................................... 7

3.1 MOUNTING YOUR NEW [PRODUCT NAME] FILTER ............................................. 7

3.2 PROPER VENTILATION ........................................................................................ 7

3.3 GROUNDING ...................................................................................................... 7

3.4 WIRE SIZING...................................................................................................... 7

3.5 CONNECTING THE LOAD..................................... ERROR!BOOKMARK NOT DEFINED.

3.6 CONNECTING TO FIELD WIRING TERMINALS ........ ERROR!BOOKMARK NOT DEFINED.

OPERATION.................................................ERROR! BOOKMARK NOT DEFINED.

4.1 COMMISSIONING THE UNIT ................................. ERROR!BOOKMARK NOT DEFINED.

TROUBLESHOOTING ...........................................................................................10

ENCLOSURE DIMENSIONS ........................ERROR! BOOKMARK NOT DEFINED.

WARRANTY ..........................................................................................................13

1 | Page

INTRODUCTION

Output filters are used to remove unwanted high frequency content from the output of a

Variable Frequency Drive (VFD). Large voltage spikes are produced when VFDs are used to

drive motors with long cable leads, which can damage motor or cable insulation systems or

motor bearing fluting due to electric discharge. This voltage spike is known as the Reflected

Wave Phenomenon. dV/dt filters extend motor and cable life by reducing the effects of the

Reflected Wave Phenomenon and removing high frequency voltage spikes. dV/dt filters

should be used when motor cables exceed 50 feet and sine wave filters should be used when

motor cables exceed 900 feet.

For additional protection, sine wave filters provide more robust removal of higher frequency

content. As well as providing protection against voltage spikes from reflected waves, a sine

wave filter additional removes lower order harmonic voltage and currents. These benefits are

realized in reduced motor losses (less heating) due to lower eddy currents and magnetic

hysteresis losses in motor steel laminations.

Figure 1shows an unfiltered VFD output voltage measured line-to-line.

Figure 1– Unfiltered VFD Output Voltage

2 | Page

Figure 2shows output voltage after being filter by the dv series dV/dt filter.

Figure 2– Output Voltage After dv Series dV/dt filter.

Figure 3shows a output voltage after being filtered by the sw series sine wave filter.

Figure 3– Output Voltage After sw Series Sine Wave Filter.

Phase Technologies output filters can be configured in Open, NEMA Type 1, or NEMA Type

3R enclosures. Open filters are intended to be installed in a panel. Type 1 filters come with

an enclosure designed for indoor use only. Type 3R enclosures are made for outdoor use.

Make sure the filter has the proper enclosure type for your application.

1.1 Receiving Instructions

Phase Technologies sine wave filters are thoroughly inspected and tested before packaging

for shipment. Upon receiving the unit, immediately inspect it for any damage that may have

occurred during shipping. If any damage is found, contact the Phase Technologies’ service

3 | Page

department at (605) 343-7934. Loose electrical connections can also cause damage to the

filter or diminish its performance. Visually inspect the filter and tighten any loose connections

found.

1.2 Nomenclature

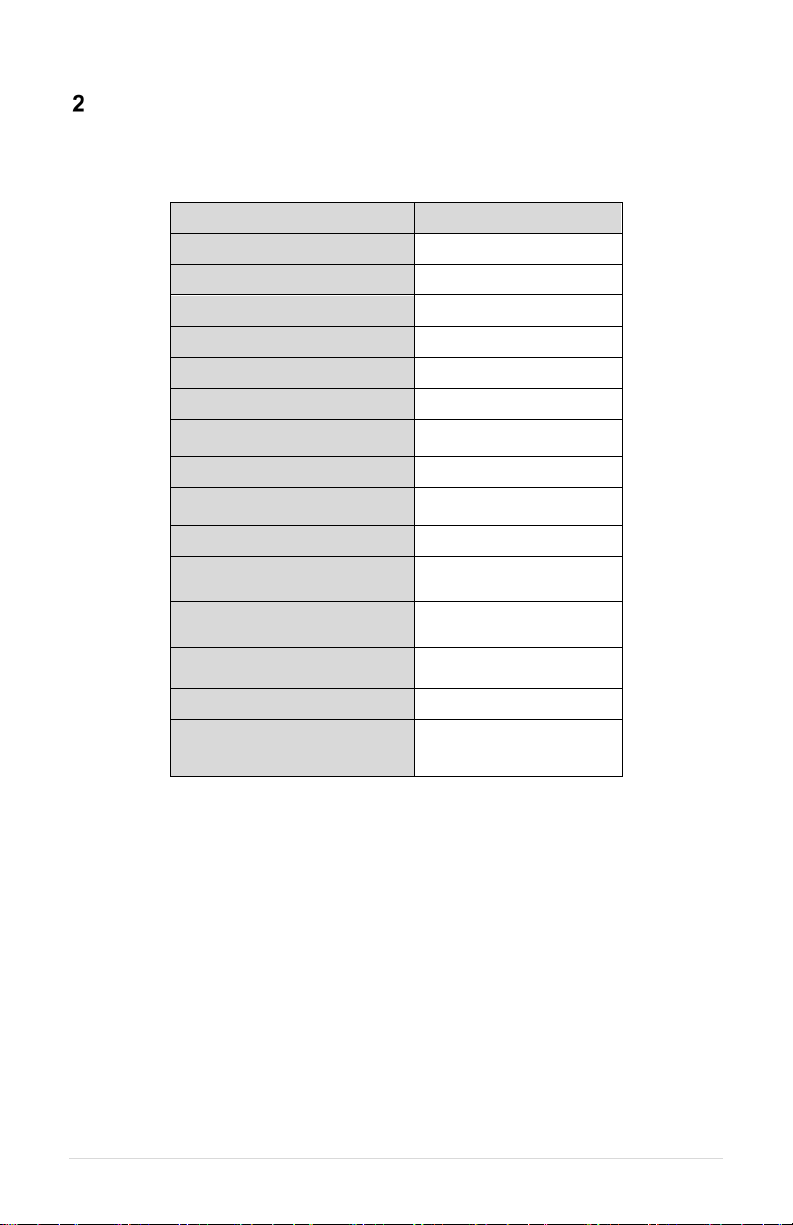

1.3 Models and Ratings

Table 1– dV/dt Filter Ratings

Model

HP

Rated Current (A)

DV009E

5

9

DV013E

7.5

13

DV018E

10

18

DV031E

20

31

DV045E

30

45

DV060E

40

60

DV077E

50

77

DV090E

60

90

DV107E

75

107

DV128E

100

128

DV160E

125

160

DV200E

150

200

DV250E

200

250

DV362E

300

362

DV480E

400

480

Table 2– Sine Wave Filter Ratings

Model

HP

Rated Current (A)

SW009E

5

9

SW013E

7.5

13

4 | Page

SW018E

10

18

SW031E

20

31

SW045E

30

45

SW060E

40

60

SW077E

50

77

SW090E

60

90

SW107E

75

107

SW128E

100

128

SW160E

125

160

SW200E

150

200

SW250E

200

250

SW362E

300

362

SW480E

400

480

5 | Page

RATINGS

2.1 Product Specifications

Table 3 –General Specifications, dv Series Filters

dV/dt Filter

Input Voltage Waveform PWM

VFD Output Voltage ≤ 480 VAC, 3-phase

VFD Output Frequency ≤ 90 Hz

VFD Switching Frequency 2 kHz – 10 kHz

Current Range 9 – 480 A

Maximum Motor Lead Length 1,000 feet

Max Peak Voltage

150% of DC bus voltage

up to 1,000 feet

Max dV/dt at Motor ≤200V/µs

Insertion Loss (Voltage)

≤1% at 60Hz

≤1.5% at 90Hz

Efficiency ≥ 99%

Enclosure Options

Open, NEMA 1, or

NEMA 3R

Operating Temperature

-20 °C to 40 °C

(-4 °F to 104 °F)

Storage Temperature

-25 °C – 74 °C

(-13 °F – 165 °F)

Maximum Humidity 95%, non-condensing

Elevation

Derate by 5 °C for every

2,000 feet over 5,500 feet

of elevation

6 | Page

Table 4 –General Specifications, SW Series Filters

SW Sine Wave Filter

Input Voltage Waveform PWM

VFD Output Mode Volts per Hertz*

VFD Output Voltage ≤ 480 VAC, 3-phase

VFD Output Frequency ≤ 90 Hz

VFD Switching Frequency 2 kHz – 10 kHz

Current Range 9 – 480 A

Insertion Loss (Voltage)

≤ 3.8% at 60 Hz

≤ 5.7% at 90 Hz

Efficiency ≥ 98%

Enclosure Options

Open, NEMA 1, or

NEMA 3R

Operating Temperature

-20 °C to 40 °C

(-4 °F to 104 °F)

Storage Temperature

-25 °C – 74 °C

(-13 °F – 165 °F)

Maximum Humidity 95%, non-condensing

Elevation

Derate by 5 °C for every

2,000 feet over 5,500 feet

of elevation

*SW200, SW250, SW362, SW480 models

7 | Page

INSTALLATION

3.1 Mounting Your New Output Filter

Proper installation of the unit is important to the performance and normal operating life. It

should be installed in a location free from:

•Corrosive gases or liquids

•Excessive vibration

•Airborne metallic particles

Open type filters should be installed in a panel by a qualified UL 508A panel shop. If wall-

mounted, mount the unit to a solid, non-flammable surface capable of bearing the weight

using the mounting brackets provided with the unit. Floor mounted filters should be attached

to the legs provided and fastened to the floor using concrete anchors or similar hardware.

3.2 Proper Ventilation

To maintain air circulation for adequate cooling, minimum clearance around the unit must be

maintained. Allow six inches on each side and top, and 18 inches below.

Ensure openings are not obstructed. If the unit is mounted in a small room, cabinet, or

building, ensure there is adequate ventilation to provide sufficient cooling for the unit.

3.3 Grounding

•Properly ground the filter according to local electrical code.

•Connect the ground lug to the branch circuit or service ground conductor.

•Resistance to ground measurement must be 25 Ohms or less, according to the

National Electric Code.

3.4 Ground Fault Protection

Devices that utilize power switching electronics like variable frequency drives, emit high

leakage current so ground fault protection devices may not be compatible with a VFD and

output filter.

3.5 Overtemperature Switch

Phase Technologies output filters have an optional self-resetting overtemperature circuit with

a Normally Closed relay that will open when an internal temperature of 180°C is reached (+/-

5°C). An overtemperature relay is highly recommended to shut down the VFD if the internal

temperature reaches an unsafe level to prevent damage to the filter in rare cases when

components overheat due to abnormal operating conditions. If using a Phase Technologies

VFD, the overtemperature relay should be connected to one of the Auxiliary terminals and

the setting AUX SELECT should be set to CLOSED = RUN, OPEN = STOP.

Table 4– Overtemperature Switch

Normally Closed (NC) Thermal Switch:

180°C open, +/-5°C

Voltage Current

250VAC 8A

8 | Page

3.6 Installing Power Wiring

WARNING: Input and output wiring to the filter should be performed by authorized

personnel in accordance with the NEC and all local electrical codes and regulations.

CAUTION: Use 600 V wire that is appropriately rated for the current rating of the motor.

Use copper wire with an insulation temperature rating of 90°C or higher. Installations must

comply with all local regulations and the National Electrical Code (NEC).

Verify that the power source is appropriate for the filter being used. Connect the VFD output

(T1, T2, T3 or U, V, W) to the input of the filter (U1, V1, W1). Connect the motor to the output

terminals of the filter (U2, V2, W2). A fused disconnect or circuit breaker should be installed

between the VFD and its power source in accordance with NEC requirements. See Figure

for a system schematic and Table 2 for field wiring terminal specifications.

Figure 4– Filter System Schematic

Table 5 – Field Wiring Power Terminal Specifications

3.7 Startup Checklist

Prior to operation, verify the following:

1. The filter is securely attached to the proper mounting surface

2. All filter ground terminals are properly bonded to earth ground

3. The filter’s input terminals are connected to the output of a VFD and the VFD is

set properly*:

oOutput frequency is less than 90 Hz

oPWM Switching Frequency is 2 – 8 kHz

oOperation mode is Volts per Hertz without DC braking

4. An appropriately rated motor is connected to the output terminals

5. The motor is secured and properly mounted

9 | Page

*Consult Phase Technologies about derate information if desired to operate outside of

these VFD settings.

Note: VFD motor auto-tuning procedures will be greatly affected and likely will result in

inaccurate results. Consult with VFD supplier if auto-tuning is desired with filter installed.

10 | Page

TROUBLESHOOTING

This section provides information on routine inspections and troubleshooting tips for potential

system problems.

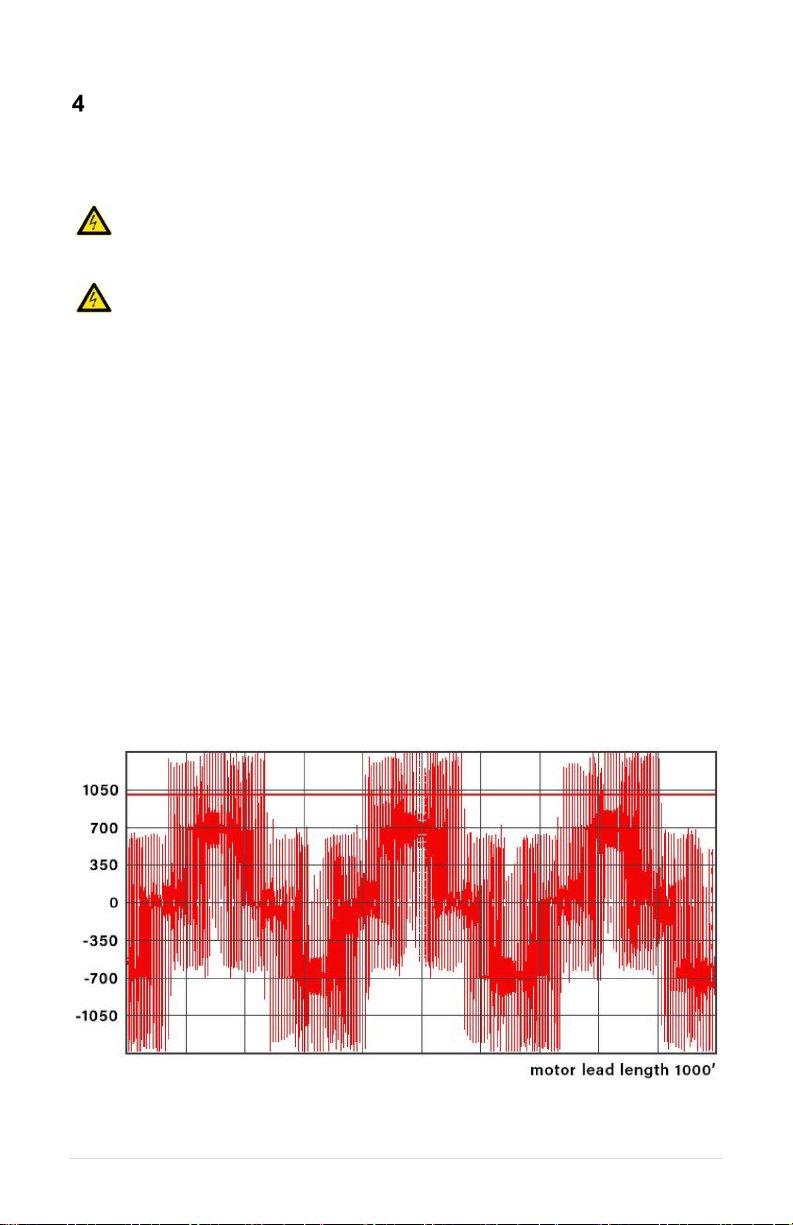

WARNING: Risk of electric shock. De-energize the unit by disconnecting all incoming

sources of power, then wait 5 minutes for internal charges to dissipate before servicing

the equipment.

HIGH VOLTAGE: This equipment is connected to line voltages that can create a

potentially hazardous situation. Electric shock could result in serious injury or death.

This device should be installed and serviced only by trained, licensed and qualified

personnel. Follow instructions carefully and observe all warnings.

4.1 Routine Inspection and Maintenance

The unit should be inspected and cleaned at least annually or more frequently if it is in an

excessively warm or dusty environment. Annual inspections should include the following:

•Ensure that the installation environment is free of excessive dirt or contaminants

•Check that all enclosure openings are unobstructed

•Visually inspect the interior of the enclosure for signs of excessive heat or arcing

on components and wires

•Verify that all ground connections are tight

•Retorque VFD and motor connections

4.2 Evaluating Output Filter Performance

Output filter performance can be evaluated by viewing the output voltage wave form with an

oscilloscope. Figure 1shows a typical VFD output voltage waveform when measured line-

to-line.

Figure 5– VFD Line-to-Line Output Voltage Waveform

Figure 2shows a typical filter output voltage as measured line-to-line with an oscilloscope.

12 | Page

Table 5 – Troubleshooting Guide

PROBLEM

POTENTIAL CAUSE

SOLUTION

Motor Will Not

Turn

No power

Check breakers and fuses and verify

incoming voltage.

Incorrect Wiring

Verify VFD and motor are properly

connected to the filter.

VFD Fault

Consult VFD User’s Manual.

VFD Overcurrent

Fault

Incorrect wiring

Verify that all VFD and motor cables are

connected properly.

Cable insulation

compromised

Check wire connections. Use Megger to

check for ground faults.

Motor damage

Check motor winding resistance and use

Megger to check for ground faults.

System compatibility

Verify that current ratings of VFD, output

filter, and motor are properly sized.

VFD parameters

Consult VFD user’s manual to configure

proper parameters.

Temperature

Switch Open

Filter Overheating

Ensure filter openings are clear and that

ambient temperature is below 40 °C.

Incompatible motor

Verify current ratings of VFD, output filter,

and motor are properly sized.

Switching Frequency

is less than 2 kHz

Verify that the VFD Switching Frequency

(or Carrier Frequency) is 2 kHz or higher.

Excessive Filter

Noise

Incompatible motor

Verify current ratings of VFD, output filter,

and motor are properly sized.

Switching Frequency

is less than 2 kHz

Verify that the VFD Switching Frequency

(or Carrier Frequency) is 2 kHz or higher.

13 | Page

WARRANTY

LIMITED WARRANTY

This Limited Warranty applies to the following

Phase Technologies’ product lines:

Output Filters

Two Year Warranty

Output Filters are warranted against defects in material and workmanship. This

warranty covers both parts and labor from the date of purchase from Phase

Technologies. Phase Technologies will repair or replace (at our option), at no

charge, any part(s) found to be faulty during the warranty period specified. The

warranty repairs must be performed by/at a Phase Technologies Authorized Service

Center or at Phase Technologies LLC, Rapid City, SD.

Obligations of Customer

1. The original Bill of Sale must be presented in order to obtain “in-warranty”

service. Transportation to Phase Technologies or an Authorized Service

Center is the responsibility of the purchaser. Return transportation is provided

by Phase Technologies.

2. Installations must comply with all national and local electrical codes.

Exclusions of the Warranty

This warranty does not cover any of the following: accident, misuse, fire, flood, and

other acts of God. Nor does this warranty cover any contingencies beyond the

control of Phase Technologies, LLC, including: water damage, incorrect line voltage,

improper installation, missing or altered serial numbers, and service performed by

an unauthorized facility.

Phase Technologies’ liability for any damages caused in association with the use of

Phase Technologies’ equipment shall be limited to the repair or replacement only of

the Phase Technologies’ equipment. No person, agent, distributor, dealer, or

company is authorized to modify, alter, or change the design of this merchandise

without express written approval of Phase Technologies, LLC.

Installations must comply with all national and local electrical code

requirements.

www.phasetechnologies.com

222 Disk Drive, Rapid City, SD 57701

866-250-7934 - Toll-Free 605-343-7934 - Main

This manual suits for next models

31

Table of contents

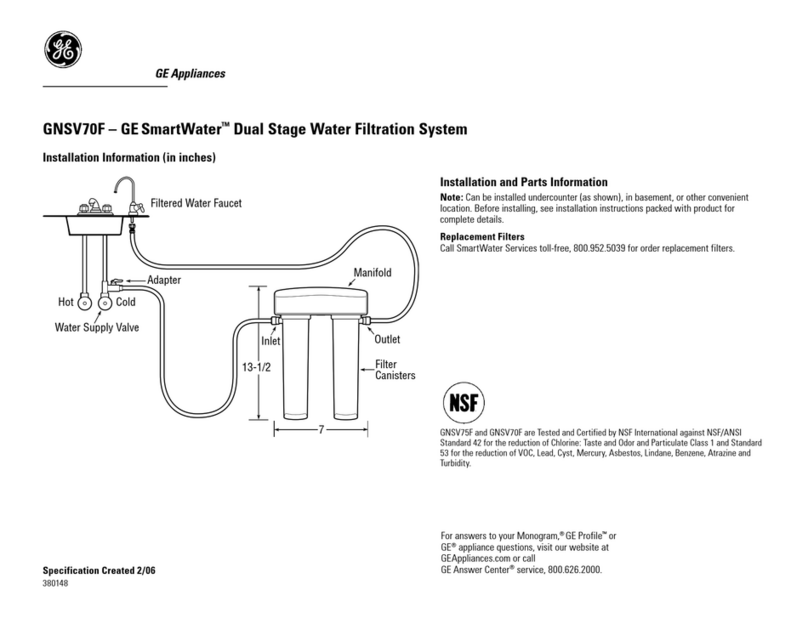

Popular Water Filtration System manuals by other brands

GE

GE SmartWater GNSV70FBL Installation information

Sera

Sera Pond fil bioactive user manual

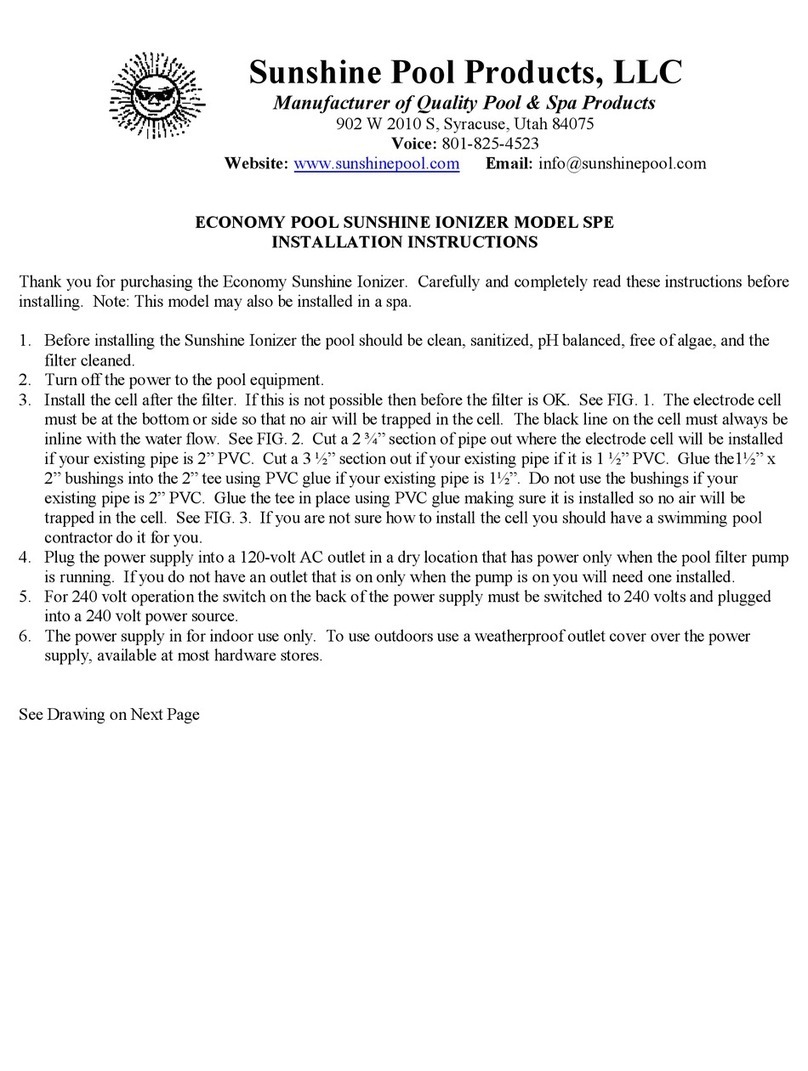

Sunshine Pool Products

Sunshine Pool Products SPE installation instructions

EcoFast

EcoFast EF500-DC Installation and operating instructions

Clarke

Clarke CAT182 Installation & maintenance instructions

Vega

Vega VEGATRENN 149A EX manual