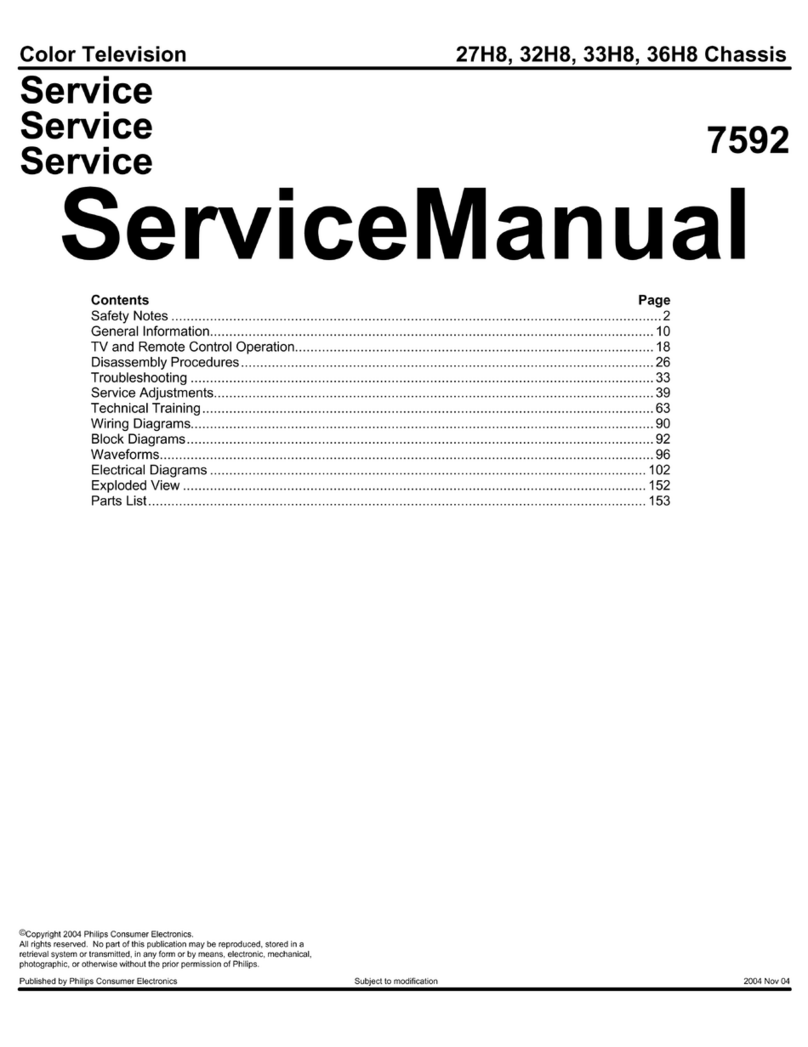

WARNINGS

. As the chaesls ls llve lnde@nddnt of the posltlon of the malns

plug the set shcrld be connected to the rnalng vla an lsolatlng

trangformer (approx, 500 VA) wben the rear panel ls removed.

. Due to the htgb tenslon (ca. 25 kV) the valves ln the HT cage

produce a certaln amount of X-radiatlon. However, when the

cage ls closed the screenlng ls so effectlve that the X-rays

ca:mot leave the cage.

To prevent that the set can operate wlth opened HT cage a

safety swltch has been provlded whlch lnterrupts the 92

voltage for the llne output valves. Thls ewltch should never

be closed or shunted when the cage ls open.

After repalr ensure tlat all Bcrews tn tle ltd are properly

tlghtened.

. Never replace valves or components whlle the set ls svltched

on.

. U6e safety goggles when replaclng the plchrre tube,

. When replaclng valves or other componenta ln the HT cage,

removlng the chasels and replaclng the plcture tube, ftrst

short-clrcult the residual charge on the plcture tube. For

thls connect a properly lnsulated wlre to the chaesls and

hold the other end agalnst the H.T. connectlon for a few

seconds.

. Be careful when meagurlng the voltages on the tube Bocket.

The focusslng voltage (on potnt 9) ls approx. 4.5 kV,

REMARKS

1. The osclllogtams have been measured under the followlng

condltlons.

a. For the black and whlte sectlon a cross hatch pattern

has been used as lnput stgnal and for the chromlnance

sectlon a colour bar pattern.

b. The brtghtness contrl, lcrob 3, at normal brlghtness.

c. The contrast control, Imob 4, set to 4 Vp-p on the

control grtd of the vldeo output valve.

d. Saturatlon control larob 5, set to 40 mV p-p on the base

of TS439.

e. The hue control, lcrob 6 ln the mechanlcal mld-posltlon

2. The dlrect voltages have been measured as follows:

No aerlal slgnal, minlmum brlghtness, maxlnum contrast

and saturatlon.

The voltages ln the chromlnance sectlon marked wlth an x

have been measured wtth the colour/black-whtte swltch ln

posltlon 'rcolour" and the collector and emltter of TS443

lnterconnected.

3. If a blank pattern ls required when the PM 5507 ls used,

thls pattern can be obtalned by means of the ralnbouw

slgnal, the vldeo knob turned fuIly clockwlse and the

black/whtte-switch of the set turned to posltlon blacVwhtte.

4. Integrated clrcult TAA550 (U414) mounted on p. c. board

8, ls avallable ln varlous verslons under one code number.

These verslons are malked as follows:

a. Red or yellow palnt dot.

The Zener voltage ls between 30 and 33 V.

Thls I. C. may be marked as follows:

No code number or code number 30 on the houslng of

the I. C.

In this case the brtdge wlre should be fttted tn parallel

wtth Rl513.

b. Green palnt dot :

The Zener voltage ls between 33 and 36 V.

Thts I.C. may be marked as follows:

Code-number 33 on the houslng of the I. C.

In thls case no brldge wire should be fltted ln parallel

wlth R1513.

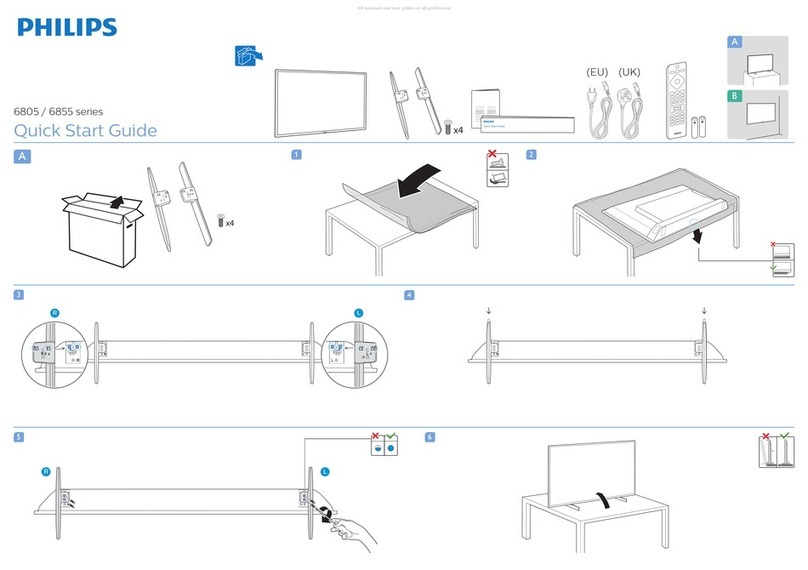

MECHANICAL INSTRUCTIONS

1. - Remove the screw from the upper slde of the cover to the

left of the rear panel, and remove thls cover.

Note: The c(nvergence panel ls provlded wlth explalnlng

slgns to facllttat€ converglng. The numbers lndtchte

- the sequence of converglng.

2. Hlnglng out the chassls

- Remove the rear panel and, subsequently, the nylon

locking pln from the rtght-hand upp€r slde of the chassls

- Push the plastic locldng plate on the rtght-hand urderslde

of the chassls to the rtght.

3. Removlng the chassls.

- Hlnge out the chassls.

- Remove the plugs A,B,C,E,F,H,L,M -T-2.

- Remove the prlnt of the plcture tube.

- Unsolder the two earth leads.

- Detach the suspenslon cord from the chassls.

- Detach the H. T. -cable from the plcfure tube.

- Llft the chassls out of the two hlnge polnts and remove lt

from the chassls.

4. Removlng the control panel

- Remove the cover from the convergence panel.

- Remove the convergenee panel from tire set.

- Remove wlth a long screwdrlver.the two screws from the

under- and the upperslde of the control panel.

- Remove the slx larobs (volume, tone , etc. ) from the front

of the set and remove the control panel backrvards.

5. Removlng the push-button unlt

- Remove the plugs X and Y.

- Remove the three flxtng screws.

- Remove the push-button unlt.

6. Replaclng the hrnlng potentlometers

- Remove the push-button unlt.

- Remove the cap from the push-button unlt.

- Unsolder the leads from the defectlve potentlometer strip.

- Bend the tag wlth whlch the strlp ls flxed, upwards.

- Replace the strtp wlth the potentlometer.

7. Replaclng the p. c. board of the band swltch of U14

- Remove the hrnlng unlt from tlre set.

- Remove the screenlng cap and the polnter.

- Loosen the ftxlng screw from the p.c.board of the band

swltch and pull the p. c. board outwards. (Attentton! Do

not damage the contact sprlngs. )

- Write down the colours of the connectlng wlres and un-

solder them.

- Connect the new p. c.board and place lt ln posltlon,

carefully ltftlng up the contact sprlngs.

- Reftt the polnter and adjust the helght of the p.c.board

so that the polnter can move unhampered.

8. Replaclng valves ln the hlgh-voltage cage.

- Flrst read the warnlngs.

- Remove the cover from the H. T. cage.

- Loosen the serews fixtng the top plate, a few hrrns; push

thls plate upwards. Consequently, the PD500 ls algo

movlng upwards so that lt can be easlly removed.

- Push the valve of valve holder GY 501 sllghtly upwards

so that the top connectlon of thls valve can be removed.

- Now the valve can remove from the holder.

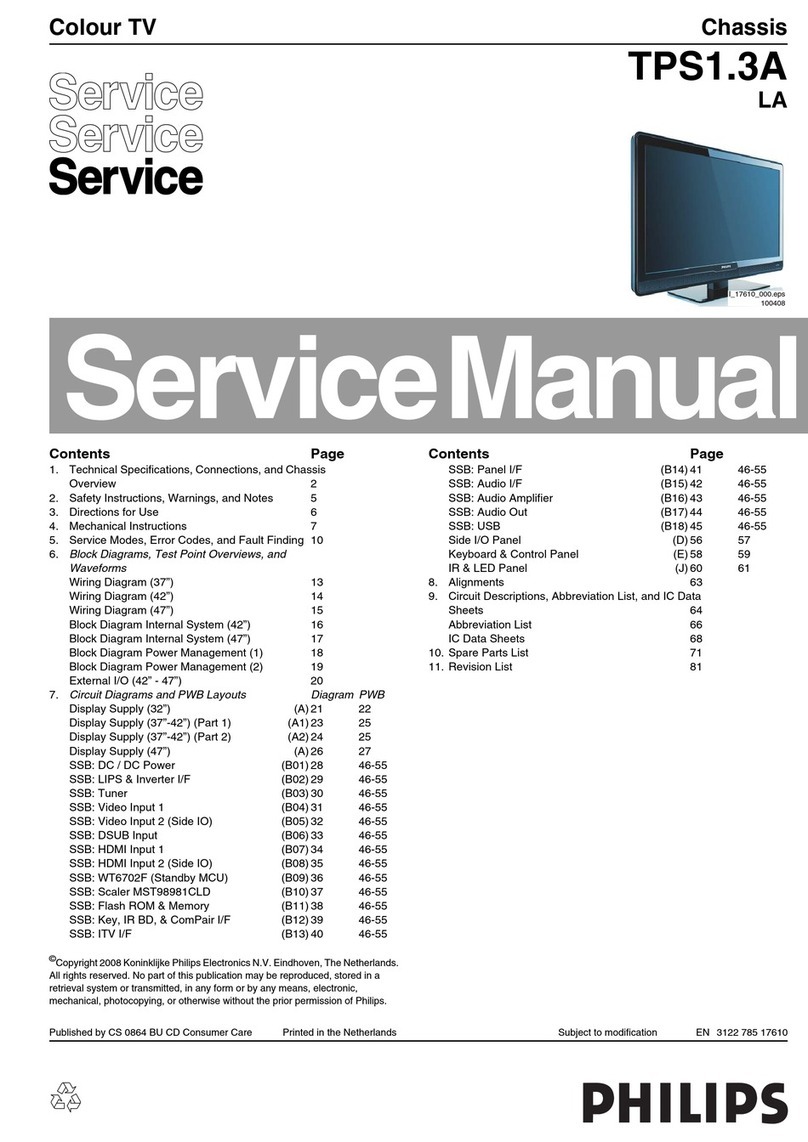

9. Removlng the convergence colls

- Remove the multlpole plugs N,O, and P.

- Insert a thln screwdrlver tnto the mlddle opening (Flg. 2)

and carefully press the screwdrlver downwards.to dlsengage

the locklng pln.

- Now the convergence coll can be wlthdrawn.

Note: When the coll ls lnserted agaln lnto the holder, one

should hear the holder cllcktng ln the openlng of the coll.

Fig.2

csz 7063