PHOENIX OVENS Installation & Operation Manual 17

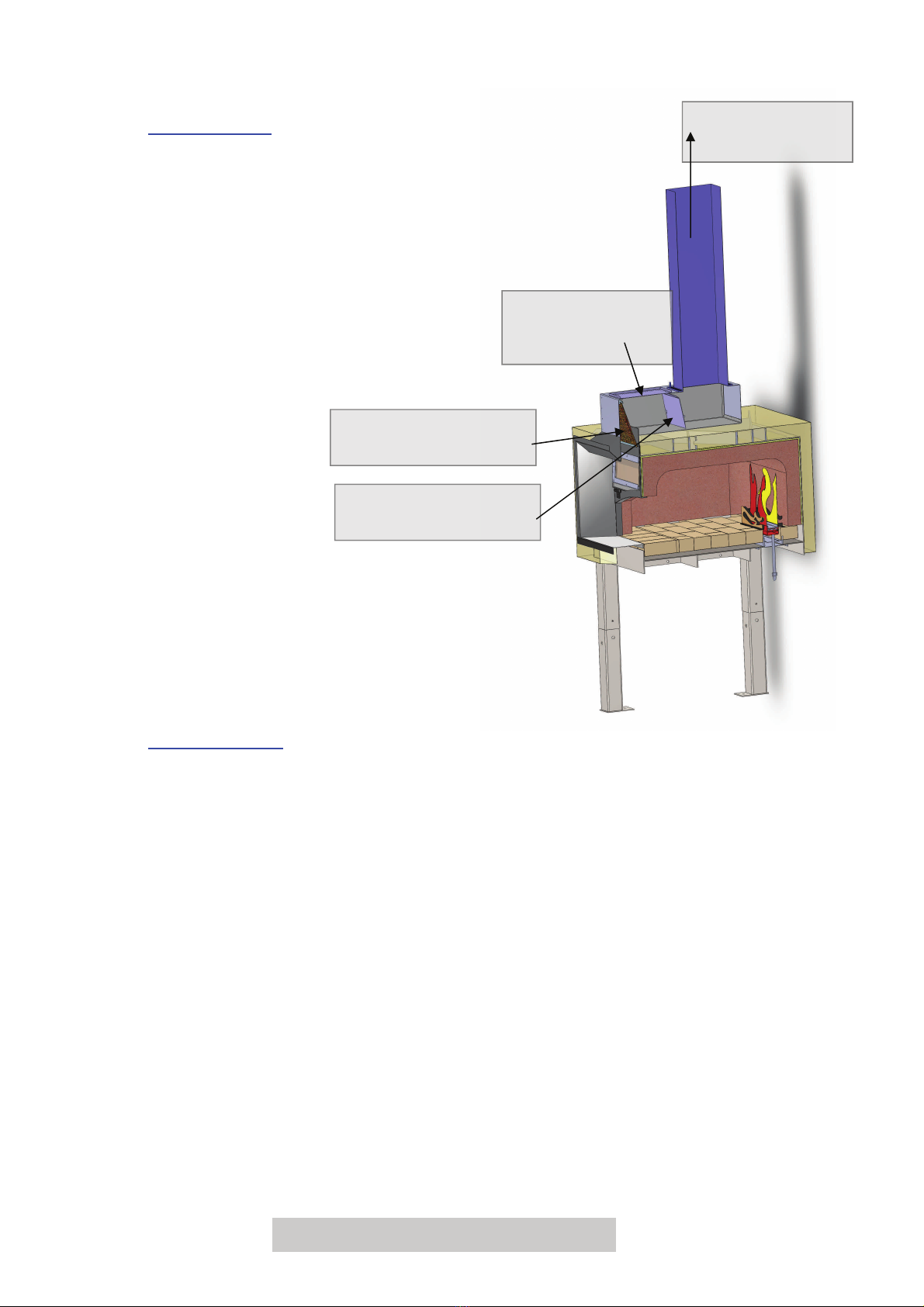

IMPORTANT: This work should be carried out by an approved Gas Technician.

For the gas system of this oven, air must be able to enter beneath the oven for

satisfactory combustion. Ensure primary air is available from beneath the oven.

Confirm with Phoenix Ovens or their distributor that the gas equipment set-up supplied is

correct for the type of gas being used.

1. Mount the thermocouple probe (twisted end) into hole near to centre of the

underneath side of the oven base. Lightly secure with screw retainer.

2. Connect interlock temperature capillary to top of lintel.

3. Connect interlock PD plastic tube to transition. Keep plastic tube away from

hot surfaces and don't allow tight bends or kinks.

4. Connect electrical power leads and spot light wiring to interlock device and

control module as per labeled sockets.

5. Check that the exhaust filter is correctly positioned above the oven door

inside the flue canopy area.

6. Connect to reticulated gas supply at the 19mm (¾”) flare fitting to the isolation

valve fitted to the oven leg.

7. Connect isolation valve to SIT control using braided 3/4” hose supplied.

8. Check all gas / mechanical and electrical connections to all equipment.

9. Ensure burner is located firmly.

10. Check gas flow logic - opening all relevant manual valves.

11. Check the adjustment of the “primary air regulator” on the inspirator connected

to the base of the burner. Initial setting should be about half way between

fully open and fully closed.

12. After the “warm up period” set out in Commissiong section below, this primary

air should be adjusted to achieve clear burning flame in the oven.

On NG it should be blue at the base with light yellow tails,

On Propane, the flame will be mostly light yellow. Deep yellow to orange is NOT

correct and will deposit soot on the roof of the oven.

There must be adequate ventilation beneath the oven to feed air to the gas flame.

The gas control system comes fitted with a standard plug for a wall socket. (Always

unplug the system while any work or inspection is carried out.)

Test operation of the exhaust flue system. This must be fully operational before any

fire can be ignited inside the oven. The exhaust is often connected to the oven

operation by an interlock system. Check with exhaust installers to be sure of operation

procedure.

NOTE: There may be a damper in the flue that may need adjusting. The flue suction

should be adjusted to ~600l/s (1300cfm) however it should be sufficient to not allow

smoke into the kitchen during normal operation.

Proceed with start up procedure outlined in ’Commissioning’

CONNECTION OF GAS SYSTEM