Introduction

1Introduction

1.1 Model Survey

The E-625 amplifier/controller is a stand-alone desktop device

designed to drive and control the displacement of a low-voltage

piezoelectric stage or actuator (LVPZT). The following models

are described in this manual; each supporting a different

position-sensor type:

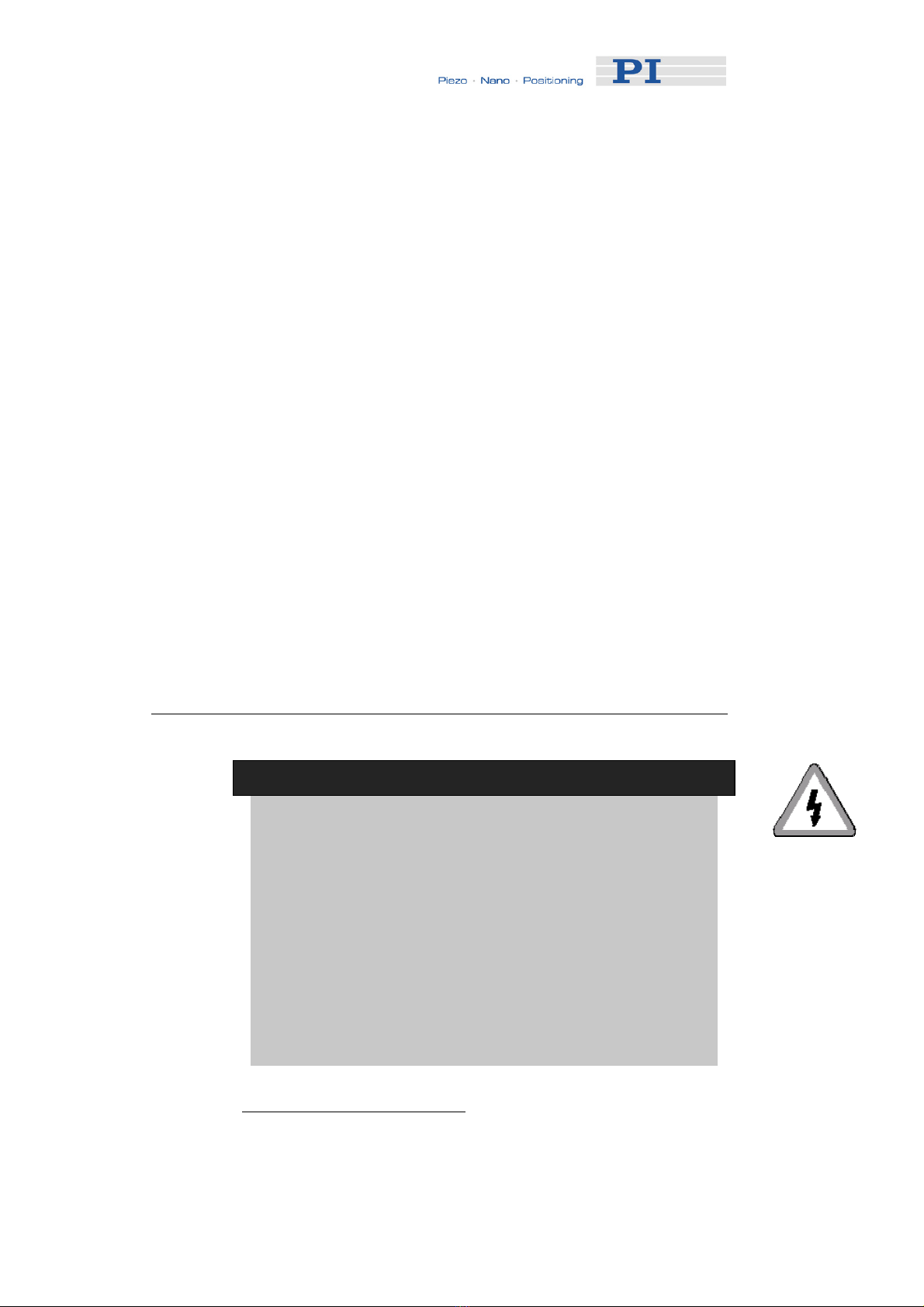

E-625.LR LVPZT controller, provides AC sensor

processing for usage with LVDT sensors

(equipped with E-801.2x sensor submodule)

E-625.SR LVPZT controller, provides DC sensor

processing for usage with strain gauge sensors

(SGS; equipped with 801.1x sensor submodule)

Both models come with an E-802 Servo-Controller and an E-

816 Computer Interface and Command Interpreter installed as

standard.

Networking of E-625’s with each other allows controlling up to

12 devices over a single RS-232 or USB computer interface.

Networking requires additional wiring and setup.

E-625s for use with capacitive sensors are described in detail in

their own manual, PZ166. The E-625.C0 is the same as the E-

625.CR, except that it has the analog control interface only. It is

described in User Manual PZ187.

1.2 Prescribed Use

Based on their design and realization, the E-625 LVPZT

Controller/Amplifier is intended to drive capacitive loads, in the

present case, piezoceramic actuators. The E-625 must not be

used for applications other than stated in this manual,

especially not for driving ohmic (resistive) or inductive loads.

E-625s can be operated in closed-loop mode using position

sensors. The type of position sensor used must be compatible

with the E-625 model to which it is attached: in particular linear

variable differential transformers (LVDT) require the AC

excitation provided by the E-625.LR, and strain gauge sensors

(SGS) require DC exitation provided by the E-625.SR.

www.pi.ws E-625 PZ167E Release 1.4.0 Page 3