Piper BERKELEY Series User manual

BERKELEY SERIES HOTPLATES

SINGLE, DOUBLE OR TRIPLE HOTPLATES

Installation and Operating Manual

For service information call 800-544-3057

Please have the following information available before calling. Information can be found

on the identification/certification tag:

•Model Number

•Serial Number

•Date of Purchase

•Part Description and number as shown in parts list

IMPORTANT INFORMATION

READ BEFORE USE

Piper Products, Inc

300 South 84th Avenue

Wausau, WI 54401

Phone: 715-842-2724 . FAX: 715-842-3125

This manual contains important safety information concerning the maintenance, use and operation of this product.

Failure to follow these instructions could result in damaging equipment, voiding the warranty, serious injury or even death.

TABLE OF CONTENTS

INTRODUCTION

FREIGHT DAMAGE CLAIMS

ELECTRICAL CONNECTION

ELECTRICAL SPECIFICATIONS

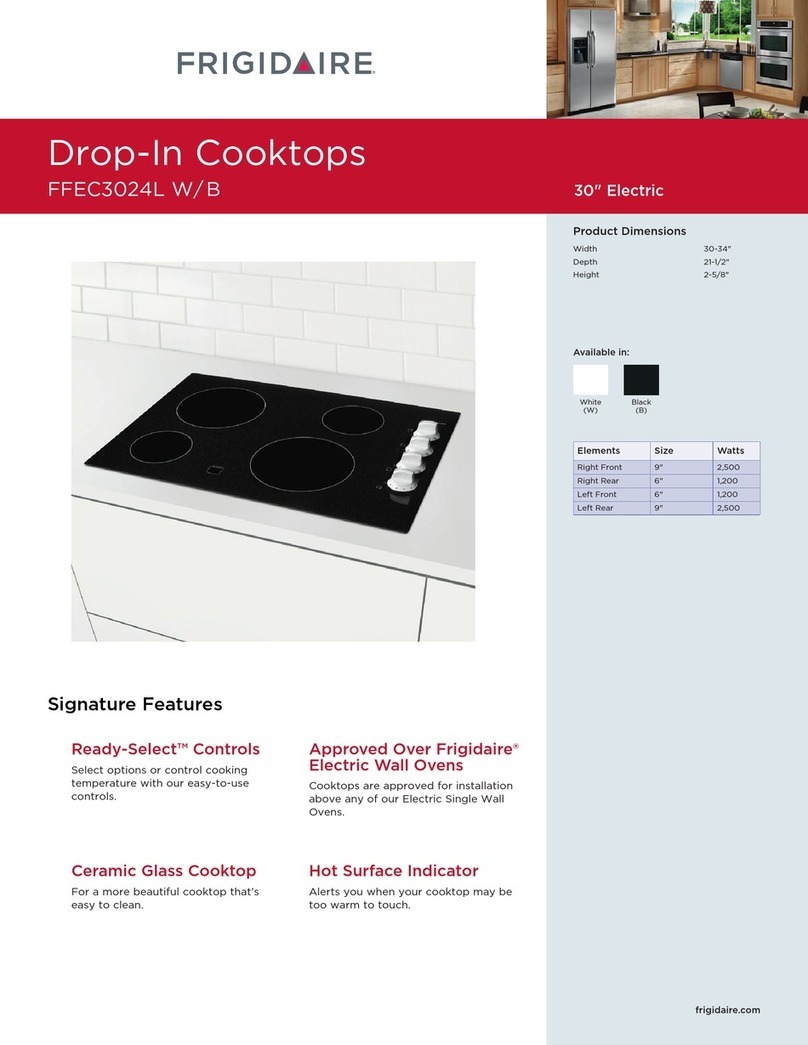

INSTALLATION OF DROP-IN HOTPLATES

DROP-IN HOTPLATE FITTING DIAGRAM

INSTALLATION OF BUILT-IN HOTPLATES

BUILT-IN HOTPLATE FITTING DIAGRAM

INSTALLATION OF PORTABLE HOTPLATES

HOTSPOTS

GLASS SNEEZE GUARDS

USE AND OPERATION OF HOTPLATES

CLEANING INSTRUCTIONS

MAINTENANCE AND REPLACEMENT PARTS

BUILT-IN EXPLODED VIEW

DROP-IN EXPLODED VIEW

CHANGING A QUARTZ LAMP

TROUBLESHOOTING GUIDE

SINGLE HOTPLATE, 120V WIRING DIAGRAM

DOUBLE HOTPLATE, 120V WIRING DIAGRAM

DOUBLE HOTPLATE, 208V/240V WIRING DIAGRAM

DOUBLE HOTPLATE, 208V/240V WITH HOT SPOT WIRING DIAGRAM

DOUBLE HOTPLATE, WITH HEAT LAMP 208V/240V WIRING DIAGRAM

TRIPLE HOTPLATE, 208V/240V WIRING DIAGRAM

WARRANTY

2

2

3

3

6

8

10

10

10

11

12

14

16

17

18

19

20

21

22

23

24

25

26

27

28

1

INTRODUCTION

Congratulations! You have just purchased one of the finest pieces of equipment on the

market today. Before installing or operating your new Piper equipment, you should read

through this manual. This manual should be retained for further reference as it contains

installation and operating instructions, service tips, part lists and warranty information.

For your safety, read and follow all cautions and warnings.

FREIGHT DAMAGE CLAIMS

Your Piper equipment was carefully inspected and packed before leaving our factory. The

transportation company assumes full responsibility for safe delivery of this equipment.

Piper Products cannot assume responsibilities for damage or loss incurred in transit.

Visible damage or loss should be noted on the freight bill and signed by the person

making the delivery.

A freight claim should be filed immediately with the transportation company. If damage is

unnoticed or concealed until equipment is unpacked, notify the transportation company

immediately and tell them you want to file a concealed damage claim. This must be done

within five (5) days after delivery was made. Be sure to retain all packing material and

cartons.

WARNING

Installation of this equipment should be done only by persons qualified or licensed

to install electrical equipment. All electrical and plumbing must meet local, state,

and federal codes.

Plumbing installation must be performed by a qualified plumber.

Adjustments and service work should be performed only by a qualified service

technician. Service is available through Authorized Piper Parts and Service

Distributors throughout the United States. For a complete listing of these call or

write Piper Products, Inc. for the name of the nearest distributor.

This equipment is intended for commercial use only. Not for household use.

Use of other than genuine Piper replacement parts or service work performed by

other than an authorized Piper service agent will void the warranty.

Do not use any corrosive cleaners. Piper only approves soap and water for

cleaning stainless steel.

2

ELECTRICAL CONNECTION

WARNING!!!! DO NOT USE EXTENSION CORDS (VOIDS WARRANTY)

Ground:

The electrical outlet must be provided with an efficient ground, and the voltage and the

frequency of the electrical line matches those indicated on the data plate.

If unsure about the efficiency of the ground, have your electrical circuit

checked by a qualified electrician.

• Carefully remove unit from carton or crate. Remove all loose packing materials

making sure that no small parts or accessories are lost. Inspect the unit for

concealed damage before discarding packing materials.

• Check the name plate for electrical requirements.

• If concealed damage is found refer to section on Freight Damage Claims on

Page 2

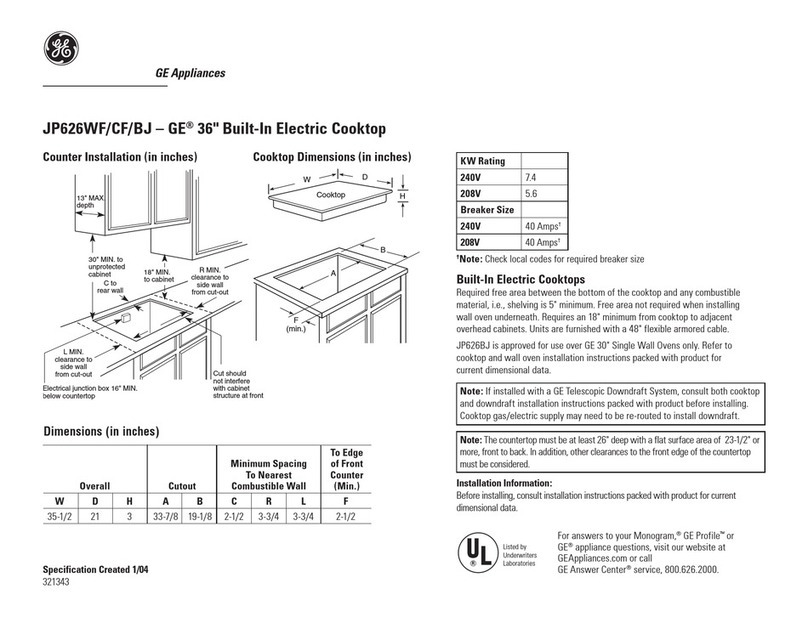

ELECTRICAL SPECIFICATIONS

3

Model Options Overall

Length

Overall

Depth

Hot Plate

Sections Volts Phase Watts Amps NEMA # Weight

(lbs.)

B14050 None 15.75” 19.69” 1 120 1 550 4.6 5-15P 65

B16050 None 23.62” 19.69” 1 120 1 600 5.0 5-15P 88

B24050 None 31.65” 19.69” 2 120 1 1100 9.2 5-15P 130

B26050 None 47.4” 19.69” 2 120 1 1200 10.0 5-15P 175

B240160 None 55.43” 19.69” 3 208 1 1700 8.2 6-15P 185

B36050 None 71.18” 19.69” 3 208 1 1800 8.7 6-15P 200

B14050-HS Hot Spot 15.75” 19.69” 1 208 1 1975 9.5 6-15P 65

B16050-HS Hot Spot 23.62” 19.69” 1 208 1 2150 10.3 6-15P 88

B24050-HS Hot Spot 31.65” 19.69” 2 208 1 2525 12.1 6-15P 130

B26050-HS Hot Spot 47.4” 19.69” 2 208 1 2750 13.2 6-15P 175

B240160-HS Hot Spot 55.43” 19.69” 3 208 1 3125 15.0 L6-20P 185

B36050-HS Hot Spot 71.18” 19.69” 3 208 1 3350 16.1 L6-20P 200

BUILT-IN SERIES - STANDARD DEPTH

Contact factory for special sizes.

4

Model Options Overall

Length

Overall

Depth

Hot Plate

Sections Volts Phase Watts Amps NEMA # Weight

(lbs.)

B17060 None 23.62” 27.56” 1 120 1 850 7.1 5-15P 124

B27060 None 47.4” 27.56” 2 208 1 1700 8.2 6-15P 245

B37060 None 71.18” 27.56” 3 208 1 1800 8.7 6-15P 280

B17060-HS Hot Spot 23.62” 27.56” 1 208 1 2400 11.5 6-15P 124

B27060-HS Hot Spot 47.4” 27.56” 2 208 1 3250 15.6 L6-20P 245

B37060-HS Hot Spot 71.18” 27.56” 3 208 1 4100 19.7 L6-30P 280

BUILT-IN SERIES - EXTRA DEEP

Model Options Overall

Length

Overall

Depth

Hot Plate

Sections Volts Phase Watts Amps NEMA # Weight

(lbs.)

D17060 None 26” 30 1 120 1 850 7.1 5-15P 124

D27060 None 49-3/4” 30 2 208 1 1700 8.2 6-15P 245

D37060 None 73-1/2” 30 3 208 1 1800 8.7 6-15P 280

D17060-HS Hot Spot 26” 30 1 208 1 2400 11.5 6-15P 124

D27060-HS Hot Spot 49-3/4” 30 2 208 1 3250 15.6 L6-20P 245

D37060-HS Hot Spot 73-1/2” 30 3 208 1 4100 19.7 L6-30P 280

ND17060-OHD4 Sneeze Guard

w/ Heat Lamp 33-1/2” 30 1 208 1 1225 5.9 6-15P 196

ND27060-OHD4 Sneeze Guard

w/ Heat Lamp 57” 30 2 208 1 2825 13.6 6-15P 336

ND37060-OHD4 Sneeze Guard

w/ Heat Lamp 78-3/8” 30 3 208 1 4050 19.5 L6-30P 385

ND17060-OHD4-HS

Hot Spot &

Sneeze Guard

w/ Heat Lamp

33-1/2” 30 1 208 1 2775 13.3 6-15P 196

ND27060-OHD4-HS

Hot Spot &

Sneeze Guard

w/ Heat Lamp

57” 30 2 208 1 4375 21.0 L6-30P 336

ND37060-OHD4-HS

Hot Spot &

Sneeze Guard

w/ Heat Lamp

78-3/8” 30 3 208 1 6350 30.5 6-50P 385

DROP-IN SERIES - EXTRA DEEP

ELECTRICAL SPECIFICATIONS (cont.)

Contact factory for special sizes.

Contact factory for special sizes.

5

Model Options Overall

Length

Overall

Depth

Hot Plate

Sections Volts Phase Watts Amps NEMA # Weight

(lbs.)

D14050 None 18 22 1 120 1 550 4.6 5-15P 65

D16050 None 26 22 1 120 1 600 5.0 5-15P 88

D24050 None 34 22 2 120 1 100 9.2 5-15P 130

D26050 None 49-3/4 22 2 120 1 1200 10.0 5-15P 175

D240160 None 57-7/8 22 3 208 1 1700 8.2 6-15P 185

D36050 None 73-1/2 22 3 208 1 1800 8.7 6-15P 200

D14050-HS Hot Spot 18 22 1 208 1 1975 9.5 6-15P 65

D16050-HS Hot Spot 26 22 1 208 1 2150 10.3 6-15P 88

D24050-HS Hot Spot 34 22 2 208 1 2525 12.1 6-15P 130

D26050-HS Hot Spot 49-3/4 22 2 208 1 2750 13.2 6-15P 175

D240160-HS Hot Spot 57-7/8 22 3 208 1 3125 15.0 L6-20P 185

D36050-HS Hot Spot 73-1/2 22 3 208 1 3350 16.1 L6-20P 200

ND14050-OHD4 Sneeze Guard

w/ Heat Lamp 25-5/8 22 1 208 1 925 4.5 6-15P 110

ND16050-OHD4 Sneeze Guard

w/ Heat Lamp 33-1/2 22 1 208 1 975 4.7 6-15P 140

ND24050-OHD4 Sneeze Guard

w/ Heat Lamp 41-3/8 22 2 208 1 1850 8.9 6-15P 185

ND26050-OHD4 Sneeze Guard

w/ Heat Lamp 57 22 2 208 1 2325 11.2 6-15P 240

ND36050-OHD4 Sneeze Guard

w/ Heat Lamp 78-3/8 22 3 208 1 3300 15.9 L6-20P 275

ND14050-OHD4-HS

Hot Spot &

Sneeze Guard

w/ Heat Lamp

25-5/8 22 1 208 1 2350 11.3 L6-20P 110

ND16050-OHD4-HS

Hot Spot &

Sneeze Guard

w/ Heat Lamp

33-1/2 22 1 208 1 2525 12.1 L6-20P 140

ND24050-OHD4-HS

Hot Spot &

Sneeze Guard

w/ Heat Lamp

41-3/8 22 2 208 1 3275 15.7 L6-20P 185

ND26050-OHD4-HS

Hot Spot &

Sneeze Guard

w/ Heat Lamp

57 22 2 208 1 3875 18.6 L6-30P 240

ND36050-OHD4-HS

Hot Spot &

Sneeze Guard

w/ Heat Lamp

78-3/8 22 3 208 1 4850 23.3 L6-30P 275

DROP-IN SERIES - STANDARD DEPTH

ELECTRICAL SPECIFICATIONS (cont.)

Contact factory for special sizes.

INSTALLATION OF DROP-IN HOTPLATES

IMPORTANT: Please ensure that there is a minimum clearance of 6 inches

(150mm) between the bottom of the hotplate and any shelf beneath it. Adequate

ventilation and access is required for service.

1. Follow the dimensions for the correct size opening in the counter surface. Refer to

spec sheet or contact Piper Support

2. Apply a bead of mastic all around the opening so the stainless steel flange will sit

directly onto the mastic to ensure a heat proof and hygienic seal (illustration 1B).

Position the unit directly over the top opening and set squarely in place. Allow

approximately 12 hours for the mastic to cure.

3. Clean excess mastic off after curing using an appropriate solvent.

4. The type of controller supplied can be either left attached to the unit or positioned

remotely from the body of the hotplate. The distance is determined by the length of

the wiring.

5. Before connection, ensure the controls are in the OFF position. The unit should then

be connected to an appropriately protected supply by a QUALIFIED TECHNICIAN.

6

DROP-IN HOTPLATE

FITTING DIAGRAM

Decorative Top

Mastic Seal

Expansion Seal

6mm SCHOTT

Ceran Pyroceramic

Electric

Elements

Insulation

25mm

Bead of Recommended Mastic

7

Illustration 1A

Illustration 1B

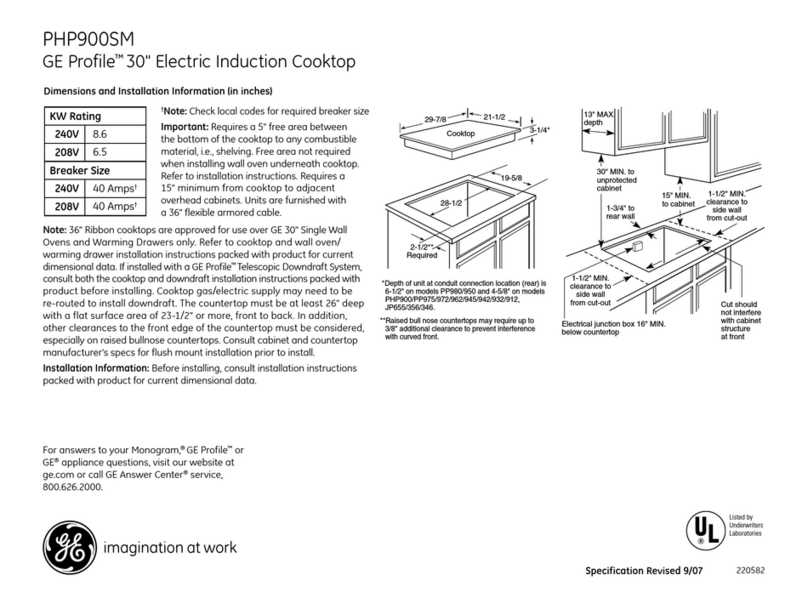

INSTALLATION OF BUILT-IN HOTPLATES

IMPORTANT: Please ensure that there is a minimum clearance of 6 inches

(150mm) between the bottom of the hotplate and any shelf beneath it. Adequate

ventilation and access is required for service.

1. Follow the dimensions for the correct size opening in the counter surface. Refer to

spec sheet or contact Piper Support

2. Position the unit from the underside of the counter work surface and ensure that

the hotplate is properly centered. Mark the holes in the adjustable bracket to the

underside of the counter surface. Using the chosen attachment method, i.e. screws

or studs, fix the hotplate in position. Loosen the adjusting screws holding the

brackets to the hotplate body and adjust the hotplate until it is level and flush to the

counter top surface. Tighten the screws/studs.

3. After the hotplate is fit into position, a high temperature, food grade silicone seal

must be applied to the perimeter of the Ceran and counter top to act as a heat proof

and hygienic seal. See illustration 2 for details. Using masking tape, lay strips of

tape around the Ceran glass panel with the edge of the tape to the extreme edge of

the Ceran. Also lay strips of tape to the extreme edge of the counter opening. Trim

the tape so no overlap occurs. Apply a continuous bead of Dow Corning silicone

or similar product into the space between the hotplate and counter using sufficient

silicone to cover the surface (illustration 2B). Use the edge of a flexible plastic card,

scrape off the excess silicone to the level of the masking tape (illustration 2C).

Immediately peel off the masking tape leaving a smooth and neat line of silicone

around the hotplate. Allow the silicone to cure for 12 hours. Clean any excess

silicone off with appropriate solvent after silicone is cured.

4. The type of controller supplied can be either left attached to the unit or positioned

remotely from the bod of the hotplate. The distance is determined by the length of

the wiring.

5. Before connection, ensure the controls are in the OFF position. The unit should

then be connected to an appropriately protected supply by a QUALIFIED

ELECTRICIAN.

8

9

Counter Top

Masking Tape

Smooth down

using plastic card

for instance

Hotplate

Illustration 2A

Illustration 2B

Illustration 2C

10

6mm Ceran

Bonded to case

3-5mm Expansion Seal

Counter Top

Wood/Ply Base

Adjustable Bracket

Level Adjuster/

Fixing Bracket

Access Panel

Fully Insulated

Heater Box

70mm

BUILT-IN HOTPLATE FITTING DIAGRAM

6mm Ceran

Bonded to case

3-5mm Expansion Seal

Stainless Steel

Counter Top

Stud Welded to

Underside of Top

by Fabricator

Adjustable Bracket

Level Adjuster/

Fixing Bracket

Access Panel

Fully Insulated

Heater Box

70mm

STAINLESS STEEL COUNTER TOP

TILED, LAMINATE, OR STONE COUNTER TOP

11

A + 8mm

B + 8mm

Example Hot Plate

Cutout Size. See

Technical Sheet for

Details.

A

B

Example Built-In

Hot Plate Size. See

Technical Sheet for

Details.

INSTALLATION OF PORTABLE HOTPLATES

WHEN CONNECTING PORTABLE HOTPLATES TO AN ELECTRICAL SUPPLY THEY

MUST CONFORM TO THE ELECTRICAL REGULATIONS OF THAT LOCATION

As these models are portable, no special installation requirements are needed apart

from the electrical details above. When setting it in place, be sure the unit is positioned

on a stable and heatproof surface and at a height suitable for safe operation. Before

connecting to a power supply be sure that all controllers are in the off position.

HOTSPOTS

All models can, if desired, incorporate a hot spot which is an 1800 watt element that

can be used for light cooking or reheating of food. When fitted, the hotspots will have a

separate controller which is independently controlled from the hotplate surface.

WARNING: BE AWARE THESE AREAS ARE VERY HOT EVEN AFTER THE UNIT

HAS BEEN SWITCHED OFF!

GLASS SNEEZE GUARDS

PLEASE BE EXTREMELY CAREFUL WHEN UNPACKING AND TRANSPORTING THE

SNEEZE GUARD GLASS.

The assembly and fitting of the glass sneeze guards must be carried out by a minimum

of 2 personnel.

We recommend the glass only be installed once the hotplate unit has been fitted and

set in place and not transported fitted in the gantry as flexing and breakage may occur.

Do not place any excess weight on the top surface of the guards that will put undue

strain on the supports and glass.

12

USE AND OPERATION OF HOTPLATES

Each hotplate surface is individually controlled by a simmerstat/infinite controller.

Preheat the unit by selecting full power for 20 minutes prior to placing any containers

of food on the hotplate. This will bring the temperature of the hotplate to approximately

250˚F (120˚C).

The temperature of the hotplate can then be preset to the required temperature. DO

NOT LEAVE ON FULL POWER. The full setting is for rapid heating of the hotplate at

the start of service and is not meant for normal use.

Dishes: Shallow depth pans are recommended (approximately 50mm or 2” deep).

They should be heatproof dishes and good conductors of heat with a smooth flat base

free from rough finishes which can scratch and damage the Ceran surface. Bain Marie

/ Steam table pans are not suitable for this purpose. Some suggestions are porcelain,

earthenware, stainless steel, enameled heat proof glass, etc.

Food: Food that is being displayed should have been adequately heated to the

required temperature of approximately 185˚F or 85˚C prior to being placed on the

preheated hotplate. Hotplates are for maintaining the food temperature only and not for

heating the food (see hotspots). Most applications will require a high heat setting (not

maximum) to adequately keep the product hot. However, each user needs to establish

the ideal settings to suit their operation and product.

Hotspots: Where fitted, hotspots can bring the products to the required temperature

quickly and can also include light cooking and are specific for that application.

Length of Display Time: This will depend on the food product being displayed.

However most products should be used within a reasonable period and during this

time the server should ensure the product is stirred for even heating and also to

avoid overheated areas and scorching etc. and also to maintain the product for good

presentation.

Hotplates with Overhead Heated Gantry: This will allow for the food to be heated

from above, however the same advice applies for even heating and presentation of the

product.

Quartz Heat Lamps: The quartz heat lights fitted over the hotplates are designed to

maintain the temperature of the surface of the food. It is controlled by an electronic

dimmer switch which provides 3 stage variable adjustment of the heat output. The

optimum setting will depend on the food being displayed and the distance of the food

to the underside of the quartz. Experimentation is the best way to find the correct

setting.

13

CLEANING INSTRUCTIONS

PYROCERAMIC HOTPLATES

STOVE ENAMELLED BODY AND OHD

STAINLESS STEEL GANTRIES

CERAMIC HOTPLATES

The following cleaners were successfully tested and approved by Schott for Ceran

cooking surfaces.

• Elco Cook Top Cleaning Crème

• Golden Ventures Cerama Bryte

• Hopes Cooktop Cleaning Crème

To keep your surface looking good and easy to use for a long time to come, follow

these hints and tips:

• When the unit is switched off and the surface has cooled, remove any burnt on de-

posits or spilled food from your Ceran surface with a suitable metal razor - free with

your purchase (similar to a paint scraper). Hold the scraper at approximately a 30

degree angle to the cook top surface.

• Apply a few dabs of an approved cleaner (see above) and work the cleaner over the

entire surface with a paper towel as if cleaning a window.

• As a final step, clean well with a damp cloth, removing all residue and finally wipe

clean with a dry paper towel.

Tip: Clean your Ceran regularly, at least at the end of each operation.

Important: If any sugar or food containing sugar (preserves, ketchup,

tomato sauce, etc.), a plastic item, or kitchen foil is accidentally allowed

to melt on the hot spot surface of your Ceran, remove the melted material

IMMEDIATELY WITH A METAL SCRAPER.

For your safety, please wear a glove pot holder while using the scraper

14

CLEANING (cont.)

DO NOT use abrasive sponges or scourers of any type. Corrosive

cleaners such as oven sprays and stain removers and bleaches should

also NOT BE USED.

EPOXY COATED BODY (PORTABLE UNITS)

• Use a damp cloth (mildly soapy) to remove any residue stains or a recommended

stove enamel cleaner.

• DO NOT USE ABRASIVE CLEANERS

QUARTZ LIGHT GANTRY

• To clean the stainless steel gantry use a recommended stainless steel cleaner or a

damp cloth.

• DO NOT TOUCH THE QUARTZ LIGHT BULB.

• Wipe over with a dry cloth to finish off.

15

16

MAINTENANCE AND REPLACEMENT PARTS

WARNING: SWITCH UNIT OFF AND DISCONNECT FROM THE

ELECTRICAL SUPPLY BEFORE CARRYING OUT ANY OF THE

FOLLOWING. IT IS HIGHLY RECOMMENDED THAT ALL PROCEDURES

BE PERFORMED BY A QUALIFIED SERVICE TECHNICIAN

Ceran GLASS AND HEATER MAT

• Carefully remove the broken glass and heater mat WHILE WEARING PROTECTIVE

GLOVES AND EYE PROTECTION, being certain to remove all glass remnants

from the edges and also removing any excess mastic leaving a clean area for re-

bonding. Disconnect the heater mat wiring from the controller noting the terminal

positions and pull through the conduit.

• Refit the new Ceran and heater mat and feed the wiring back through the conduit to

the control box. Reconnect the wires to their original positions. (If you are unable to

access from the top of the hotplate, remove the base plate and insulation and carry

out the replacement from below).

• Refit the Ceran glass by running a bead of Dow Corning 781 or comparable mastic

to the underside of edge of Ceran (built-in) or fill in the area between the glass and

flange (drop-in). Carefully set the glass and heater mat on the top surface of the

hotplate making sure the surface is flat and level. (In the case of a drop-in, masking

tape is needed on the edges of the glass and stainless flange to ensure a neat

finish.) Allow approximately 12 hours to cure.

• Refit the hotplate to the counter worktop by following the procedures for either

built-in or drop-in model. After re-installation of the hotplate in the counter, allow the

mastic to cure for about 12 hours, then switch the unit on and test it.

HEATER MAT

• To gain access you will need to remove the access panel from the underside of the

main body and carefully remove the insulation board from the interior.

• The mat will be stuck to the underside of the Ceran glass by a suitable adhesive.

Disconnect the wiring noting their positions, lift up one corner and carefully peel off

the mat. Remove as best as you can any excess adhesive prior to replacing with a

new mat.

• Peel off the backing of new mat (if self-adhesive type) and starting from one

end smooth the mat across the glass TAKING CARE NOT TO LEAVE ANY AIR

POCKETS.

• Reconnect the wiring. Replace the insulation and access panel and test.

17

MAINTENANCE AND REPLACEMENT PARTS (cont.)

WARNING: SWITCH UNIT OFF AND DISCONNECT FROM THE

ELECTRICAL SUPPLY BEFORE CARRYING OUT ANY OF THE

FOLLOWING. IT IS HIGHLY RECOMMENDED THAT ALL PROCEDURES

BE PERFORMED BY A QUALIFIED SERVICE TECHNICIAN

TOGGLE/ROCKER/PUSH BUTTON ON/OFF SWITCH

• Note position of wires and pull off connections.

• Remove locknut on switch and remove from control panel.

• Re-fit new switch/toggle/rocker and re-connect

NEON INDICATOR LAMP

• Pull off wires from spade terminals.

• Remove retaining nut and remove indicator lamp.

• Replace with new lamp and reconnect.

SIMMERSTAT/INFINITE CONTROL

• Remove indicator knob.

• Remove retaining nut and washer.

• Remove spade terminals (noting their positions).

• Remove simmerstat and replace with new, reversing the above procedure.

DIMMER SWITCH

Follow same procedure as above.

HOT SPOT

• Note position of wiring.

• Remove connections.

• Remove retaining bracket and replace with new Hot Spot.

• Replace wiring and bracket.

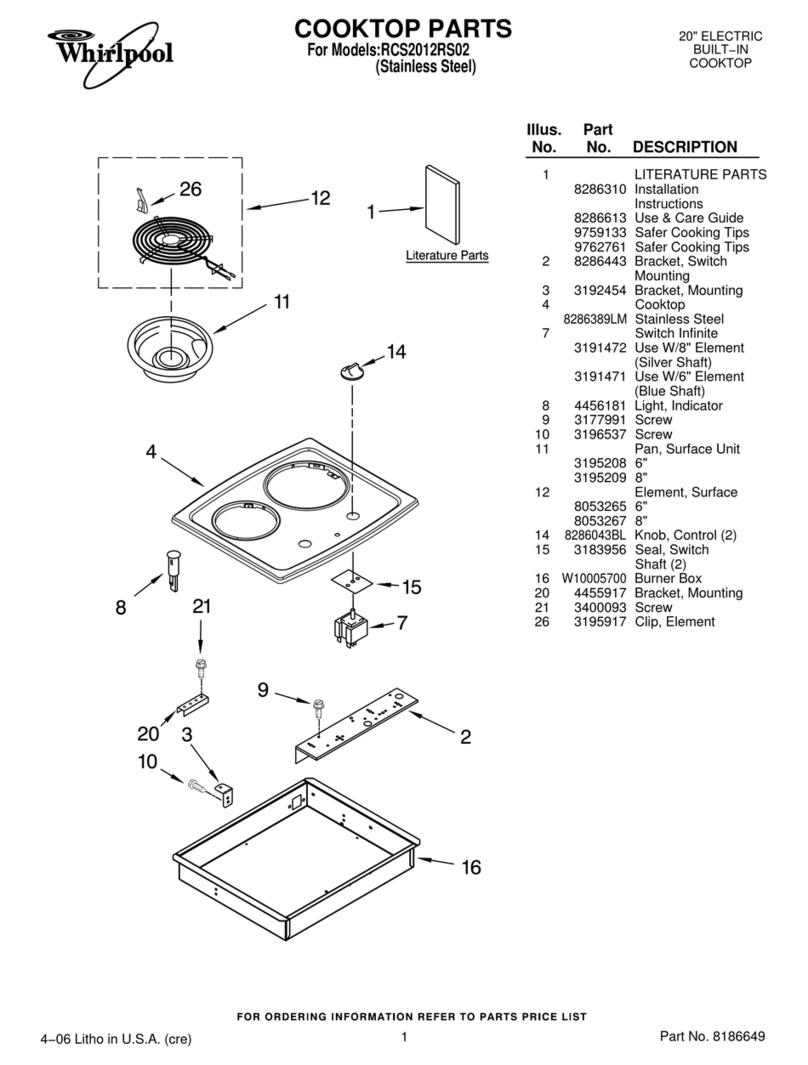

BUILT-IN EXPLODED VIEW

18

6mm Thick Schott Pyroceramic Glass

Self Adhesive Heater Mat.

Wattage as per O&M Manual

Monolux Heat Resistant Board

Adjustable Angle Supports and Sides

304 Grade Stainless Steel Case

Stainless Steel Removable Base Plate

Controller (3 switch shown)

Comes with 2 meters of cable

This manual suits for next models

52

Table of contents