6

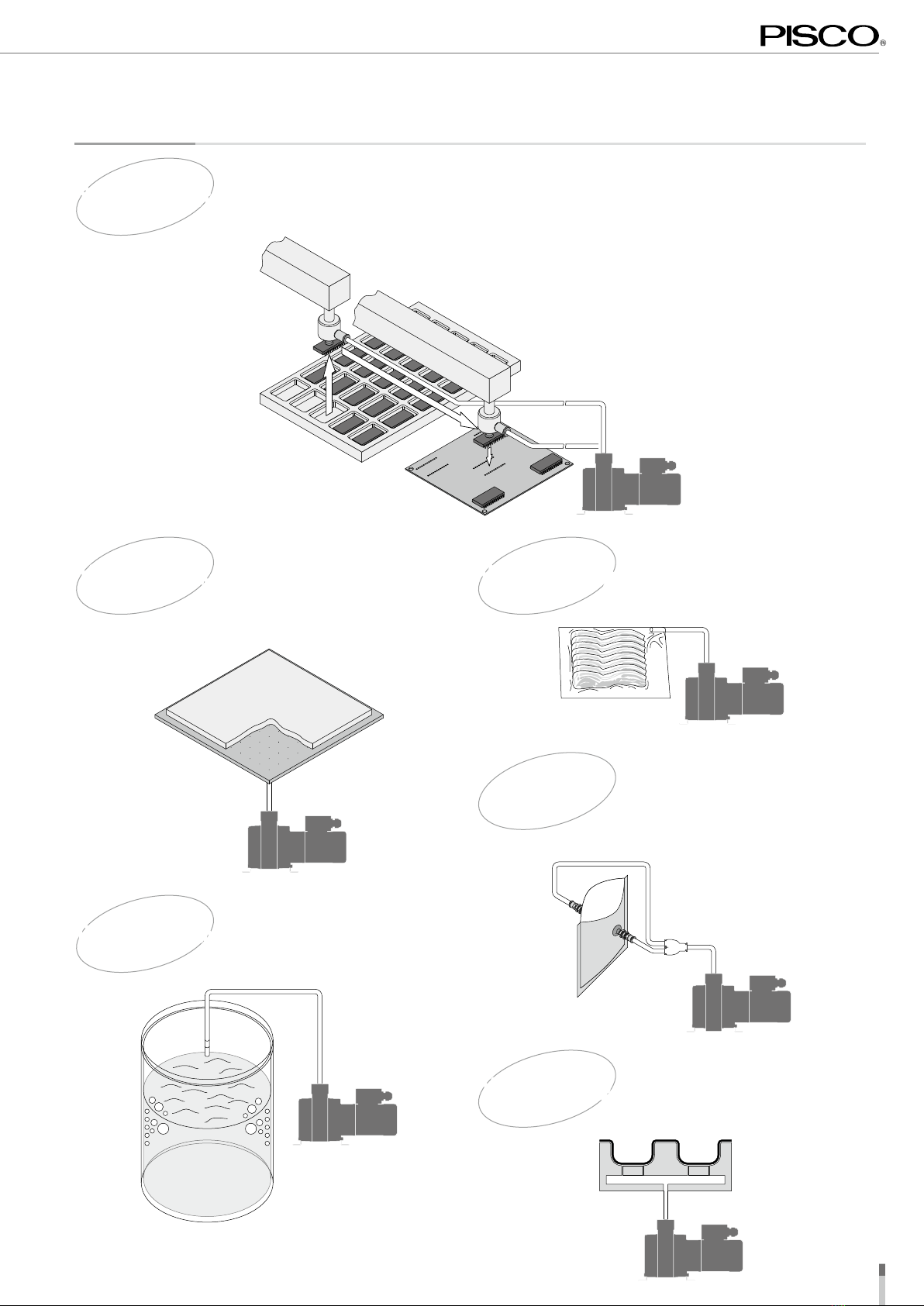

Thermal protector

MCCB

Relay(Ry)

SW B

Ry

Ry

Ry

SW A

Capacitor

Blue (P)

White (U1)

Gray (U2)

Black (Z2)

Blue (P)

Motor

Single-phase power source

Thermal protector

SW

E

L

N

Capacitor

Fuse

(5A)

Blue

(P)

White

(U1)

Gray

(U2)

Black

(Z2)

Blue

(P)

Motor

3-pin power cable connection

MCCB

S

R

T

U

V

W

Motor

Thermal protector

Thermal protector

3-phase power source

Blue (P)

Blue (P)

Black(W)

Gray (V)

White (U)

SW A

Ry

Ry

SW B

MCCB

Ry

Ry

R

S

T

3-phase power source

Relay(Ry)

Thermal protector

Motor

■Single phase motor with a built-in power switch wiring diagram (RPV06A-40S100SW, RPV062-60S100SW)

■3-phase motor wiring diagram (RPV064-120)

The motor is equipped with an automatic reset type thermal protector in the coil. Therefore, operation restarts automatically when the temperature of the motor

drops to safety level after thermal protector activation. To prevent a danger by unexpected restart, provide a recovery switch which uses switch and relay as like

above circuit diagram to restart the pump.

●Thermal protector activation temperature : Open (motor stop) ▶130 ±5ºC, Close (motor restart) ▶90 ±15ºC

Note: The motor is equipped with an automatic reset type thermal protector in the

coil. Thermal protector activates to stop the motor in case the temperature

inside the motor exceeds the specified temperature below. Operation

restarts automatically when the temperature of the motor drops to safety

level. To prevent a danger by unexpected restart, make sure to turn off the

main power supply before maintenance and inspection.

●Thermal protector activation temperature

Open (motor stop) ▶130 ±5ºC, Close (motor restart) ▶90 ±15ºC

Note: Therefore, in the case of the circuit (left figure) given in the handling

instruction of motor, after activation of thermal protector, operation will be

resumed automatically when motor temperature falls.

In order to prevent a risk by unexpected reboot, please take safety

measures when operating the pump, such as making a self-hold circuit

using relays and switches.

●Thermal protector activation temperature

Open (motor stop) ▶130 ±5ºC, Close (motor restart) ▶86 ±20ºC

①

②③ ③ ④④

⑤

⑱

⑥

⑦

⑧

⑨

⑩

⑪

⑫

⑬

⑭

⑮⑯

⑰

⑱

⑲ ⑳

⑦ ⑨

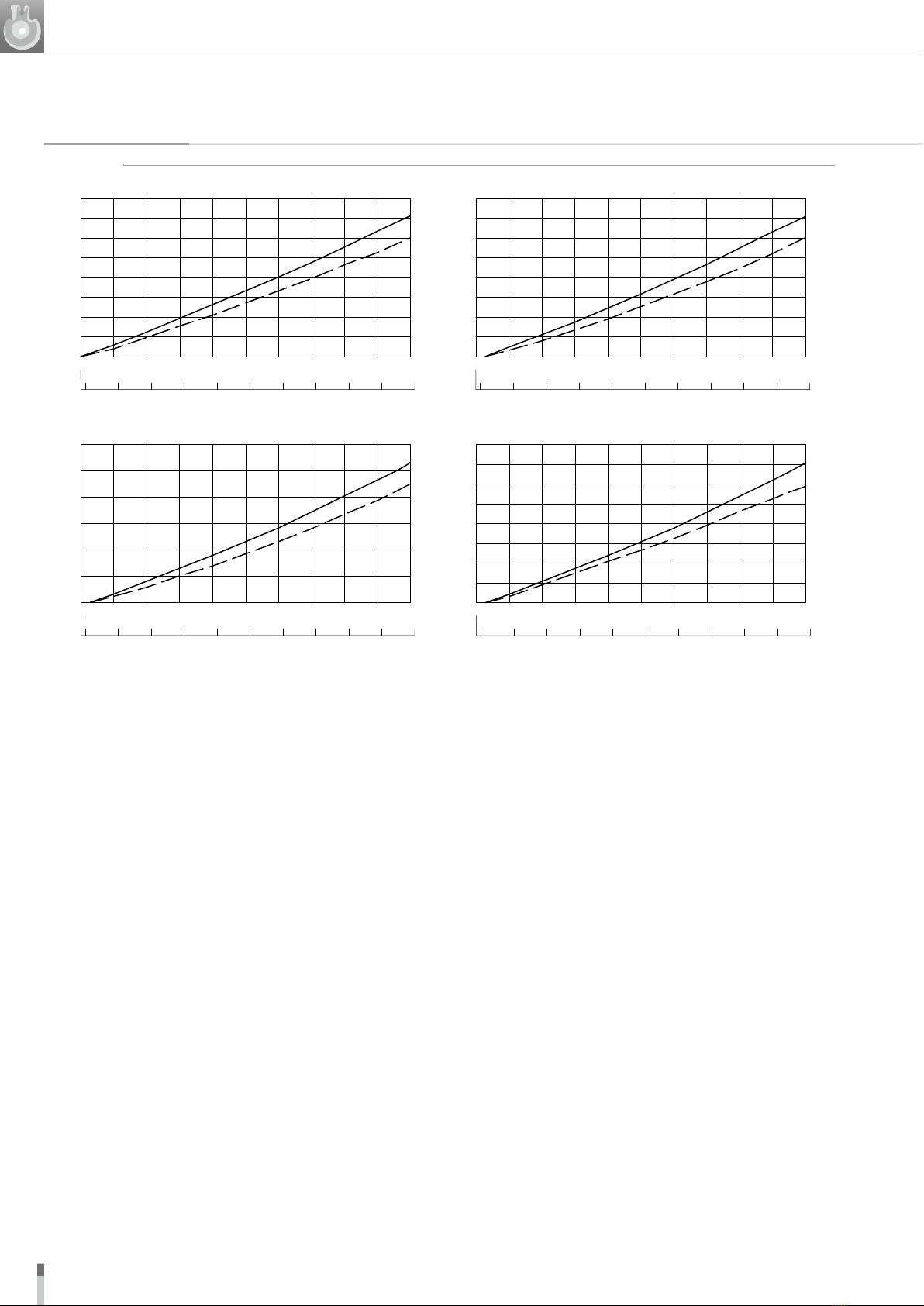

Rotary Vacuum Pump

No. Part description Material

①Cyliner Aluminum alloy

②Rotor PPS resin

③Bearing Stainless steel

④Crank plate Stainless steel

⑤Main shaft Stainless steel

⑥Side block E Aluminum alloy

⑦Bearing Stainless steel

⑧Blancer E Stainless steel

⑨Blancer R Stainless steel

⑩Side plate Aluminum alloy

⑪Center plate Aluminum alloy

⑫Manifold Aluminum alloy

⑬Side block M Aluminum alloy

⑭Magnet Neodymium magnet

⑮Cooling fan PPS resin

⑯Sealing cup PPS resin

⑰Motor Aluminum alloy

⑱Cap screw Stainless steel

⑲Inner coupling Stainless steel

⑳Magnet Neodymium magnet

* All seal rubber is made of FKM.

Structure (e.g. parallel twin - 60W motor type: RPV062-60)

Motor Wiring diagram

■Single phase motor wiring diagram (RPV06A-40S100/S110, RPV062-60S100/S110)

■3phasemotor wiring diagram(RPV06A-40T200, RPV062-60T200, RPV063-90T200)