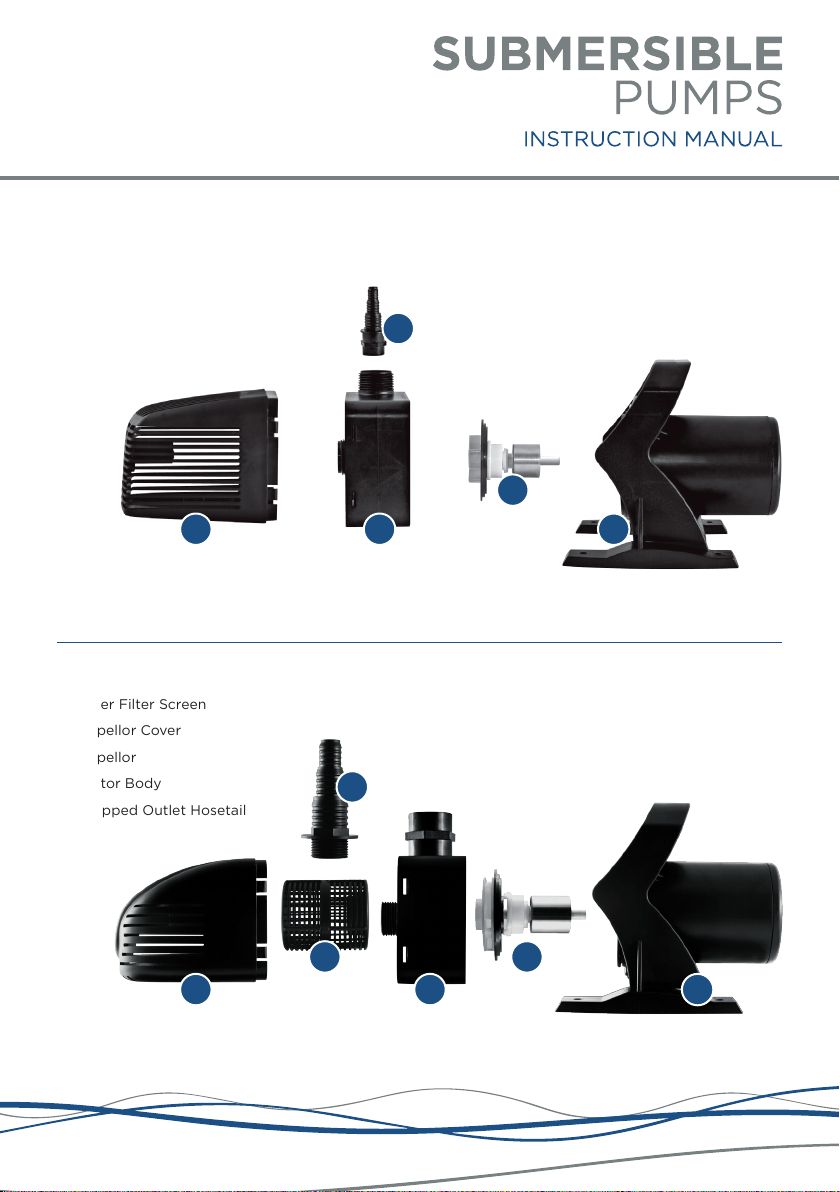

DESCRIPTION & FEATURES

YOUR PLATYPUS PUMP HAS BEEN

MANUFACTURED WITH ADVANCED

TECHNOLOGY TO PROVIDE YOU WITH THE

BEST QUALITY PUMP FOR YOUR POND OR

WATER FEATURE.

• The power cord cannot be replaced, if the cord is

damaged, the pump must be discarded.

• The complete vortex impellor set is a wearing

consumable part. Regular inspections, cleaning and

maintenance of impellor is necessary to ensure longer

impellor life. If the vortex impellor becomes worn

or damaged it should be replaced (available from

your local dealer). failure to do so may cause serious

damage to the pump.

1. Disconnect the power cord beforeperforming

maintenance.

2. Remove from water and detach tubing.

3. Remove front filter cage by gentlysqueezing sides.

4. Unscrew the four large screws facing the rear of the

motor and remove theimpellor housing. Note: You do

not need to remove impellor cover.

(Models: PP65, PP85, PP110, PP30, PP60)

5. Remove the impellor cover by turning anticlockwise

and pulling out (it may be quite sti due to algae and

grime build up. Gently remove the impellor and shaft,

use long nose pliers if needed. Take care not to break

ceramic shaft (if applicable) because they are brittle.

(Models: PP10LV, PP25LV, PP40LV, PP12, PP25, PP40)

6. Gently remove O’Ring seal & impellor set. Clean

the impellor & impellor chamber taking care not to

damage or scour surfaces. Check for any signs of

wear or damage.

7. Reinstall the complete impellor set making sure the

locator probe fits into the hole on the impellor set.

Put the impellor set in firmly. Carefully replace O’ring

seal. Check the impellor can spin freely. This step

is important, ensure impellor is refitted correctly or

the pump could be damaged. If unsure contact your

dealer.

8. Put impellor housing back on and screw the four

screws back in, making sure the screws are done up

evenly. Apply pressure to the impellor while replacing

housing to ensure impellor remains locked in correct

position.

9. Replace front filter cage, re-attach tubing to outlet,

submerse in water and turn on.

INSTALLATION

MAINTENANCE

• Platypus pumps are suitable for use in many dierent

applications including fountains, water features, small

ponds and hydroponics.

• Your Platypus pump has a single moving part (an

impellor set) therefore enabling easy cleaning and

maintenance.

• The motor and electrical components are

encapsulated in epoxy resin, ensuring safe operation

under water.

• The pump has a robust bearing and shaft design so

no oil/grease lubrication is required. Check out the

Platypus range of pond lights and accessories.

1. If required, have a qualified electrician install

weatherproof power point near to the pond or water

feature, (within the cable length of the pump).

2. Place the pump in desired location, ensure it is on

a stable surface free of sludge/debris and connect

tubing to the outlet.

3. Ensure pump is submerged, then plug in power cord

and switch on.

• Disconnect power cord from the power supply before

performing maintenance. Never lift the pump by the

power cord.

• The only serviceable item is the impellor set.

• The motor unit of the pump is encapsulated with

epoxy resin and does not need lubrication.

• All Platypus submersible pumps are water cooled; if

pump becomes restricted it will overheat and could

cause permanent damage. Ensure pump does not

become blocked or restricted.

IMPORTANT SAFEGUARDS

Please read the operating instructions and familiarize yourself with the equipment before placing it in service. Correct and safe use

of the system requires strict compliance with the safety instructions. For safety reasons persons less than 16 years of age or people

that are not familiar with these instructions should not use this equipment.