TABLE OF CONTENTS

Section 1 .............................................................................................................. 1

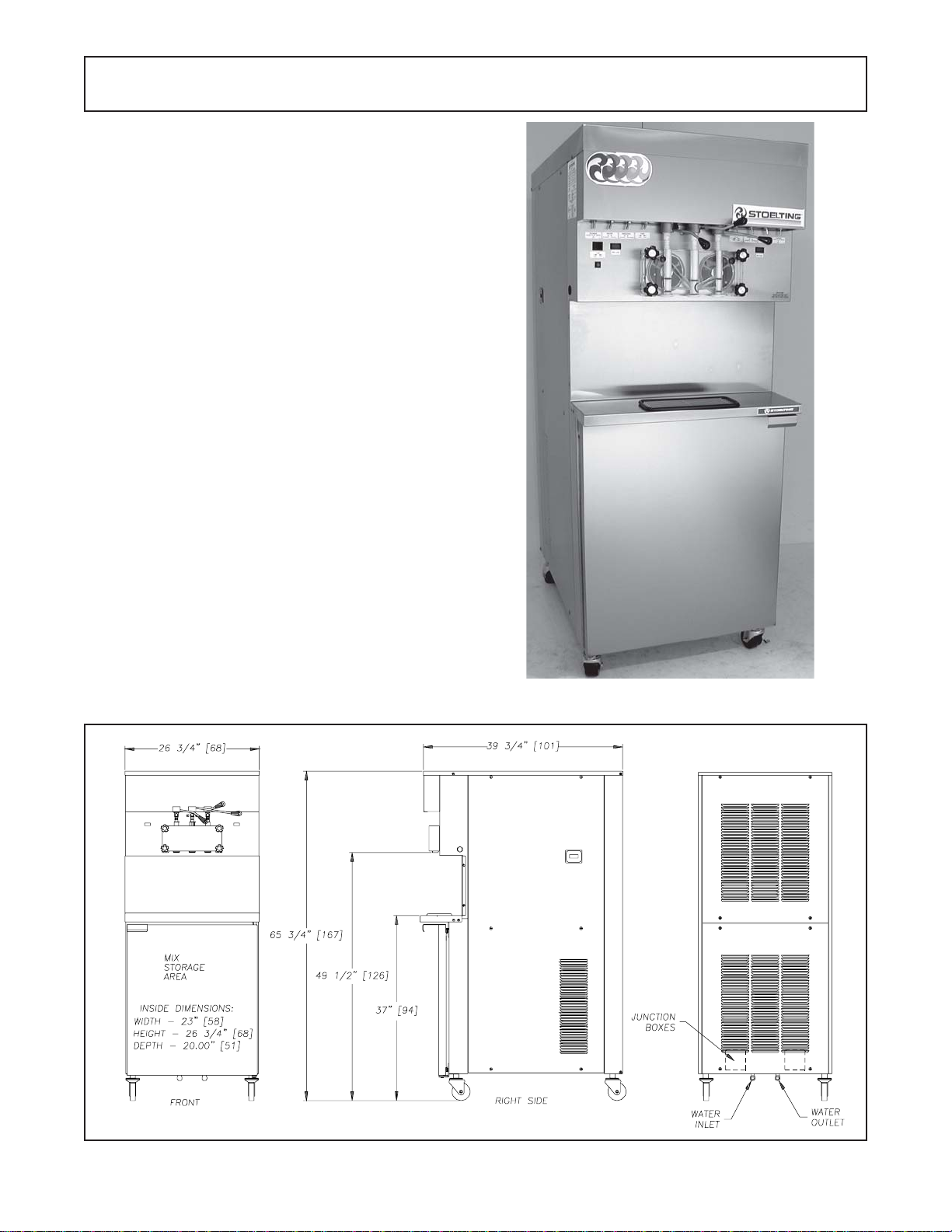

1.1 Description.............................................................................................. 1

1.2 Specifications.......................................................................................... 2

Section 2 .............................................................................................................. 3

2.1 SafetyPrecautions .................................................................................. 3

2.2 Shipment &Transit .................................................................................. 4

2.3 FreezerInstallation................................................................................... 4

2.4 Installing PermanentWiring...................................................................... 4

2.5 Mix Pump ................................................................................................ 5

Section 3 .............................................................................................................. 9

3.1 SafetyPrecautions .................................................................................. 9

3.2 OperatingControls andIndicators............................................................ 9

3.3 Sanitizing ................................................................................................ 10

3.4 InitialFreeze DownandOperation ........................................................... 11

3.5 MixInformation ........................................................................................ 11

3.6 OperationofMix Pump ............................................................................ 11

3.7 RemovingMix fromthe Freezer ............................................................... 12

3.8 Cleaningthe Freezer ............................................................................... 12

3.9 Disassemblyof Freezer Parts.................................................................. 12

3.10 RoutineCleaning ..................................................................................... 13

3.11 MixPump Cleaning ................................................................................. 14

3.12 SanitizeFreezerParts ............................................................................. 14

3.13 AssemblyofFreezer................................................................................ 14

Section 4 .............................................................................................................. 17

4.1 Freezer Adjustment ................................................................................. 17

4.2 ProductTemperatureAdjustment ............................................................. 17

4.3 OverrunAdjustment ................................................................................. 17

4.4 Mix PumpHoseReposition ..................................................................... 18

4.5 MixPump HoseReplacement.................................................................. 18

4.6 CabTemp.Adjustment............................................................................. 18

4.7 DriveBeltTensionAdjustment.................................................................. 18

4.8 Condenser Cleaning(Air Cooled Freezers) ............................................. 19

4.9 PreventativeMaintenance........................................................................ 19

4.10 ExtendedStorage ................................................................................... 19

4.11 Troubleshooting ....................................................................................... 20

Section 5 .............................................................................................................. 25

5.1 How toOrderReplacement Parts ............................................................ 25

5.2 PartsLists and ReferenceDrawings........................................................ 25