Power Fist 8700718 User manual

V4.0 8700718

Please read and understand all instructions before use. Retain this manual for

future reference.

User Manual

2,000WInverter

Generator

8700718 2,000W Inverter Generator V4.0

2 For technical questions call 1-800-665-8685

SPECIFICATIONS

Engine

OHV, Air Cooled, Single Cylinder

Engine Displacement

80 cc

Continuous Output

1,600 Watts

Peak Output

2,000 Watts

Electric Start

No

Recoil Start

Yes

Fuel Type

Gas

Fuel Tank Capacity

1.18 Gallons (4.5 litres)

Run Time @ 50% Load

6.5 Hours

Engine Oil

Type

SAE 10W30

API Grade

SE or Greater

Capacity

350 ml / 11.8 oz

Receptacle(s)

2 x 120V AC, 1 x 12V DC

Noise Level

62.5 dB

Low Oil Shutdown

Yes

GFCI Protection

No

Spark Plug

Type

E6TC/E6RT/BPR6HS

Gap

0.7 – 0.8 mm (0.028 – 0.031 in.)

Torque

14.8 ft-lb (20.0 N-m)

INTRODUCTION

The 2,000W Inverter Generator provides clean AC power that can safely run

electronic devices such as televisions, computers, microwaves, etc. The ECO

Control saves on fuel and reduces noise by automatically adjusting the engine

speed to match the electrical load. The parallel outlets can be used to connect to

a second inverter generator for even more power.

2,000WInverter

Generator

V4.0 2,000W Inverter Generator 8700718

Visit www.princessauto.com for more information 3

SAFETY

WARNING! Read and understand all instructions before using this tool. The

operator must follow basic precautions to reduce the risk of personal injury

and/or damage to the equipment.

Keep this manual for safety warnings, precautions, operating or inspection and

maintenance instructions.

HAZARD DEFINITIONS

Please familiarize yourself with the hazard notices found in this manual. A notice

is an alert that there is a possibility of property damage, injury or death if certain

instructions are not followed.

DANGER! This notice indicates an immediate and specific hazard that will

result in severe personal injury or death if the proper precautions

are not taken.

WARNING! This notice indicates a specific hazard or unsafe practice that

could result in severe personal injury or death if the proper

precautions are not taken.

CAUTION! This notice indicates a potentially hazardous situation that may result

in minor or moderate injury if proper practices are not taken.

NOTICE! This notice indicates that a specific hazard or unsafe practice will

result in equipment or property damage, but not personal injury.

WORK AREA

1. Operate in a safe work environment. Keep your work area clean, well-lit

and free of distractions.

2. Keep anyone not wearing the appropriate safety equipment away from the

work area.

3. Store unused tools properly in a safe and dry location to prevent rust or

damage. Lock tools away and keep out of the reach of children.

4. Do not install or use in the presence of flammable gases, dust or liquids.

8700718 2,000W Inverter Generator V4.0

4 For technical questions call 1-800-665-8685

PERSONAL SAFETY

WARNING! Wear personal protective equipment approved by the Canadian

Standards Association (CSA) or American National Standards Institute (ANSI).

PERSONAL PROTECTIVE EQUIPMENT

1. Always wear impact safety goggles that provide front and side protection

for the eyes. Eye protection equipment should comply with CSA Z94.3-07

or ANSI Z87.1 standards based on the type of work performed.

2. Wear gloves that provide protection based on the work materials or to

reduce the effects of tool vibration.

a. Do not wear gloves when operating a tool that can snag the material

and pull the hand into the tool.

3. Wear protective clothing designed for the work environment and tool.

4. Non-skid footwear is recommended to maintain footing and balance in the

work environment.

PERSONAL PRECAUTIONS

Control the tool, personal movement and the work environment to avoid

personal injury or damage to tool.

1. Do not operate any tool when tired or under the influence of drugs, alcohol

or medications.

2. Avoid wearing clothes or jewelry that can become entangled with the

moving parts of a tool. Keep long hair covered or bound.

3. Do not overreach when operating a tool. Proper footing and balance

enables better control in unexpected situations.

SPECIFIC SAFETY PRECAUTIONS

WARNING! DO NOT let comfort or familiarity with product (gained from

repeated use) replace strict adherence to the tool safety rules. If you use

this tool unsafely or incorrectly, you can suffer serious personal injury.

1. Use the correct tool for the job. This tool was designed for a specific

function. Do not modify or alter this tool or use it for an unintended purpose.

2. All users must understand the operation of all controls and learn how to

stop the generator quickly in case of emergency.

V4.0 2,000W Inverter Generator 8700718

Visit www.princessauto.com for more information 5

3. Do not tamper with governor spring, links or other engine parts to increase

speed or power.

4. The engine and exhaust become very hot during operation. Severe thermal

burns can occur on contact, especially with the muffler.

a. Keep the generator at least 3 feet (1 meter) away from buildings and

other equipment during operation.

b. Do not place anything on the generator while it is running.

5. The manufacturer of the equipment, on which this engine is installed, specifies

the engine’s top speed during operation. DO NOT exceed this speed.

6. Never exceed the generator’s wattage or amperage capacity as this can

damage the generator or the connected appliances

7. Disconnect all electrical appliances from the generator before starting or

stopping the gas engine. Leaving the appliances attached may result in

damage to the generator or appliances.

CARBON MONOXIDE

All gas appliances consume air (oxygen) and can produce carbon monoxide

which is toxic and has no odour and can cause death. Using a gas appliance in a

small and enclosed area can be harmful. Never use this appliance in a small and

enclosed area. Always have fresh air venting.

CARBON MONOXIDE POISONING

DANGER! Never operate a gas engine indoors or in a confined space as the

exhaust contains carbon monoxide gas. Inhalation of carbon monoxide gas

can lead to illness or death. The area must be well ventilated. Opening

windows and doors is not enough to ventilate an area.

Carbon monoxide is a colourless and odourless gas that is difficult to detect.

Carbon monoxide poisoning results from inhalation of the gas and may be lethal

if left untreated. Evacuate all people to an area with clean air and seek

immediate medical attention for any person experiencing the following

symptoms:

1. Headache

2. Confusion

3. Shortness of breath

4. Weakness

5. Chest pain

6. Dizziness

7. Vision trouble

8. Nausea and vomiting

9. Unconsciousness

8700718 2,000W Inverter Generator V4.0

6 For technical questions call 1-800-665-8685

ELECTRICAL SAFETY

WARNING! Do not touch or handle a live tool with any part of your body that is

wet or damp. Wet skin reduces resistance to electrical current, increasing

the danger of a serious or fatal shock.

WARNING! To reduce risk of electric shock, be certain that the plug is

connected to a properly grounded receptacle.

1. The generator (stator winding) is isolated from the frame and from the AC

receptacle ground pin. Electrical devices that require a grounded receptacle pin

connection will not function if the receptacle ground pin is not functional.

2. Protect yourself against electric shocks when working on electrical

equipment. Avoid body contact with grounded surfaces. There is an

increased chance of electrical shock if your body is grounded.

3. Do not expose the tool to rain or wet conditions. Water entering a power

tool will increase the risk of electric shock.

4. Do not alter any parts of the tool or accessories. All parts and accessories are

designed with built-in safety features that may be compromised if altered.

5. When wiring an electrically driven device, follow all electrical and safety

codes, as well as the most recent Canadian Electrical Code (CE) and

Canadian Centre for Occupational Health and Safety (CCOHS).

WARNING! All wiring should be performed by a qualified electrician.

ENGINE REFUELING PRECAUTIONS

1. Never remove the fuel cap or add fuel with the engine running. Stop the engine

and allow both the engine and exhaust components to cool before refueling.

2. Never add or drain fuel from the engine while indoors.

3. Never refuel or store the machine in a place where there is open flame,

spark or other ignition source.

4. Do not attempt to start the engine if fuel is spilled. Clean up the spill and

dispose of any rags properly before restarting.

5. Replace and tighten the fuel cap after refueling.

V4.0 2,000W Inverter Generator 8700718

Visit www.princessauto.com for more information 7

UNPACKING

WARNING! Do not operate the tool if any part is missing. Replace the

missing part before operating. Failure to do so could result in a malfunction

and personal injury.

Remove the parts and accessories from the packaging and inspect for damage.

Make sure that all items in the parts list are included.

Contents:

• Generator • Funnel • Spark Plug Wrench

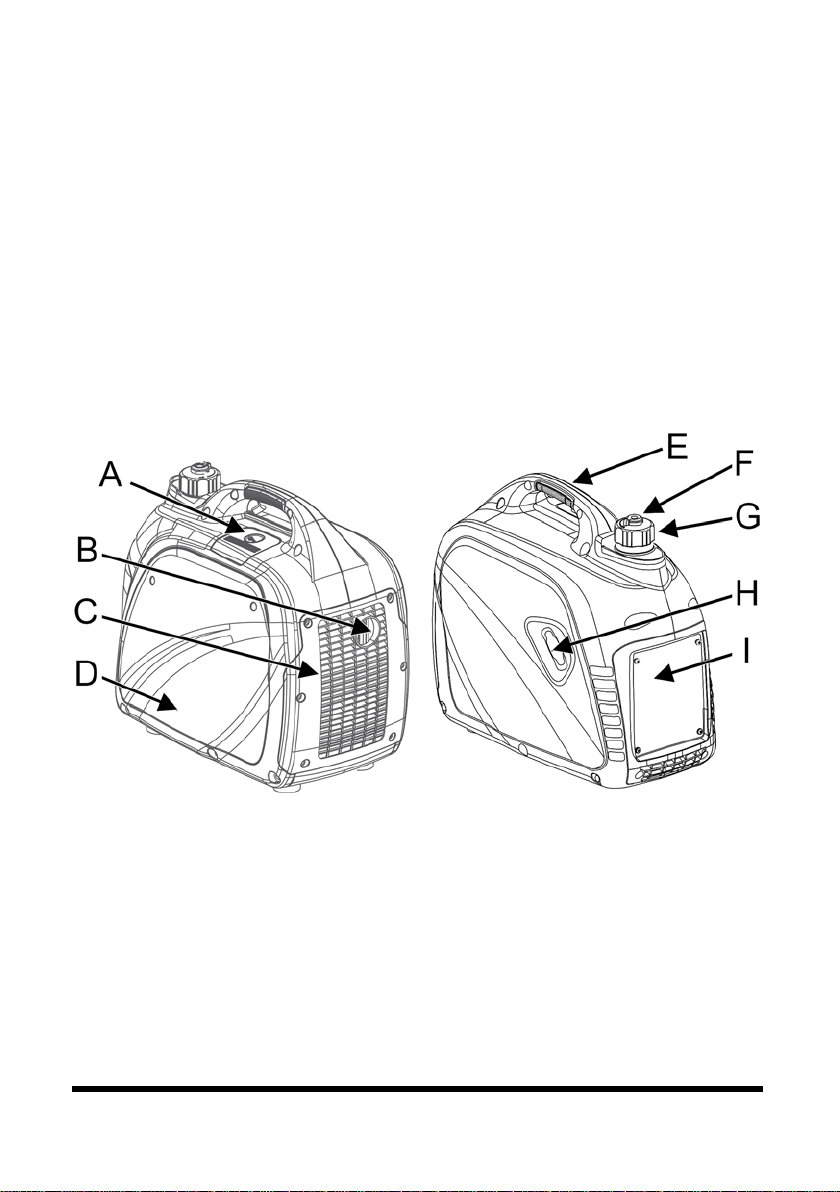

IDENTIFICATION KEY

A Spark Plug Cover

B Spark Arrestor

C Muffler Cover

D Outer Casing (Side Panel)

E Handle (Grip)

F Air Vent

G Fuel Cap

H Recoil Starter

I Control Panel

Fig. 1

8700718 2,000W Inverter Generator V4.0

8 For technical questions call 1-800-665-8685

CONTROL PANEL

J Overload Indicator

K Oil Warning Indicator

L AC Pilot Indicator

M 12V DC Port

N DC Circuit Breaker

O AC Circuit Breaker

P Ground Terminal

Q 3-in-1 Start Switch (OFF,

RUN and CHOKE)

R Economy Switch

S 120V AC Outlet

T Parallel Outlets

CONTROL PANEL FUNCTIONS

3-IN-1 START SWITCH (Q)

Start Switch (OFF)

The start switch position shuts off the fuel valve and

the engine will not run (Fig. 3-1).

Start Switch (RUN)

The start switch position 1 opens the fuel valve and

the engine can start (Fig. 3-2).

Start Switch (CHOKE)

The start switch position CHOKE opens the fuel valve but restricts the air flow

(Fig. 3-3). Use this position when starting a cold engine. Once the engine has

warmed, switch to position 1 (ON).

INDICATOR LIGHTS

Oil Warning Indicator (K)

The oil warning indicator (Fig. 4-1) glows when the engine’s oil level is too low.

The engine stops automatically. The engine will not run until the oil is

replenished. See the Engine Oil section for information on the oil system alert,

how to check and change oil.

Fig. 3

Fig. 2

V4.0 2,000W Inverter Generator 8700718

Visit www.princessauto.com for more information 9

If the engine stops running without the indicator lighting up, then the oil level

isn’t the issue. Try to restart the engine.

Engine Overload Indicator (J)

The overload indicator (Fig. 4-2) glows when

the connected electrical devices exceeds the

generator’s wattage/amperage capacity or by

a power surge. The engine continues to run,

but power is no longer supplied to the

outlets until the generator is reset.

The engine overload indicator light may turn

on for a few seconds when attaching a load

due to a power surge. This is normal.

Resetting the Generator

1. Disconnect all electronic devices, then stop the engine.

2. Reduce the number of electric devices until the total wattage is within the

generator’s rated output. Include the highest peak wattage in this calculation.

3. Inspect the air inlet and control panel for any blockage. Remove

blockage if found.

4. Restart the engine, then reconnect the electric devices.

AC Pilot Indicator (L)

The pilot indictor (Fig. 4-3) glows when the engine starts and the generator is

providing power.

ENGINE ECO CONTROL (R)

1. Push the ECO toggle switch to activate the economy control unit. The

engine speed will increase or decrease based on the power needed for the

electric load. This improves fuel economy and reduced engine noise.

2. When the ECO switch is in the OFF position, the engine runs at the rated

speed of 4,850 RPM.

3. The ECO switch must be turned to the OFF position when using electronic

devices that require a large starting current, such as a compressor.

4-1 4-2 4-3

Fig. 4

8700718 2,000W Inverter Generator V4.0

10 For technical questions call 1-800-665-8685

PARALLEL OUTLETS (T)

The parallel outlets allow two 2,000W Inverter Generators to be run together to

increase the rated output to 3.0 kV-A, and the rated current to 25A/120V. This

requires a parallel cable kit (sold separately).

GROUND TERMINAL (P)

Grounding the generator protects you from electric shock that results from a

build-up of static electricity or undetected ground faults.

DC AND AC CIRCUIT BREAKERS (N & O)

The circuit breakers automatically turn OFF when the wattage of connected electronic

devices exceeds the generator’s rated output. Reduce the load of connected electronic

devices until the load is within the rated output. To re-establish DC power, push the

DC 8A button (N). To reestablish AC power, push the AC 15A button (O).

OPERATION

Letter references in parenthesis (A) refer to the included Identification Key.

Dashed numbers in parenthesis (Fig. 1-1) refer to a specific point in an

illustration or image.

PRE-OPERATION CHECKS

WARNING! Do not start or run the generator in an enclosed area, even if

doors or windows are open. Engine exhaust contains carbon monoxide, an

odourless and colourless poison gas.

NOTICE! The generator is not shipped with oil. Before starting the engine,

add oil according to the instructions in this manual. Starting the engine

without oil will damage the engine beyond repair.

Check the generator’s condition before operating to maximize the user’s safety

and the service life of the generator. Ensure that the generator is level and the

engine switch is in the OFF position before beginning the pre-operation checks.

GENERAL CONDITION

1. Look around and underneath the generator for signs of oil or gasoline leaks.

2. Remove any excessive dirt or debris, especially around the spark arrestor

(B) and recoil starter (H).

V4.0 2,000W Inverter Generator 8700718

Visit www.princessauto.com for more information 11

3. Look for signs of damage.

4. Check that all shields and covers are in place.

5. Check that all nuts, bolts and screws are tight.

CHECK THE ENGINE

1. Check the fuel level.

2. Check the engine oil level. Running the engine with a low oil level can

cause engine damage (see Engine Oil section).

3. Check the air filter element. A dirty air filter will reduce engine performance

(see Service the Air Filter).

GROUND THE GENERATOR

The generator must be properly grounded to prevent

electric shocks. Connect the generator to a ground

rod with an 8 AWG copper wire. Twist the wire onto

the generator’s ground connector between the lock

washer and nut and secure the nut. Consult municipal

electrical codes or a qualified electrician to confirm

grounding requirements.

STARTING THE GENERATOR

Do not crank engine with spark plug removed. Ensure spark plug lead is

securely connected to spark plug, otherwise unintentional sparking can result,

causing fire or electric shock.

RECOIL START

WARNING! Failure to follow the steps below will result in rapid retraction of

the starter cord faster than the user can let go. This will pull the user’s hand

and arm toward the engine, possibly resulting in serious injury.

1. Remove all the loads from AC and DC power outlets.

2. Turn the Eco Switch (R) to OFF.

a. The ECO switch may be left on, but allow three minutes for the engine

to warm up before use if the ambient temperature is below 32ºF (0ºC).

It will be ready for normal operation after warming up.

3. Rotate the gas cap air vent (F) to the ON position (Fig. 6).

Fig. 5

8700718 2,000W Inverter Generator V4.0

12 For technical questions call 1-800-665-8685

4. Turn the start switch (Q) to the CHOKE

position to start the engine. This opens the fuel

valve and allows fuel to flow from the fuel tank

to the carburetor.

a. Turn the start switch (Q) directly to the ON

position if the engine is warm.

5. Pull Start.

a. Pull the recoil starter handle (H) lightly

until you feel resistance.

b. Pull the recoil starter handle briskly as soon as resistance is felt.

c. Do not allow the recoil starter handle to snap back against the engine.

Instead, return the starter grip gently by hand.

6. Turn the start switch to the RUN position once the engine is running.

Occasionally you may hear a light ‘spark knock’ or ‘pinging’ (metallic rapping

noise) while operating under heavy loads. This is no cause for concern.

Consider replacing the fuel if the spark knock or pinging continue to occur when the

engine speed is steady under a normal load. If the sounds continue after changing

the fuel, contact Princess Auto Ltd. for a solution or see a qualified technician.

NOTICE! Running the engine with persistent spark knock or pinging can

cause engine damage.

RUNNING THE GENERATOR

1. Make sure the green AC pilot indicator (L) is on.

2. Warm up the generator without load for 3 minutes.

3. Be sure that all appliances are in good working condition before connecting

them to the generator.

4. Attach appliances, one at a time starting with the appliance with the highest

current rating. Most appliance motors require more than their rated

wattage for start-up. Do not exceed the current limit specified for any one

socket. See Wattage Reference Chart.

a. If the attached load is small, turn the ECO switch to the ON

position. For a larger load, or if attaching multiple electronic

devices turn the ECO switch to the OFF position.

Fig. 6

V4.0 2,000W Inverter Generator 8700718

Visit www.princessauto.com for more information 13

b. Allow generator output to stabilize (engine and attached devices

run evenly) before plugging in the next load.

5. Turn off the generator immediately if an appliance becomes sluggish,

stops suddenly or acts in an abnormal manner. Disconnect and inspect

the appliance.

6. Reduce the electric load on the circuit if the circuit breaker trips. Wait a few

minutes before resuming operation.

7. When using the AC and DC electrical output at the same time, do not

exceed the maximum output of the generator.

8. Ensure a skilled electrician connects the generator when incorporating the

generator into a home power circuit. A properly installed transfer switch is

required. An improper connection can damage the house’s electrical

system, generator and any attached appliances or cause a fire.

TURN OFF THE GENERATOR

IMPORTANT! To stop the generator in an emergency, turn the main generator

switch to the OFF position.

1. Turn the ECO switch to the OFF position.

2. Disconnect all electric devices from the generator.

3. Turn the start switch to the OFF position.

4. Rotate the gas cap to the OFF position to prevent air flow.

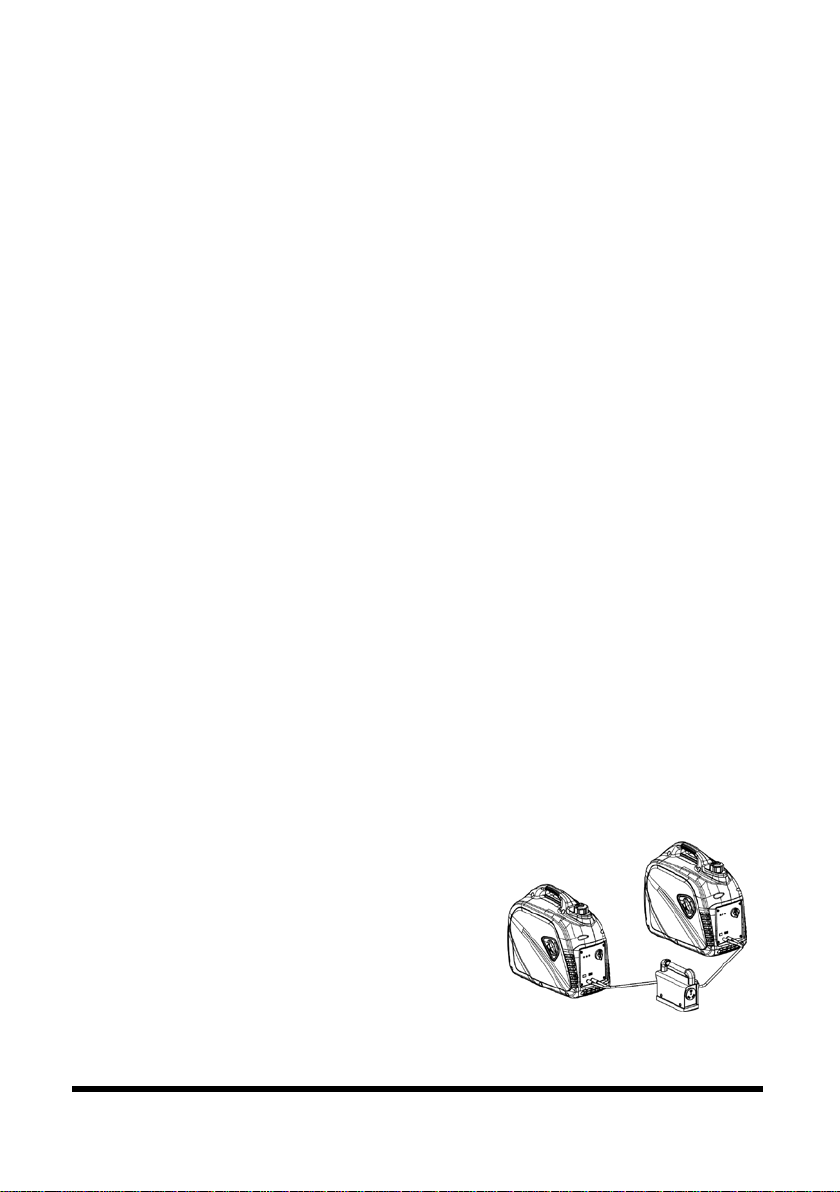

AC PARALLEL OPERATION

WARNING! Do not connect or disconnect the parallel cables when the

generators are running to avoid an electric shock.

The parallel outlets allow two 2,000W Inverter

Generators to be run together to increase the

rated output to 3.0 kV-A, and the rated

current to 25A/120V. The maximum power is

4.0 kV-A. This requires a parallel cable kit

(sold separately) (Fig. 7).

1. Connect the two generators together with

the parallel cables.

2. Make sure the ECO switch is set to the same position on both generators.

Fig. 7

8700718 2,000W Inverter Generator V4.0

14 For technical questions call 1-800-665-8685

3. Disconnect all electronic devices from the generators prior to starting them.

4. Start each generator’s engine. Make sure the green output indicator light

comes on for each generator.

5. Wait for each engine to stabilize before plugging in the first electronic

device into the AC receptacle (starting with the largest wattage item). Turn

the device on and wait for the output to stabilize.

a. Many electric devices draw more power in the first couple of seconds

when starting, than is required during normal operation. The red indicator

light may glow. This is normal and will stop after a few seconds.

6. Continue to connect additional devices and wait for the engine to stabilize

each time.

GENERATOR OVERLOAD

Make sure you can supply enough rated watts for all electronic devices

connected to the generator. Rated watts refer to the power a generator must

supply to keep a device running. Peak watts refer to the power a generator must

supply to start an electronic device.

This power surge for starting a device usually lasts between 2-3 seconds, but

this additional output must be taken into account when selecting the electronic

devices you plan to attach to the generator. To prevent overloading the

generator take the following steps:

1. Add up the total rated wattage of all electronic devices that will be

connected to the generator simultaneously.

2. Estimate peak watts by adding the item(s) with the highest output (it is

unnecessary to calculate the peak output for all devices as they should be

connected one at a time).

3. Add the peak watts to the total rated watts in step 1. Keep total load within

generator’s power capacity.

a. If an appliance begins to operate abnormally, becomes sluggish, or

stalls, turn off and disconnect appliance immediately. The appliance

may have a fault or its rated load capacity exceeds the power supply

of the generator.

V4.0 2,000W Inverter Generator 8700718

Visit www.princessauto.com for more information 15

CHARGING A 12 VOLT BATTERY

The 2,000W Inverter Generator can recharge a 12V car battery with a set of

special cables that plug into the DC outlet (sold separately).

1. Clean corrosion from the battery terminals with a wire brush.

2. Start the generator and turn the 3-in-1 start switch to the RUN position.

Ensure the DC circuit breaker (N) is also set.

3. Securely connect the red cable clamp to the positive (+) battery terminal.

4. Securely connect the black cable clamp to the negative (-) battery terminal.

5. Turn the ECO switch to the OFF position to start charging the battery.

6. The battery is considered fully charged when the gravity of its fluid is

between 1.26 and 2.28 when measured by a hydrometer.

CARE & MAINTENANCE

1. Maintain the tool with care. A tool in good condition is efficient, easier to

control and will have fewer problems.

2. Inspect the tool components periodically. Repair or replace damaged or

worn components. Only use identical replacement parts when servicing.

3. Only use accessories intended for use with this tool.

4. Keep the tool handles clean, dry and free from oil/grease at all times.

5. Maintain the tool’s labels and name plates. These carry important information.

If unreadable or missing, contact Princess Auto Ltd. for replacements.

6. Disconnect the spark plug lead and keep it away from the spark plug

during maintenance and repairs.

WARNING! Only qualified service personnel should repair the tool. An

improperly repaired tool may present a hazard to the user and/or others.

FUEL RECOMMENDATIONS

NOTICE! Do not use unapproved gasoline, such as E85. Do not mix oil in

gasoline or modify the engine to run on alternate fuels. This can damage the

engine components. To protect the fuel system from gum formation, mix a

fuel stabilizer into the fuel.

8700718 2,000W Inverter Generator V4.0

16 For technical questions call 1-800-665-8685

This engine is certified to operate on unleaded gasoline with a minimum of 87

octane/87 AKI (91 RON). Use gasoline without ethanol or similar alcohol based

additives. Gasoline with up to 10% ethanol (gasohol) or up to 15% MTBE

(methyl tertiary butyl ether) may be used if required.

If the engine is routinely operated at altitudes over 5,000 ft (1,524 meters), it

will be necessary to have a qualified technician modify the engine for increased

performance. Fuel should be a minimum of 85 octane/85 AKI (91 RON) to

prevent decreased performance.

The emissions control system for this engine is EM (Engine Modifications).

1. Use only an approved fuel container for refueling the engine.

2. Store fuel out of direct sunlight in a cool and dry location.

3 Inspect container for fuel leaks. Replace any container that leaks.

4. You may occasionally hear a light spark knock or pinging (metallic rapping

noise) while the engine is operating under heavy loads. This is no cause for

concern. If spark knock or pinging occurs at a steady engine speed under

normal load, switch to a premium gasoline or change brands of gasoline. If

spark knock or pinging persists, see an authorized repair centre.

5. Never use stale or contaminated gasoline or an oil/gasoline mixture

designed for two-stroke motors.

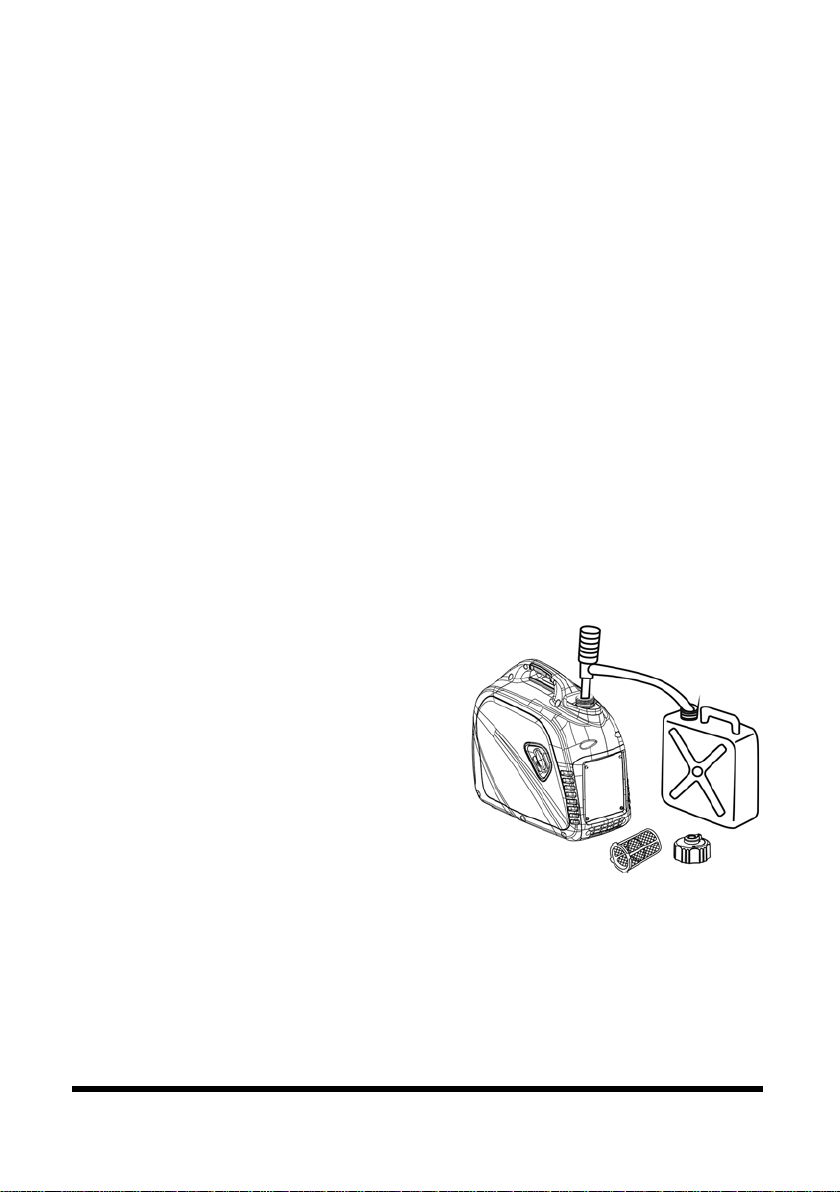

HOW TO ADD FUEL

DANGER! Fuel is very flammable. Use extreme care when handling or storing

fuel. An ignition source contacting the fumes or fuel may result in a fire or

explosion and cause fatal or serious injuries to you or a bystander.

1. Refuel outdoors or in a well-ventilated area and immediately wipe up spills.

Fuel can damage paint and plastic.

2. Stop the engine and position equipment on a level surface.

3. Let engine cool for at least two minutes before removing the fuel cap.

4. Clean the fuel cap (G) area of dirt and debris. Do not allow dirt or water to

enter the fuel tank.

5. Remove the fuel cap slowly to allow the pressure to equalize.

6. Check the fuel level.

V4.0 2,000W Inverter Generator 8700718

Visit www.princessauto.com for more information 17

7. Fill the tank to approximately 1.5 in. (38 mm) below the top of the fuel tank

to allow for fuel expansion. Take care to not overfill the tank. It may be

necessary to lower the fuel level depending on operating conditions.

8. Reinsert the fuel tank cap and tighten.

9. Wipe up any spilled fuel before starting the engine or allow to evaporate.

Spilled fuel is both a fire hazard and an environmental hazard. Dispose of

the fuel soaked rags in a proper hazardous waste container.

HOW TO DRAIN FUEL

1. Turn the 3-in-1 switch to the OFF position.

2. Remove fuel cap and fuel tank filter.

3. Use a siphon to transfer gasoline from generator into a gasoline approved

container.

4. Wipe up any spilled fuel with a clean rag.

5. Start generator engine and let it run until it stops and all remaining fuel

is consumed. Do not connect electronic devices to the generator during

this process.

6. Turn the 3-in-1 switch to OFF.

7. When the engine has completely

cooled down, turn the Fuel Cap Air

Vent to the OFF position.

8. Remove the outer casing screws, then

remove outer casing.

9. Drain fuel from the carburetor by

loosening the drain screw on the

carburetor float chamber.

10. Tighten the drain screw.

11. Install the outer casing and tighten screws.

ENGINE OIL

NOTICE! Engine oil is a major factor affecting engine performance and

service life. Non-detergent and 2-stroke engine oils will damage a 4-stroke

engine and are not recommended.

Fig. 8

8700718 2,000W Inverter Generator V4.0

18 For technical questions call 1-800-665-8685

High-quality detergent engine oils are acceptable if the (API) performance rating

is SE, SF, SG, SH, SJ or higher. Always check the API service label on the oil

container for the performance rating.

1. Check the oil level before each use with a cool engine that is level.

2. Use 4-stroke motor oil that meets or

exceeds the requirements for API

(American Petroleum Institute) service

classification SE. Always check the API

Service label on the oil container to be

sure it includes the letters SE.

3. Do not use special additives.

4. SAE 10W30 is recommended for

general, all-temperature use. Other

viscosities shown on the chart may be used when the average temperature

in your area is within the indicated range (Fig. 9).

5. Above 27°C (80°F), using 10W30 oil may increase oil consumption. Check

the oil level more often.

6. Below 4°C (40°F), using SAE 30 oil will cause hard starting.

OIL ALERT SYSTEM

The oil alert system is designed to prevent engine damage caused by an

insufficient amount of oil in the crankcase. Before the oil level in the crankcase

can fall below a safe limit, the oil alert system will automatically stop the engine

(the engine switch will remain in the ON position) and the oil warning indicator

(K) will glow. The oil alert system should not take the place of checking the oil

level before each use. If the engine stops and will not restart, check the engine oil

level before troubleshooting in other areas.

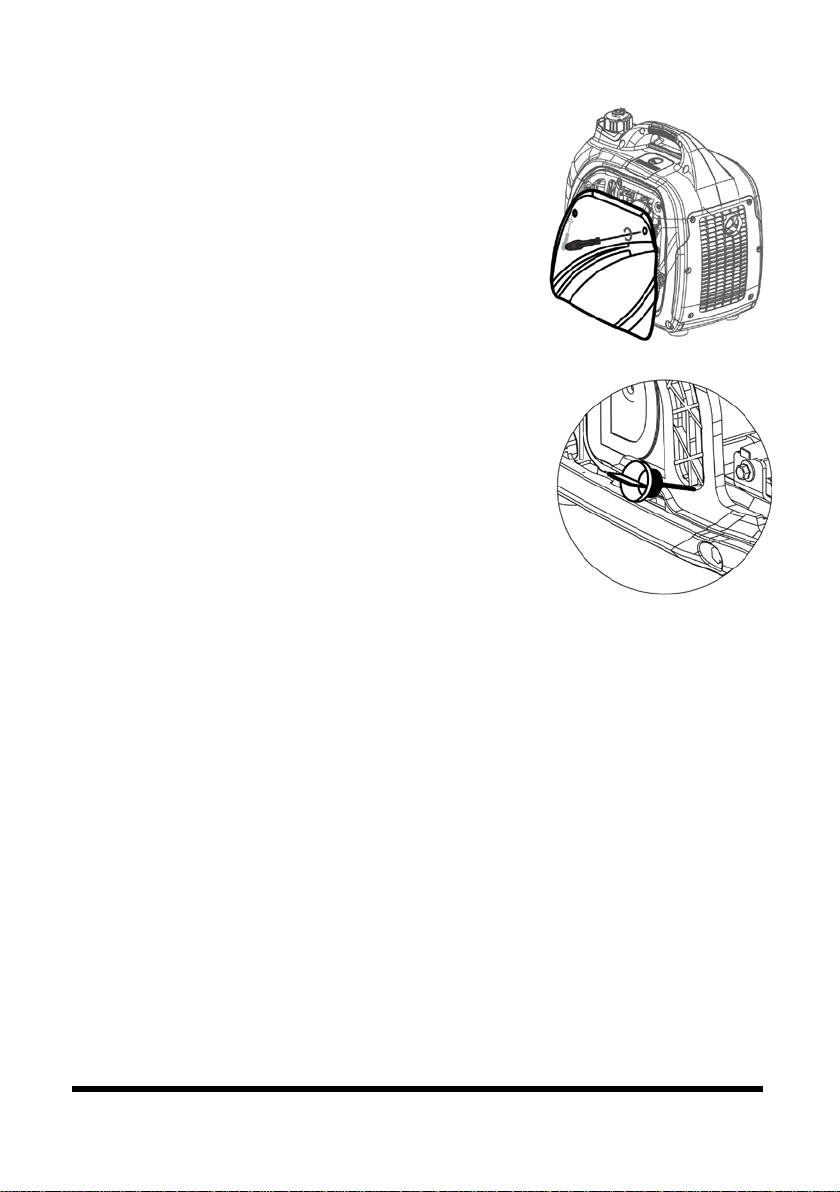

HOW TO CHECK OIL

1. Place the generator on a level surface.

2. Run the generator several minutes until the engine is warm. Turn off the

generator.

3. Remove the spark plug cover (A). Remove the screws from the right side

panel (D). This will allow you to push the panel off from the inside (Fig. 10).

Fig. 9

V4.0 2,000W Inverter Generator 8700718

Visit www.princessauto.com for more information 19

4. Clean the oil fill area of any dirt and debris to

prevent contamination that can damage the engine.

5. The engine has a dipstick that is either part of the

oil fill plug (Fig. 11) or a separate component.

a. Remove the dipstick and wipe with a

clean cloth.

b. Reinsert the dipstick into the filler neck until

it rests on the opening’s rim. Do not screw

the oil fill plug back into the opening.

c. Remove the dipstick and check that the oil is

between the Full and Fill marks. Add or drain

oil based on the measurement.

d. Reinsert the dipstick and either press firmly

to hold in place or screw the oil fill cap

hand tight.

6. Replace the side panel and secure with screws.

Replace the spark plug cover.

HOW TO ADD OIL

IMPORTANT! Read the Engine Oil section before adding oil to ensure that it

is suitable for the engine.

1. Follow steps 1 to 4 in HOW TO CHECK OIL.

2. Remove the oil filler cap and place to one side.

3. Place a funnel into the oil fill neck. The funnel opening should be wide

enough to prevent the oil from collecting in the funnel’s cone.

4. Pour oil into the funnel. Allow the oil to settle for one minute and recheck

the level. Repeat until the oil reaches the outer edge of the oil fill hole.

5. Insert and hand tighten the oil filler cap.

6. Wipe up any spilled oil. Dispose of oil soaked rags in a proper hazardous

waste container.

7. Replace the side panel and secure with screws. Replace spark plug cover

Fig. 10

Fig. 11

8700718 2,000W Inverter Generator V4.0

20 For technical questions call 1-800-665-8685

HOW TO DRAIN OIL

1. Follow steps 1 to 4 in HOW TO CHECK OIL.

2. Remove the crankcase dipstick.

3. Place an oil pan underneath the engine (Fig. 12). Tilt generator to collect

used oil. Allow oil to drain completely.

4. Return generator to a level surface.

5. Carefully add 4-Cycle engine oil (SAE 10W30)

to empty reservoir until oil reaches the outer

edge of the oil fill hole.

6. Use a clean rag to wipe up any spilled oil.

7. Replace crankcase dipstick.

8. Reinstall outer casing and tighten screws.

IMPORTANT! Used oil must be disposed of properly. Do not pour it on the

ground, down a drain or throw it in the trash. Take the oil to your local

recycling centre or a service station for reclamation.

SERVICE THE AIR FILTER

NOTICE! Operating the engine with a damaged or missing air filter will allow

dust and debris to enter the engine, causing rapid engine wear or scoring on

the engine pistons. Always ensure the air filter is in place.

A dirty air filter will restrict airflow to the carburetor, reducing engine performance. If the

engine is used in very dusty areas, clean the air filter more frequently than specified in

the maintenance schedule.

1. Remove the side panel and filter housing cover (Fig. 13).

2. Remove the foam air filter from the air filter housing.

3. Clean the housing interior with warm soap and

water. Allow to dry before reassembly.

4. Pour a small amount of oil onto the foam

element and squeeze out the excess. Do not

wring the oil out.

5. Reinsert the foam element into the air filter case.

6. Screw the side panel back into place.

Fig. 12

Fig. 13

Table of contents

Languages:

Other Power Fist Inverter manuals

Popular Inverter manuals by other brands

Sofar solar

Sofar solar SOFAR 7KTLM-G3 user manual

Tripp Lite

Tripp Lite PowerVerter PV100USB owner's manual

Magnum Energy

Magnum Energy MicroGT 500 owner's manual

Solark

Solark 8K-2P-N Install Guide & Owner’s Manual

Go Power

Go Power GP-DC-KIT2 owner's manual

Tripp Lite

Tripp Lite PowerVerter RV3012OEM Specifications

FRONIUS

FRONIUS Symo Hybrid 3.0 installation instructions

CO/Tech

CO/Tech ig2400s Original instructions

Delta

Delta RPI M30A_120 Operation and installation manual

FRONIUS

FRONIUS Symo Hybrid installation instructions

Sofar solar

Sofar solar 7KTLM-G3 user manual

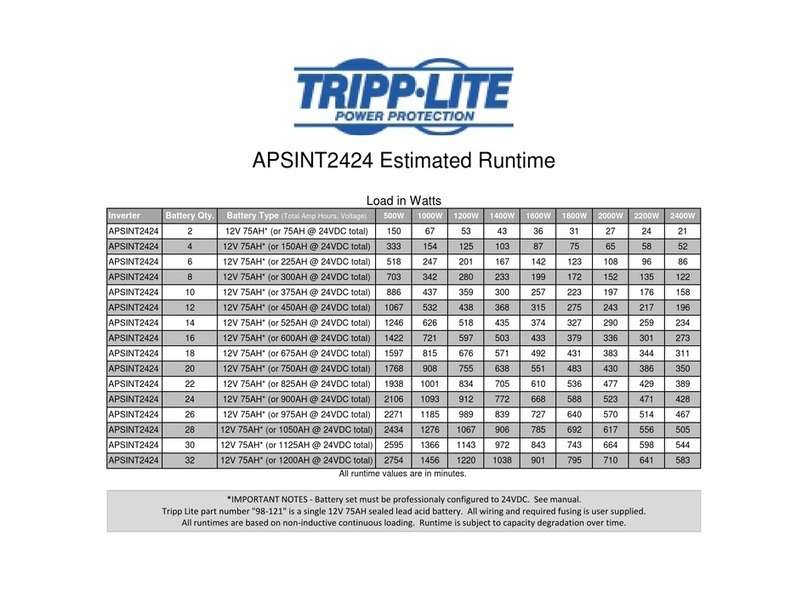

Tripp Lite

Tripp Lite PowerVerter APSINT2424 datasheet