Power House Force 1800 User manual

Dear Valued Customer,

Thank you so much for your order. We are a family-owned

business in Lincoln, NE and customer service is our priority.

If you have any quesons about your product, please feel

free to email me at nepowerhouse@gmail.com or call or

text my personal cell number at 402-890-6306. We also

have a tutorial and assembly video on YouTube. Please

search The Force 1800 assembly tutorial or you can nd it

on our website (www.powerhouse-intl.com). We are fairly

new to selling online and posive feedback and 5-star prod-

uct reviews are very important to our family business. If you

are happy with our customer service and/or our product,

would you please leave us posive seller feedback and a

posive product review? It would mean A LOT to us! If you

have ANY quesons or concerns please do not hesitate to

contact me. We want you to be happy with your purchase.

Thanks again!

Nichole Ernst

CEO Powerhouse Internaonal

SET UP & OPERATING MANUAL

WARNING: Do not use the appliance without reading this manual rst.

1 Year Warranty

All Powerhouse Internaonal products come with a 1 Year Warranty

valid only in the 48 connental United States. If you purchase this

product and ship it to a desnaon outside the 48 connental United

States, this warranty becomes null and void!

The rst 30 days are covered from the date of receipt of the product.

If your product becomes damaged in shipment or is found to be de-

fecve in any way during this period, we will replace it or issue a com-

plete refund for your product, and we will pay all shipping involved,

to and from, within this rst 30-day period.

If you have “buyer’s remorse” and decide that you do not want the

product, it must be returned new and unused in the original box and

you must pay the return shipping. PLEASE NOTE: There will be a 10%

restocking fee and original shipping costs will not be refunded. Used

product cannot be returned!

The remainder of the rst year (aer the rst 30 days) is covered by a

“Free Repair” warranty (parts and labor included). If anything be-

comes defecve during this period, we will x it and give a full service

inspecon to your product, but shipping (to and from) may be paid by

buyer. Please email us at [email protected] for a service au-

thorizaon number and tell us what is wrong with your unit.

Please keep this page and write the rst and last name of who or-

dered and the date you received the product in case you ever need to

use this warranty. This informaon WILL BE REQUIRED for any type of

service/repair or return/refund!

First and last name on order _________________________________

Date received_________________

KEEP THIS WARRANTY for your records. DO NOT send it back to us. Your

purchase has been recorded in our database.

Parts Overview 2

Technical Data 2

General Safety Instrucons 3

Servicing a Double-Insulated Appliance

Extension Cords

Operang Precauons for the Force 1800

Assembly & Connecons 6

Aach the Wheels

Connect the High-Pressure Hose

Aach the Trigger Gun

Aach the Lance

Aach a Nozzle

Connect the Garden Hose

Plug-in the Power Cord

Operang the Pressure Washer 10

Safety Devices

Starng the Washer

Stopping the Washer

Cleaning Aachments

Aer Use Instrucons

Maintenance 13

Clean the Inlet Filter

Clean the Air Vents

Grease the Couplings

Unclog Nozzles

Troubleshoong 14

1

Contents

Unpack the carton and check that you have all the parts listed here:

The Force 1800 pressure

washer

High-pressure hose

Trigger gun and lance

Soap foam sprayer

Brush aachment

Three nozzles

Two wheels

One wrench

A bag containing this

manual, a cleaning nee-

dle, and an extra washer

2

Parts Overview

Rated Pressure 1600 psi

Max. pressure 1800 psi

Rated Flow 1.35 GPM

Max. Flow 1.60 GPM

Current 13A

Voltage 120V/60Hz

Inlet (max) 80 psi

Protecon class II

Water temperature (max) 60 F

Technical Data

Stay alert! Watch what you are doing.

Do not operate the washer when fagued or

under the inuence of alcohol or drugs.

This washer is provided with a Ground Fault Cir-

cuit Interrupter (GFCI) built into the power cord

plug. If replacement of the plug or cord is need-

ed, use only idencal replacement parts.

The washer is intended for outdoor use. Do not use inside.

Follow the maintenance instrucons specied in this manual.

Store the washer in an area that is clean and protects the washer

from freezing.

Servicing a Double-Insulated Appliance

In a double-insulated product, two systems of insulaon are provided

instead of grounding. No grounding means is provided on a double-

insulated product, nor should a means for grounding be added to the

product. Servicing a double-insulated product requires extreme care

and knowledge of the system, and should be done only by qualied

service personnel. Replacement parts for a double-insulated product

must be idencal to the parts they replace.

A double-insulated product is marked with the words “DOUBLE INSU-

LATION” or “DOUBLE INSULATED.” The following symbol may also be

marked on the product:

Extension Cords

Use only extension cords that are intended for outdoor use. These

extension cords are idened by a marking:

“Acceptable for use with outdoor appliances; store indoors while not

in use.”

3

General Safety Instrucons

IMPORTANT! DO NOT LET THIS PRODUCT FREEZE!

Use only extension cords having an electrical rang greater than the

rang of the product. Do not use damaged extension cords. Examine

extension cord before using and replace if damaged. Do not abuse

extension cord and do not yank on any cord to disconnect. Keep cord

away from heat and sharp edges. Always disconnect the extension

cord from the receptacle before disconnecng the product from the

extension cord.

WARNING: To reduce the risk of electrocuon, keep all con-

necons dry and o the ground. Do not touch plug with wet

hands or while standing in water.

Operang Precauons for the Force 1800

When using this product, basic precauons should always be fol-

lowed:

Read all instrucons before using the washer.

To reduce the risk of injury, close supervision is necessary, espe-

cially when the washer is being used near children or animals.

Do not use the washer in areas where ammable items are pre-

sent.

Know how to stop the washer and bleed pressures quickly. Be

thoroughly familiar with the controls of the washer. Before each

use, pressure must be released! Press the trigger on the wand,

then start the washer.

Do not over-reach or stand on unstable support. Keep good

foong and balance at all mes.

To reduce the risk of electrocuon, don’t start or run the washer

in the rain or a storm. Keep all connecons dry and o the

ground. Do not touch plug with wet hands. Do not let water leak

into the washer, as this will invalidate the warranty.

Do not leave the washer running unaended.

4

This washer has been designed for only using clean water. Do not

use corrosive chemicals.

When the washer is running, maintain a constant water supply.

Without water circulaon the sealing rings of the washer will be

damaged.

Don’t start and run the washer in a place excessively cold to pre-

vent the washer from freezing.

Do not use the washer within the range of persons unless they

wear protecve clothing and eyewear.

Do not direct the jet against yourself or others to clean clothes or

footwear.

Disconnect from the electrical power supply before carrying out

any user maintenance.

5

In addion to these instrucons, a video tutorial is also available at

www.powerhouse-intl.com or YouTube (search for The Force 1800).

Throughout this manual numbers are used to help idenfy parts. Use

the following diagram to reference the parts:

(1) Wheels (8) Turbo nozzle

(2) High-pressure hose (9) Water hose connecon

(3) High-pressure hose quick (10) Safety locking device

connector to washer (11) Foot power switch

(4) Trigger gun (12) Soap foam sprayer

(5) Lance (13) Storage pins

(6) Mul-funcon nozzle (14) Brush aachment

(7) Angle nozzle

6

Assembly & Connecons

Aach the Wheels

Snap the wheels (1) onto the washer.

Connect the High-Pressure Hose

Press the buon on the high-pressure hose (2) quick

connector (3) at the front of the washer (see diagram

at le) and snap in the hose.

Aach the Trigger Gun

As indicated in the diagram at

right, aach the high-pressure hose to the

trigger gun (4) by pressing it into the connect-

or. You will hear and feel a click.

Aach the Lance

As shown at le, push the lance (5)

into the trigger gun (4). When insert-

ed, turn it unl it locks in place.

Cauon: Make sure the lance is

properly aached to the gun.

Aach a Nozzle

When aaching the nozzle, the buon ((A) in the diagram above) on

the nozzle should pop out again. Check before pressing the trigger

that the nozzle is properly inserted and the buon has popped back

out. You must line up the indents on the nozzle for it to connect cor-

rectly.

The Force 1800 pressure washer comes with

three dierent nozzles, as shown in the pic-

ture at right. From top to boom, the Angle

Nozzle (7), the Turbo Nozzle (8), and the Mul-

-Funcon Nozzle (6). Each is described be-

low.

7

When not in use, nozzles can be stored on the storage pins (13) on

the body of the washer.

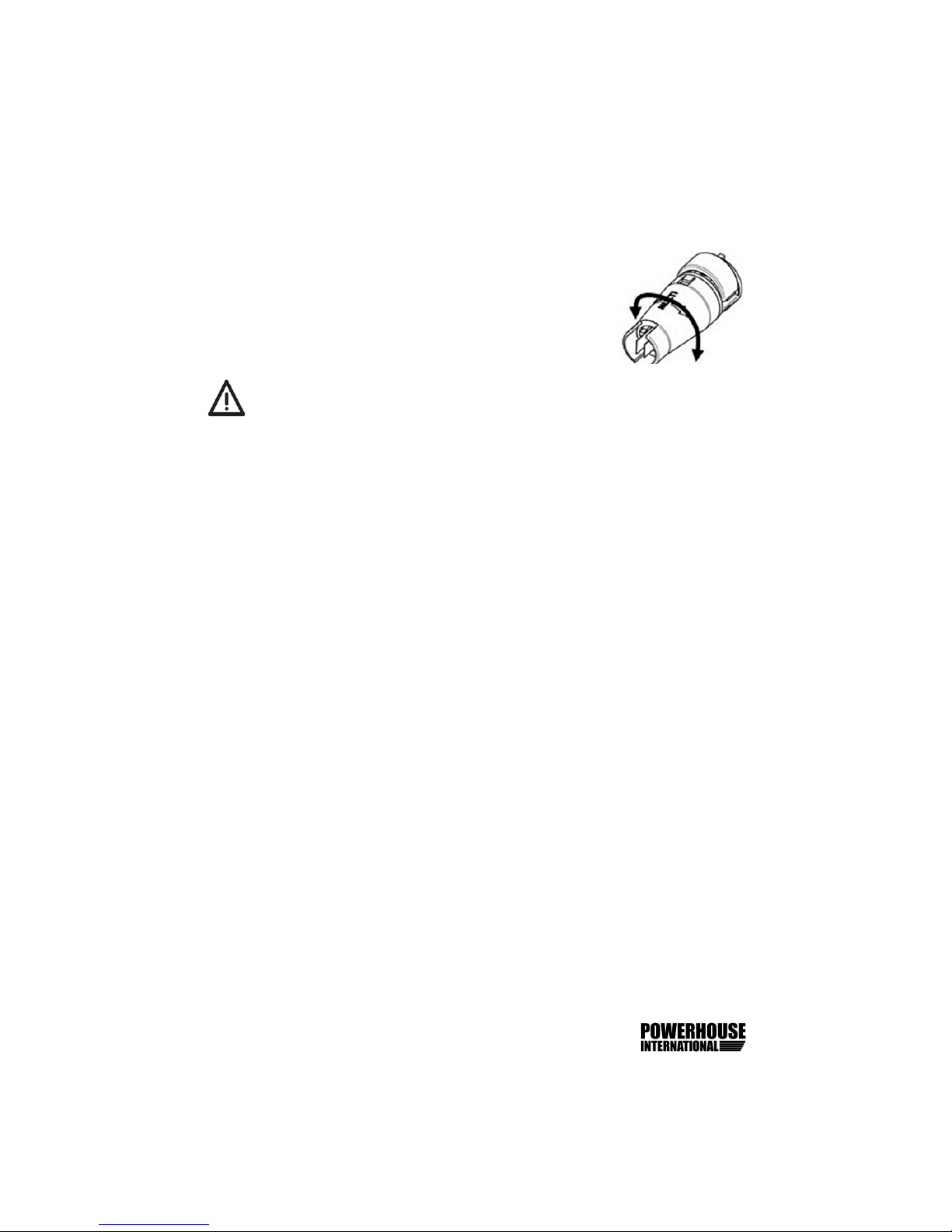

Mul-Funcon Nozzle

The spray from the mul-funcon nozzle, from a

direct stream to a fan spray, can be adjusted by

turning it.

WARNING: Do not adjust the nozzle while operang, as injury

to hands can occur.

Angle Nozzle

The angle nozzle can be used for many applicaons, such as cleaning

guers, the underbody of a car, or underneath a lawn mower. Please

use cauon when doing so since debris can come loose and injury can

occur. Aer aaching the angle nozzle use cauon with the trigger

gun and lance as the water jet will spray perpendicular to these.

Turbo Nozzle

The turbo nozzle is a high-pressure nozzle that makes a circular

paern to clean debris and can be used for most cleaning tasks.

Connect the Garden Hose

A ½" garden hose between 10 and 25 . in length will be suitable. Let

the water run through the water hose to ush any sand and dirt be-

fore connecng it to the washer to prevent damage to the washer.

Important! Only use water without any impuries. If there is a risk

of sand parcles in the inlet water (i.e., from a well), an addional l-

ter should be used.

Note: Check that the lter is in place, clean, and not clogged.

Cauon: Failure to use the lter will invalidate the warranty.

8

Connect the water hose to the water hose con-

nector (9) on the back of the washer. There is

an inlet lter already ed in the coupling to

lter out impuries, as these will damage the

pump valves. There is also a rubber gasket

ed into the inlet (and an extra in the bag

with this manual). If the hose leaks where it

connects to the machine, make sure that the

gasket is in place. Two gaskets can be used if necessary. You can ght-

en the connecon with the enclosed

wrench. At le is a picture of the lter

locaon , if you need to clean it.

Turn the water fully on.

Plug-in the Power Cord

Refer to the “General Safety Instruc-

ons” secon above for safety precau-

ons.

9

Refer to the diagram on page 6 for the numbered parts and features

referenced in this secon.

Safety Devices

Safety Locking Device. The trigger gun (4) features a

safety-locking device (10). When the safety is acvat-

ed (shown at right), the trigger gun cannot be oper-

ated.

Thermal Sensor. A thermal sensor protects the mo-

tor against overloading. The washer will restart aer

a few minutes when the thermal sensor has cooled.

Starng the Washer

The trigger gun (4) and lance (5) have a kick (thrust) when operated.

Please hold them rmly with both hands.

Important! Point the nozzle at the ground.

1. Check that the washer is in upright posion. Note: Do not place

the washer in high grass. The washer needs air circulaon!

2. Release the trigger safety lock (10).

3. Press the trigger of the trigger gun (4) and let the water run unl

all air has escaped from the water hose.

4. Step on the power switch (11) to turn on the washer.

5. Press the trigger of the trigger gun.

Important! The washer only runs when the trigger is depressed on

the spray gun. It takes a minute to force the air out of the hose and

pump. The water spray may spuer and change PSI during this me,

but this is normal and will become consistent when the air is out of

the washer.

6. Always adjust the distance (and thus the pressure) of the nozzle

to the surface you are cleaning.

10

Operang the Pressure Washer

Do not cover the washer during operaon!

Stopping the Washer

Note: The washer must be switched o, using the foot power

switch (11), when le unaended or not used:

1. Step on the power switch (11) to turn o the washer.

2. Disconnect the electrical plug from the socket (do not pull cord).

3. Shut o the water supply.

4. Press the trigger to relieve the washer of pressure.

5. Lock the trigger gun safety.

When releasing the trigger of the trigger gun, the washer motor auto-

macally stops. The washer motor will start again when you re-press

the trigger of the trigger gun.

Cleaning Aachments

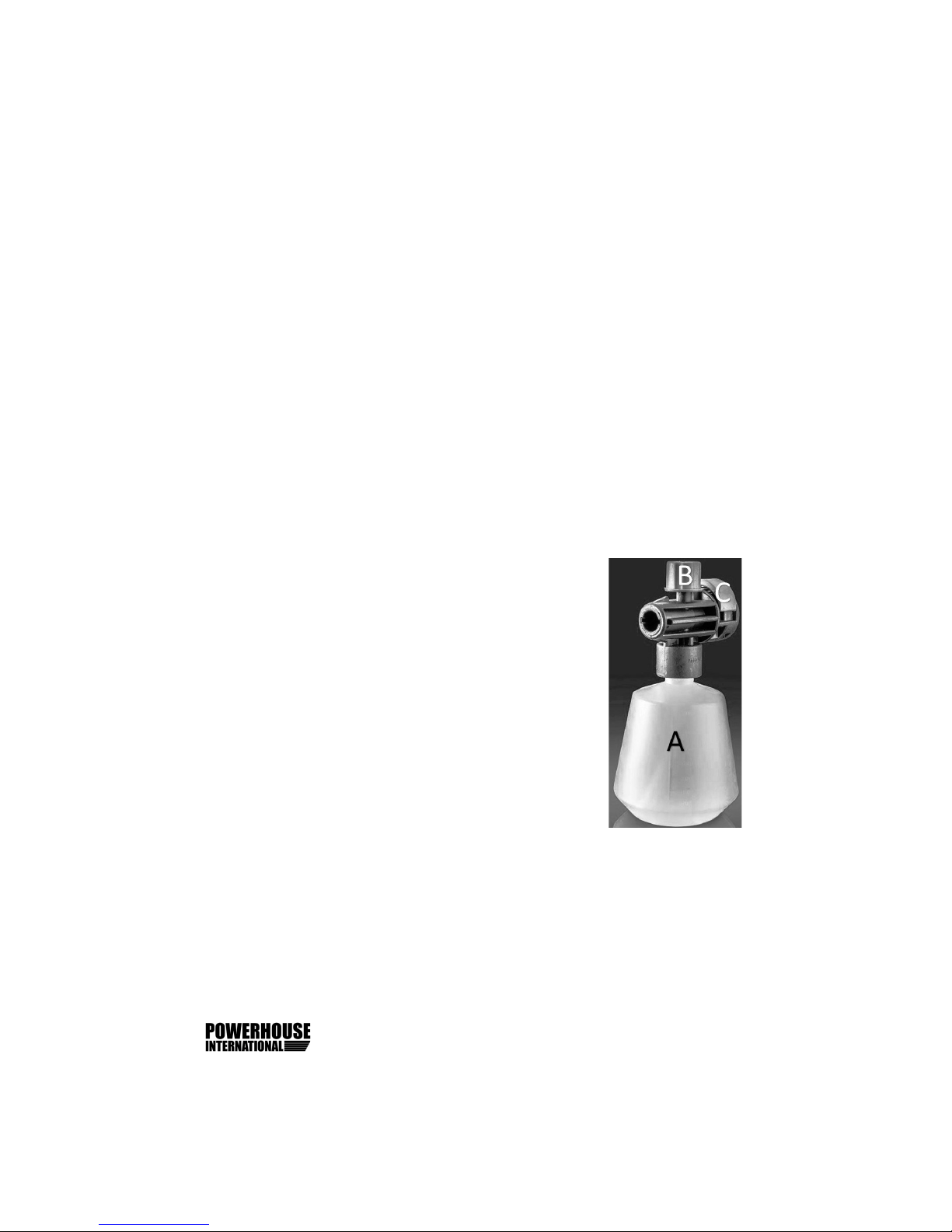

Soap Foam Sprayer (12)

Unscrew the container (A) from the foam sprayer.

Add soap to the container and screw the container

to the foam sprayer. Adjust the amount of soap

with the knob (B).

Note: Adjust the foam spray with Knob B. If you

want to spray water only, turn it to close.

The soap sprayer is equipped with a quick connect-

or. Press C, then insert into the lance (5).

Since the soap output is adjustable, the bole has

air intake holes at the top. It will leak soap if it is not upright. To avoid

this, store the soap bole on the pin on the back of the washer (13) in

the upright posion when not in use.

Cauon: When aaching the soap bole, the buon (C) should pop

back out. Check before pressing the trigger that the nozzle is properly

aached.

11

Brush Aachment

The brush aachment can be used aer the soap foam sprayer. For

best results, spray with the soap foam sprayer rst, let soak for a few

minutes, then switch to the brush aachment. It is eecve on cars

and boats, and cleaning stains from concrete paos, vinyl siding, or

wood decks.

Aer Use Instrucons

The washer and accessories should be stored in a room that is 60-80

degrees (never store in a room that will freeze or outside).

Pump, hose, and accessories should always be dry prior to storing:

1. Step on the power switch (11) to turn o the washer and detach

the water hose aer shung o the water supply.

2. Restart the washer (step on the power switch (11)) and press the

trigger of the trigger gun (4). Let the washer run unl no more wa-

ter runs through the trigger gun.

3. Step on the power switch (11) to turn o the washer and remove

the high pressure hose (2) and nozzle (6/7/8). Detach the high-

pressure hose by pressing the quick release buon on the trigger

gun and the high-pressure hose quick connector (3).

Cauon: When you detach the high-pressure hose, be sure you have

released the water pressure by turning o and disconnecng garden

hose and expelling remaining water

from the washer by depressing the

trigger. This will enable disassembly.

4. Unplug, and wind up hose.

5. As shown at right, store trigger

gun (4), lance (5), nozzles

(6/7/8), and other accessories in

storage pins (13) and holders on

the washer.

WARNING: Never start up a frozen washer. Frost damages are

not covered by our warranty!

12

Clean the Inlet Filter

Clean the water inlet lter once a month, or more frequently, accord-

ing to use.

Carefully loosen the lter with a screwdriver and clean it (see the dia-

gram at the boom of page 6). Check that it is undamaged before re-

mounng it.

The inlet lter must always be ed inside the water inlet connector

to lter out sand, limestone, and other impuries, as they will dam-

age the pump valves.

Cauon: Failure to use the lter will invalidate the warranty.

Clean the Air Vents

The washer should be kept clean so as to let cooling air pass freely

through the vents.

Grease the Couplings

For an easy connecon, and so the o-rings do not dry up, the cou-

plings should be greased regularly.

Unclog Nozzles

The needle in the bag can be used if a nozzle is clogged.

13

Maintenance

Troubleshoong

14

Troubleshoong

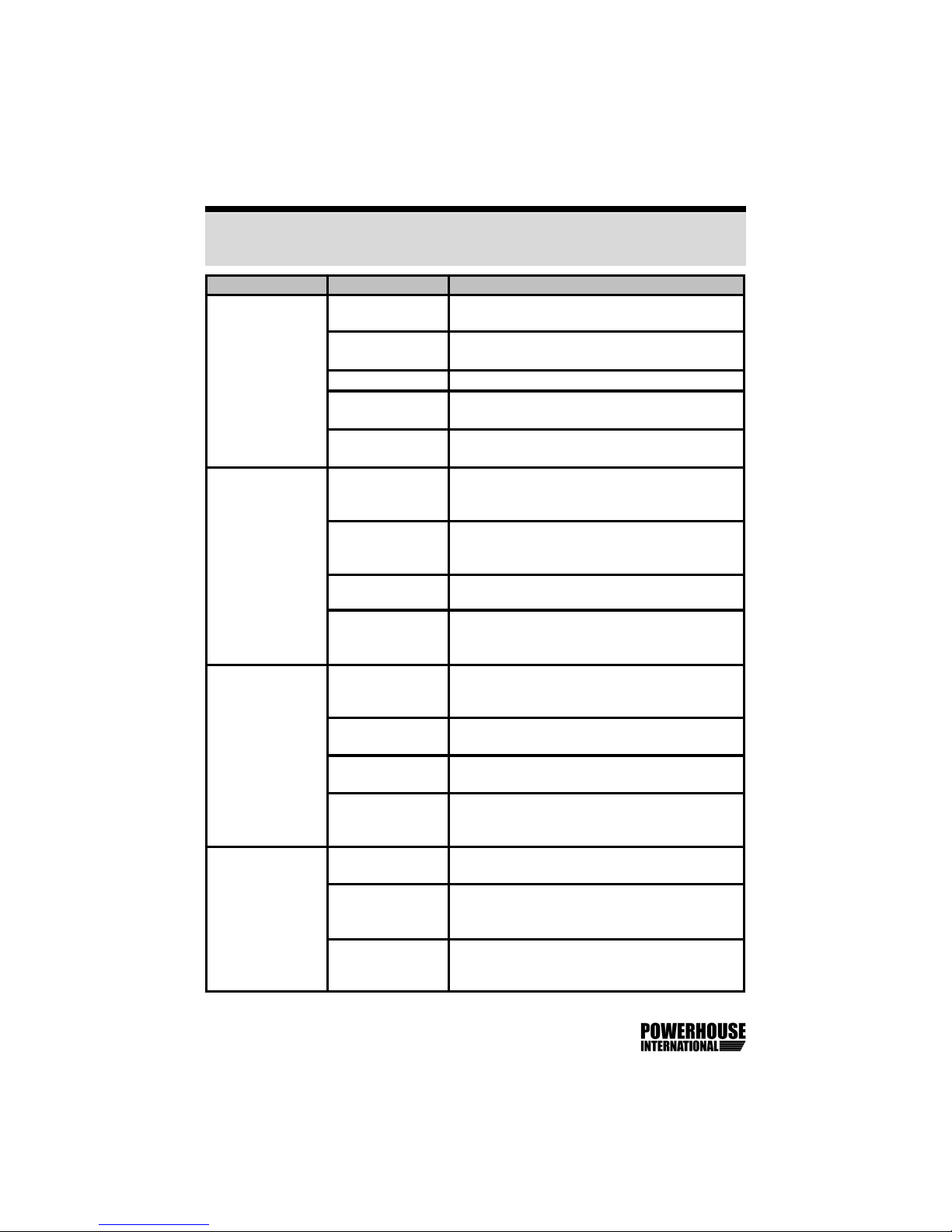

Symptom Cause Recommended acon

Washer refuses

to start

Trigger not de-

pressed

The washer only runs when the trigger is

depressed on the spray gun.

Washer not

plugged in

Plug in washer.

Defecve socket Try another socket or check GFIC in socket.

GFIC has tripped

on washer

Follow direcons to reset GFIC on back of

washer plug.

Defecve exten-

sion cable

Try without the extension cable.

Fluctuang pres-

sure (this will

happen for the

rst couple

minutes of use

while air is being

pumped from

washer)

Water supply not

sucient

Increase water pressure, check for blockage

of garden hose, and/or change to larger

hose.

Valves dirty,

worn out, or

stuck

If within the 1 Year Warranty period, e-mail

us at nepowerhouse@gmail.com. If not, take

it to a qualied appliance repair shop.

Pump is sucking

air

Check that hoses and connecons are air-

ght.

Pump seals worn If within the 1 Year Warranty period, e-mail

us at nepowerhouse@gmail.com. If not, take

it to a qualied appliance repair shop.

Washer stops GFIC has tripped Follow direcons on the back of the plug to

reset GFIC. Also check reset buon on the

outlet.

Incorrect voltage Check that the voltage corresponds to speci-

caon on the name plate.

Thermal sensor

acvated

Turn washer o and wait 5 minutes for

washer to cool down.

Nozzle parally

blocked

Clean the nozzle with the needle included

with manual, and by spraying water back-

wards through the nozzle.

Washer pul-

sang

Air in inlet hose/

pump

Depress trigger unl regular working pres-

sure resumes.

Inadequate sup-

ply of water

Increase water pressure, check for blockage

of garden hose, and/or change to bigger

hose.

Nozzle parally

blocked

Clean the nozzle with a needle included with

manual, and then by spraying water back-

wards through the nozzle.

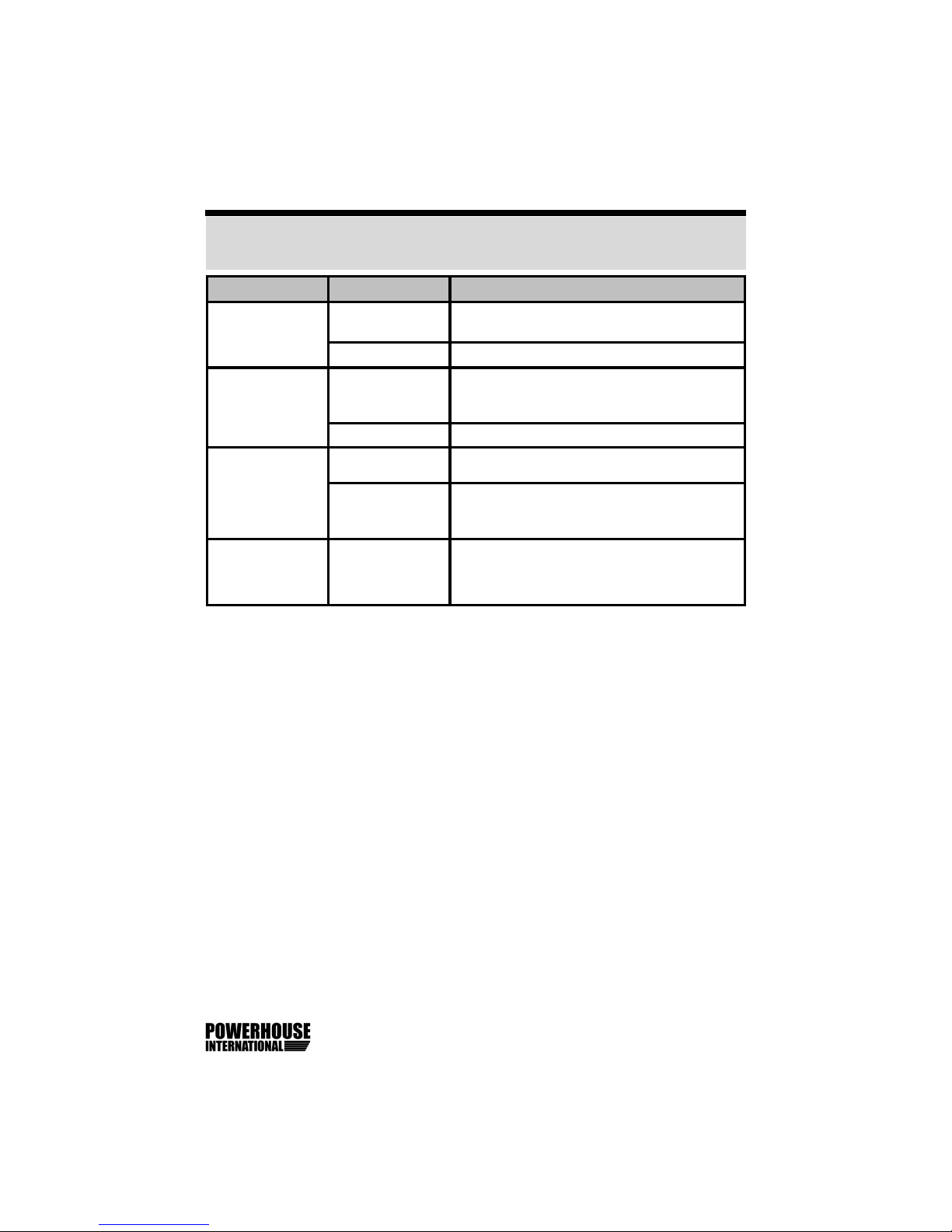

Troubleshoong

Troubleshoong

Symptom Cause Recommended acon

Washer pul-

sang

Water lter

blocked

Clean the lter.

Hose kinked Straighten the hose.

Washer oen

starts and stops

by itself

Pump and/or

trigger gun is

leaking

If within the 1 Year Warranty period, e-mail

us at nepowerhouse@gmail.com. If not, take

it to a qualied appliance repair shop.

No water supply Connect inlet garden hose.

Water lter

blocked

Clean the lter.

Washer starts

but no water

comes out Nozzle blocked Clean the nozzle with a needle included with

the manual, and by spraying water back-

wards through the nozzle.

Water leaks from

hose intake

Washer missing

or damaged, or

connecon is

loose

Check for washer, ghten with wrench, and

make sure hose intake is not bent.

15

Table of contents

Popular Pressure Washer manuals by other brands

Kranzle

Kranzle WS-RP 1000 TS operating manual

Streamline

Streamline HIGHLINE HP-T12150PHR instruction manual

PowerWasher

PowerWasher TN-1200 Operator's manual

Shark Pressure Washers

Shark Pressure Washers DG-3022 Operating instructions and parts manual

Nilfisk-ALTO

Nilfisk-ALTO NEPTUNE NEPTUNE 1 operating instructions

Kärcher

Kärcher Cage Classic HD 13/35-4 manual