520-259-000 6/00 Powerwise Models 4061, 4063 Page 10

PRINCIPLE OF PUMP OPERATION

This ball type check valve pump is

poweredbycompressedair andis a1:1

ratio design. The inner side of one

diaphragm chamber is alternately

pressurized while simultaneously

exhaustingtheotherinnerchamber.This

causes the diaphragms, which are

connected by a common rod secured

by plates to the centers of the

diaphragms,to move in a reciprocating

action.(As onediaphragm performsthe

discharge stroke the other diaphragm

is pulled to perform the suction stroke

in the opposite chamber.) Air pressure

is applied over the entire inner surface

of the diaphragm while liquid is

dischargedfromthe oppositeside ofthe

diaphragm.The diaphragm operates in

a balanced condition during the

dischargestrokewhich allowsthe pump

tobe operated atdischarge heads over

200feet (61 meters) of water.

For maximum diaphragm life, keep

the pump as close to the liquid being

pumped as possible. Positive suction

headinexcess of10 feetof liquid(3.048

meters) may require a back pressure

regulating device to maximize

diaphragmlife.

Alternate pressurizing and

exhausting of the diaphragm chamber

isperformed by an externallymounted,

pilot operated, four way spool type air

distributionvalve. Whenthe spoolshifts

to one end of the valve body, inlet

pressure is applied to one diaphragm

chamber and the other diaphragm

chamber exhausts. When the spool

shifts to the opposite end of the valve

body, the pressure to the chambers is

reversed.Theair distributionvalve spool

is moved by a internal pilot valve which

alternately pressurizes one end of the

air distribution valve spool while

exhaustingtheother end.The pilotvalve

is shifted at each end of the diaphragm

stroke when a actuator plunger is

contacted by the diaphragm plate. This

actuatorplunger thenpushesthe end of

the pilot valve spool into position to

activatethe air distributionvalve.

The chambers are connected with

manifolds with a suction and discharge

check valve for each chamber,

maintainingflowin onedirection through

thepump.

INSTALLATION AND START-UP

Locate the pump as close to the

productbeingpumpedaspossible.Keep

the suction line length and number of

fittingsto a minimum.Do not reduce the

suctionline diameter.

Forinstallations of rigid piping,short

sections of flexible hose should be

installed between the pump and the

piping. The flexible hose reduces

vibration and strain to the pumping

system. A surge suppressor is

recommended to further reduce

pulsationin flow.

AIR SUPPLY

Air supply pressure cannot exceed

100 psi (7 bar). Connect the pump air

inlettoan airsupply ofsufficient capacity

and pressure required for desired

performance. When the air supply line

is solid piping, use a short length of

flexible hose not less than ½" (13mm)

in diameter between the pump and the

pipingto reducestrain to thepiping. The

weight of the air supply line, regulators

and filters must be supported by some

meansotherthantheairinletcap.Failure

to provide support for the piping may

resultindamagetothe pump.Apressure

regulating valve should be installed to

insure air supply pressure does not

exceedrecommended limits.

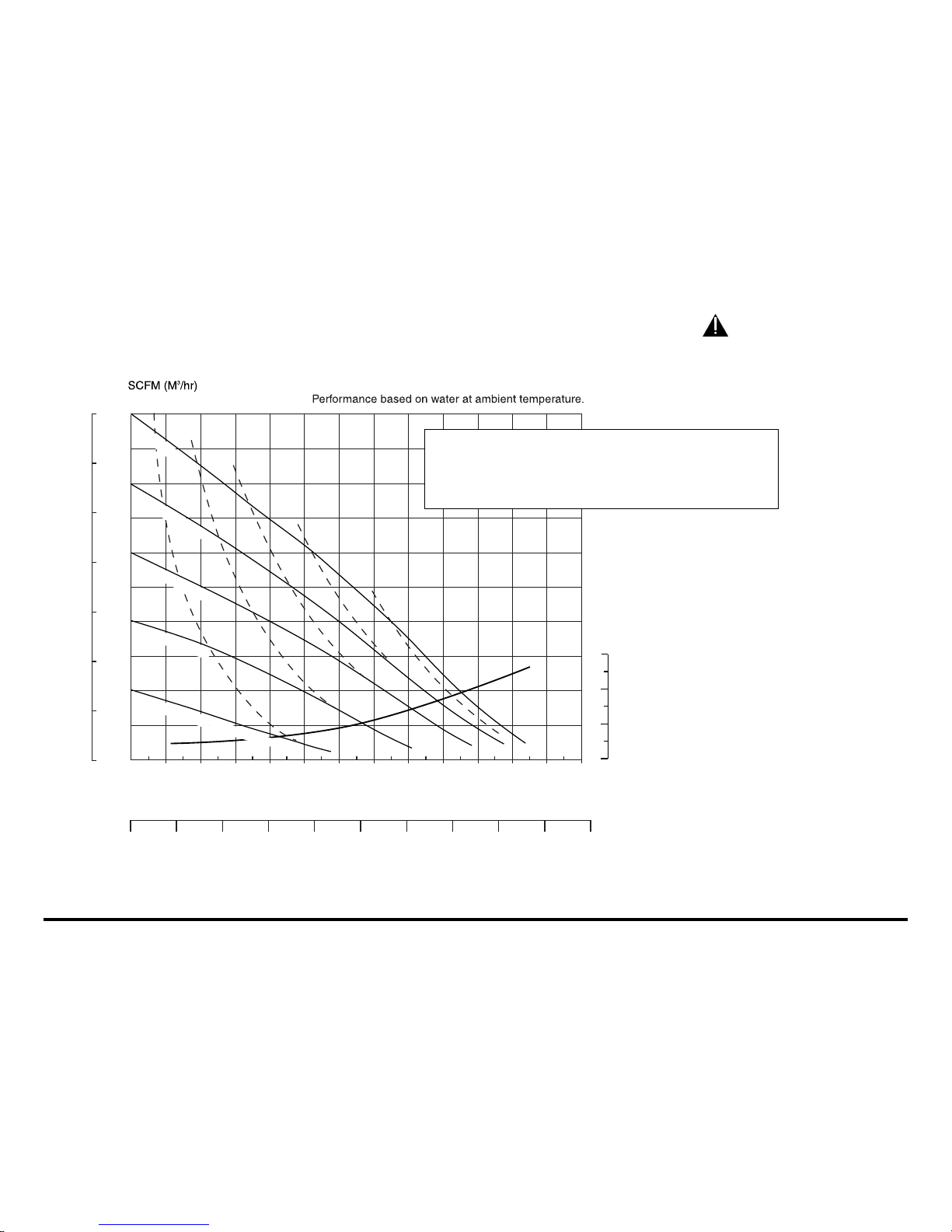

AIRVALVE LUBRICATION

Theairdistribution valveand thepilot

valvearedesignedtooperate WITHOUT

lubrication.Thisisthe preferredmode of

operation. There may be instances of

personal preference or poor quality air

supplies when lubrication of the

compressed air supply is required. The

pump air system will operate with

properly lubricated compressed air

supply. Proper lubrication requires the

useof an air line lubricatorsetto deliver

one drop of SAE 10 non-detergent oil

for every 20 SCFM (9.4 liters/sec.) of

air the pump consumes at the point of

operation.Consultthe pump’spublished

Performance Curve to determine this.

AIR LINE MOISTURE

Water in the compressed air supply

can create problems such as icing or

freezing of the exhaust air, causing the

pump to cycle erratically or stop

operating. Water in the air supply can

be reduced by using a point-of-use air

dryerto supplementthe user’sair drying

equipment. This device removes water

from the compressed air supply and

alleviatestheicingor freezingproblems.

AIR INLET AND PRIMING

To startthe pump, open theairvalve

approximately ½ to ¾ turn. After the

pumpprimes,theairvalvecanbeopened

toincreaseair flowasdesired.Ifopening

thevalveincreasescyclingrate,butdoes

not increase the rate of flow, cavitation

hasoccurred.Thevalveshouldbeclosed

slightly to obtain the most efficient air

flowto pump flow ratio.

BETWEEN USES

Whenthe pumpis used formaterials

that tend to settle out or solidify when

notinmotion,thepumpshouldbeflushed

after each use to prevent damage.

(Productremaininginthepumpbetween

uses could dry out or settle out. This

could cause problems with the

diaphragmsandcheck valvesatrestart.)

Infreezing temperaturesthe pumpmust

becompletely drained between uses in

all cases.