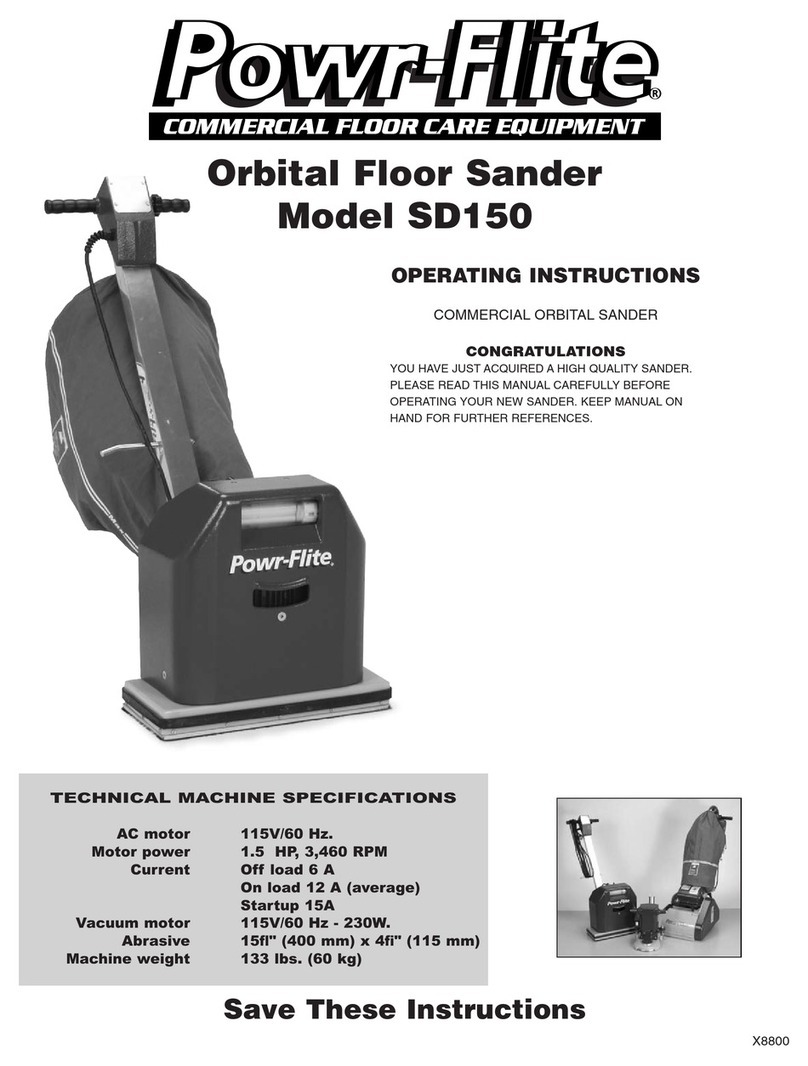

Powr-Flite SD70 User manual

Edger/Disc Sander

Model SD70

Save These Instructions

X8802

OPERATING INSTRUCTIONS

COMMERCIAL EDGER

CONGRATULATIONS

YOU HAVE JUST ACQUIRED A HIGH QUALITY SANDER.

PLEASE READ THIS MANUAL CAREFULLY BEFORE

OPERATING YOUR NEW SANDER. KEEP MANUAL ON

HAND FOR FURTHER REFERENCES.

TECHNICAL MACHINE

SPECIFICATIONS

Single-phase AC motor 115V/60 Hz

Motor power 1800 W

Sandpaper disk 7 inches

Disk speed 4300 RPM

Machine weight 20 lbs.

2

CONTENTS

Important Parts of the Machine ...........................3

Machine Set-up

Fitting t h e d u s t b a g . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

How to Operate the Machine

Fitting t h e s a n d p a p e r . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Sanding a n g l e a d j u s t m e n t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Connection t o p o w e r s u p p l y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Starting t h e m a c h i n e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

How to operate the machine .................................5

Maintenance

Brush r e p l a c e m e n t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Changing a n d a d j u s t i n g t h e V-belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Cleaning t h e d i s k p u l l e y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Wheel r e p l a c e m e n t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Dust s u c t i o n . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Equipment .............................................................9

Assembly Drawing and Spare Parts List ...........10

CAUTION

Read all instructions, warnings and

cautions before using!

These guidelines are provided for your

protection and convenience. Please read

them carefully. If you have any questions

regarding the use of your equipment call

Powr-Flite Technical Service at

800.880.2913. This manual contains

important information for the use of this

machine and safety instructions for

preventing personal injuries, damage to

the machine or to other property. Failure

to adhere to instructions provided can

potentially void any warranties.

INTRODUCTION

Congratulations on your purchase of a Powr-Flite

Edger Sander. Read this entire manual before

operating or servicing the sander.

Unpacking the Edger Sander

The Powr-Flite Edger Sander was thoroughly

inspected, tested, and packaged to deliver the

equipment in good operating condition. The freight

carrier received and signed for the equipment in good

condition. Damage can occur during shipping and to

protect your interest, all cartons must be inspected for

damage (including any concealed damage) that might

have occurred during shipment. Any damage is the

responsibility of the freight carrier and should be

reported immediately to the carrier.It is your

responsibility to issue a claim and to receive

compensation from the freight carrier for any damage

done in transit. Shipping damage is not warranted.

3

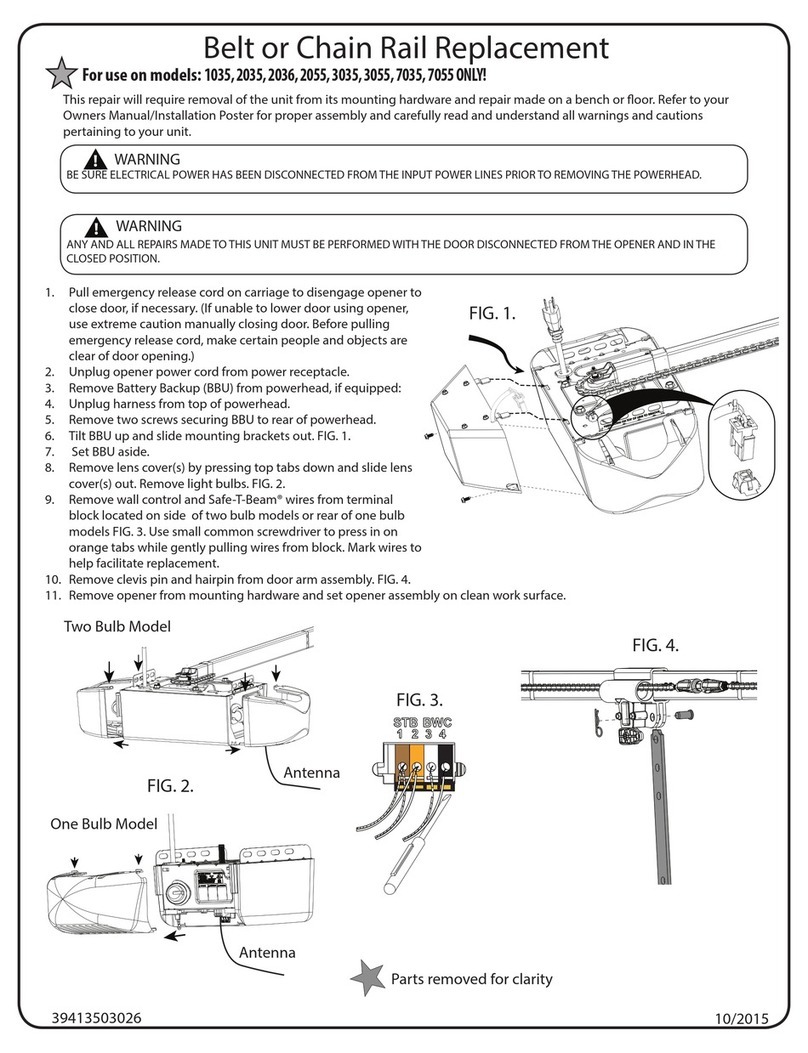

Fig. 1

Fig. 2

Fig. 3

Fig. 4

IMPORTANT PARTS OF THE MACHINE

The machine is fitted with a protected switch.

Push the button to “ON” to start the motor and

the “OFF” to stop.

Suction dust tube

The suction dust tube is placed at the back of the machine

next to the dustbag holder.

Dustbag

The dustbag must be clipped to the suction tube and its

holder placed inside the bag.

V-belt tensioner

The V-belt tensioner is located at the back of the machine

and underneath it.

Electric switch

4

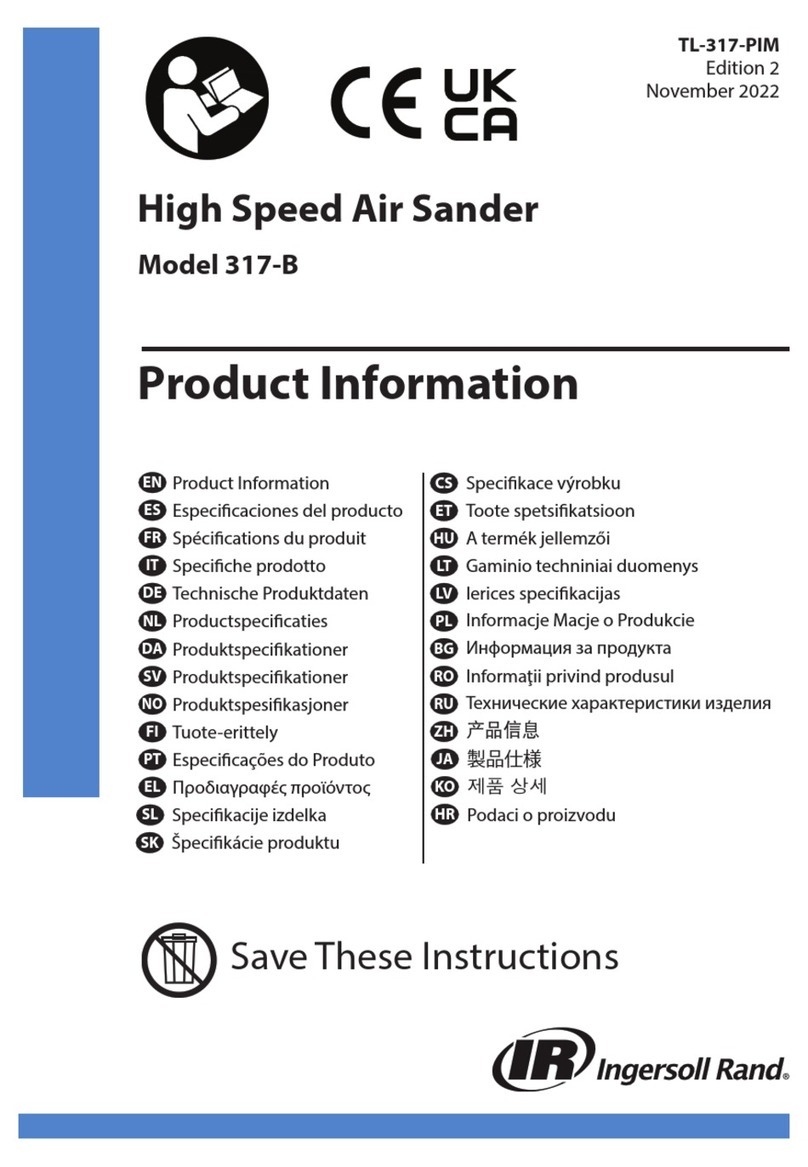

Fig. 5

Fig.6

Fig.7

MACHINE SET-UP

Sandpaper disk holder

Fitting the dustbag

The sandpaper disk holder is a tapered nut.

After unpacking the machine, proceed as follows:

1Fit the suction tube

2Fit the dustbag holder

3Fit the dustbag

1Sandpaper discs with an adhesive backing:

use 178 mm. disks and simply place the sandpaper disk

on the sanding disk (Fig. 6).

2Sandpaper discs with a paper backing:use 178

mm disks with a 22 mm hole.

3Take offthe taper nut.

HOW TO OPERATE THE MACHINE

4Place the sandpaper disk, then the taper nut and

secure it. (Fig. 7).

Fitting the sandpaper

5

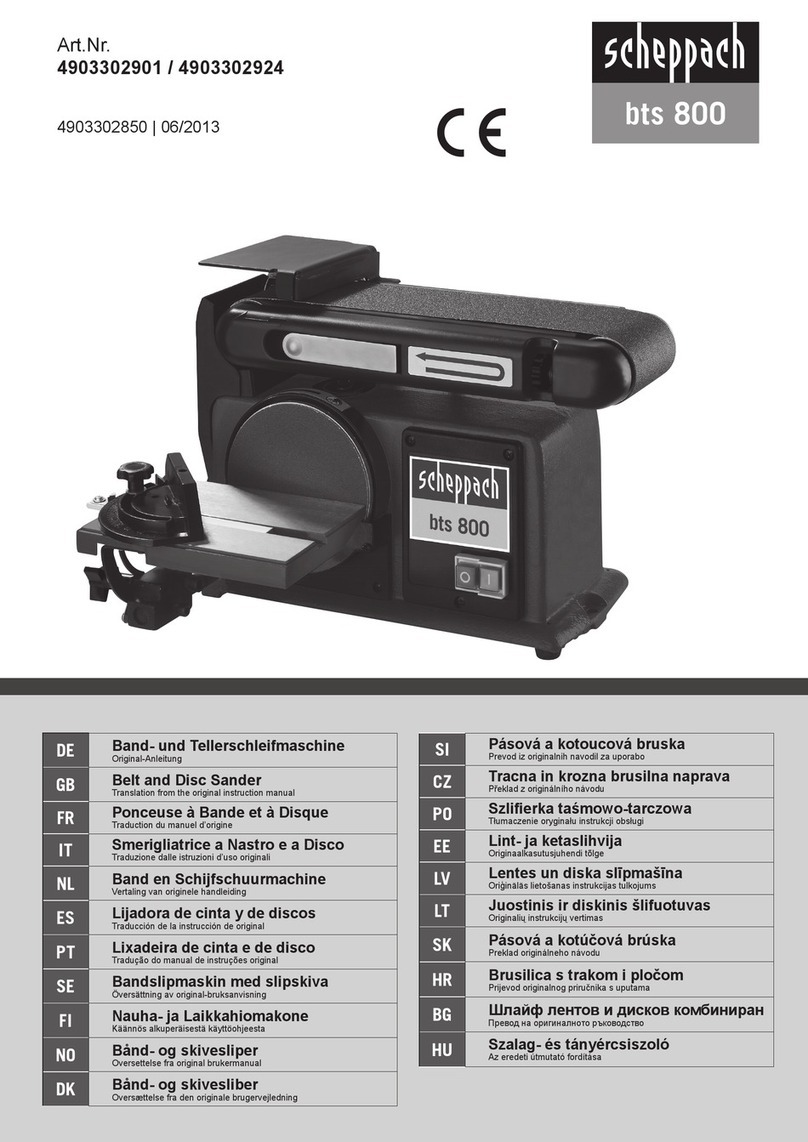

Fig. 8

Fig. 9

5Fasten the nut with the wrench included in the wrench

kit (Fig. 8).

Sanding angle adjustment

The sanding angle is set up at the factory for sanding with a

1/3 disk.

If you wish to change this angle, unloosen the nut securing

the wheel shaft. Then move the wheels up and down to

change the working angle as follows:

Wheels down: the machine sands point first

Wheels up: the machine sands flat. (Fig. 9).

Connection to power supply

The sander must be connected to a 115V/60 Hz power

supply with grounded plugs.

CAUTION!

To prevent electrocution keep the machine in a dry place. Do

not expose the machine to rain.

Use 3 wire of 14 AWG section cable.

The machine cord, extension cords and connection plugs

must be in perfect condition.

1Before connecting the cord to the power supply make

sure that the switch is in the “0” position.

2Place the machine in a vertical position and tilted

backward.

3Hold the machine with your left hand.

4Push the switch down with your right hand.

5Press the disk on the floor and start sanding.

6Do not press on the sander. Its own weight and the high

speed of the disk are sufficient for sanding.

HOW TO OPERATE THE MACHINE

Starting the machine

How to use the machine

The sander is usually held with both hands and placed

between the legs with your body leaning backward. You can

also use it on your knees.

The high speed of the disc will sand the surface without any

additional pressure. Do not press on the edger while

sanding.

Pressing on the machine could leave marks on the floor,

burn the wood, overheat the motor and wear the brushes

faster; shortening the life of the machine.

4Remove the plastic cover securing the brushes with a

screwdriver (Fig. 13).

5Remove the brushes carefully and replace them (Fig.

14).

IMPORTANT:

The motor is fitted with two brushes, one at each side of the

motor.

In universal motors, the brushes have an approximate life of

500 hours of machine use under normal conditions and

without pressing too much on the sander when working.

The brushes and their housing should be cleaned using

compressed air.

Inspect brushes on a regular basis. They should be replaced

before the automatic disconnection stops the machine. This

will occur when the brushes are worn out and less than ⁄ inch

long. Damage can occur if the brushes are allowed to wear

completely out. Make sure you always have a brush set

available.

6

Fig. 11

Fig.12

Fig.13

Fig.14

Brush replacement

3Remove the vertical bracket (Fig. 12).

MAINTENANCE

1Disconnect the machine from the power supply.

2Remove side and front screws.( Fig.11).

7

Fig.15

Fig.16

Fig.17

Fig.18

MAINTENANCE

Changing and adjusting the V-belt

Due to the high speed of the motor, it is important to check

the tension of the V-belt. DONOT TIGHTEN THE BELT

TOO MUCH.

This type of machine, equipped with high speed motors,

needs a regular replacement of the belt.

1For adjusting or replacing the belt, disconnect the power

supply.

2Loosen both screws without removing them (Fig. 15).

3Loosen the nut without removing it (Fig. 16).

4The belt is either tightened or loosened when adjusting or

loosening the tension screw (Fig. 17).

5Place the machine as shown in Fig. 18 and remove the

four screws securing the guard which covers the belt

(Fig. 18).

8

Cleaning the disk pulley

6Take off the taper nut which holds the sandpaper

(Fig. 19).

8When the disk and the pulley are loose, lift them up,

remove the belt and replace it by a new one (Fig. 21).

MAINTENANCE

Material debris, waxes, glues, plasters, leveling pastes, etc.

could stick to the disk pulley causing the machine to be out

-of-balance and show an unusual belt wear.

Clean the pulley track where the belt slides. (Fig. 22).

7Remove the guard which covers the central screw with a

screwdriver. Holding the disk with one hand, ease the

central screw with an Allen wrench (Fig.20 a-b).

To pull out the pulley from the bearing, strike the central

screw slightly with a plastic hammer (Fig.20 c).

Toset up the pulley again, tighten the screw at the disk

side, adjust the pulley to the bearing and strike the screw

slightly with a plastic hammer until the pulley gets in

(Fig.20 d).

Remove the screw and set it in place again.

Fig.19

Fig.20

Fig.21

Fig.22

ab

cd

9

Fig.23

Fig.24

Fig.25

MAINTENANCE

EQUIPMENT

Wheel replacement

For proper machine operation, inspect the wheels for

wearing and to ensure the working angle is not altered

as the wheels wear down.

The proper working angle is necessary to maintain:

-Adequate dust suction

-proper sanding finish

Replace wheels as required to maintain the proper

working angle.

Dust suction

The machine is equipped with a dustbag. For

optimum performanc:

1The working angle should be the adequate. A tilted

machine is not able to vacuum properly.

2Empty the dustbag when it is 1/3 full. Suction

becomes less effective when the bag gets too full.

3Do not use the machine with more than one disk of

sandpaper.

4The bag is made with a special material which lets

air through, but not dust.

5Change the dustbag several times a year,even if it

is not torn; the aging of material due to dust

accumulation will obstruct the air circulation and

therefore cause faulty suction.

Tool bag

A tool bag with wrenches is provided for machine

maintenance.

10

ASSEMBLY DRAWING AND SPARE PARTS LIST

11

ASSEMBLY DRAWING AND SPARE PARTS LIST

ref# part # desc

1 SD157 HILT

2 SD158 HANDLE

2.3 SD159 HANDLE BRACKET

5 SD160 DUST BAG CLAMP

6 SD161 DUST BAG

8 SD162 O RING OR 44,2 x 3

11 SD163 FAN

12 SD164 MOTOR PULLEY (disc ø 178 mm)

18.1 SD165 WHEEL ø 40

ref# part # desc

21 SD166 GASKET

28 SD167 O RING OR 90 X 3

32 SD168 SCREW DIN 7991 M 10 x 40

41 SD169 BELT Z - 19 3/4 (disc ø 178 mm)

43 SD170 STEEL DISC ø 178 mm

45 SD172 CONICIAL NUT

46 SD173 FELT DISC ø 178 mm

47 SD174 UNIVERSAL MOTOR MOG USA

57 SD175 KEY

ref# part # desc

1SD176 BALLBEARING 6001 VVC3

2SD177 BRUSH BRACKET

3SD178 BRUSHES

4 SD179 COVER

5 SD180 MOTOR HOUSING

6SD181 STATOR USA

7 SD182 COVER

8 SD183 BALLBEARING 6202 VVC3

10 SD184 ROTOR USA

13 SD185 V-RING JOINT V 28 S

14 SD186 AXIAL DISC INA AS3047

15 SD187 SPACER

12

WARRANTY

Powr-Flite warrants new products manufactured and sold under the name of Powr-Flite to be free from

defects in materials and workmanship under normal use and service, provided such goods are installed,

operated and maintained in accordance with written manuals or other instructions for a period of 1-year.

Powr-Flite’s obligation under this warranty is limited to repairing or replacing, at our option, such products

or parts which are returned to our factory authorized service center, within the warranty period and are

found to be defective in materials or workmanship. This warranty does not apply to excessive wear caused

by abnormal use, nor does it apply to normal wear parts such as main cable, wheels, switches, relays,

brushes, rubber parts, hoses and bearings.

This warranty is in lieu of all other warranties expressed or implied, and releases Powr-Flite from all other

obligations and liabilities.

Powr-Flite assumes no responsibility for repairs, and the costs of such repairs, made or attempted by

persons other than those specifically authorized by Powr-Flite. Any such unauthorized repairs shall void

this warranty.

DECLARATlON OF CONFORMlTY

QUIDE, S.A. declare under our responsability that the floor sanding machine model EASY 7 meets the requires

standards of safety and health with respect to the design and manufacture of machinery, according to the below

mentioned regulations.

EEC regulations regarding to:

Machines (89/392/EEC)

Low voltage (73/23/EEC)

Electromagnetic compatibility (89/336 EEC)

(Last changed through 93/68/EEC from 22.7.1993.)

In conformity with the following standards:

EN 292 Part 1 and Part 2 (Safety of machinery, equipment and systems)

EN 60204.1 (Electrical equipment of industrial machines)

DECLARATION OF CONFORMITY

WARRANTY

Table of contents

Other Powr-Flite Sander manuals