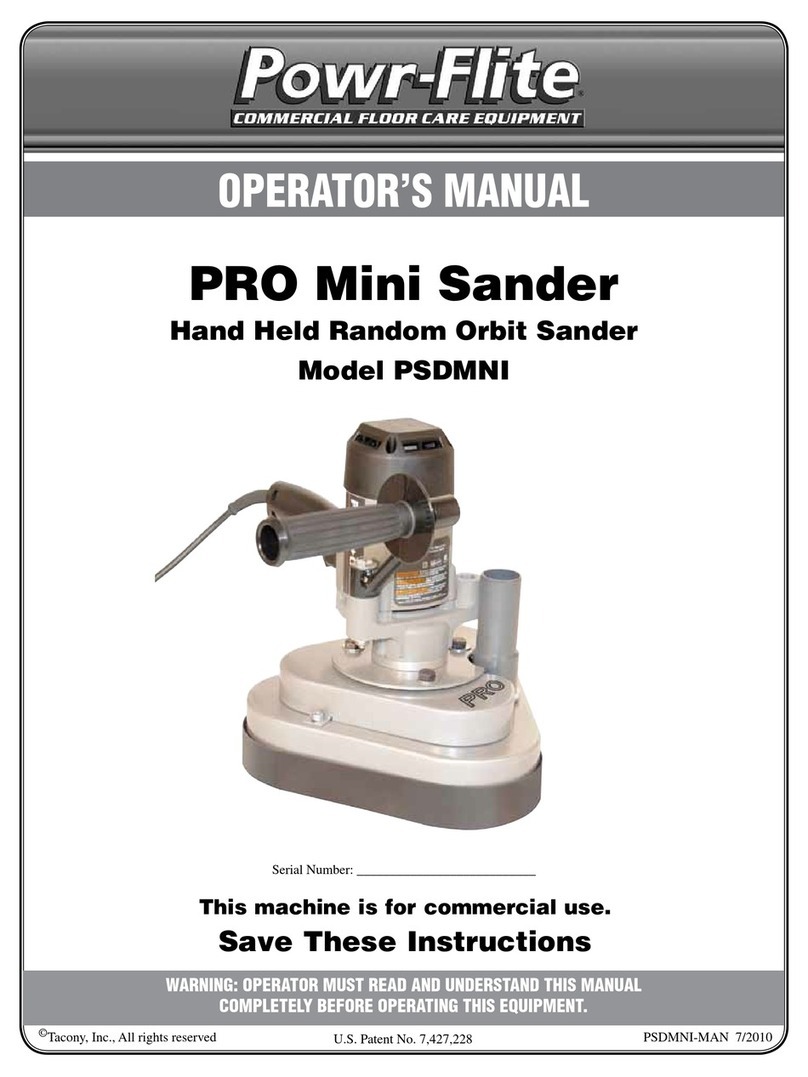

Powr-Flite SD150 User manual

Save These Instructions

Orbital Floor Sander

Model SD150

X8800

OPERATING INSTRUCTIONS

COMMERCIAL ORBITAL SANDER

CONGRATULATIONS

YOU HAVE JUST ACQUIRED A HIGH QUALITY SANDER.

PLEASE READ THIS MANUAL CAREFULLY BEFORE

OPERATING YOUR NEW SANDER. KEEP MANUAL ON

HAND FOR FURTHER REFERENCES.

TECHNICAL MACHINE SPECIFICATIONS

AC motor 115V/60 Hz.

Motor power 1.5 HP, 3,460 RPM

Current Off load 6 A

On load 12 A (average)

Startup 15A

Vacuum motor 115V/60 Hz - 230W.

Abrasive 15fl" (400 mm) x 4fi" (115 mm)

Machine weight 133 lbs. (60 kg)

2

CONTENTS

Safety Instructions .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Important Parts of the Machine ..............................4

Machine Set-up

Setting up the dust b a g . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Setting up the handle s u p p o r t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Fitting the sandpaper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

How to Start the Machine

Setting up and leveling the sanding plate ............................6

Connection to power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Starting the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

How to Operate the Machine ...................................7

Maintenance

Replacement of the wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Replacement of the lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Dust suction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Accessories ................................................................9

Assembly Drawing and Spare Parts List ...............10

CAUTION

Read all instructions, warnings and

cautions before using!

These guidelines are provided for your

protection and convenience. Please read

them carefully. If you have any questions

regarding the use of your equipment call

Powr-Flite Technical Service at

800.880.2913. The manual contains

important information for the use of this

machine and safety instructions for

preventing personal injuries, damage to

the machine or to other property. Failure

to adhere to instructions provided can

potentially void any warranties.

INTRODUCTION

Congratulations on your purchase of a Powr-Flite

Orbital Sander. Read this entire manual before

operating or servicing the sander.

Unpacking the Orbital Sander

The Powr-Flite Orbital SAnder was thoroughly

inspected, tested, and packaged to deliver the

equipment in good operating condition. The freight

carrier received and signed for the equipment in good

condition. Damage can occur during shipping and to

protect your interest, all cartons must be inspected

for damage (including any concealed damage) that

might have occurred during shipment. Any damage is

the responsibility of the freight carrier and should be

reported immediately to the carrier. It is your

responsibility to issue a claim and to receive

compensation from the freight carrier for any damage

done in transit. Shipping damage is not warranted.

3

SAFETY INSTRUCTIONS

• Operators must be trained to operate this machine

and must read and understand this manual

completely before operating the equipment.

• Machines can cause flammable materials and

vapors to burn. Do not use the machine with or

near solvents, thinners, fuels, or other flammable

materials.

• To prevent the risk of fire or explosion:

a) Empty the dustbag when it is 1/3 full.

b) Empty the dustbag when the work is over. Do

not leave contents in the dust bag.

c) Do not put the contents of the dust bag into a

fire or furnace.

d) Use a hammer and punch to countersink all

nails against the floor so that the sanding drum

will not touch them and create sparks which

might cause a fire in the dust bag.

•Do not use the machine if it is not completely

assembled.

• To prevent personal injury, always disconnect the

power supply before changing the sandpaper,

emptying the dust bag, leaving it unattended or

attempting any maintenance or service of the

machine.

•Toprevent electrocution, avoid contact with

grounded devices, i.e. electric stoves, radiators,

refrigerators, etc.

• Do not expose the machine to rain.

• Keep the electrical parts dry. The machine should

be stored in a dry place.

• When you operate the machine, make sure that

the power cord is free from under the sanding

plate.

• Check the cord and plugs and replace them if

damaged. Do not use the machine if the cord is

damaged. Keep the cord away from heat, oil and

water.

• Always use a 3-wire electrical cord (GA 14-3) and

connect the machine to grounded plugs.

• Make sure that the switch is in the “0” - “Off”

position before connecting the machine to the

power supply.

• Be careful not to accidentally start the machine,

make sure that your hands are empty when you

press the switch.

• Always use a dust mask. if the sanding operation

is dusty.

• Do not operate the machine when you are tired,

avoid positions which can cause fatigue. Keep

proper footing and balance at all times.

•Always keep the machine clean. Check it for

damaged parts before use, change damaged

moving parts and always follow maintenance

instructions.

• Keep children away from the machine.

Read these instructions carefully before operating or attempting to

carry out any service or maintenance procedure on the machine.

To reduce the risk of fire, electric shock and personal injury when using

electrical tools, the following basic safety precautions should always be

taken.

4

Fig. 1

Fig. 2

Fig. 3

Fig. 4

IMPORTANT PARTS OF THE MACHINE

The double-bladed switch is located in the condenser

box beside the motor.

When the switch is pushed to the left the motor is

off. The motor starts when the switch is pressed

to the right.

Suction system

This is fitted with a suction tube operated by a 230W

power motor which suctions dust through a flexible

hose when the machine is working.

Lamp

Sanding plate holder

The PL-9 W type lamp is directly connected to the

power supply. This means that the light comes on

automatically when the machine is started.

This is located underneath the machine and is fitted

with 2 pins that secure the sanding plate.

Switch

5

1Loosen the lever.

2Push the handle tube in as far as possible.

3Adjust the lever.

1Sandpaper with an adhesive backing.

Place the sandpaper on the plate support (Fig. 7).

Fig. 5

Fig. 6

Fig. 7

Fig. 8

MACHINE SET-UP

Dust bag

Setting up the handle

The dust bag must be placed at the suction tube

outlet and hung from the machine handle.

2Sandpaper with a paper backing.

Cut to the appropriate length and hold both ends

firmly with the sandpaper holder to prevent the

sandpaper from slipping during operation (Fig. 8).

Fitting the sandpaper

6

Fig. 9

Fig. 10

Fig.11

Setting-up and leveling the sanding plate

1Disconnect the sander from the power supply.

2Place the machine in the position shown in (Fig. 9.)

4To level the height of the caster wheels in relation

to the sanding plate, unloosen both screws and

turn the eccentric shaft wheels: the wheels will go

up and down (Fig. 11).

5The wheels must reach the plate height.

3Fit the sanding plate by matching up the two plate

holes with the two hooking pins (Fig. 10).

HOW TO START THE MACHINE

7

Fig. 12

Fig.13

Fig. 14

The sander must be connected to a 115V/60 Hz power

supply with grounded plugs.

CAUTION!

To prevent electrocution keep the machine in a dry place.

Do not expose the machine to rain.

Use 3-wire (GA 14-3) power cords connected to grounded

plugs.

The machine cord, extension cords and connection plugs

must be in perfect condition.

1Before connecting the cord to the power supply, make

sure that the switch is in the “O” position.

2After placing the sander as shown in Fig. 12, push the

switch down with one hand and hold the machine with

the other.

3Do not press on the sander. Its own weight is sufficient

for achieving efficient work.

MAINTENANCE

How to start the machine

How to operate the machine

The sander is usually held by the handle with both hands

and rolled along to the places to be sanded. Move the

machine to avoid marks on the floor.If the floor is not

level, use the support plate for the mesh sandpaper, as

shown in (Fig. 13.)

Connection to power supply

Replacement of the wheels

1Disconnect the machine from the power supply.

2Unloosen and remove both screws from the wheel

shaft bracket.

3Remove the wheels beside the shaft.

4Remove the shaft wheels with an hexagonal wrench

andreplace them.

HOW TO START THE MACHINE

8

Replacement of the lamp

The machine has a light fitted with a PL-9W lamp.

To replace it:

1Remove the front plastic part by gently pressing

on its sides (Fig. 15).

2Replace the lamp with a new one (Fig. 16).

Fig.17

Dust suction

The machine is equipped with a dustbag.

For optimum vacuum performance:

1The caster wheels should be level with the

sanding plate.

2Empty the dustbag when it is 1/4 full. Suction

becomes less effective when the bag gets too full.

3Do not use the machine with more than one sheet

of sandpaper on the plate.

4The bag is made with a special material which lets

air get through it, but not dust.

5Change the dustbag several times a year, even if

it is not torn; the ageing of material due to dust

accumulation will obstruct the circulation of air and

therefore cause faulty suction.

Accessories

Included with the machine:

2sanding plates (one is already fitted on the sander).

1dust bag.

Screen & white pad.

3-wire electrical cord (GA 14-3).

ACCESSORIES

Fig.18

Fig.15

Fig.16

9

ASSEMBLY DRAWING AND SPARE PARTS LIST

ref# part # desc

1.1 SD129 CAPACITOR USA 100 MF

1.4 SD130 CABLE WITH PLUG USA

8SD131 SPLIT PIN ø 1,5 x 12

14 SD132 SPRING

10 SD133 SCREW DIN 913 M 6 x 5

16 SD134 SHAFT

17 SD135 PRESSIONING SCREW M 10

26 SD136 HOUSING

27 SD137 BUMPER

29 SD138 SANDPAPER SUPPORT

31 SD139 BUSHING

32 SD140 SANDPAPER PLATE

34 SD141 RUBBER

36 SD142 DUST BRUSH (SHORT)

ref# part # desc

37 SD143 DUST BRUSH

39.2 SD144 LAMP 9W 115V/60Hz

53 SD145 HANDLE ACCESS M 8

54 SD146 WASHER DIN 125 M 10

59 SD147 PROFIL BRACKET

62 SD148 WHEEL ø 80

68 SD149 SCREW DIN 931 M 8 x 130

82 SD151 FAN HOUSING

79 SD152 VACUUM MOTOR USA

SD153 DUST BAG

SD154 PLATE WITH WING NUTS COMPLETE

SD155 PLATE WITH FOAM COMPLETE

SD156 VELCRO 115/400

10

ASSEMBLY DRAWING AND SPARE PARTS LIST

11

DECLARATlON OF CONFORMlTY

QUIDE, S.A. declare under our responsibility that the floor sanding machine model ORBI meets the requires

standards of safety and health with respect to the design and manufacture of machinery, according to the below

mentioned regulations.

EEC regulations regarding to:

Machines (89/392/EEC)

Low voltage (73/23/EEC)

Electromagnetic compatibility (89/336 EEC)

(Last changed through 93/68/EEC from 22.7.1993.)

In conformity with the following standards:

EN 292 Part 1 and Part 2 (Safety of machinery, equipment and

systems)

EN 60204.1 (Electrical equipment of industrial machines)

DECLARATION OF CONFORMITY

WARRANTY

Powr-Flite warrants new products manufactured and sold under the name of Powr-Flite to be free from

defects in materials and workmanship under normal use and service, provided such goods are installed,

operated and maintained in accordance with written manuals or other instructions for a period of 1-year.

Powr-Flite’s obligation under this warranty is limited to repairing or replacing, at our option, such products

or parts which are returned to our factory authorized service center, within the warranty period and are

found to be defective in materials or workmanship. This warranty does not apply to excessive wear caused

by abnormal use, nor does it apply to normal wear parts such as main cable, wheels, switches, relays,

brushes, rubber parts, hoses and bearings.

This warranty is in lieu of all other warranties expressed or implied, and releases Powr-Flite from all other

obligations and liabilities.

Powr-Flite assumes no responsibility for repairs, and the cost of such repairs, made or attempted by

persons other than those specifically authorized by Powr-Flite. Any such unauthorized repairs shall void

this warranty.

WARRANTY

Table of contents

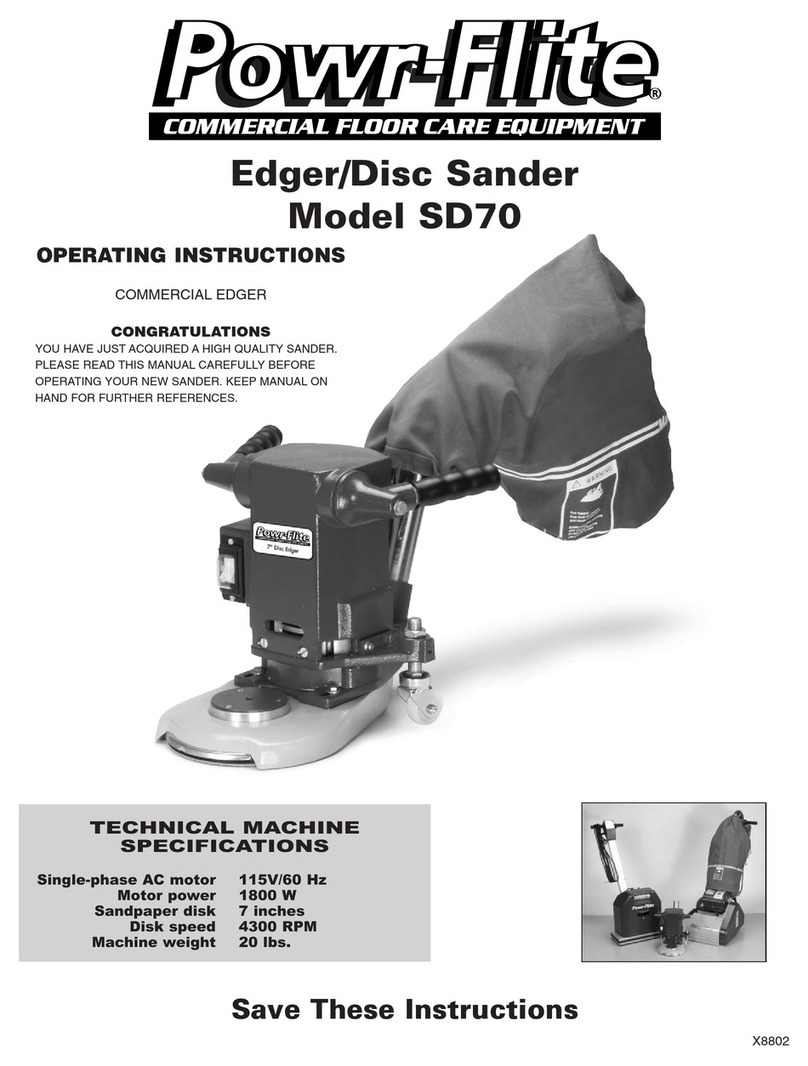

Other Powr-Flite Sander manuals