Preifer Vaccum MDP 5011 User manual

User’s manual

User’s manual

Original/ Translated from original version

Original/ Translated from original version

MDP 5011

Molecular pump

EN

EN

G 02594 - Edition 03 - July 11

1/2

MDP 5011

Molecular pumps

ApplicAtions:

Fast evacuation of small volumes – Interseal pumping –

Regeneration of cryopumps – Leak detection – Spectrometry –

Production of electronic tubes.

INSTRUMENTATION: Mass spectrometry, Surface analysis...

Benefits:

The design of the MDP pump offers the reliable and the robustness

with performances adapted to numerous applications.

controller:

The MDP 5011 works with the ACT 100 or ACT 200 TH controller (refer

to the ACT User’s manual).

Dear customer,

You have just purchased an

adixen Molecular pump.

We would like to thank you

and are proud to count you

as one of our customers.

This product has benefited

from adixen Vacuum

Produst’s many years of

experience in the field of

molecular pump design.

To guarantee high

performances and full

satisfaction from this

equipment, we suggest

that you study this

manual before any

intervention on your

pump, particularly the

chapter on installation

and start-up.

This product is designed to gererate vacuum by pumping on gases, but

no liquids neither solids. It is dedicated for running in industrial and

laboratory environments.

The products must not operate in an area with risk of explosion. Consult

us to study a solution.

This user’s manual includes only the instructions to connect the hybrid

turbo pump to the equipment. Refer to the controller user’s manual to

power and use the pump (chapter B, C and D).

adixen Vacuum Products - MDP 5011 User's Manual

2/2

MDP 5011

Molecular pumps

G 02594 - Edition 03 - July 11

Copyright/Intellectual property:

The use of adixen products are subject to copyright and

intellectual property rights in force in any jurisdiction.

All rights reserved, including copying this document in whole

or any part without prior written authorization from adixen

Vacuum Products.

Specifications and information are subject to change without

notice by from adixen Vacuum Products.

This product complies with requirements of European Directives, listed in

the Declaration of Conformity contained in G 100 of controller’s manual.

adixen Vacuum Products - MDP 5011 User's Manual

G 02617 - Edition 03 - July 11

1/2

Manual Part nuMber : 062 199

edition:14 - July 11 Contents

User’s manual

Molecular pumps MDP 5011

Translated from original

version

Chapter A INTRODUCTION

A 200 - MDP 5011 molecular pump overview

A 210 - The different version operating principle

A 400 - MDP 5011 technical characteristics

A 401 - Pump dimensions

A 510 - MDP 5011 accessories

Chapter B START-UP

B 100 - Safety instructions

B 300 - Pump connection to an installation

B 320 - Nitrogen purge connection (MDP5011CP)

B 330 - Venting valve connection

B 340 - Water cooling connection

B 350 - Air cooling kit connection

Chapter C OPERATION

C 100 - Safety instructions for product use

C 150 - Molecular pump operation in a pumping application

Chapter D MAINTENANCE

D 100 - Precautions before maintenance

D 300 - MDP 5011 pump maintenance frequency

Chapter E MAINTENANCE INSTRUCTIONS

E 200 - MDP 5011 pump lubrication

Chapter F MAINTENANCE COMPONENTS

F 000 - Spare parts - Instruction of use

F 100 - MDP 5011 first level of maintenance

Chapter G APPENDIX

G 010 - MDP 5011 pumping curves

G 200 - Safety questionnaire

adixen Vacuum Products - MDP 5011 User's Manual

2/2

Contents

User’s manual

Molecular pumps MDP 5011

G 02617 - Edition 03 - July 11

Manual Part nuMber : 062 199

edition:14 - July 11

Translated from original

version

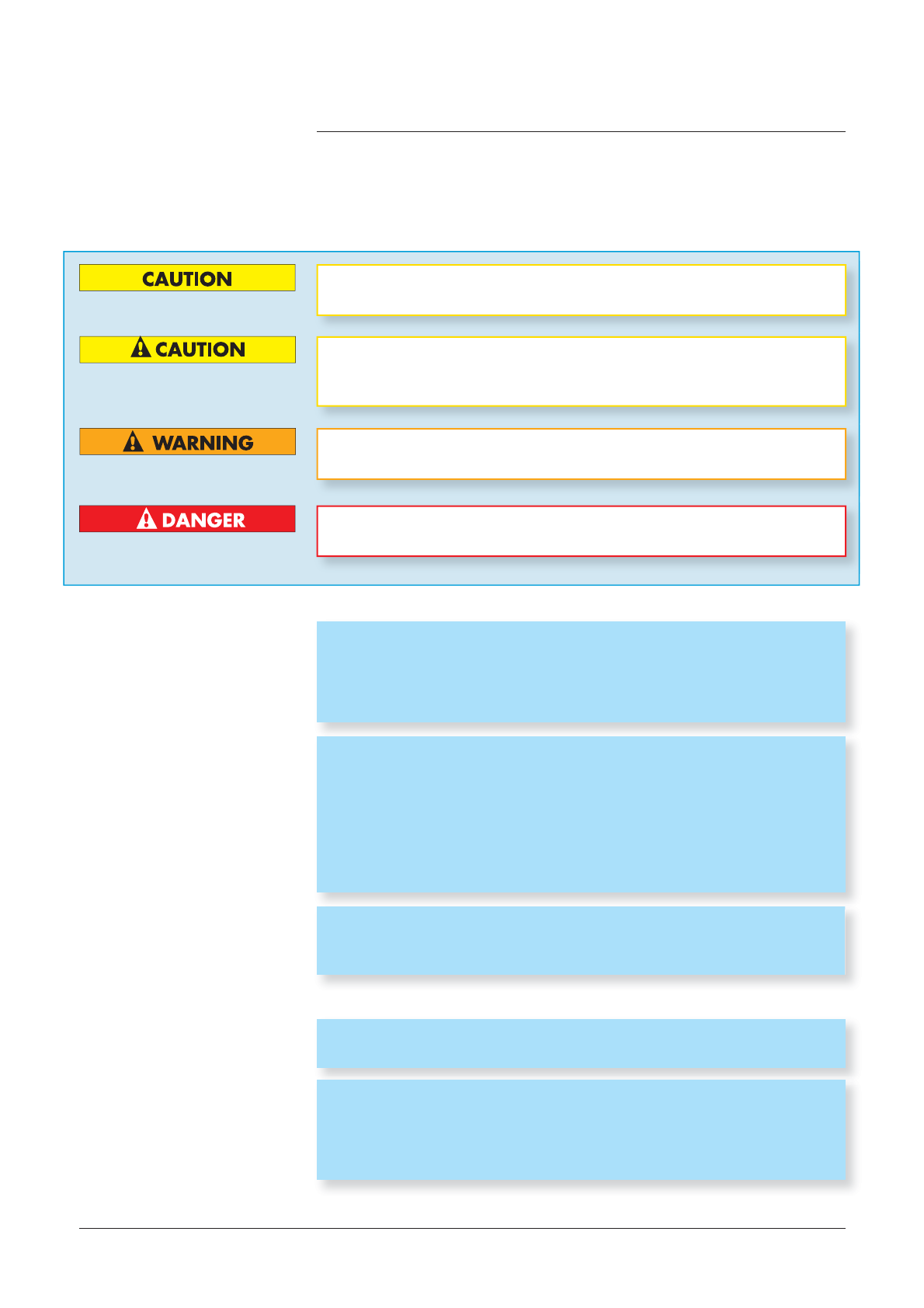

Before switching on the product, study the user’s manual and make

sure you follow the safety instructions. You can recognise these by the

‘Caution’, ‘Warning’ and ‘Danger’ symbols.

Good practice tips and manufacturer’s recommendations are in a blue

box.

The performance and operational safety of this product are guaranteed

provided it is used normally in the operating conditions defined in this

manual.

It is the customer’s task to:

– train operators to use the product if they do not speak the language

the manual is written in,

- ensure operators know the safe practices to apply when using the

product.

Indicates an imminently hazardous situation that, if not avoided, will

result in death or severe injury (extreme situations).

Indicates a potentially hazardous situation which, if not avoided, could

result in death or severe injury.

Indicates a potentially hazardous situation which, if not avoided, could

result in property damage.

Indicates a potentially hazardous situation which, if not avoided, could

result in moderate or minor injury. It may also be used to alert against

unsafe practices.

adixen Vacuum Products - MDP 5011 User's Manual

G 02618 - Edition 03 - July 11

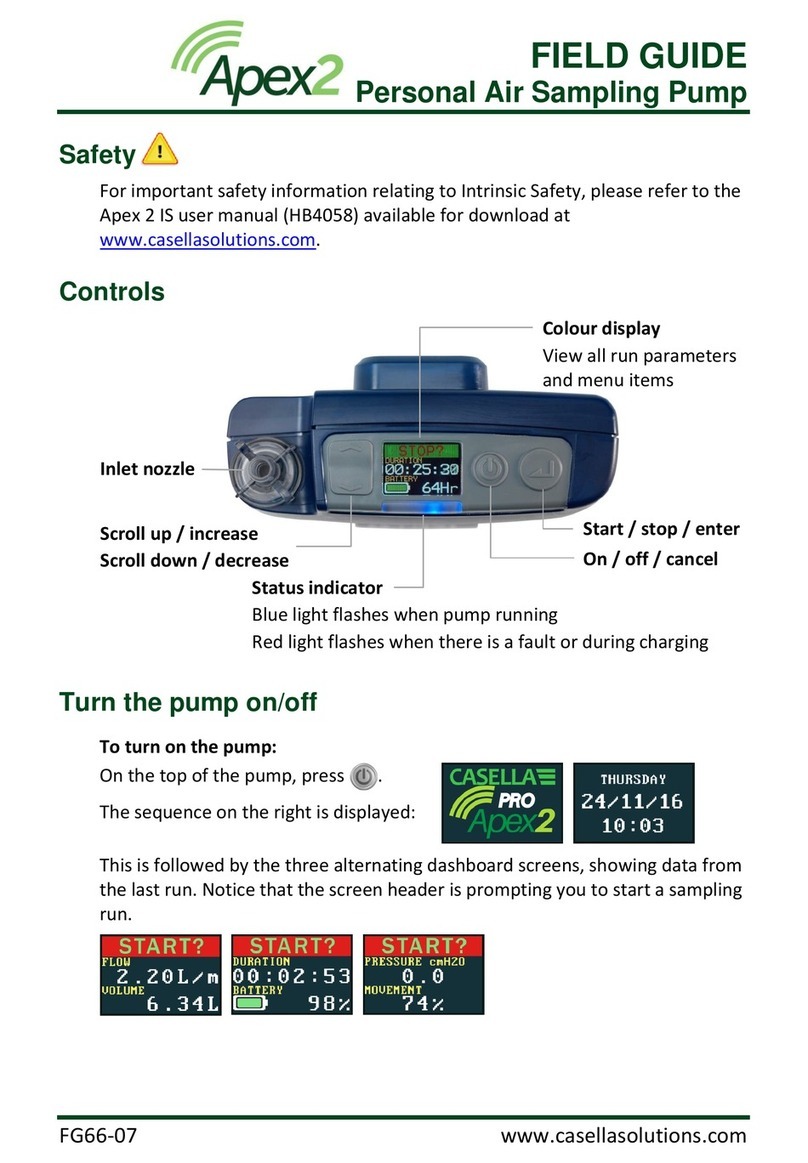

A 200

MDP 5011 molecular pump overview

1/1

Two pump versions The standard version: MDP 5011 pump.

The version for corrosive gases: MDP 5011CP pump.

The MDP 5011 offers high pumping performances between 10 mbar

and 10-5 mbar and a maximum flowrate fo 400 sccm.

With a simple construction but robust rotor and low rotational

speed (27,000 rpm), the MDP is robust against accidental air in-rush,

shock venting and gyroscopic effects.

Including built in ceramic ball bearings, The MDP is easily field

maintainable.

At the pump exhaust, the gases are evacuated to the atmosphere

by a roughing pump. Since the MDP compression rate is set by the

design, the MDP limit pressure is given by that of the roughing

pump used.

The MDP 5011 pump work with the ACT 100 or ACT 200 TH

controller. Refer to the corresponding Controller User’s Manual to

used the pump.

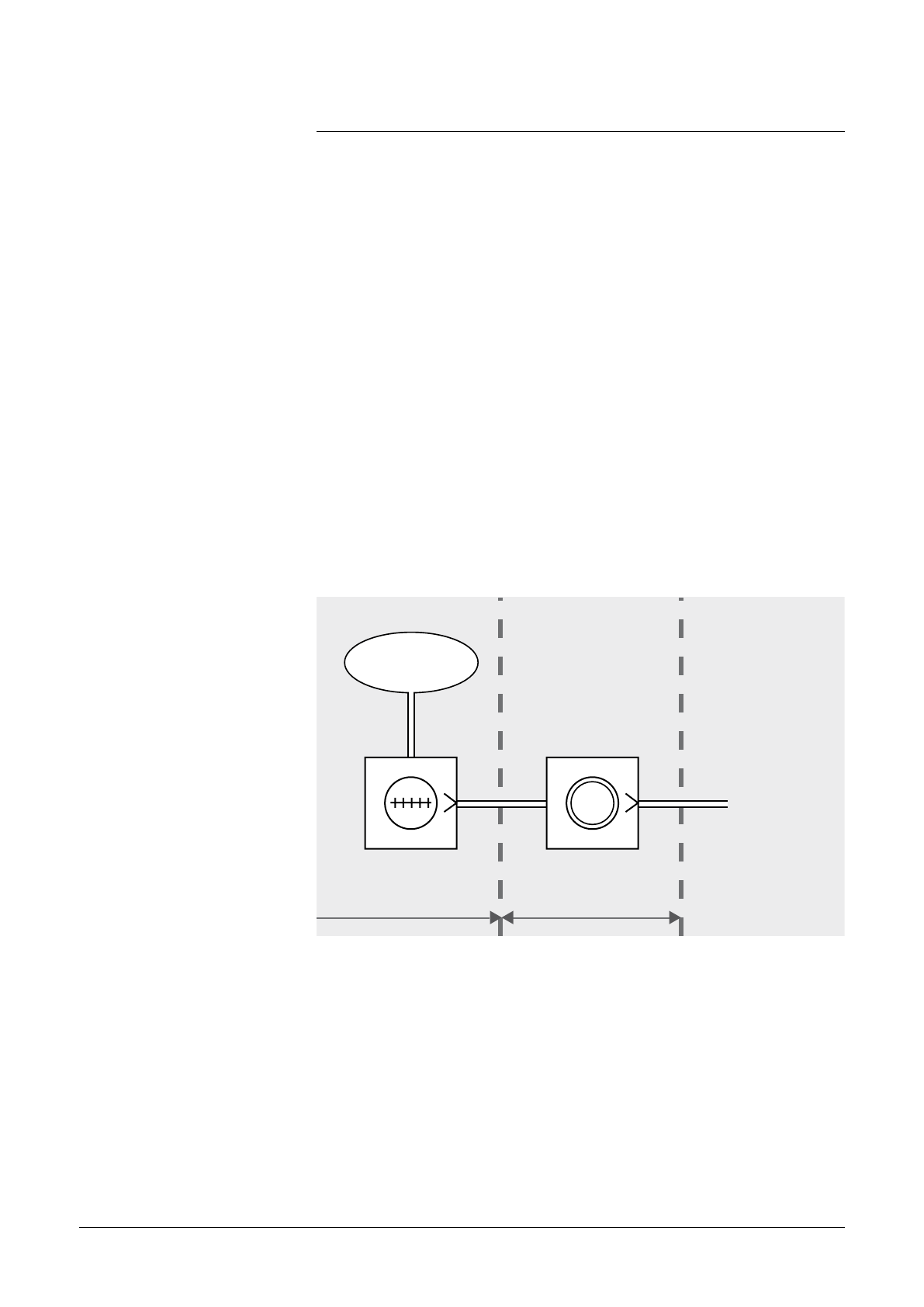

Main characteristics

The molecular pump

in an installation

Inlet

pressure

Chamber to

be pumped

High

pumping

Rough

pumping

Atmospheric

pressure

High vacuum Rough vacuum

Controller

adixen Vacuum Products - MDP 5011 User's Manual

G 02596 - Edition 02 - March 06

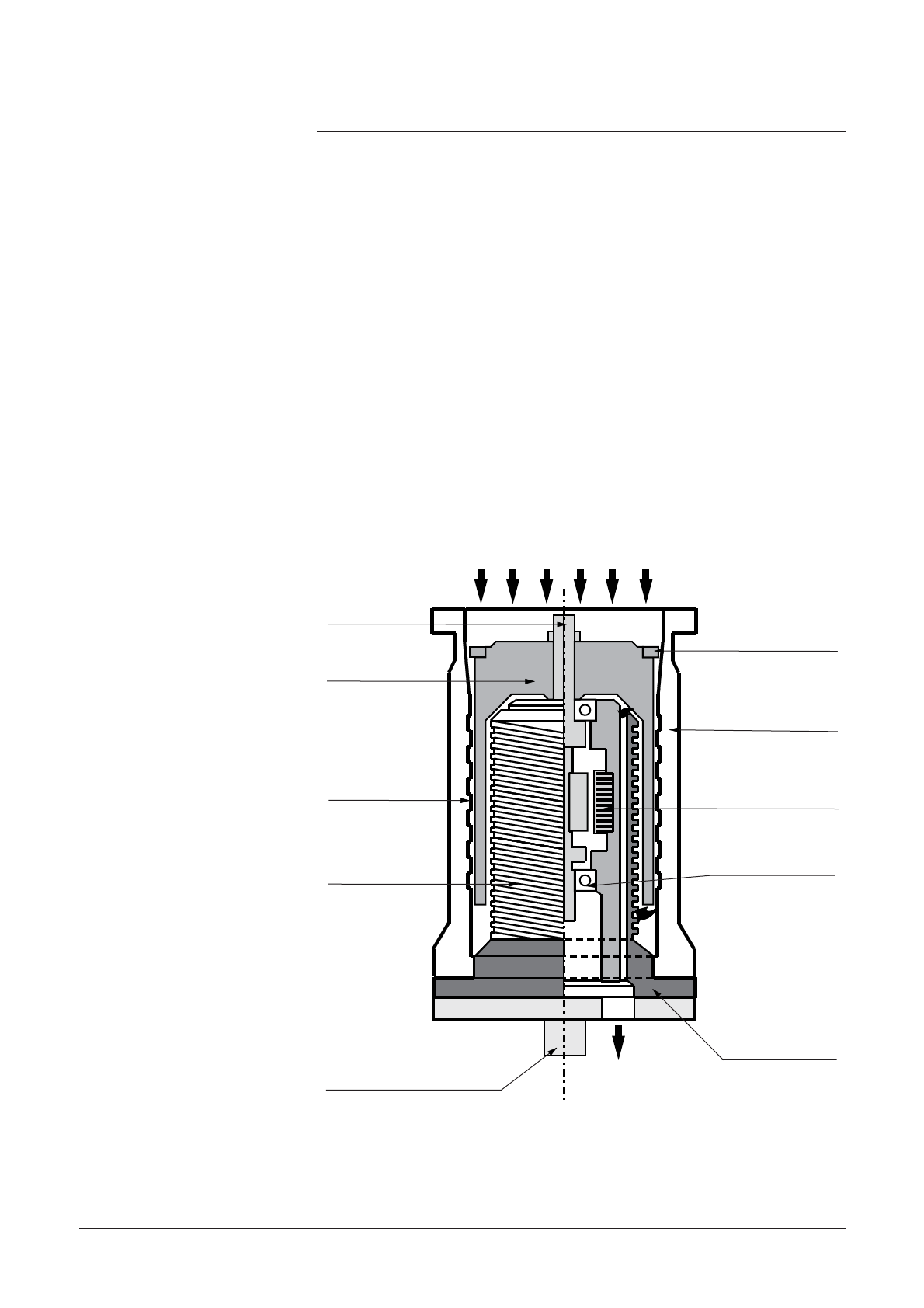

A 210

The different version operating

principle

1/2

MDP 5011 The rotor, a smooth drum with a row of blades at the top, is

mounted at the end of a shaft turning in two high-precision ball

bearings lubricated with grease, and located in the low-vacuum

area. All pumping elements are aluminium.

The pump is rotated by a single-phase electronically controlled

electric motor. The rotor is mounted directly on the shaft, while the

stator is attached to the pump body.

MDP 5011 standard molecular pump

Cross section drawing

SHAFT

ROTOR

DYNAMIC SEAL

ELECTRICAL CONNECTOR

IMPELLER

BALL BEARING

MOTOR

HOUSING

MOTOR HOUSING

EXHAUST

DRAG PUMP

INLET

adixen Vacuum Products - MDP 5011 User's Manual

2/2

A 210

The different version operating

principle

G 02596 - Edition 02 - March 06

MDP 5011 CP

version for

corrosive gases

The MDP 5011 CP is specially designed for aggressive environments.

Ball bearings and motor are isolated from process gases by a

dynamic inert gas purge system.

MDP 5011 CP can operate with the same controller than the

MDP 5011 standard.

MDP 5011 CP Molecular pump

Cross section drawing

SHAFT

ROTOR

DYNAMIC SEAL

ELECTRICAL CONNECTOR

IMPELLER

BALL BEARING

MOTOR

HOUSING

MOTOR

HOUSING

PURGE SYSTEM

DN 16

DRAG PUMP

INLET

EXHAUST

adixen Vacuum Products - MDP 5011 User's Manual

G 02599 - Edition 03 - July 11

1/1

A 400

Technical characteristics

Characteristics Units MDP 5011 MDP 5011 CP

Inlet flange DN 63 ISO-K

Exhaust flange DN 16 ISO-KF

Rotation speed tr/mn 27,000

Starting time (0 to 27000 tr/mn) mn < 1

Pumping speed

N2

L/s

7.5

He 4

H2 3

Compression rate

N2 1x1091x106

He 2x104250

H2 1x10350

Ultimate pressure (CP with purge 50 sccm)* mbar 1x10-6 1x10-5

Maximum pressure at inlet

in continuous operation**

Natural convection

mbar

1x10-1

Air cooling 10

Water cooling 10

Maximum pressure at

exhaust in continuous

operation**

Natural convection

mbar 40 5

Air cooling

Water cooling

Ambient operating

temperature

Natural convection

°C

5 to 35°C (41 to 95 °F)

Air cooling 5 to 35°C (41 to 95 °F)

Water cooling 5 to 50°C (41 to 122 °F)

Recommanded primary pump Ultimate pressure < 20 mbar

Weight

Natural convection

kg

2.3

Air cooling 3

Water cooling 2.5

Environmental conditions:

Ingress Protection

Use of the product

Altitude

Maximum relative humidity

Pollution degree

IP 20

indoor use

up to 2000m (6562 pied)

80 % for temp. up to 31°C (87°F)

decreasing linearly to 50 % at 40°C (104°F)

rate 2

* According to Pneurop Specifications.

**The 2 maximum pressures can not occur at the same time.

Note: the MDP 5011 pump must not be baked.

The compression rate of the MDP 5011 CP is lower than this of the standard MDP 5011 pump.

A part of the dynamic seal allows the protection against corrosion.

adixen Vacuum Products - MDP 5011 User's Manual

G 02600 - Edition 01 - Sept. 04

1/3

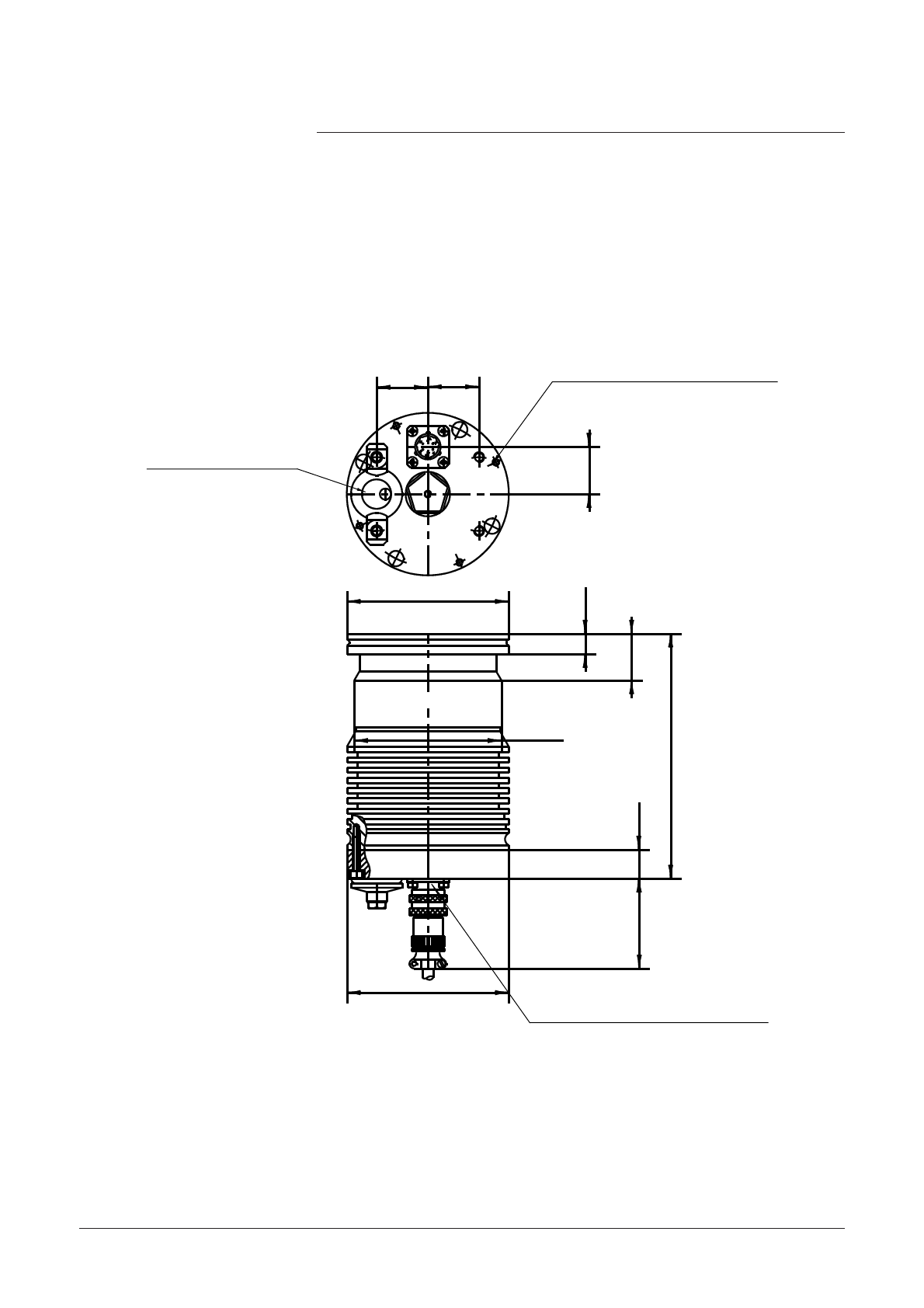

A 401

Pump dimensions

MDP 5011 DN 63 ISO-K

cooled by natural

convection

Power supply - Connector

Screwing by 4 threaded holes

diam. 0.16 (4) on diam.3.46 (88)

+ 12 mm (0.47)

for disassembling

Exhaust

DN 16 ISO-KF

Ø95 h11 (Ø3.75 h0.43)

Ø95 (Ø3.75)

Ø86.2

(Ø3.39)

INLET DN 63 ISO-KF

30

1.18

30

1.18

52

(2.05)

27.7

1.09

27.3

1.07

17

0.67

143

5.63

12

0.47

Dimensions mm/inch

adixen Vacuum Products - MDP 5011 User's Manual

2/3

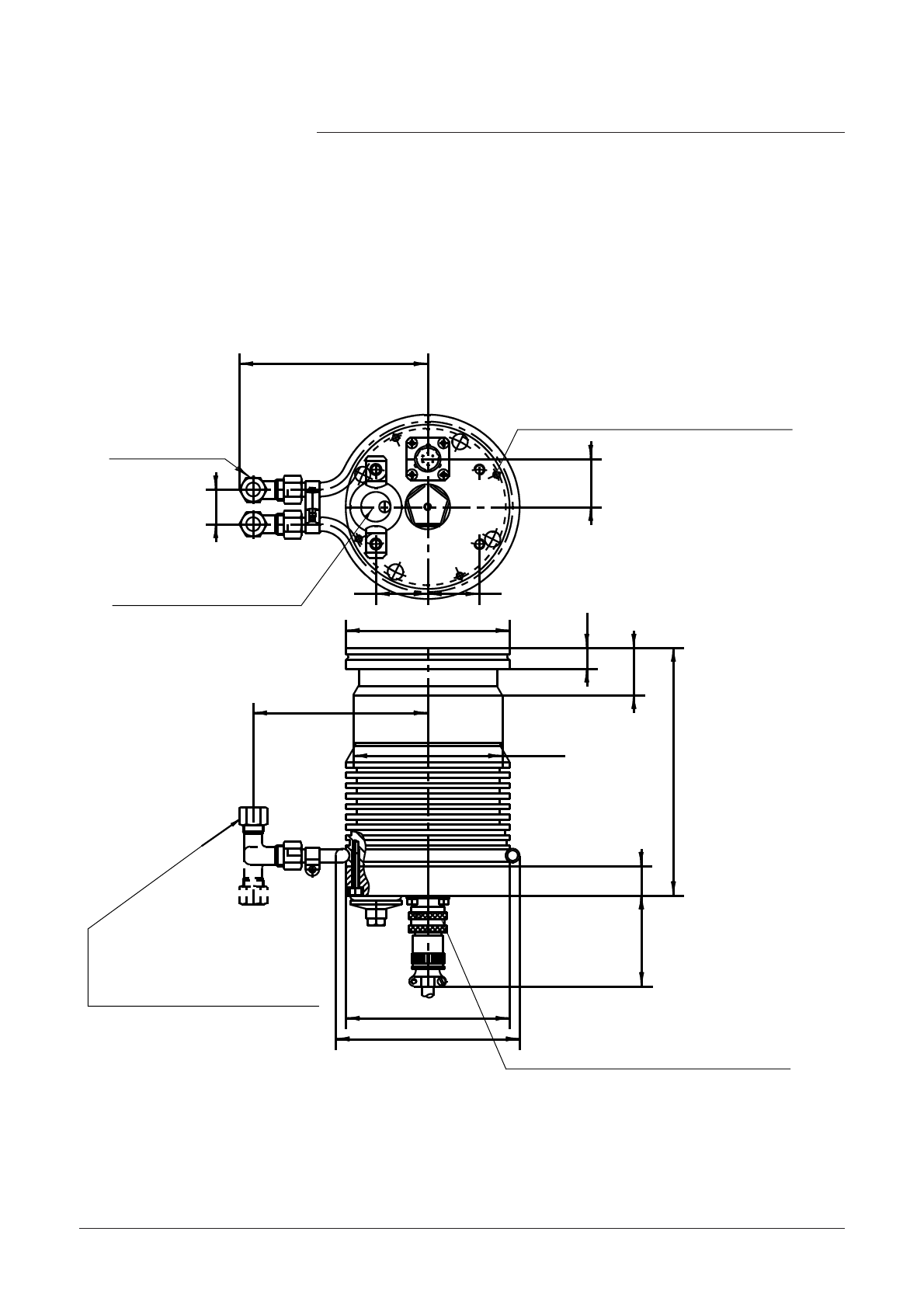

A 401

Pump dimensions

G 02600 - Edition 01 - Sept. 04

MDP 5011 DN 63 ISO-K

water cooling

Water cooling connections for

0.23 x 0.31 (6 x 8 mm) plastic

tubing or copper tubing

E

FA

D

C

B

Exhaust

DN 16 ISO-KF

Orientable 360 °

Power supply - Connector

Screwing by 4 threaded holes

diam. 0.16 (4) on diam.3.46 (88)

+ 12 mm (0.47)

for disassembling

Ø95 h11 (Ø3.75 h0.43)

Ø95 (Ø3.75)

Ø106.5 (Ø4.19)

Ø86.2

(Ø3.39)

INLET DN 63 ISO-KF

30

1.18

109.1

4.30

101

3.98

30

1.18

52

(2.05)

27.7

1.09

20

0.78

27.3

1.07

17

0.67

143

5.63

12

0.47

Dimensions mm/inch

adixen Vacuum Products - MDP 5011 User's Manual

G 02600 - Edition 01 - Sept. 04

3/3

A 401

Pump dimensions

MDP 5011 DN 63 ISO-K

Air cooling

Power supply - Connector

Exhaust

DN 16 ISO-KF

E

FA

D

C

B

Fan

Screwing by 4 threaded holes

diam. 0.16 (4) on diam.3.46 (88)

+ 12 mm (0.47)

for disassembling

Ø95 h11 (Ø3.75 h0.43)

Ø95 (Ø3.75)

Ø86.2

(Ø3.39)

INLET DN 63 ISO-KF

30

1.18

30

1.18

52

(2.05)

98

(3.86)

27.7

1.09

80

3.15

27.3

1.07

80

3.15

84.5

3.33

17

0.67

143

5.63

12

0.47

Dimensions mm/inch

adixen Vacuum Products - MDP 5011 User's Manual

G 02598 - Edition 03 - July 11

1/1

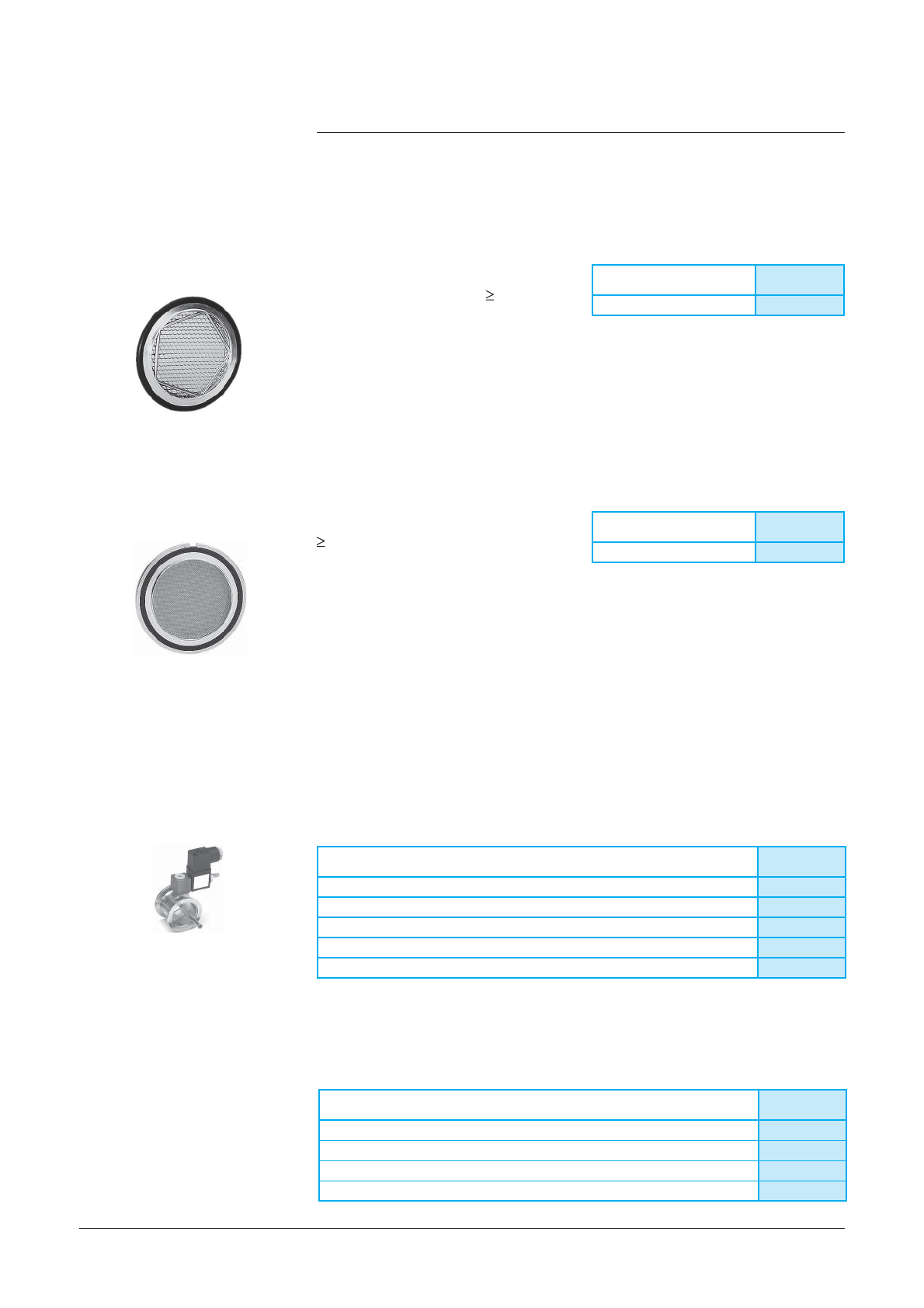

A 510

Pump accessories

Description P/N

DN 63 ISO-K 063117

Screen filter 2.5 mm This filter protects the pump

against solid particles 2.5 mm.

Description P/N

DN 63 ISO-K 062912

Compact filter The filter stops particles

20 microns and is used in the

event of high densities of dust or

risk of implosion when pumping

tubes or lamps.

Description P/N

Electrical venting valve DN16- ISO-KF 100 V - 50/60 Hz 063165

Electrical venting valve DN16- ISO-KF 115 V - 50/60 Hz 063171

Electrical venting valve DN16- ISO-KF 200 V - 50/60 Hz 063173

Electrical venting valve DN16- ISO-KF 220 V - 50/60 Hz 063169

Electrical venting valve DN16- ISO-KF 240 V - 50/60 Hz 063172

Electrical

venting valve

This valve is used to refill the pump with air after pump stopping

or after a power failure.

P/N of electrical venting valve compatible with ACT 100.

Description P/N

Water cooling kit 062184

Air cooling kit 110 V (ACT 100) 062187

Air cooling kit 220 V (ACT 100) 062186

Air cooling kit 12 V (ACT 200 TH) 118809

Cooling kit It is easy to install or replace a cooling kit by another :

adixen Vacuum Products - MDP 5011 User's Manual

1/4

B 100

Safety instructions for pump and

controller installation

GB 00725 - Edition 04 - Aug 11

Indicates a potentially hazardous situation which, if not avoided, could

result in moderate or minor injury. It may also be used to alert against

unsafe practices.

Indicates a potentially hazardous situation which, if not avoided, could

result in property damage.

Indicates an imminently hazardous situation that, if not avoided, will result

in death or severe injury (extreme situations).

Before switching on the product, study the user’s manual and make

sure you follow the safety instructions. You can recognise these by the

‘Caution’, ‘Warning’ and ‘Danger’ symbols.

Good practice tips and manufacturer’s recommendations are in a blue

box.

For emergencies and breakdowns, contact the manager of your local

service center (see addresses at back of manual).

We took care to provide you with a clean product. To keep it in this

condition, unpack it only in contamination free area and at final place of

use.

The performance and operational safety of this product are guaranteed

provided it is used normally in the operating conditions defined in this

manual.

It is the customer’s task to:

train operators to use the product if they do not speak the language

the manual is written in,

ensure operators know the safe practices to apply when using the

product.

–

–

Make sure the equipment shows no sign of transport damage. If it has

been damaged, take the necessary steps to record this with the carrier

and inform the manufacturer. In all cases, we recommend keeping the

packaging (reusable materials) for further transport of the equipment or

for prolonged storage.

Indicates a potentially hazardous situation which, if not avoided, could

result in death or severe injury.

Overview

For emergencies

adixen Vacuum Products - MDP 5011 User's Manual

2/4

B 100

Safety instructions for pump and

controller installation

GB 00725 - Edition 04 - Aug 11

Our products are designed to comply with current EEC regulations. Users

making their own modifications to the product are liable to break its

compliance with these regulations, degrade its EMC (electromagnetic

compatibility) rating, and make it unsafe to use. The manufacturer

declines all liability for the consequences of such operations.

The product’s EMC rating is obtained on the understanding that it is

installed in compliance with EMC rules.

Specially in environments that are prone to emit interference, use

shielded cables and connections on interfaces.

This pump is not equipped with an emergency stop EMO device because

it is designed for use on process tools and integration with the process

tool EMO.

Check that the pump is correctly connected to the equipment emergency

stop device.

Fire protection:

The pump is not intended to be installed on process containing flammable

materials or in hazardous atmosphere.

The pump body is made of aluminium. The main part enclosure and the

majority of the non metallic parts (mainly electrical components and

frequency converter) have a fire rating of UL94V0 and/or are UL approved.

Smoke hazard due to the presence of electrical components.

The smoke hazard is low due to the use of approve components and the

containment smoke in the pump cover.

When units containing control circuits are equipped with dry contact

outputs, it is the responsability of the customer to use these outputs in

compliance with extra low voltage installation and security standards.

Ensure that the product is connected to an electrical installation:

in compliance with the local and national safety requirements,

equipped with electrical protection (fuses, circuit breaker, …) which

has a suitable earth (ground) point, properly connected.

–

–

Electric shock hazard.

Some components have capacitors charged to over 60VDC, or motor

operating as generator. When power is switched off, they keep their

charge for a time. Take precautions concerning the access to the connector

pins. Wait at least 5 minutes after the turbopump comes to complete stop

before starting any work on the product.

adixen Vacuum Products - MDP 5011 User's Manual

3/4

B 100

Safety instructions for pump and

controller installation

GB 00725 - Edition 04 - Aug 11

The units containing control circuits are designed to guarantee normal

safety conditions taking their normal operating environment into account

(use in rack).

In specific cases of use on tables, make sure that no objects enter the

ventilation openings or block the openings when handling the units.

Pump connection to the installation:

It is strongly recommended to secure the turbopump installation to

prevent any safety hazard to the user in standard operating conditions :

(B 300).

The user and /or OEM are ultimately responsible for operating the

equipment in a safe manner. The manufacturer has no control over the

types of gases exposed to this pump. This is the user and/or the OEM’s

responsibility to follow the necessary safety requirements.

Frequently process gases are toxic, flammable, corrosive, explosive and/or

otherwise reactive.

Toxic gases can cause serious injury or death. Operators and users must

take the appropriate safety recommendations to prevent injury. Consult

the responsible department for instructions and safety information.

Hazardous gases through the pump can cause serious injury or death.

It’s mandatory by regulations to connect the turbomolecular pump’s

exhaust to a rough pumping line compatible with the process gases.

Check that pump is correctly connected to the equipment (B300).

This label informs the user that moving parts present inside the pump

coud cause personal injury, like crushing or cutting.

The user must keep all body parts away from moving parts.

MOVING PARTS PRESENT

Moving parts can crush and cut.

Keep hands or feet away from moving parts.

WARNING

Do not operate the pump until it is securely fixed. If the pump seizes,

the stored energy of the rotor can cause rapid movement of the pump,

which may cause further damage and injury to people. It is mandatory to

respect installation instructions described in the pump user’s manual.

The adixen constructor declines any responsibility if the pump installation

is not made in accordance with the installation specifications.

Operation

adixen Vacuum Products - MDP 5011 User's Manual

4/4

B 100

Safety instructions for pump and

controller installation

GB 00725 - Edition 04 - Aug 11

Do not expose any part of the human body to vacuum. The product is

supplied with the inlet and exhaust sealed. Remove these blanking plates

when you are ready to connect the product on your vacuum system.

As well as, don’t operate the product unless the inlet and exhaust are

connected to a vacuum and exhaust pumping line.

Risk of cut injury:

The access to the rotor of a turbomolecular pump with an unconnected inlet

port is dangerous. In the meantime, if the pump is not switched on, it may

be driven by another pump in operation.

Always connect the pump inlet port before starting the pump.

Storage

The products are factory tested to ensure they will not leak in normal

operating conditions. It is the user’s responsibility to ensure this level of

leak tightness is maintained.

Risk of tilting: although the product meets EEC safety regulations (topple

angle ± 10 °), it is advisable to guard against the risk of tilting during

handling, installation, and use.

The product is supplied with the inlet and exhaust sealed. These are to

prevent foreign bodies entering the pump during transport and storage.

Do not remove these blanking plates until you are ready to install the

product on the vacuum line.

When the pump is new, if it is going to be put into storage, keep it in its

packaging in the following conditions:

in a clean and dry environment,

at an ambient temperature between -5°C and +40°C,

for a period of 2 years maximum with a running period every 6 months

(refer to C100).

If you need to store a pumping unit which has run on clean process, don’t

forget to purge the pump with N2. Seal the inlet, exhaust and purge ports

with blanking plates (refer to F100). Don’t store the pump more than 6

months in a clean and dry environment.

Never store a pump which has been used on corrosive process. Return it

to an adixen repair service center (refer to G200).

–

–

–

adixen Vacuum Products - MDP 5011 User's Manual

G 02602 - Edition 02 - July. 11

1/4

B 300

Pump connection to an installation

b

a

c

The connection of the

pump to the

installation must be

sufficiently rigid

The dimensions of the connection parts should be study carefully:

reduce the following as much as possible:

dimensions aand bthe flexibility of the connection plate

the overhang cbetween the pump and its anchor point.

–

–

Some examples of unrecommanded conncections:

Support plate

Spacer

Rigid support

Bellows

It is absolutely necessary to install the pump according to the following

installation specifications to secure the user and the equipment.

The adixen constructor declines any responsibility if the pump

installation is not designed in accordance with the installation

specifications described in this section.

The equipment attachment devices should be sufficiently rigid to prevent

potential risks in the event of failure of a rotary component or a violent

shock on the pump (exceptional phenomena). For this use the rotary

flange attachment holes.

If the inlet flange is attached with claw clamps, use:

– 6 claw clamps for flange < DN 100

– 8 claw clamps for flange ≥DN 100.

adixen Vacuum Products - MDP 5011 User's Manual

2/4

B 300

Pump connection to an installation

G 02602 - Edition 02 - July. 11

The pump can operate

in any position

In.

In.

In.

In.

Cooling

recommendations and

temperature limits

Ambient operating temperature:

MDP with natural convection or air cooled T < 35°C (95°F)

MDP water cooled T < 50°C (122°F)

Pumping conditions In cases of high pressure pumping or frequent cycling, the pump

temperature is higher, so water or air cooling are recommended.

adixen Vacuum Products - MDP 5011 User's Manual

G 02602 - Edition 02 - July. 11

3/4

B 300

Pump connection to an installation

Pump line

connections

Do not expose any part of the human body to vacuum.

The product is supplied with the inlet and exhaust sealed. Remove

these blanking plates when you are ready to connect the product on

your vacuum system.

As well as, don’t operate the product unless the inlet and exhaust are

connected to a vacuum and exhaust pumping line.

Pollution risk:

Unclean and contaminated component can increase the pumping down

time. Use only dry and clean pipe lines, and wear glooves to make the pump

connections.

Make sure all parts and chambers connected to the inlet, exhaust and

purge of the maglev pump can withstand a negative pressure of 1 bar

below atmospheric pressure and that they are impervious to damage

from vacuum (seals, etc.).

Materials in direct contact with process gases

COMPONENTS IN THE PUMP MATERIALS

From inlet to exhaust Stainless steel, aluminium alloy

O-ring Fluorinated elastomers, FPM

After connecting the product to the pumping line, check for leaks along

the entire to ensure proper connections.

Risk of injury by cutting.

Contact with the pump rotor cell may cause cuts. Alternatively, protective

gloves may be worn when servicing the product.

For safety reasons, use accessories on the inlet and exhaust lines whose

materials and sealing properties are compatible with the gases being used.

adixen Vacuum Products - MDP 5011 User's Manual

Table of contents

Popular Water Pump manuals by other brands

Wilo

Wilo Comfort-Vario COR-1***-GE Series Installation and operating instructions

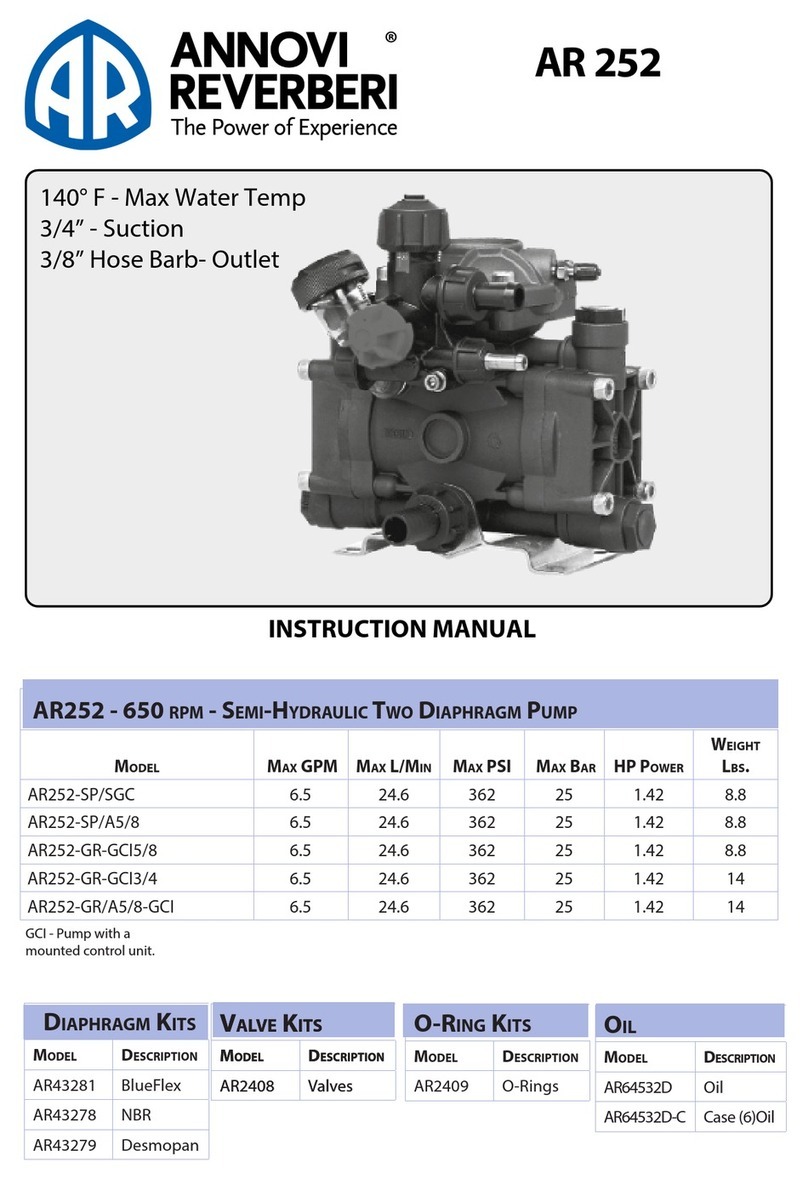

Annovi Reverberi

Annovi Reverberi AR252 instruction manual

Flotec

Flotec E50TLT owner's manual

Gardenline

Gardenline GLSP 1002 quick guide

Hozelock

Hozelock EASYCLEAR 6000 quick start guide

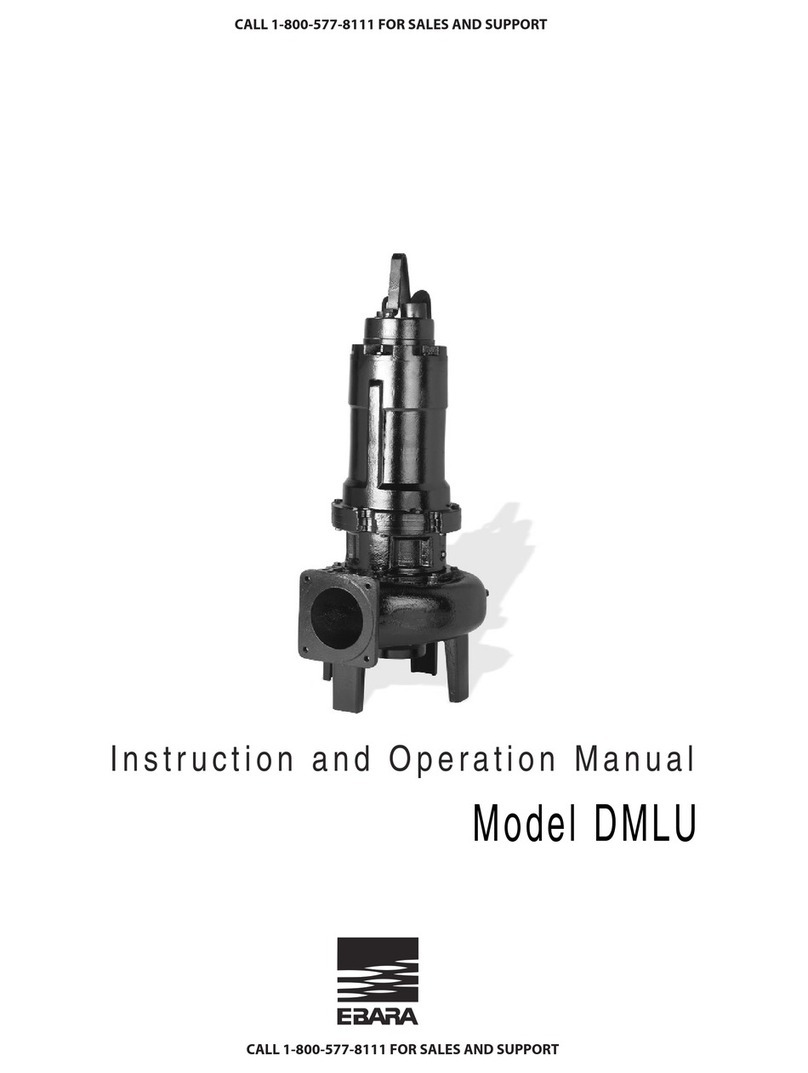

EBARA

EBARA DMLU Instruction and operation manual

Stuart Turner

Stuart Turner Mainboost MJ3 VM Installation, operation & maintenance instructions

dosatron

dosatron D25RE5 Maintenance manual

Westfalia

Westfalia 163188 instruction manual

GORMAN-RUPP

GORMAN-RUPP 2P5X Specifications information and repair parts manual

Reliable

Reliable N2-Blast DDX Instructions for installation, operation care and maintenance

Fultz Pumps

Fultz Pumps SP-400 manual