Printing Innovation iCUBE 1 User manual

-1-

Revision: 2014-09-25

User Guide for iCUBE Series

iCUBE 1-3

-2-

Copyright statement

© 2014 Printing Innovation AG. This document, attachments, and information contained herein

are the confidential and proprietary property of Printing Innovation AG and their suppliers. As

such, this document, attached files, and information contained herein are subject to all

nondisclosure and proprietary information agreements currently in effect with your organization.

Copies of this document, any portion of this document, or attachments may not be transmitted

or disclosed to any third party without the prior written permission of Printing Innovation AG.

© 2014 Printing Innovation AG. All content is the confidential property of, or licensed to, Printing

Innovation AG. (“We” or “us”) are protected under European and Foreign copyright, trademark

and other intellectual property laws.

The following statements will be included in the Appendix:

Warranty

Safety precautions

Regulatory information

Environmental policy and information

Recycling

-3-

Table of Contents

1. Introduction 6

1.1. Introduction to Memjet print technology 6

2. Printer Parts and their functions 8

2.1. Printer 8

2.2. Print Engine 8

2.3. Printhead 8

2.4. Printhead Cartridge Dock 8

2.5. Print Mechanism 9

2.6. Cutter 9

2.7. Ink Cartridges 10

2.8. Ink Connection Ports 12

2.9. Ink Delivery System (IDS) 12

2.10. Bulkhead Assembly 12

2.11. Other IDS Components 13

2.12. Maintenance Module 14

2.12.1. Wiper Station 16

2.12.2. Printing Platen 16

2.12.3. Capping/Spitton Station 17

2.12.4. Printhead servicing events 17

2.13. Print Zone 17

2.14. Onboard Print Engine Controller (OmniPEC) and Main Board 17

2.15. The Controlling System 18

3. Installing the Printer 19

3.1. Choose a location 19

3.2. Unpacking and Setup 19

3.3. Checking the Contents 19

3.4. Connecting the iCUBE 20

3.5. Setting up the Printer 22

3.5.1. Maintenance Module (MM) 22

3.5.2. Installing the Ink Cartridges 24

3.5.3. Installing the Printhead 25

3.5.4. Switch on the Printer 30

3.5.5. Media Handling 31

3.5.1.1. Print Area 31

3.5.1.2. Load Media 31

3.6. Connecting the Printer to a computer 32

3.6.1. Direct connection to a personal computer 32

3.7. Install Printer Driver 33

3.7.1. Driver specifications 38

3.7.1.0. General Tab 38

-4-

3.7.1.1. Layout Tab 39

3.7.1.2. Media Tab 40

3.7.1.3. Import/Export 41

3.8. Label printing, generating print jobs 42

3.8.1. Printing labels from softwares 42

3.8.2. Printing labels from print jobs 42

3.9. Printer buttons 43

4. TOOLBox 44

4.1. User interface 45

4.2. Diagnostics 46

4.3. Ink usage 47

4.4. Network configuration 48

4.5. Service Menus 49

5. Maintenance Guide 50

5.1. Maintenance Overview 50

5.2. Standard Maintenance 50

5.2.1.Daily Maintenance Tasks 52

Aerosol and debris removal

5.2.2.Bi-Weekly Maintenance Tasks 54

Aerosol and debris removal

Paper Path, optical sensor cleaning

Wiper Inspection

5.2.3.Monthly Maintenance Tasks 57

Aerosol and debris removal

Paper Path optical sensor cleaning

Wiper inspection

Waste Ink Absorber inspection

Ink Tubing inspection

Lift Motor Gear inspection

Paper Path Grit Roller inspection

5.2.4.Annual Maintenance Tasks 62

Aerosol and debris removal

Paper Path optical sensor cleaning

Wiper Inspection

Waste Ink Absorber inspection

Ink Tubing inspection

Lift Motor Gear inspection

Paper Path Grit Roller inspection

Moving Part (Motor Test)

Maintenance Module Sled Assembly cleaning

Paper Dust removal

-5-

Ink tank latch/Ink Bay inspection

Cutter ispection

5.2.5. As Needed Maintenance Tasks 70

Printhead Cartridge cleaning (Manual Wipe while installed)

Printhead Cartridge cleaning (Remove Cartridge)

Waste Ink Absorber replacement

6. Troubleshooting 82

6.1. Maintenance Module Troubleshooting 82

6.2. Printhead Troubleshooting 83

6.3. Print Quality Troubleshooting 83

6.4. iCUBE Troubleshouting guide 84

General 84

Checklist before doing any support 84

Troubleshouting Tools 85

Dead engine,EWS,Firmware 86

Print engine error messsage 86

Crit 63-03-phead offline cancel page 87

CARTRIDGE_MISSING 87

DATA_PATH_UNDERRUN 87

Fatal 7102 offline cancel page 88

MAINTENANCE_BUSY 90

PAPERPATH_CUTTER_ERRROR 91

PAPERPATH_FEED_TIMEOUT 91

PAPERPATH_PAPERJAM 91

6.5. Print Quality Issues 92

Color Mixing (CM) 92

Streaking (SR) 102

Dot Misplacement (DP) 108

Banding (BD) 111

Other General Print Quality Errors (GE) 117

Paper Handling (PA) 126

Inkdelivery System (ID) 131

Paper Cutting 133

Firmware Error Message (ER) 134

Maintenance Module (MM) 136

7. Printer Specifications 137

-6-

1. Introduction

The purpose of this manual is to describe the operation of the iCUBE label printer. The

first section provides and overview of the Memjet™ print technology to make you familiar with

the terms and basics of this new technology that forms the basis of the iCUBE printer series. The

following sections walk you through the installation steps, explain the components of the printer

and their roles, and then teach you how to operate your printer. The manual ends with

maintenance and troubleshooting guide.

1.1. Introduction to MemjetRprint technology

Memjet™ Technology is a revolutionary printing technology developed by Silverbrooks

Research (Sidney, Australia). The core of this technology is a full paper width printhead capable

of printing the entire page width at the same time without head movement. The result of this

setup is a breakthrough 12 inch (305 mm) per second printing speed. The printhead is

manufactured with state-of-the art semiconductor technology; an A4 head contains 70,400

nozzles delivering 1600 dpi native resolution at full colour. The nozzles are arranged in 10 rows

having 2 rows for each ink channels. The fixed head spans the width of the label and feeds an

entire label at a time similar to a laser printer. This architecture dramatically improves

performance and ink drop placement accuracy during printing, while decreasing noise and

vibration.

Figure 1 Printing with a traditional moving head and with the

Memjet printhead.

Figure 2: The Memjet 8.5” printhead cartridge showing the ink inlet, outlet

ports, various print-related parts and the printhead.

-7-

Figure 3 The Memjet printhead contains 70,400 nozzles in 10 rows (brown stripe in Figure a).

It shows an electron microscope image of a single nozzle (Figure b).

The small size of the nozzles results in very small (1-2 picolitre) paint drops,

approximately 14 micron drop diameter on paper, effectively achieving the highest print

resolution the human eye can see.

Printing with this type of precision requires many technical details to be solved including

printhead cooling, using special fast drying inks, feeding paper accurately, controlling the

operation of the unit, etc. A unique property of Memjet printing is the special print processor

that uses a custom hardware print pipeline processing engine to render images at a very high

speed. The level of technical standards are reflected by the fact that Silverbrooks Research hold

2500 patents related to Memjet Technology along with another 2000 pending.

a)

b)

-8-

2. Printer parts and their functions

2.1. Printer

The iCUBE printer is a state of the art Memjet printer designed for maximum

usability and performance. The major components of the printer are the print engine, the

controller and the control panel.

2.2. Print engine

The print engine is the heart of the iCUBE printer. It is responsible for the actual print

process. The major subsystems of the engine are the mechanics (paper transport), ink

delivery system (including print head and ink tanks), the print controller and a paper

cutter. The iCUBE controller is responsible to control the operation for the print engine.

You do not need to access and use the print engine directly except when changing print

heads and ink tanks.

2.3. Printhead

2.4. Printhead Cartridge Dock

The printhead cartridge dock positions the page-wide, static, high-speed Memjet

printhead in the correct location to maintain correct position with the print zone.

Picture of the Print Engine

Picture of the printhead

-9-

2.5. Print Mechanism

During printing, the print mechanism moves the paper through the print zone below the

static printhead.

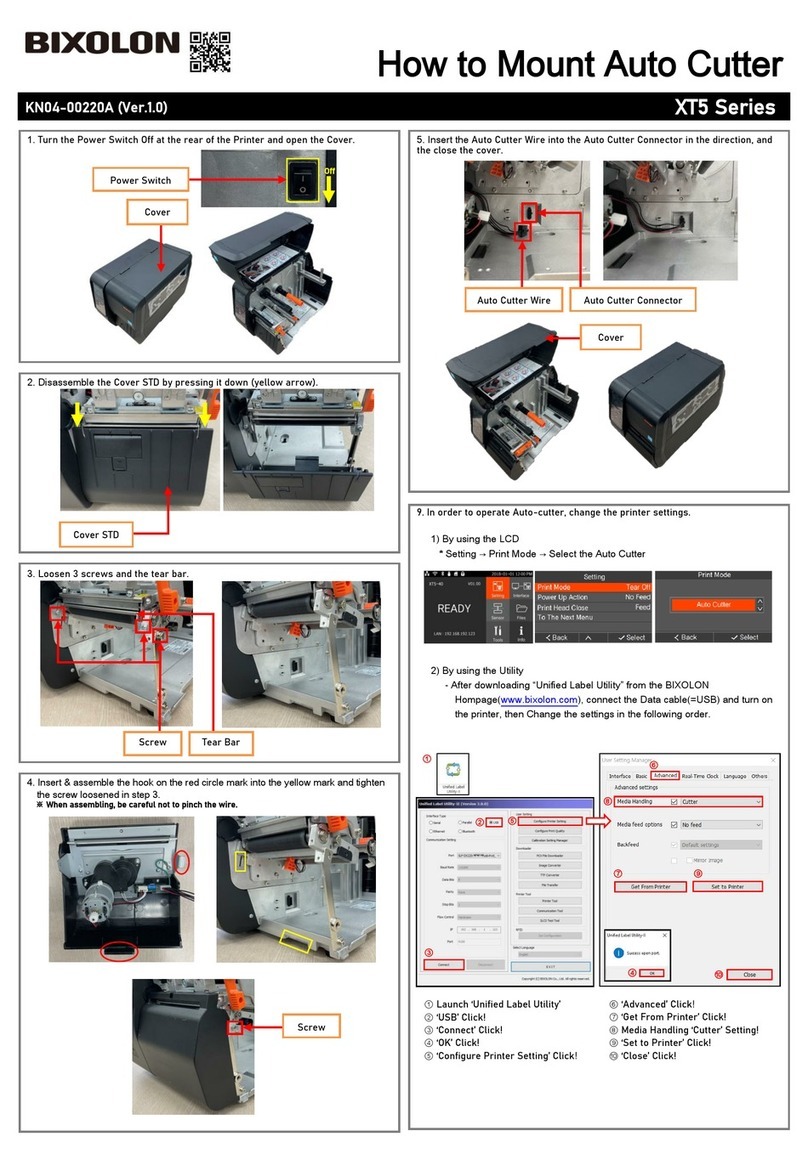

2.6. Cutter

The NorthStar cutter is designed to provide a complete cut of continuous media in

the crossweb direction. This will provide the ability to singulate labels and enable a break

in continuous media to allow servicing of the printhead.

The cutter has a design target of providing a 400,000 cut life on thin tag media. Cuts are

expected to execute in 0.4 seconds at up to 80 8.5inch cuts/minute.

The cutter unit can be removed or replaced, if necessary, without affecting the

performance of the NorthStar.

Picture of

Fluidic

Connectors and Memjet Printhead Cartridge

-10-

2.7. Ink Cartridges

iCUBE series printers use a single printhead-cartridge and five ink tanks: two black,

one cyan, one magenta and one yellow. During installing the ink cartridges the printer

should be turned off.

Picture of the ink cart

r

idge

-11-

Picture of Ink Cartridge Cross

-

Section

Picture of Ink Cartridge Cross-Section with Air Vent Path Detail

-12-

2.8. Ink Connection Ports

Ink connection ports allow the connection of the external ink supply houses to the print

engine. Unique, zero insertion-force, ganged connectors allow all 10 ink hoses to be engaged

with the printhead in one movement. The printhead can be removed or installed without

disconnecting any of the ink hoses.

2.9. Ink Delivery System (IDS)

The Ink Delivery System (IDS) is a complex system designed to cleanly and reliably

deliver ink to the printhead while minimizing color mixing, drop weight variation, and

dehydration.

The major components of the Ink Delivery System (IDS) are:

•The disposable ink cartridges

•The printhead

•The tubing

•The peristaltic pump

•The pinch valve assembly

•The QA and ink level sensing electronics

•The buffer box

2.10. Bulkhead Assembly

The bulkhead assembly includes the ink cartridges, the septum for connecting to the

bulkhead plate; ink level PCAs, the QAI chip for each ink cartridge and the buffer boxes for

each ink cartridge.

-13-

2.11. Other IDS Components

Picture of Bulkhead Assembly

Picture of Other IDS Components

-14-

2.12. Maintenance Module

Aka Service Station (SS)

The multi-station, maintenance module (MM) maintains and cleans the printhead by

wiping off waste ink and contamination. In addition, the MM assists with printing by

priming the printhead, as well as protecting it when not in use, and guiding the paper as

it passes under the printhead.

The maintenance module (MM) is a sled that contains stations for wiper, cap/spittoon,

and print zone platen.

To position the correct station into place, a stepper motor moves the sled horizontally,

and a DC motor moves the sled vertically.

The maintenance module:

•Cleans the printhead of excess ink and debris.

•Keeps the printhead protected and hydrated while not in use.

•Provides a safe place to spit ink that is used to keep the nozzles clear.

•Provides a suitable base for supporting the media during printing. This is done with

the print zone platen station.

Picture of the Maintenance Module

-15-

The maintenance module should be replaced as part of annual maintenance or after printing

one million inches.

NOTE: The maintenance module is not intended to be end-user serviceable, although it is a

service part for technicians.

Picture of Maintenance Module (MM) Assembly (exploded view)

-16-

2.12.1. Wiper station

The printhead must be wiped to remove ink cross-contamination and particulates.

The cylindrical wiper rotates to wipe the entire width of the printhead. The roller rotates

for the duration of the lift-dwell-lower cycle. The intent is not to merely blot the nozzles

but to have functionally translational wiping. The wiper is programmable and can be

rotated numerous times to perform multiple wiping operations. Once wiping is complete

the station drops back down. A metal transfer roller cleaned by a doctor blade helps

remove ink from the wiper. The removed ink dries or evaporates within the wiper

station. When the wiper becomes contaminated to such an extent that it is no longer

effective, the wiper must be replaced by unlatching the two wiper retaining clips. These

clips can be released while the maintenance module is in the wipe position.

2.12.2. Printing platen

The platen provides a smooth writing surface and the correct spacing between the

media and the printhead. During printing, the paper below the printhead is maintained at

a fixed dive angle from the drive roller nip and platen below the nozzles to ensure print

quality. Along the center of the platen there are four Porex (tm) micro sponges to collect

ink overspray.

Picture of the wiperstation

Picture of Printing platen

-17-

2.12.3. Capping/spittoon station

The printhead should not be allowed to dry out after priming. The cap station is used

when the printer is idle. The cap station limits evaporation from the printhead by sealing

around the nozzles and maintaining a humid environment. The cap is an elastomer seal

that fits around and over the printhead nozzles. It is held against the printhead by the lift

springs on the maintenance module. The cap aligns with the printhead by features at

each end of the maintenance module. The spittoon portion of the station has a waste ink

receptacle used to capture ink ejected during maintenance processes. The used ink wicks

and drains into the waste tank. The wicking bar is a plastic frame and channel of

absorbent material. The absorbent material can be replaced by trained service personnel.

2.12.4. Printhead servicing events

The printhead requires cleaning after any of the following events occur:

A new printhead is installed and primed

The printhead is removed and then replaced

The printhead is primed or re-primed with ink

The printhead is showing signs of contamination

Be aware that ink is used by the print engine during printhead maintenance as well

as during printing. All waste ink from the printhead nozzles is contained by the

maintenance carousel, either in the spittoon (holds waste ink generated by

priming/cleaning) or in the platen (holds waste ink generated during printing). Therefore,

periodic maintenance will be required to remove the waste ink.

2.13. Print Zone

The clamshell design allows for accessibility during paper loading and paper jam

clearance in the print zone.

2.14. Onboard Print Engine Controller (OmniPEC) and Main Board

The OmniPEC controls all electronic aspects of the printing and print engine operation.

The custom 95-pin WaveTech connector connects the printhead to the printhead board,

which is connected by cables to the OmniPEC main board. The OmniPEC allows connections to

paper motors, ink level sensors, ink pump and additional sensors.

Picture of Capping/spittoon station.

-18-

•Dual resolution file format to

•achieve crisp Print Quality (PQ) yet

•reasonable file size

•1600 dpi lossless text expansion

•800 dpi contone JPEG expansion

•Two processors: 650MHz RISC CPU with customized HW assist (image processing

focus) and 192MHz SPARC CPU dedicated to the printing pipeline

•Dedicated printing pipeline in HW

•Real-time JPEG compression

•Color Space conversion

•Half-toning

•Dead nozzle compensation

•Printhead data formatting

2.15. The Control System

The Printer engine is controlled by the OmniPEC, the Quality Assurance Infrastructure

(QAI), and the firmware.

Full-page array printing:

•Calculates 900 million drops/sec

•Drives 70,400 nozzles on the printhead

•JPEG expansion in hardware

•On-chip memory

•Extensive motor control and I/O

•Xscale –compatible 650 MHz CPU

•> 40 million transistors

•USB 2.0

-19-

3. Installing the Printer

3.1. Choose a location

The iCUBE printer should be placed on a properly levelled worktable or cabinet which

is able to handle the printer’s weight and minimum 62 cm (24,4 inch) wide.

3.2. Unpacking and Setup

The printer is shipped in a strong cardboard or wooden box. Before opening the box,

check that the box is not damaged in any way and was not turned upside down during

shipment. If signs of damage are found, contact your reseller and inspect the box together.

If the box is undamaged, carefully cut the tape on the box, open the box. Before taking

the printer out of the box, make sure a strong and level work surface is prepared for the

printer.

NOTE: The printer is heavy. Never attempt to lift and take it out of the box on your own as it

can cause lasting injuries. The printer should always be lifted by two persons.

Place the printer on the desk and inspect that no damages are found on the unit.

Unpack the unwinder and the optional rewinder units and place them on the desk next

to the printer.

3.3. Checking the contents

Check the parts list to ensure you have received all required components. If the shipment

is complete, proceed to the next chapter.

iCUBE Printer

1 set of CMYKK ink cartridges (5 cartridges per set)

1 printhead

1 mains power cable

-20-

3.4. Connecting the iCUBE

Make sure the printer is used with the mains cable suited to the requirements of the

electrical system of your country. The internal power supply in the printer is rated 115 to

240VAC, 50/60 Hz.

Insert the cable into the printer first. The cable connector should sit in the socket

securely.

Insert the cable into the mains socket.

CAUTION

Do not use an outlet that shares the same circuit with large electrical machines or

appliances

Turning Power On/Off

Powering Up:

Turn on the mains-switch

This manual suits for next models

2

Table of contents