Processor Technology CUTS Reference guide

CUTS, COMPUTER USERS TAPE SYSTEM

ASSEMBLY and TEST INSTRUCTIONS

Processor

Technology

Corporation

6200

Hollis

Street

Emeryville

CA

94608

PROCESSOR

TECHNOLOGY

CORPORATION

CUTS,

COMPUTER

USERS

TAPE

SYSTEM

SECTION

I

II

TITLE

INTRODUCTION

and

GENERAL

INFORMATION

1.1

Introduction

• • . • •

1.2

General

Information

1.2.1

1.2.2

1.2.3

1.2.4

1.2.5

CUTS

Description

Receiving

Inspection

Warranty

Information

Replacement

Parts

•

Factory

Service

. . •

ASSEMBLY

and

TEST

2.1

2.2

2.3

Parts

and

Components

.

Assembly

Tips

• • •

Assembly

Precautions

2.3.1

Handling

MOS

Integrated

2.3.2

Soldering

· · · · · · ·

2.3.3

Installing

and

Removing

Module

. · · · · · · ·

Circuits

· · · ·

CUTS

· · · · ·

2.3.4

Installing

and

Removing

Integrated

2.4

2.5

2.6

Circuits

· · · · · · · · · · ·

2.3.5

Use

of

Clip

Leads

· · · · · · ·

Required

Tools,

Equipment

and

Materials

Orientation

Assembly-Test

. . . • • • • •

2.6.1

Circuit

Board

Check

••••

2.6.2

Assembly-Test

Procedure

••

III

OPTION SELECTION

IV

3.1

3.2

3.3

Option

Selection

Port

Address

Selection

(DIP

Switch,

Sl)

Audio

Output

Selection

•

3.4

Data

Rate

Selection

OPERATING

PROCEDURES

4.1

Tape

Recorder

4.2

CUTS-Recorder

Interconnect

(Single

·

· ·

·

·

Recorder)

•••••...••••••••

4.3

CUTS-Recorder

Interconnect

(Two

Recorders)

••••.••••••

i

© Processor Technology Corp. 1977

CONTENTS

I-I

I-I

I-I

I-I

1-2

1-2

1-2

II-l

II-l

1I-6

1I-6

1I-6

1I-6

1I-6

1I-7

1I-7

1I-7

1I-7

1I-8

1I-9

III-l

III-l

III-l

1II-2

IV-l

IV-l

IV-l

PROCESSOR

TECHNOLOGY

CORPORATION

CUTS,

COMPUrER

USERS

TAPE

SYSTEM

SECTION

IV

V

VI

APPENDICES

TITLE

OPERATING

PROCEDURES

continued

4.4

Recorder

Adjustments

.

4.4.1

4.4.2

Volume

Control

Tone

Control

4.5

write

Operations

.••••

4.6

Read

Operations

THEORY

OF

OPERATION

5.1

5.2

5.'3

Introduction

.

Block

Diagram

Analysis

.

•••..••

Theory

of

Operation

• • • • . . . • • • •

5.3.1

Timing

• •

••

.

.•.

5.3.2

Control..

•

•••••

5.3.3

write

Mode

.•••••••

5.3.4

Read

Mode

.•.•••.•••.••

DRAWINGS

CUTS

Assembly

Drawing

•

CUTS

Schematic

• • • • • .

I

Statement

of

Warranty

II

8080

Operating

Codes

III

Standard

and

Tantalum

Dipped

Capacitor

Color

Codes

IV

Loading

DIP

Devices,

Soldering

Tips

and

Installing

Augat

Pins

V

IC

Pin

Configurations

ii

CONTENTS

IV-2

IV-2

IV-2

IV-4

IV-4

V-I

V-I

V-2

V-2

V-4

V-6

V-8

VI-l

VI-2

PROCESSOR

TECHNOLOGY

CORPORATION

CUTS,

COMPUTER

USERS

TAPE

SYSTEM

TABLES/ILLUSTRATIONS

TABLE

2-1

5-1

FIGURE

2-1

2-2

2-3

4-1

5-1

TITLE

CUTS

Parts

List

. • • • • • • • •

Strobe

Decoder

(U23)

Truth

Table

TITLE

Identification

of

components

Heat

sink

and

U7

installation

.

CUTS-transport

interconnect

cabling

• •

CUTS-recorder

interconnect

(two

recorders)

CUTS

simplified

block

diagram

• • • • • • •

iii

PAGE

II-2,3

IV-6

PAGE

II-4,5

II-9

II-18

IV-3

V-3

SECTION I

INTRODUCTION

and

GENERAL

INFORMATION

CUTS,

COMPUTER

USERS TAPE

SYSTEM

Processor

Technology

Processor

Technology

Corporation

6200

Hollis

Street

"Emeryville

CA

94608

PROCESSOR

TECHNOLOGY

CORPORATION

CUTS,

COMPUTER

USERS TAPE

SYSTEM

SECTION I

1.1

IN'rRODUCTION

This

manual

supplies

the

information

needed

to

assemble,

test

and

use

the

CUTS,

Computer

Users

Tape

System.

We

suggest

that

you

first

scan

the

entire

manual

before

starting

assembly.

Then,

make

sure

you

have

all

the

parts

and

components

listed

in

the

IIParts

List

ll

(Table

2-1)

in

Section

II.

When

assembling

the

module,

follow

the

instructions

in

the

order

given.

Should

you

encounter

any

problem

during

assembly,

calIon

us

for

help

if

necessary.

If

your

completed

module

does

not

work

pro-

perly,

recheck

your

assembly

step

by

step.

Most

problems

stem

from

poor

soldering,

backward

installed

components,

and/or

installing

the

wrong

component.

Once

you

are

satisfied

that

the

module

is

correct-

ly

assembled,

feel

free

to

ask

for

our

help.

1.2

GENERAL

INFORMATION

1.2.1

CUTS

Description

CUTS,

The

Computer

Users

Tape

System

is

a

high

speed,

simple

to

use

audio

cassette

interface

that

operates

at

300

and

1200

bps

data

rates

under

program

control.

The

recording

technique

used

is

asynchronously

Manchester

coded

at

1200

or

2400

Hz

and

is

CUTS/Byte/

Kansas

City

Standard

compatible.

Two

separate

tape

transport

control

outputs

and

two

cornmon

audio

inputs

and

outputs

are

provided

to

drive

one

or

two

recorders.

In

addition,

CUTS

has

provision

for

selecting

1)

a

low

level

audio

output

signal

for

driving

the

microphone

input

to

an

audio

recorder,

2)

a

high

level

audio

output

signal

for

driving

the

auxiliary

input

to

an

audio

recorder,

and

3)

a

5-volt

peak-to-peak

square

save

out-

put

for

driving

a

digital

recorder.

A

fully

automatic

gain

control

operates

in

the

read

mode.

Unlike

other

cassette

interfaces,

CUTS

has

absolutely

no

critical

adjustments

that

must

be

preset

or

adjusted

during

operation.

1.2.2

All

Processor

Technology

software

is

available

on

CUTS

cassettes

at

lower

cost

than

equivalent

paper

tapes.

Receiving

Inspection

When

your

kit

arrives,

examine

shipping

container

for

signs

of

possible

damage

to

the

contents

during

transit.

Then

inspect

the

contents

for

damage.

(We

suggest

you

save

the

shipping

materials

for

use

in

returning

the

module

to

Processor

Technology

should

it

become

necessary

to

do

so.)

If

your

CUTS

kit

is

damaged,

please

write

us

at

once

describing

the

condition

so

that

we

can

take

appropriate

action.

I-I

PROCESSOR

TECHNOLOGY

CORPORATION

CUTS,

COMPUTER

USERS TAPE

SYSTEM

SECTION I

1.2.3

warranty

Information

In

brief,

parts

that

fail

because

of

defects

in

materials

or

workmanship

are

replaced

at

no

charge

for

3

months

for

kits,

and

one

year

for

assembled

products,

following

the

date

of

purchase.

Also,

products

assembled

by

the

buyer

are

warranted

for

a

period

of

3

months

after

the

date

of

purchase;

factory

assembled

units

carry

a

one

year

warranty.

Refer

to

Appendix

I

for

the

complete

"Statement

of

Warranty".

1.2.4

Replacement

Parts

Order

replacement

parts

by

component

nomenclature

(DM8131

IC

or

lN2222

diode,

for

example)

and/or

a

complete

description

(680

ohm,

~

watt,

5%

carbon

resistor,

for

example).

1.2.5

Factory

Service

In

addition

to

in-warranty

service,

Processor

Technology

also

provides

factory

repair

service

on

out-of-warranty

products.

Before

returning

the

unit

to

Processor

Technology,

first

obtain

our

authorization

to

do

so

by

writing

us

a

letter

describing

the

problem.

After

you

receive

our

authorization

to

return

the

unit,

proceed

as

follows:

1.

Write

a

description

of

the

problem.

2.

Pack

the

unit

with

the

description

in

a

container

suitable

to

the

method

of

shipment.

3.

Ship

prepaid

to

Processor

Technology

Corporation,

6200

Hollis

Street,

Emeryville,

CA

94608.

Your

unit

will

be

repaired

as

soon

as

possible

after

receipt

and

return

shipped

to

you

prepaid.

(Factory

service

charges

will

not

exceed

$20.00

without

prior

notification

and

your

approval.)

1-2

SECTION

II

ASSEMBLY

CUTS,

COMPUTER

USERS TAPE

SYSTEM

Processor

Technology

Processor

Technology

Corporation

6200

Hollis

Street

Emeryville

CA

94608

PROCESSOR

TECHNOLOGY

CORPORATION

CUTS,

COMPUTER

USERS

TAPE

SYSTEM

SECTION

II

2.1

PARTS

AND

COMPONENTS

Check

all

parts

and

components

against

the

"Parts

List"

(Table

2-1

on

Page

11-2).

If

you

have

difficulty

in

identifying

any

parts

by

sight,

refer

to

Figure

2-1

on

Page

11-3.

2.2

ASSEMBLY

TIPS

1.

Scan

Section

II

in

its

entirety

before

you

start

to

assemble

your

CUTS

kit.

2.

In

assembling

your

CUTS,

you

will

be

following

a

step-

by-step

assembly

procedure.

FOLLOW

THE

INSTRUCTIONS

IN

THE

ORDER

GIVEN.

3.

Assembly

steps

and

component

installations

are

pre-

ceded

by

a

set

of

parentheses.

Check

off

each

installation

and

step

as

you

complete

them.

This

will

minimize

the

chances

of

omitting

a

step

or

component.

4.

When

installing

components,

make

use

of

the

assembly

aids

that

are

incorporated

on

the

CUTS

PC

board

and

the

assembly

drawing.

(These

aids

are

designed

to

assist

you

in

correctly

in-

stalling

the

components.)

a.

The

circuit

reference

(R3,

C10

and

U7,

for

example)

for

each

component

is

silk

screened

on

the

PC

board

near

the

location

of

its

installation.

b.

Both

the

circuit

reference

and

value

or

nomenclature

(1.5K

and

74LS08,

for

example)

for

each

component

are

included

on

the

assembly

drawing

near

the

loca-

tion

of

its

installation.

5.

To

simplify

reading

resistor

values

after

installation,

install

resistors

so

that

their

color

codes

read

from

left-to-right

and

top-to-bottom

as

appropriate

(board

oriented

as

defined

in

Para-

graph

2.5

on

Page

11-

.)

6.

Unless

specified

otherwise

in

the

instructions,

install

components--especially

disc

capacitors--as

close

to

the

board

as

possible.

7.

Should

you

encounter

any

problem

during

assembly,

call

on

us

for

help

if

needed.

11-1

PROCESSOR

TECHNOLOGY

CORPORATION

CUTS,

COMPUTER

USERS

TAPE

SYSTEM

SECTION

II

Table

2-1.

CUTS

Parts

List

INTEGRATED

CIRCUITS

1

1458

or

5558

(U6)

1

6011

(U18)

2

4013

(U3 & U4) 1

74LS04

(U24)

1

4019

(U9) 2

74LS08

(U25 &

U26)

1

4023

(Ul)

1

74LSI09

(U20)

1

4024

(UI0)

1

74LS132

(U21)

1

4027

(U2) 2

74LS136

(U14

&

U15)

1

4030

(U19)

1

74LS155

(U23)

1

4046

(Ull)

1

74LS163

(U12)

1

4049

(U22)

1

74LS175

(U13)

1

4520

(U8 ) 2

74367

(U16 &

U17)

REGULATORS

TRANSISTORS

1 7805UC

or

LM340T-5.0.

(U7 ) 3

2N2222

(Ql,

Q3

& Q4)

1

78L12

(U5)

1 2N2907 (Q5)

1

2N4360

(Q2)

DIODES

RELAYS

3

lN4148

(Dl,

D2

& D4) 2

DIP

Reed,

SIGMA

191TEIAl-55

(Kl

& K2)

1

IN5242

(D3)

II-2

PROCESSOR

TECHNOLOGY

CORPORATION

CUTS,

COMPUTER

USERS TAPE

SYSTEM

SECTION

II

Table

2-1.

CUTS

Parts

List

(Continued).

RESISTORS CAPACITORS

1

39

ohm,

2

watt,

5%

1

470

pfd,

disc

1

100

ohm,

~

watt,

5%

4

.001

ufd,

disc

2

470

ohm,

~

watt,

5%

1

.001

ufd,

Mylar

tubular

3

1.5K

ohm,

~

watt,

5%

1

.01

ufd,

Mylar

tubular

9

10

K ohm,

~

watt,

5%

19

.1

ufd,

disc

4

100

K ohm,

~

watt,

5%

2 1

ufd,

tantalum

dipped

2

150

K ohm,

~

watt,

5%

3

15

ufd,

tantalum

dipped

2 1 M ohm,

~

watt,

5%

1

2.2M

ohm,

~

watt,

5%

1

50

K ohm

Potentiometer

2

2.2K

ohm

Resistor

Network

MISCELLANEOUS

1

CUTS

PC

Board

10

Molex

Crimp

Pins

for

Female

1

Heat

Sink

Mating

Connector

11

14-pin

DIP

Socket

3

Augat

Pin

11

16-pin

DIP

Socket

1

Length

#24

Bare

Wire

1

40-pin

DIP

Socket

1

Length

Solder

1

8-position

DIP

Switch

3

6-32

x

J..z

Screw

2

Right

Angle

Molex

Connector,

3

#6

Lockwasher

Male

(Jl

&

J2)

3

6-32

Hex

Nut

2

Mating

Connector

for

Above,

1

Manual

Female

(PI

&

P2)

11-3

PROCESSOR

TECHNOLOGY

CORPORATION

CUTS,

COMPUTER

USERS TAPE

SYSTEM

TRANSISTOR

TO-IS

Package

(Metal

Can)

TRANSISTOR,

POWER

or

REGULATOR

IC

TO-220

Package

METAL

FILM PRECISION RESISTOR

(1%

Tolerance)

SECTION

II

TRANSISTOR

TO-92

Package

(Plastic)

c

CARBON

RESISTOR

5%

(gold),

10%

(silver.

See

Appendix

III

for

Color

Code

RESISTOR

NETWORK

Figure

2-1.

Identification

of

components.

11-4

PROCESSOR

TECHNOLOGY

CORPORATION

CUTS,

COMPUTER

USERS TAPE

SYSTEM

ELECTROLYTIC CAPACITOR

(Vertical

Mount)

DISC CAPACITOR

Monolythic

(left)

and

Ceramic

SECTION

II

DIPPED

TANTALUM

ELECTROLYTIC

CAPACITOR

VEI-LOW

~

BRO~N}

=~::".:~~

GREeN,

BLUE. .

'--~

\5"

.t{.+d

See

Appendix

III

for

Color

Code

MYLAR

TUBULAR

CAPACITOR

INTEGRATED

CIRCUIT,

Dual

Inline

Package

(DIP)

(6,8,14,16,24

and

40

pin)

?tNl..!

Figure

2-1.

Identification

of

componentso

11-5

PROCESSOR

TECHNOLOGY

CORPORATION

CUTS,

COMPUTER

USERS TAPE

SYSTEM

SECTION

II

2.3

ASSEMBLY

PRECAUTIONS

2.3.1

Handling

MOS

Integrated

Circuits

Many

of

the

IC's

used

in

the

CUTS

are

MOS

devices.

They

can

be

damaged

by

static

electricity

discharge.

Always

handle

MOS

IC's

so

that

gQ

discharge

will

flow

through

the

IC.

Also,

avoid

unneces-

sary

handling

and

wear

cotton--rather

than

synthetic-~clothing

when

handling

these

IC's.

2.3.2

Soldering

**IMPORTANT**

1.

Use

a

fine

tip,

low-wattage

iron,

25

watts

maximum.

2.

DO

NOT

use

excessive

amounts

of

solder.

DO

solder

neat-

ly

and

as

quickly

as

possible.

3.

Use

only

60-40

rosin-core

solder.

NEVER

use

acid-core

solder

or

externally

applied

fluxes.

4.

To

prevent

solder

bridges,

position

iron

tip

so

that

it

does

not

touch

adjacent

pins

and/or

traces

simultaneously.

5.

DO

NOT

press

tip

of

iron

on

pad

or

trace.

To

do

so

can

cause

the

pad

or

trace

to

"lift"

off

the

board

and

permanently

damage

it.

6.

The

flow

through

to

solder

bridges.

component.

CUTS

circuit

board

has

plated-through

holes.

Solder

the

component

(front)

side

of

the

board

can

produce

Check

for

such

bridges

after

you

install

each

7.

The

CUTS

circuit

board

has

an

integral

solder

mask

(a

lacquer

coating)

that

shields

selected

areas

on

the

board.

This

mask

minimizes

the

chances

of

creating

solder

bridges

during

assem-

bly.

DO,

however,

check

all

solder

joints

for

possible

bridges.

8.

Additional

pointers

on

soldering

are

provided

in

Appen-

dix

III

of

this

manual.

2.3.3

Installing

and

Removing

CUTS

Module

NEVER

install

the

CUTS

in,

or

remove

it

from

the

computer

with

the

power

on.

To

do

so

can

damage

the

module.

2.3.4

Installing

and

Removing

Integrated

Circuits.

NEVER

install

or

remove

integrated

circuits

while

power

is

applied

to

the

CUTS.

To

do

so

can

damage

the

IC.

11-6

PROCESSOR

TECHNOLOGY

CORPORATION

CUTS,

COMPUTER

USERS

TAPE

SYSTEM

SECTION

II

2.3.5

Use

of

Clip

Leads

NEVER

attach

clip

leads

to

the

top

edge

of

the

CUTS

PC

board.

To

do

so

can

short

the

+8,

+16

and

-12

V

dc

buses

to

one

another.

2.4

REQUIRED TOOLS,

EQUIPMENT

AND

MATERIALS

The

following

tools,

equipment

and

materials

are

recommended

for

assembling

and

testing

the

CUTS

Module:

1.

Needle

nose

pliers

2.

Diagonal

cutters

3.

Scredriver

4.

Sharp

knife

5.

Controlled

heat

fine

tip

soldering

iron,

25

watts

6.

60-40

rosin-core

solder

(supplied)

7.

#24

bare

wire

(supplied)

8.

Volt-ohm

meter

2.5

ORIENTATION

The

heat

sink

area

(large

foil

area)

will

be

located

in

the

upper

right-hand

corner

of

the

board

when

the

edge

connector

is

at

the

bottom.

In

this

position,

the

component

(front)

side

of

the

board

is

facing

up

and

the

solder

(back)

side

is

facing

down.

In

addition.

the

IC

legends

(Ul

through

U4,

U8

through

U15,

etc.)

will

read

from

left

to

right.

Subsequent

position

references

in

the

in-

structions

related

to

the

CUTS

PC

board

assume

this

orientation.

2.6

ASSEMBLY-TEST

Refer

to

the

assembly

drawing

in

Section

VI.

CAUTION

THE

CUTS

MODULE

USES

MANY

MOS

b~D

CMOS

INTEGRATED

CIRCUITS.

THEY

CAN

BE

DAM-

AGED

BY

STATIC ELECTRICITY DISCHARGE.

HANDLE

THESE

IC's

SO

THAT

NO

DISCHARGE

FLOWS

THROUGH

THE

IC.

AVOID

UNNECESSARY

HANDLING

AND

WEAR

COTTON--RATHER

THAN

SYNTHETIC--CLOTHING

WHEN

YOU

DO

HANDLE

THESE

IC's.

(STATIC

CHARGE

PROBLEMS

ARE

MUCH

WORSE

IN

LOW

HUMIDITY CONDITIONS.)

11-7

PROCESSOR

TECHNOLOGY

CORPORATION

CUTS,

COMPUTER

USERS

TAPE

SYSTEM

SEC'l'ION

II

2.6.1

Circuit

Board

Check

(t

Visually

check

CUTS

PC

board

for

solder

bridges

(shorts)

between

traces,

broken

traces

and

similar

defects.

Check

board

to

insure

that

the

+S-volt

line,

+16-volt

line,

+5-volt

bus,

+12-volt

bus

and

-12-volt

bus

are

not

shorted

to

one

another

or

to

ground.

Using

an

ohmmeter,

make

the

following

measurements

(refer

to

CUTS

assembly

drawing

in

Section

VI.):

(~

(~

(~

+S-volt

Line

Test.

Measure

between

edge

connector

pin

1

or

51

(left

end

of

connector)

and

pin

50

or

100

(right

end

of

connector).

There

should

be

no

continuity.

+16-volt

Line

Test.

Measure

between

edge

connector

pin

2

or

52

and

pin

50

or

100.

There

should

be

no

continuity.

S/16

Volt

Line

Test.

Measure

between

edge

connector

pin

1

or

51

and

pin

2

or

52.

There

should

be

no

continuity.

+5-volt

Bus

Test.

Measure

between

the

upper

mounting

pad

for

D2

(to

the

left

of

location

K2)

and

pin

50

or

100

of

the

edge

connector.

There

should

be

no

continuity.

+12-volt

Bus

Test.

Measure

between

upper

mounting

pad

for

C9

(in

upper

right

corner

below

CS)

and

pin

50

or

100

of

edge

connector.

There

should

be

no

continuity.

-12-volt

Bus

Test.

Measure

between

upper

mounting

pad

for

CIS

(between

U16

and

U17)

and

pin

50

or

100

of

edge

connector.

There

should

be

'no

continuity.

5/12/(-12)

Volt

Bus

Test.

Measure

between

upper

mounting

pad

for

C2l

(lower

left

corner)

and

upper

pad

for

C9,

between

upper

pad

for

C21

and

upper

mounting

pad

for

CIS,

and

between

upper

pad

for

C9

and

upper

pad

for

CIS.

You

should

measure

no

conti-

nuity

in

any

of

the

three

measurements.

If

visual

inspection

reveals

any

defects,

or

you

measure

continuity

in

any

of

the

preceding

tests,

return

the

board

to

Processor

Technology

for

replacement.

If

the

board

is

not

defective,

go

on

to

next

paragraph.

II-S

PROCESSOR

TECHNOLOGY

CORPORATION

CUTS,

COMPUTER

USERS TAPE

SYSTEM

SECTION

II

2.6.2

Assembly-Test

Procedure

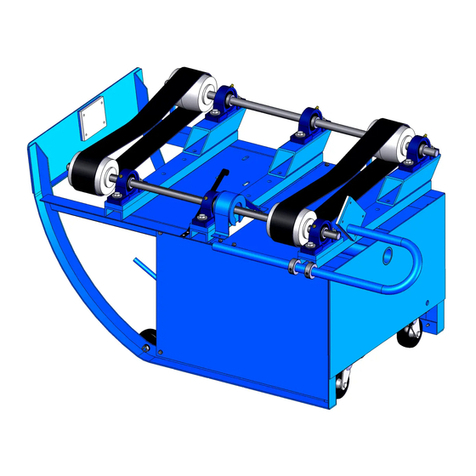

Step

1.

Install

heat

sink.

position

the

large,

black

heat

sink

(flat

side

to

board)

over

the

square

foil

area

in

the

upper

right

corner.

Orient

the

sink

so

that

the

two

tri-

angles

of

mounting

holes

in

the

board

are

under

the

two

triangular

cutouts

in

the

sink.

Using

two

6-32

screws,

lockwashers

and

nuts,

attach

heat

sink

to

board.

Insert

the

screws

from

back

(solder)

side

of

board.

(See

Figure

2-2.)

Step

2.

Install

U7

(7805UC

or

LM340T-5.0).

position

u7

over

left-hand

cutout

in

heat

sink

and

observe

how

the

leads

must

be

bent

to

fit

the

mounting

holes.

Note

that

the

center

lead

(3)

must

be

bent

downwards

at

a

point

approximately

0.2

inches

further

from

the

body

than

the

other

two

leads.

Bend

the

leads

so

that

no

contact

is

made

with

the

heat

sink

when

U7

is

flat

against

the

sink

and

its

mounting

hole

is

aligned

with

the

hole

in

the

sink.

Fasten

U7

to

sink

using

a

6-32

screw,

lockwasher

and

nut.

Insert

screw

from

back

(solder)

side

of

.board.

Solder

and

trim

leads.

(Refer

to

Figure

2-2.)

.

Heat

Upper

right-hand~

corner

of

board

@

I

~

J

•.

~

,~.

c..--U7

Figure

2-2.

Heat

sink

and

u7

installation.

II-9

PROCESSOR

TECHNOLOGY

CORPORATION

CUTS,

COMPUTER

USERS TAPE

SYSTEM

SECTION

II

(W{

Step

3.

Install

male

Molex

right

angle

connectors

in

loca-

tions

Jl

and

J2.

Position

connector

with

longer

pins

facing

the

top

of

the

board,

insert

leads

in

mounting

holes

and

-

solder.

(v(

Step

4.

Install

diodes

Dl,

D2

and

D4

(lN4148)

l

respective

locations.

position

Dl

and

D2

with

band

mark

(cathode)

at

the

top

and

position

D4

in

their

their

dark

with

its

band

!

at

the

right.

Solder

and

trim

leads.

(')

step

5.

Install

diode

D3

(lNS242)

in

its

location.

Posi-

tion

D3

with

its

dark

band

mark

,(cathode)

at

the

right.

(~

(~

Step

6.

Install

transistors

Ql,

Q3

and

Q4

(2N2222)

in

their

respective

locations.

position

Ql

with

its

emitter

lead

(closest

to

tab

on

can)

at

the

top

and

its

base

lead

at

the

left.

Position

both

Q3

and

Q4

with

their

emitter

leads

at

the

right

and

their

base

leads

at

the

top.

Insert

leads

and

push

straight

down

on

transistor

until

it

is

3/16"

above

the

surface

of

the

board.

Solder

and

trim

leads.

Step

7.

Install

transistor

Q2

(2N4360)

in

its

location.

position

Q2

with

its

flat

side

at

the

bottom,

insert

leads

and

push

straight

down

on

transistor

until

it

is

3/16"

above

the

surface

of

the

board.

Solder

and

trim

leads.

(

~

Step

8.

Install

transistor

QS

(2N2907)

in

its

location.

Position

QS

with

its

emitter

lead

(closest

to

tab

on

can)

at

the

right

and

its

base

lead

at

the

top.

Insert

leads

and

push

straight

down

on

transistor

until

it

is

3/16"

above

the

surface

of

the

board.

Solder

and

trim

leads.

(~

Step

9.

Install

all

resistors

in

numerical

order

in

the

in-

dicated

locations.

Bend

leads

to

fit

distance

between

mount-

ing

holes,

insert

leads,

pull

down

snug

to

board,

bend

leads

outward

on

solder

(back)

side

of

board,

solder

and

trim.

LOCATION

VALUE

(ohms)

COLOR

CODE

(~

Rl

100

K

brown-black-yellow

( , ) R2

10

K

brown-black-orange

( ) R3

1.SK

brown-green-red

( ) R4

10

K

brown-black-orange

C

RS

1.SK

brown-green-red

( R6

1.SK

" " "

(

R7

10

K

brown-black-orange

( R8

150

K

brown-green-yellow

( . R9

10

K

brown-black-orange

~~

RIO 1 M

brown-black-green

Rll

10

K

brovm

-black-orange

Continued

on

Page

II-II.

11-10

PROCESSOR

TECHNOLOGY

CORPORATION

CUTS,

COMPUTER

USERS

TAPE

SYSTEM

Step

9

continued.

LOCATION

~d~

~i~

( -

R14

( .

R15

R16

R17

R18

R19

R20

(

.)

R2l

j!m

(:,r

VRI

VALUE

(

ohms)

2.2M

10

K

150

K

10

K

470

100

100

K

K

K

10

10

470

39,2

watt

100

K

100

K

1 M

50

K

SECTION

II

COLOR

-CODE

red-red-green

brown-balck-orange

brown-green-yellow

brown-black-orange

yellow-violet

brown

brown-black-brown

brown-black-yellow

brown-black-orange

II II

II

yellow-violet-brown

orange-white-black

brown-black-yellow

II

II

II

brown-black-green

Potentiometer

"A

Step

10.

Install

resistor

networks

RXI

and

RX2

(2.2K

ohms)

in

their

respective

locations.

Position

RXI

so

that

the

dot

on

its

package

is

at

the

right

end.

Position

RX2

with

its

dot

at

the

left

end.

CAUTION

THESE RESISTOR

NETWORKS

ARE

DELICATE.

HANDLE

WITH CARE.

( )

Step

11.

Install

the

five

tantalum

capacitors

in

the

fol-

lowing

locations.

Take

care

to

observe

proper

values

and

the

correct

orientation.

,

LOCATION

VALUE

(ufd)

ORIENTATION

l~

C7

15

11+11

lead

left

C8

15

11+11

lead

top

left

~

·f

C21 1

11+11

lead

top

C24

15

11+11

lead

right

(t%

C29 1

11+11

lead

top

( )

Step

12.

Install

the

following

capacitors

in

the

indicated

locations.

Take

care

to

observe

the

proper

value

and

type

for

each

installation.

Bend

leads

outward

on

solder

(back)

side

of

board,

solder

and

trim.

Continued

on

Page

11-12.

II-II

PROCESSOR

TECHNOLOGY

CORPORATION

CUTS,

COMPUTER

USERS

TAPE

SYSTEM

SECTION

II

(

JJ)

(

(

(

, (

'-

(

(

( )

(

Ii

)

( )

( )

(

(-

( )

( . )

( )

(

(

(

('

)

(~)

( )

( . )

( )

un

(If

)

(J

Step

12

continued.

Disc

capacitor

leads

are

usually

coated

with

wax

during

the

manufacturing

pro-

cess.

After

inserting

leads

through

mounting

holes,

remove

capacitor

and

clear

the

holes

of

any

wax.

Re-insert

and

install.

LOCATION

VALUE

(ufd)

Cl

.1

C2

.1

C3

.1

C4

.01

C5

.1

C6

.1

C9

.1

CIO

.1

Cll

.001

C12

.1

C13

.1

C14

.001

C15

.1

C16

.1

C17

.1

C18

.1

C19

.1

C20

.001

C22

.001

C23

.1

C25

.001

C26

.1

C27

.1

C28

.1

C30

.1

C31

470

pfd

Disc

II

II

Mylar

tubular

Disc

Mylar

tubular

Disc

II

II

II

II

Step

13.

Install

Augat

pins

in

mounting

holes

A,

Band

C.

(These

three

holes

are

located

to

the

left

of

U16,

just

below

the

lower

mounting

hole

for

R17.)

NOTE

You

will

find

it

helpful

to

hold

the

board

between

two

objects

so

that

it

stands

on

edge.

Continued

on

Page

11-13.

11-12

Table of contents

Popular Storage manuals by other brands

Thermo Scientific

Thermo Scientific Cryo 740 Series Operating and maintenance manual

Compaq

Compaq StorageWorks ESL9000 Series installation guide

Seagate

Seagate DB35.2 product manual

morse

morse 201B Series Operator's manual

Tandberg Data

Tandberg Data LTO-5 user guide

Shugart

Shugart Kennedy 9610 Operation and maintenance manual