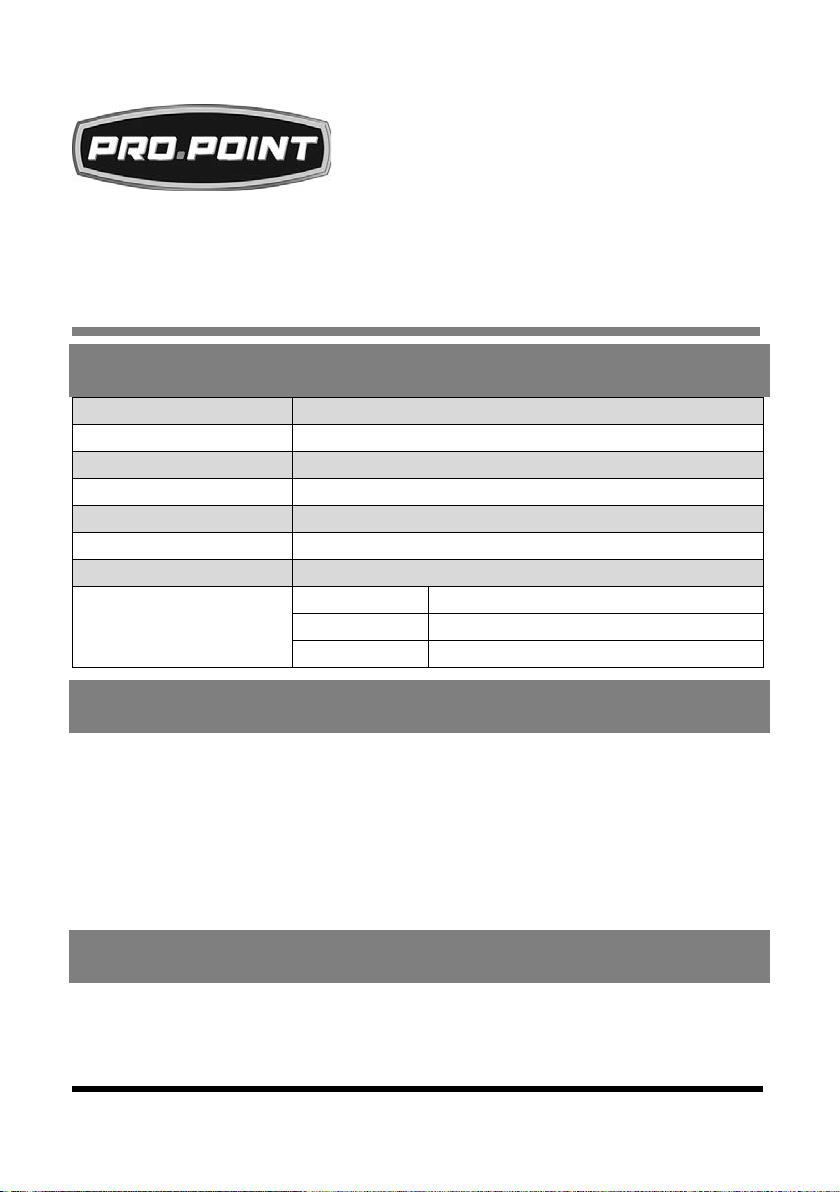

8656852 10 IN. HEAVY-DUTY BENCH GRINDER V1.0

8 For technical questions call 1-800-665-8685

6. Remove adjusting keys and wrenches before turning the

tool on. A wrench or a key that is left attached to a rotating

part of the tool increases the risk of personal injury.

7. Never force the tool. Excessive pressure could break the

tool, resulting in damage to your workpiece or serious

personal injury. If your tool runs smoothly under no load,

but does not run smoothly under load, then excessive

pressure is being used.

8. Do not touch an operating motor. Motors can operate at

high temperatures and can cause a burn injury.

9. Only use accessories that are specifically designed for use

with the tool. Ensure the accessory is tightly installed.

10. Only use an accessory that exceeds the No Load Speed

rating (see Specifications).

ELECTRICAL SAFETY

WARNING! To reduce risk of electric shock, be certain that the

plug is connected to a properly grounded receptacle.

1. Disconnect tool from power source before cleaning,

servicing, changing parts/accessories or when not in use.

2. Protect yourself against electric shocks when working on

electrical equipment. Avoid body contact with grounded

surfaces. There is an increased chance of electrical shock if

your body is grounded.

3. Do not expose tool to rain or wet conditions. Water entering

a power tool will increase the risk of electric shock.

4. Do not disconnect the power cord in place of using the

ON/OFF switch on the tool. This will prevent an accidental

startup when the power cord is plugged into the power supply.

4.1 In the event of a power failure, turn off the machine as

soon as the power is interrupted. The possibility of

accidental injury could occur if the power returns and

the unit is not switched off.