16 Electronic Controller

Service Manual

SKOPE ProSpec Upright Series

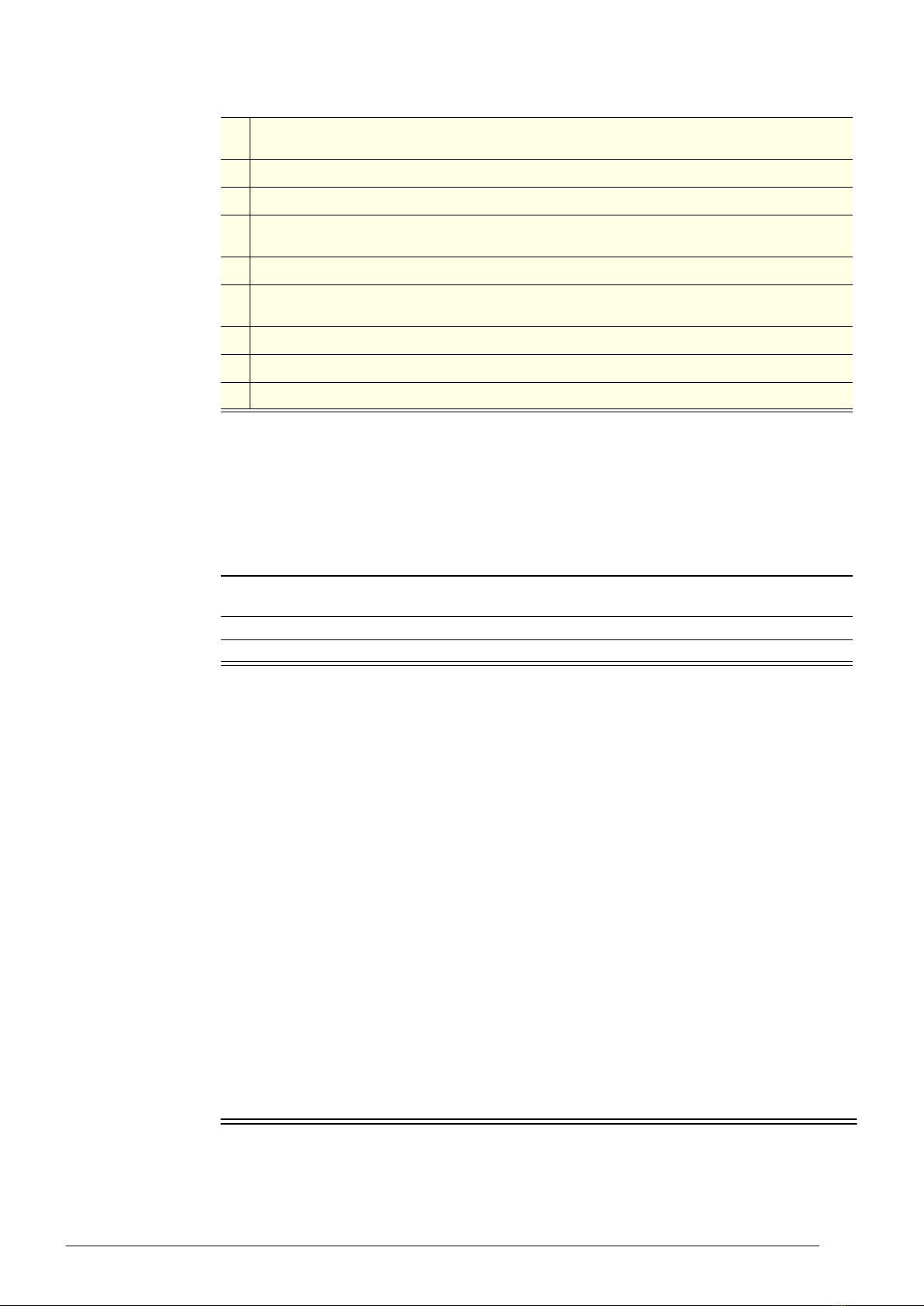

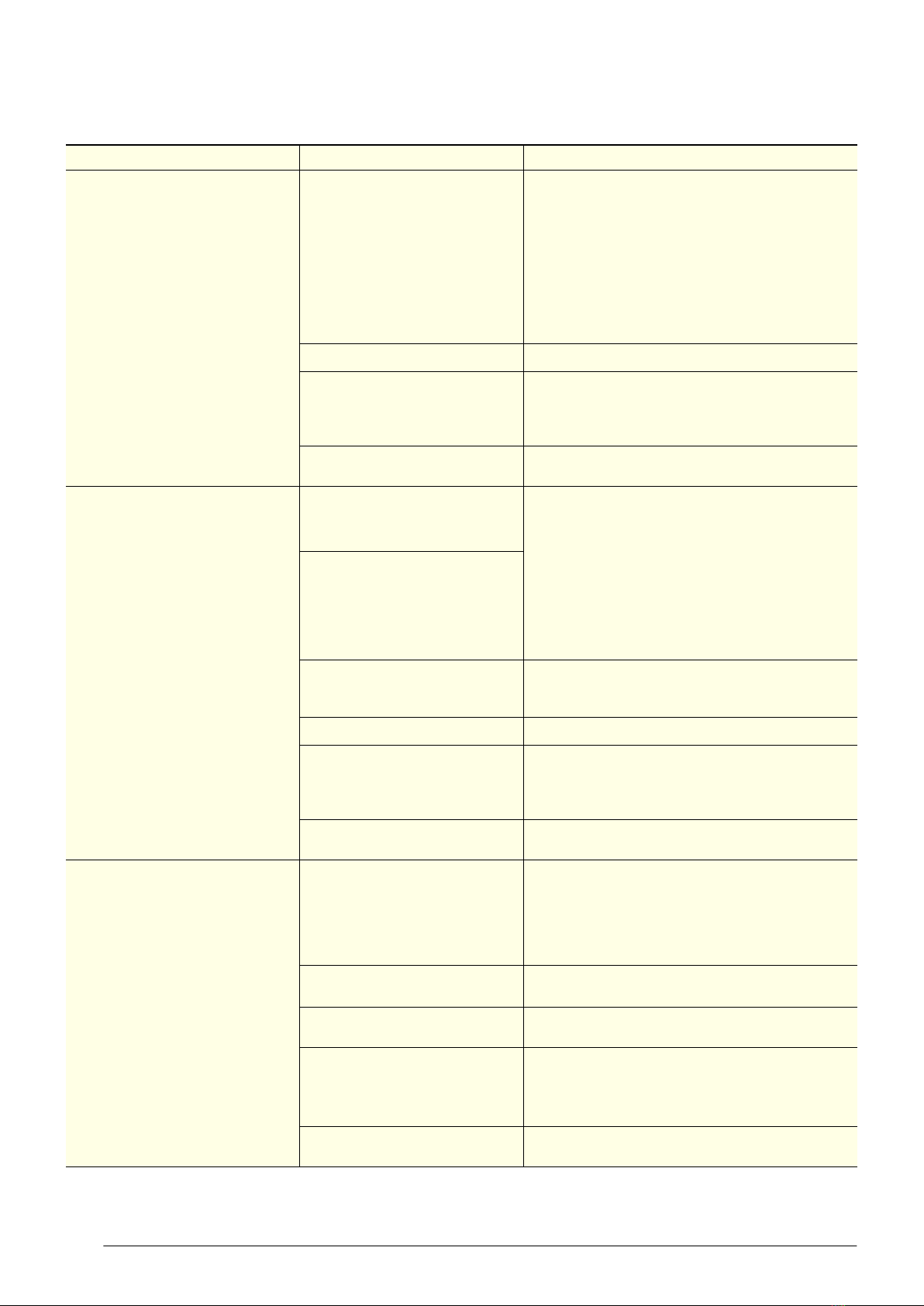

Table 4: Faults

Description Possible root cause Actions

Over-voltage protection

The maximum allowable mains supply

voltage has been exceeded. The

cabinet has temporarily shut down to

prevent damage and will restart once

the supply voltage decreases.

Should be a one-off. If it continues,

consider:

• poor line voltage

Test the incoming voltage to ensure it is correct. The

test voltage needs to be between 198 and 264 volts.

• If outside this, the controller will shut the system

down until the voltage returns to between these

measurements.

• If the voltage is correct and the controller is still

showing a fault, replace the controller.

• rural location

• voltage setting parameter

• Check the voltage parameter settings are between

198 and 264 volts. If this parameter is outside the

correct voltage, changing it may damage the

controller.

• controller • The controller may be reading incorrectly and need

replacing.

Under-voltage protection

The mains supply voltage has dropped

below the minimum allowable level.

The cabinet has temporarily shut down

to prevent damage and will restart once

the supply voltage increases.

Should be a one-off. If continues,

consider:

• power supply overloaded Test the incoming voltage to ensure it is correct. The

test voltage needs to be between 198 and 264 volts.

• If outside this, the controller will shut the system

down until the voltage returns to between these

measurements.

• If the voltage is correct and the controller is still

showing a fault, replace the controller.

• poor line voltage

• multi-box use

• Check that there are not too many plugs using the

same multi-box adaptor causing the voltage to

drop.

• rural location

• voltage setting parameter

• Check the voltage parameter settings are between

198 and 264 volts. If this parameter is outside the

correct voltage, changing it may damage the

controller.

• controller • The controller may be reading incorrectly and need

replacing.

High condensing temperature

protection

The system was operating at an

elevated temperature and has

temporarily shut down to prevent

damage. Extended operation in this

condition may result in ALARM 15,

increased energy consumption and a

reduction in cabinet life.

Cartridge swap is not required.

• Condenser not clean

• Remove and clean the condenser filter.

• Check that the condenser is free of debris.

• If the coil is dirty, clean it with a vacuum cleaner or

soft brush.

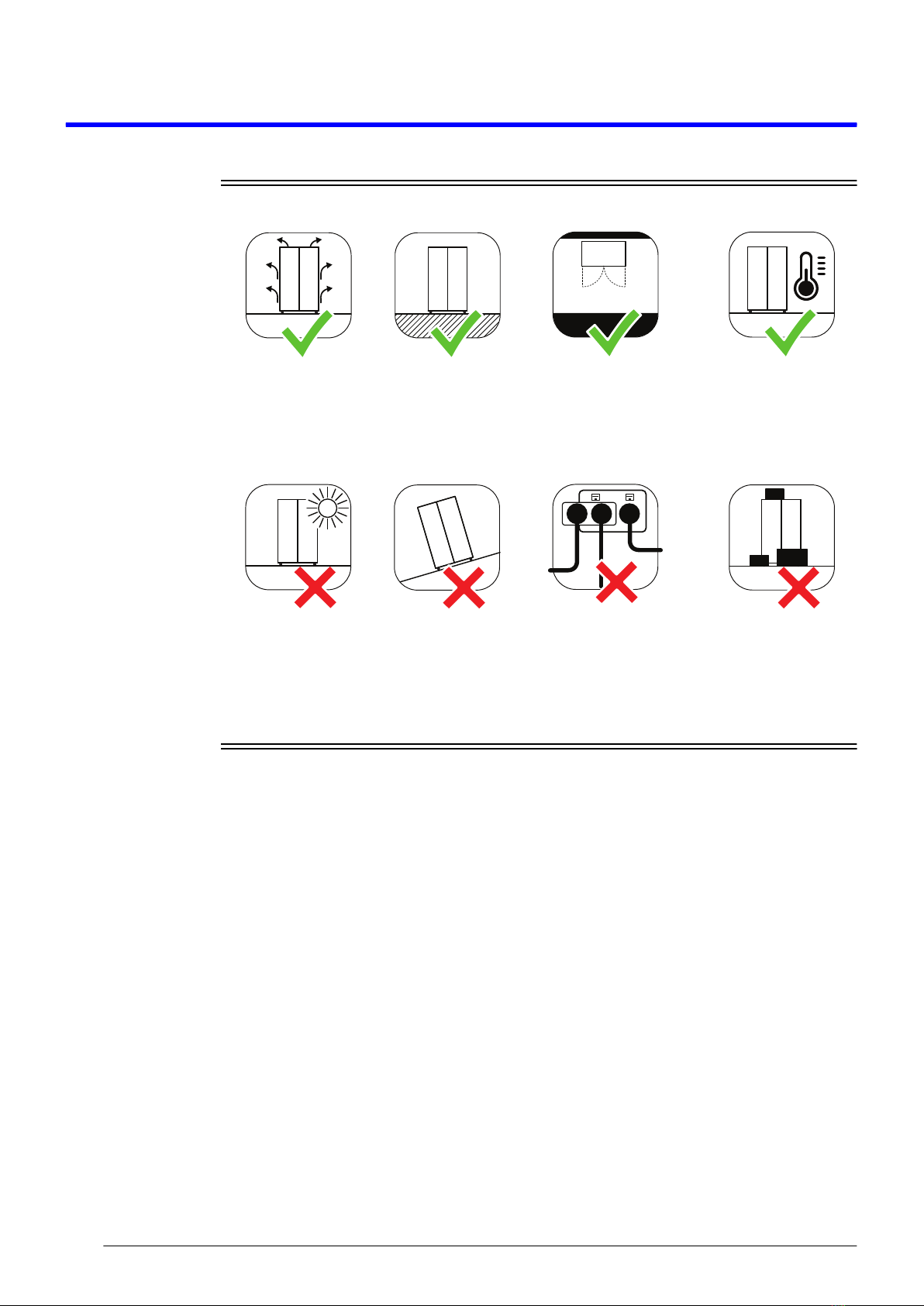

• Poor installation or ventilation • Check the installation guidelines.

• If fitted, check the rear stand-offs are extended.

• Condenser fan motor or blade • Check that the condenser fan blades are in place

and all condenser fans are operating correctly.

• Controller

The controller may be reading incorrectly and need

replacing.

• Confirm the temperature reading with an

independent thermometer.

• Very high ambient temperature • Check if the probes are faulty and reading

incorrectly.