Proton InteliSENS PD30 User manual

Page 2 of 68

Proton Products InteliSENS PD30 Instruction Manual (Issue 1a)

Table of Contents

DECLARATION OF CONFORMITY (CE)..........................................................5

INTRODUCTION..........................................................................................6

SPECIFICATIONS........................................................................................7

STANDARD INTERFACES ........................................................................................................................7

OPTIONAL INTERFACES..........................................................................................................................8

OPTIONAL FUNCTIONALITY.....................................................................................................................8

DIMENSIONAL DRAWINGS...........................................................................9

ANNOTATED DRAWINGS...........................................................................10

CONNECTORS.....................................................................................................................................10

OPTIONAL ACCESSORIES .........................................................................11

OPTIONAL INTERFACES........................................................................................................................11

Industrial bus interfaces .............................................................................................................................. 11

Electrical interfaces ..................................................................................................................................... 12

OPTIONAL FIRMWARE ..........................................................................................................................12

INTERFACE DISPLAY MODULES .............................................................................................................14

POWER SUPPLIES AND CONNECTIVITY ..................................................................................................14

INSTALLATION.........................................................................................15

PRECAUTIONS.....................................................................................................................................15

OPTICAL WINDOW CLEANING PROCEDURE.............................................................................................16

INSTALLATION SEQUENCE ....................................................................................................................16

MECHANICAL INSTALLATION................................................................................................................17

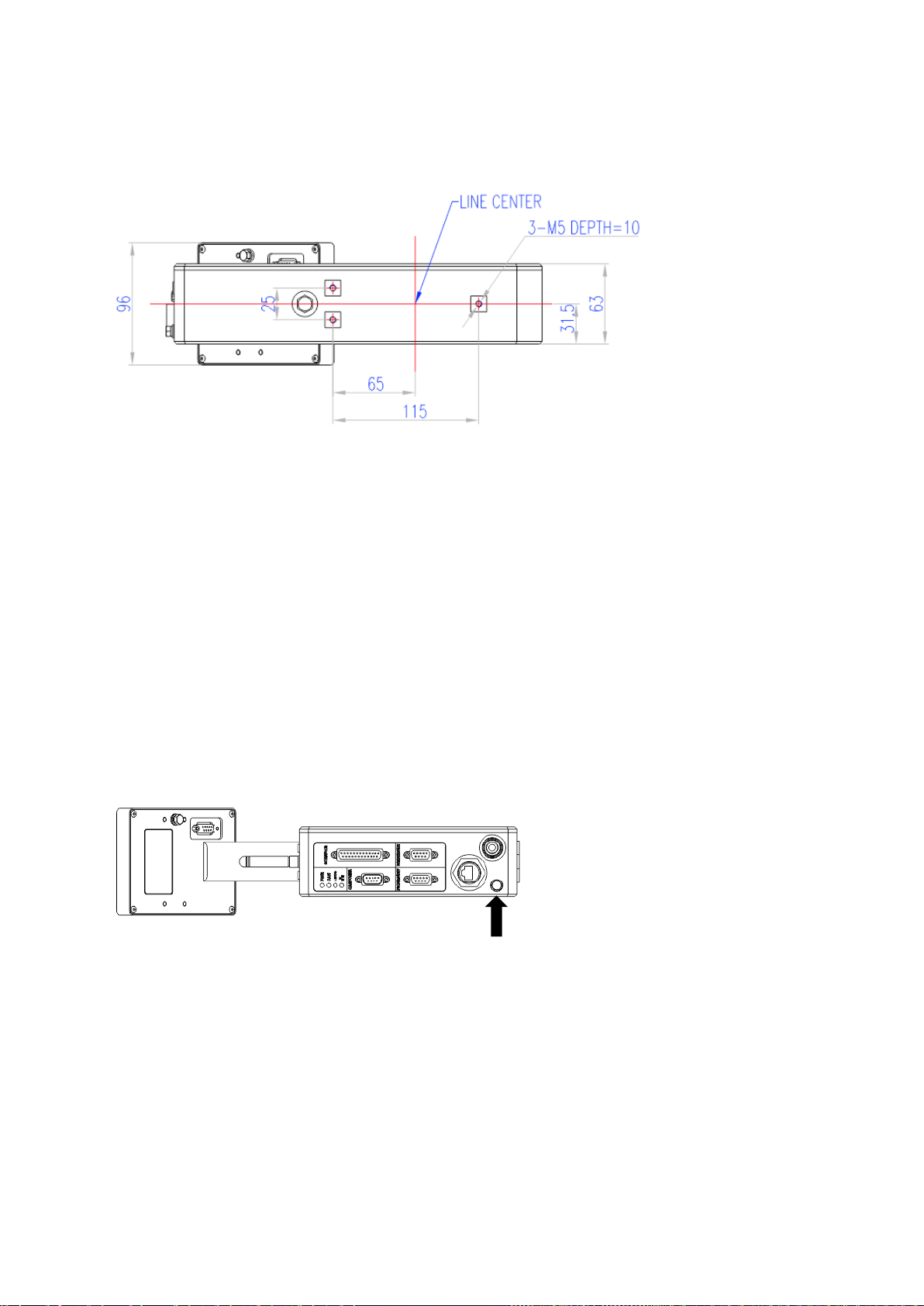

GAUGE HEAD DIMENSIONS:PD30........................................................................................................17

INSTALLATION NOTES: ....................................................................................................................................... 17

ELECTRICAL INSTALLATION..................................................................................................................17

Earth connection ......................................................................................................................................... 17

Shielded Cables ........................................................................................................................................... 17

Optional CDI4 interface display unit installation......................................................................................... 18

DC Power supply.......................................................................................................................................... 19

Powering on the gauge ............................................................................................................................... 19

Power indications........................................................................................................................................ 20

Powering off the gauge............................................................................................................................... 20

CONFIGURATION VIA CDI4.......................................................................20

POWER ON SCREEN.............................................................................................................................20

HOME PAGE 1.....................................................................................................................................21

HOME PAGE 2.....................................................................................................................................21

HOME PAGE 3.....................................................................................................................................22

HOME PAGE 4.....................................................................................................................................22

FUNCTION MENUS ...............................................................................................................................23

PRESET..............................................................................................................................................24

COMMUNICATIONS...............................................................................................................................29

INTERFACE......................................................................................................................................31

GAUGE INFORMATION..........................................................................................................................34

STORE................................................................................................................................................35

STATISTICS.........................................................................................................................................35

FFT ...................................................................................................................................................36

ACCESS LEVELS.............................................................................................................................37

STANDARD COMMUNICATIONS INTERFACES ...............................................38

CAN-BUS COMMUNICATIONS ...............................................................................................................38

CAN-bus interface ....................................................................................................................................... 38

CAN-bus LED indicator ................................................................................................................................ 38

Page 3 of 68

Proton Products InteliSENS PD30 Instruction Manual (Issue 1a)

RS-232 COMMUNICATIONS .................................................................................................................39

RS-232 interface .......................................................................................................................................... 39

RS-232 SINGLE LETTER PROTOCOL (SLP)..........................................................................................39

RS-422 /RS-485 COMMUNICATIONS...................................................................................................40

RS-422 / RS-485 interface ........................................................................................................................... 40

ETHERNET COMMUNICATIONS ..............................................................................................................40

Ethernet interface ....................................................................................................................................... 40

Ethernet LED indicator ................................................................................................................................ 41

OPTIONAL COMMUNICATIONS INTERFACES ................................................42

WIFI WIRELESS COMMUNICATIONS......................................................................................................42

WiFi interface .............................................................................................................................................. 42

PROFIBUS COMMUNICATIONS............................................................................................................42

PROFIBUS interface ..................................................................................................................................... 42

PROFIBUS LED indicator .............................................................................................................................. 42

PROFINET communications ......................................................................................................................... 43

PROFINET interface ..................................................................................................................................... 43

ETHERNET /IP COMMUNICATIONS........................................................................................................44

EtherNet / IP interface ................................................................................................................................ 44

EtherNet / IP LED indicator.......................................................................................................................... 44

STANDARD ELECTRICAL INTERFACES........................................................45

SPEED PULSE INPUT............................................................................................................................45

Speed pulse input connection...................................................................................................................... 45

ANALOGUE INPUT................................................................................................................................46

Analogue input connection ......................................................................................................................... 46

LOGIC INPUTS.....................................................................................................................................47

Logic inputs connection............................................................................................................................... 47

Logic inputs configuration........................................................................................................................... 48

Interrogating External Alarm 1 and External Alarm 2 Logic Input Status ................................................... 48

RELAY OUTPUTS.................................................................................................................................50

Relay outputs connection............................................................................................................................ 50

Relay outputs electrical specifications ........................................................................................................ 50

OPTIONAL ELECTRICAL INTERFACES.........................................................51

ANALOGUE OUTPUTS ..........................................................................................................................51

Analogue outputs connection ..................................................................................................................... 51

PI FEEDBACK CONTROLLER.................................................................................................................52

PI feedback controller connection ............................................................................................................... 52

PI feedback controller electrical specifications ........................................................................................... 52

PI feedback controller connection to production equipment ...................................................................... 53

INTERFACE CONNECTOR PIN OUTS.........................................................55

PROTON STANDARD PARAMETER ACCESS PROTOCOL .................................56

PARAMETER WORD FORMATS...............................................................................................................56

Bit pattern words ........................................................................................................................................ 56

Numerical value words................................................................................................................................ 56

Double length words ................................................................................................................................... 56

READING INPUT PARAMETERS..............................................................................................................56

Reading a single input parameter ............................................................................................................... 56

Reading a block of input parameters .......................................................................................................... 56

WRITING INPUT PARAMETERS...............................................................................................................57

Writing a single input parameter................................................................................................................ 57

READING OUTPUT PARAMETERS...........................................................................................................57

Reading a single output parameter ............................................................................................................ 57

Reading a block of output parameters........................................................................................................ 57

Reading a continuous stream of a single output parameter....................................................................... 57

Reading a continuous stream of a block of output parameters.................................................................. 58

Page 4 of 68

Proton Products InteliSENS PD30 Instruction Manual (Issue 1a)

MODBUS PARAMETER ACCESS PROTOCOL .................................................59

INPUT PARAMETERS.................................................................................60

OUTPUT PARAMETERS .............................................................................65

CONTACT DETAILS FOR ENQUIRIES,SALES AND SERVICE .............................68

WEB SITE............................................................................................................................................68

ENQUIRIES AND SALES.........................................................................................................................68

SERVICE ENQUIRIES............................................................................................................................68

MANUAL FEEDBACK AND COPYRIGHT ........................................................68

Page 5 of 68

Proton Products InteliSENS PD30 Instruction Manual (Issue 1a)

DECLARATION OF CONFORMITY (CE)

Proton Products International Limited declares that the equipment listed below fulfils the requirements

of directive EMC: 2014/30/EU and Low Voltage: 2014/35/EU.

The following standards were applied:

Radio -ETSI EN 300 328 V2.1.1 (2016-11)

EMC - EN 61326-1:2013

Low Voltage - EN 61010-1:2010 (Scientific and measuring instruments)

Health and Safety - EN 60950-1:2006+A11:2009+A1:2010+A12:2011+A2:2013, EN 62311:2008

Equipment Covered

Product name

Description

Part number

PD30

Single Axis diameter gauge

00054MC021

SiDi-CDi4

Colour touch screen display interface

00049MC021

These products carry the CE Mark:

Warning –laser equipment

The diameter gauge contains a laser source that complies with EN60825 Class 2 under normal use. If

the gauge is opened, the laser source removed and tampered with then the source can become Class

3.

The manufacturer of the above named equipment is:

Proton Products International Limited

10 Aylesbury End

Beaconsfield

Bucks

HP9 1LW

ENGLAND

Proton Products is an ISO9001:2015 registered company.

The declaration is signed by:

Paul Sives ………………………

Page 6 of 68

Proton Products InteliSENS PD30 Instruction Manual (Issue 1a)

INTRODUCTION

GAUGE PD30 WITH CDI4 DISPLAY

The InteliSENS PD30 Single Axis Laser Scanning Diameter Gauge provides fast, accurate and

repeatable diameter measurements of cables or other objects manufactured in a continuous process.

The PD30 measures objects or cables up to 30 mm in diameter, by a non-contact method. The

gauge contains a single-axis optical scanning system and a processing circuit to produce diameter

and statistical data.

When fitted with the optional CDI4 interface display unit, the InteliSENS PD30 diameter gauge can

operate as a standalone unit.

RS-232, RS-422, RS-485 and Ethernet communication interfaces are installed as standard for

straightforward connection to computers or PLCs. Optional industrial standard communication

interfaces (PROFIBUS, PROFIBNET, EtherNet/IP or WiFi) can be specified for installation at time of

manufacture.

Analogue and pulsed line speed inputs are fitted as standard to provide line speed data to the gauge

for optional PI feedback control and SMFD (Single Measurement Flaw Detection).

User configurable logic inputs are provided as standard to reset gauge measurements and trigger

printing. User configurable relay outputs are provided as standard to signal gauge status, lump and

neck detection and measurements exceeding preset error limits.

Page 7 of 68

Proton Products InteliSENS PD30 Instruction Manual (Issue 1a)

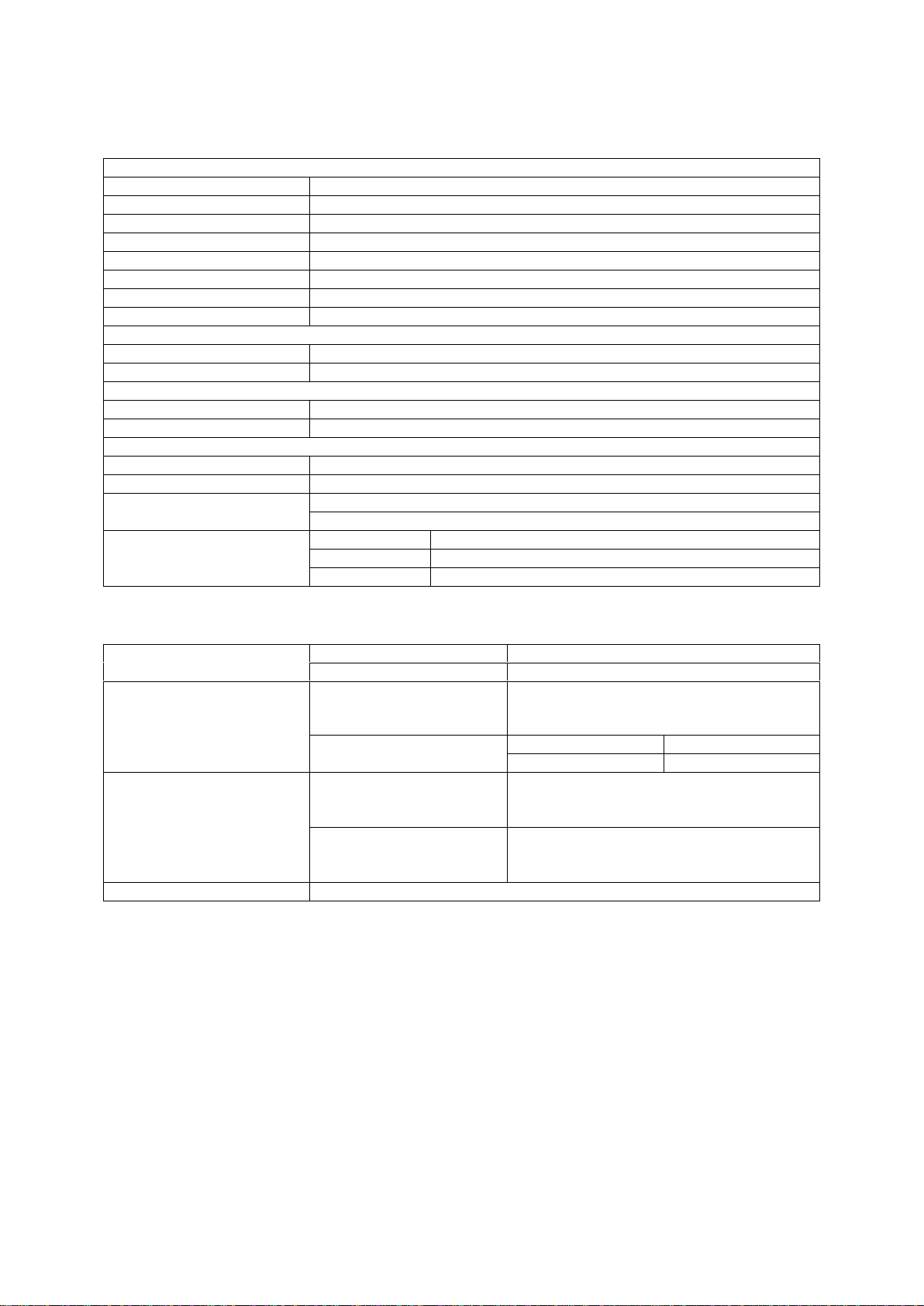

SPECIFICATIONS

PD30 specifications

Number of axes

1

Scan rate

600 scan/s/axis

Cumulative scan rate

600 scan/s

Update time

1.667ms

Object diameter

0.1~27 mm

Optical gate diameter

30 mm

Accuracy

±(1μm + 0.008% of object diameter) μm

Output resolution

1 μm

Operating temperature

5 ~ 45°C

Environmental protection

IP65

DC Power supply voltage

18~30VDC

DC Power consumption

30W

Light source

Laser (class 2)

Air wipe

Integrated air wipe system

Measurement units

(user configurable)

millimetres (line speed: millimetres / minute, length: metres)

inches (line speed: feet / minute, length: feet)

Measurement modes

Solid

Solid object diameter

Glass

Transparent object diameter

Helix

Twisted / braided multi-core cable envelope diameter

STANDARD INTERFACES

2x digital inputs

User configurable function

Reset, Print Activation

Maximum input voltage

24 Vdc

4x relay outputs

User configurable function

Gauge OK, Upper tolerances exceeded,

Lower tolerances exceeded, Single

Measurement Flaw Detection (SMFD)

Isolated contact rating

Maximum voltage

24 Vdc

Maximum current

1 A

Line speed inputs

Analogue input

0 - 10 Vdc, user scalable (only when PID

function is available).

Speed pulse input

250 kHz max frequency, 30 V or 50 V max

pulses (on two distinct inputs), user

scalable

Communication interfaces

RS-232*, RS-422, RS-485, CAN-bus**, Ethernet

*An optional RS-232-to-USB converter cable is available for connection to USB equipped computers.

**CAN-bus protocol is proprietary and reserved for connection to other Proton Products equipment

such as a CDI4 interface display unit.

Page 8 of 68

Proton Products InteliSENS PD30 Instruction Manual (Issue 1a)

OPTIONAL INTERFACES

3x Analogue outputs

±10 Vdc output of diameters or errors, user scalable

Communication interfaces

WiFi*

PROFIBUS, PROFINET or EtherNet/IP.

OPTIONAL FUNCTIONALITY

PI feedback controller

Proportional Integral feedback controller

Statistics

Maximum, minimum, mean, standard deviation, Cp, Cpk

SPC

Statistical Process Control automatic set point for PI feedback

controller (requires PI feedback controller option)

FFT

Fast Fourier Transform analysis for amplitude and frequency of

periodic diameter variations

SMFD

Single Measurement Flaw Detection (Lump and Neck detection)

Page 9 of 68

Proton Products InteliSENS PD30 Instruction Manual (Issue 1a)

DIMENSIONAL DRAWINGS

Page 10 of 68

Proton Products InteliSENS PD30 Instruction Manual (Issue 1a)

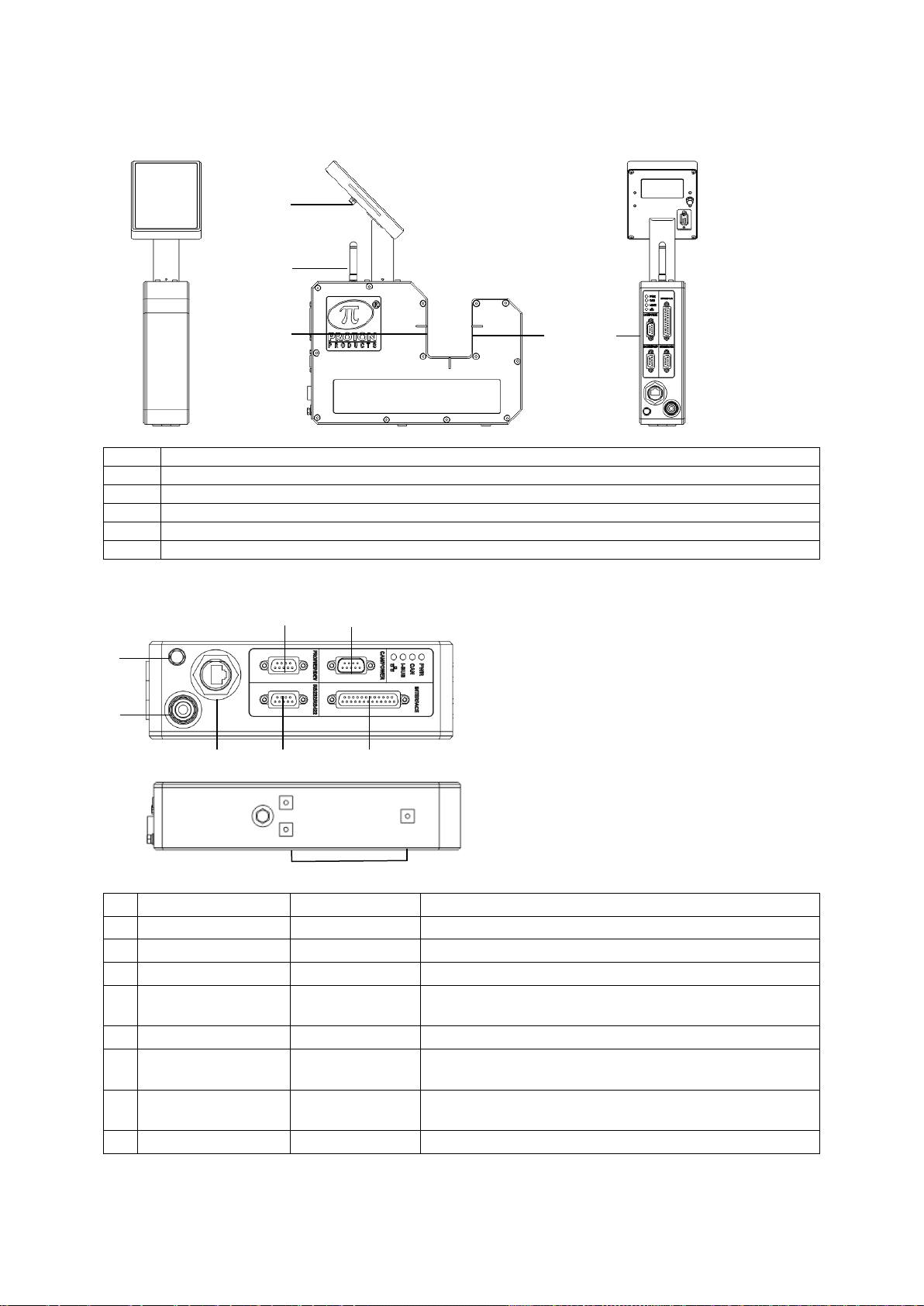

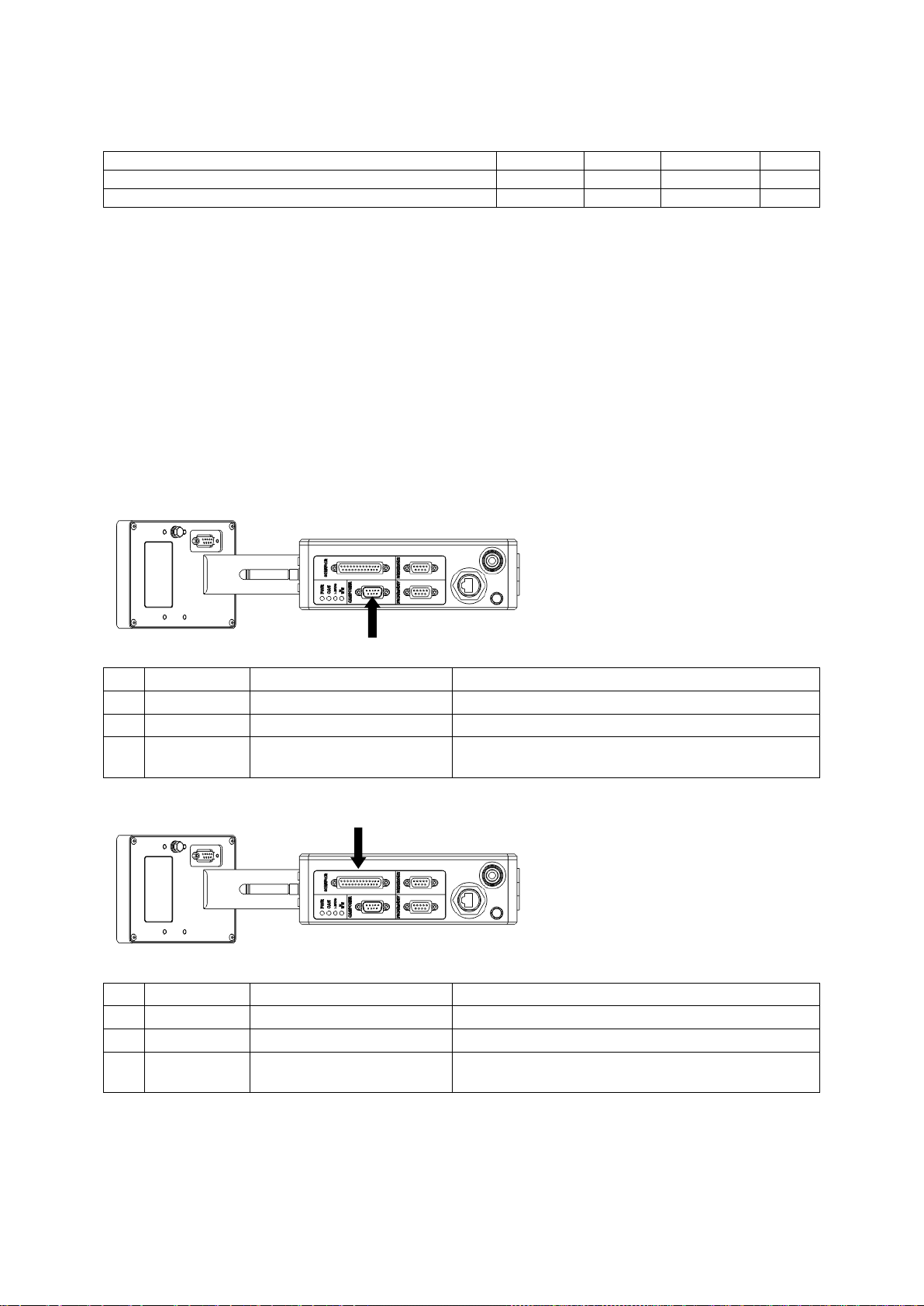

ANNOTATED DRAWINGS

Label

Description

1

Optional CDI4 interface display unit.

2

WiFi antenna

3

X-axis detector window.

4

X-axis light source window.

5

Connector panel.

CONNECTORS

Designation

Connector type

Description

1

Air wipe air inlet

6mm push-fit

Air wipe air inlet for optical windows

2

Earth bolt

M5 bolt

Earth point for the gauge enclosure

3

Ethernet

RJ45 socket

Ethernet communications interface

4

PROFI / EIP / DEV

DB9 female

Optional PROFIBUS, EtherNet/IP, PROFINET

communications interfaces

5

RS232 / 485

DB9 female

RS-232, RS-422/485 communications interface.

6

CAN / POWER

DB9 male

CAN-bus communications interface and DC power

input

7

INTERFACE

DB25 female

Logic and speed pulse inputs, relay outputs, optional

analogue input, optional PI feedback controller I/O

8

Mounting holes

M5 x 10 mm

Securely mount the gauge before operation.

3

2

4

5

1

2

3

4

5

6

7

8

1

Page 11 of 68

Proton Products InteliSENS PD30 Instruction Manual (Issue 1a)

OPTIONAL ACCESSORIES

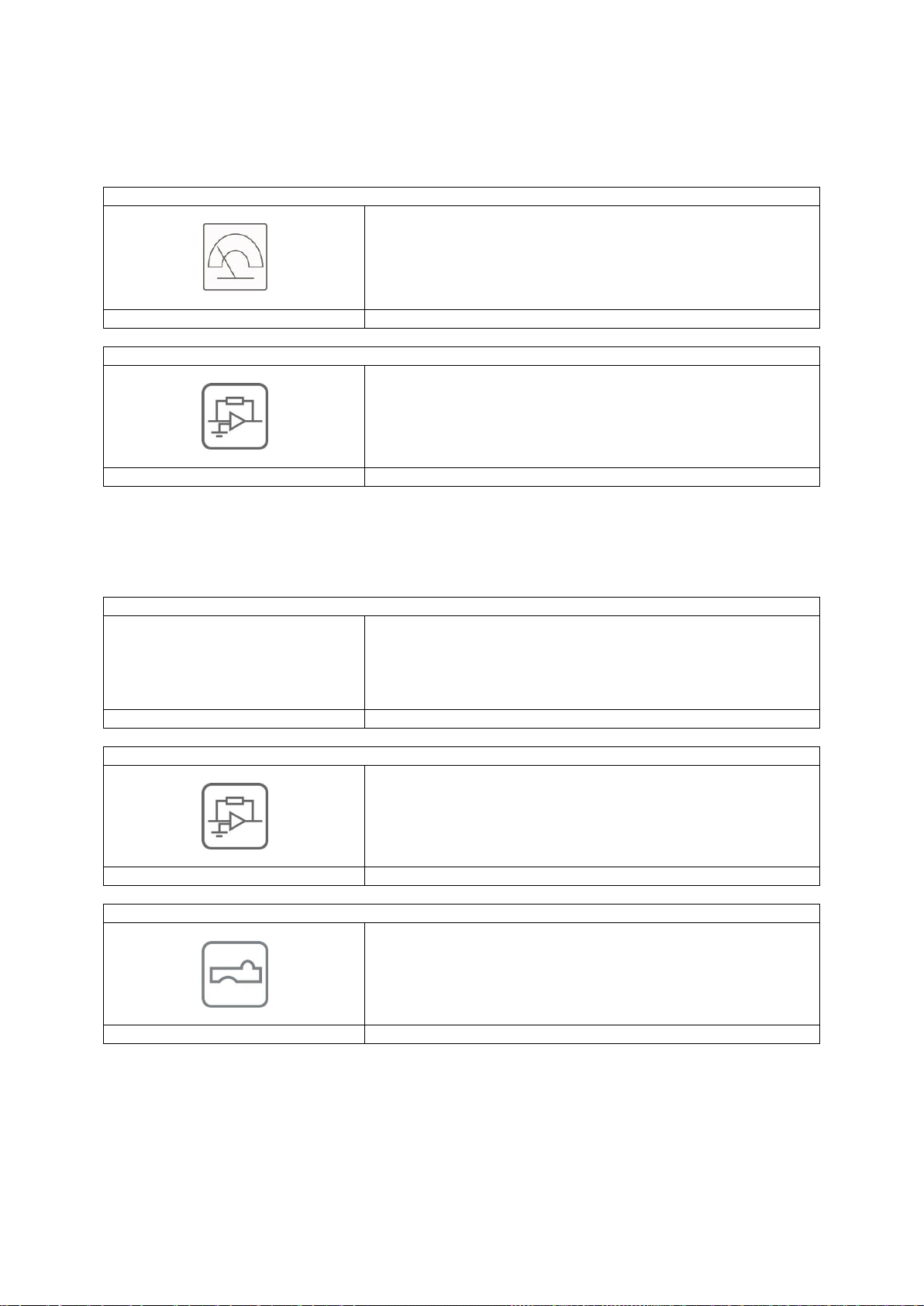

OPTIONAL INTERFACES

The WiFi wireless interfaces may be specified for installation at time of order placement; cannot be

field-retrofitted.

WiFi wireless interface

For wireless configuration and monitoring of the gauge from

smart phones, tablet and laptop PCs.

Proton part number

00054MC067

Industrial bus interfaces

Only one of the following 3 industrial bus interfaces may be specified for installation at time of order

placement; cannot be field-retrofitted.

PROFIBUS interface

For connection to PLCs and other process control

instrumentation via an industry-standard PROFIBUS

network.

Proton part number

00054MC062

PROFINET interface

For connection to PLCs and other process control

instrumentation via an industry-standard PROFINET

network.

Proton part number

00054MC063

EtherNet/IP interface

For connection to PLCs and other process control

instrumentation via an industry-standard EtherNet/IP

network.

Proton part number

00054MC064

RJ45 to DB9 converter

For connecting a RJ45 8P8C terminated network cable to

the DB9 industrial bus port.

Comes as a pair for connecting to either type A or type B

terminated network cables.

Proton part number

00041MC048

Page 12 of 68

Proton Products InteliSENS PD30 Instruction Manual (Issue 1a)

Electrical interfaces

Must be specified for factory installation at time of ordering; cannot be field-retrofitted.

Analogue outputs

3x analogue (±10V) outputs.

Independently programmable functions for X, Y, Z

(DG3030/3060 only) diameters, average diameter, diameter

errors from preset value, ovality and ovality error.

Proton part number

00047MC062

Proportional Integral (PI) feedback controller

PI feedback diameter control via adjustment of insulation

extruders or capstan drives.

Isolated ±20V analogue input and ±10V analogue output for

connection to insulation extruders or capstan drives.

Proton part number

00047MC061

OPTIONAL FIRMWARE

Optional firmware may be end-user enabled through the purchase of a license key. Some optional

firmware functions are dependent on the presence of optional interfaces.

Fast Fourier Transform (FFT) Analysis

FFT

Calculates FFT frequency spectra of measured diameters.

Identifies periodically occurring diameter fluctuations caused

by production line problems.

Essential for telecommunications cable lines where periodic

diameter fluctuations can degrade cable bandwidth.

Proton part number

00054SW013

Statistical Process Control (SPC) automatic set point control

Minimises insulation material consumption whilst holding the

insulation diameter in tolerance.

Requires the PI feedback controller interface option

(00047MC061) to be installed.

Proton part number

00054SW011

Single Measurement Flaw Detection (SMFD)

High-speed lump and neck flaw detection.

Proton part number

00054SW014

Page 13 of 68

Proton Products InteliSENS PD30 Instruction Manual (Issue 1a)

PCIS_DG

PC Interface Software

PC-based software package.

User-friendly graphical user interface.

Displays all measurements.

Provides menu-based setting of all parameters.

Provides data logging, presets and alarms.

Connection via RS-232, Ethernet or EtherNet/IP.

Proton part number

00054SW015

Page 14 of 68

Proton Products InteliSENS PD30 Instruction Manual (Issue 1a)

INTERFACE DISPLAY MODULES

SiDi-CDi4

Touch screen display module

Touch screen display.

Connects via the CAN-bus port.

Displays measured speed and length.

Provides menu-based setting of all parameters.

Mounts directly on the gauge body or remotely via an

extension cable.

Proton part number

00049MC023

POWER SUPPLIES AND CONNECTIVITY

PSU-BOB-DG

Power supply and break-out box

Connects via the DB25 “INTERFACE” connector.

Supplies 24VDC electrical power to the gauge.

Provides screw terminal access to all “INTERFACE”

connector input and output pins.

End user cables are sealed with three cable glands.

Input voltage range: 90 –260 VAC @ 45 –65 Hz.

Select the required length of DB25 cable from below.

Proton part number

00047MC660

Terminal Strip-DIN

Breaks out the DB25 “INTERFACE” connector to a DIN

rail mountable set of screw terminals.

Select the required length of DB25 cable from below.

Proton part number

00041MC730

DB25 “INTERFACE” port to PSU-BOB-DG, Terminal Strip-DIN cable

Length / m

Proton part number

3

00041CT003

5

00041CT005

10

00041CT010

20

00041CT020

30

00041CT030

Page 15 of 68

Proton Products InteliSENS PD30 Instruction Manual (Issue 1a)

INSTALLATION

PRECAUTIONS

Operating temperature

Specification

Minimum

Typical

Maximum

Units

Operating temperature

+5

+45

°C

Do not operate the gauge in temperatures outside of the specified range.

Do not install the gauge near high temperature surfaces or objects which may cause it to

overheat.

Operation of the gauge outside the specified temperature range may result in degraded

measurement accuracy, malfunction or damage to the gauge.

Protect from impact

The gauge contains delicate optical and electronic assemblies and must never be dropped or

struck by other objects.

The gauge must be securely mounted by its base to prevent toppling.

Measured objects threaded through the optical gate cavity must be secured against contact

with the optical windows or catching upon the gauge body. For cable production line

applications, Proton Products can supply optional adjustable cable guides for securing the

passage of a cable through the optical gate cavity.

Do not open or disassemble

The gauge contains no user serviceable components.

Loosening the gauge screws or removing its cover will invalidate the product warranty.

Periodic maintenance

The physical condition of the gauge, optional CDI4 interface display unit and connecting

cables should be checked periodically; if any damage is suspected, then the unit should be

taken out of service for inspection and repair or replacement of damaged parts.

Optical windows

Do not allow smoke, water, steam, dust or other debris to come into contact with any of the

optical windows.

Obstruction of the optical windows may degrade measurement accuracy or inhibit

measurement.

If any optical window appears to be damaged or misaligned, then the unit should be taken out

of service for repair.

If any optical window requires cleaning, then refer to the cleaning procedure detailed in this

manual to minimise the risk of scratching the windows.

Page 16 of 68

Proton Products InteliSENS PD30 Instruction Manual (Issue 1a)

OPTICAL WINDOW CLEANING PROCEDURE

The optical windows are manufactured from anti-reflection coated optical glass; they must be

treated with the same level of care as a high-performance camera lens.

Before inspecting or cleaning the optical windows, ensure that the gauge is powered

off and no light is emitted.

Required items

Notes

Small blower brush

Such as the type used to remove dust from camera lenses.

Lens cleaning tissues or

micro-fibre lens cleaning cloth

Do NOT use facial tissues as these can scratch delicate optics.

Lens cleaning solution

Such as the type specified for cleaning camera lenses.

1. Use the small blower brush to remove any visible dust on the optical window.

2. Apply a few drops of lens cleaning solution to a fresh lens cleaning tissue or a clean micro-

fibre lens cleaning cloth.

3. Gently wipe the optical window from the centre outwards; apply only light pressure to the

tissue or cloth when wiping the optical window.

4. Repeat as necessary with fresh tissues or a clean section of cloth until the optical window is

clean and free of all smears and smudges.

INSTALLATION SEQUENCE

Unpack the gauge and check for missing accessories and shipping damage.

Mechanical installation:

1. Mount the gauge securely on a user supplied platform using the four mounting brackets.

Electrical installation:

1. Install earth connections.

2. Install optional CDI4 interface display unit.

3. Depending on the model, install either an AC power cable or DC power supply (such as an

optional Proton Products PSU-UNI, PSU-BOB or PSU-CAN power supply).

4. Install interface connections (RS-232, RS-422/485, Ethernet or optional PROFIBUS,

EtherNet/IP or WiFi antenna).

5. Install speed input (analogue or pulse).

6. Install optional electrical interfaces (Logic inputs, Relay outputs, Analogue outputs, PI

feedback controller connections) using the optional Proton Products PSU-BOB breakout box

or terminal strip.

7. Configure the gauge either via an optional CDI4 interface display unit or any of the above

interfaces.

Page 17 of 68

Proton Products InteliSENS PD30 Instruction Manual (Issue 1a)

MECHANICAL INSTALLATION

GAUGE HEAD DIMENSIONS:PD30

INSTALLATION NOTES:

Do not open the gauge or loosen the cover screws.

Do not overtighten the fixing screws.

Do not use fixing screws that are too short or long. The correct screws [M5 by 16] are supplied

with the gauge head for mounting it to the HST3 height stand which has a thickness of 8mm. If a

stand of different thickness is used then the screw length supplied may not be suitable.

Do not place in a position close to a hot surface.

Do not allow the cable being measured to touch the gauge head.

If a large cable is being measured then ensure that it is supported so that the cable end does not

catch on the gauge.

Ensure that the cable alignment is perpendicular to the face of the gauge with the least error

practically possible, an angle error of one degree gives a measurement error of 0.013%, at two

degrees this becomes 0.05%.

ELECTRICAL INSTALLATION

Earth connection

Connector type: M5 bolt

An earth wire of at least 6mm2must be attached via a crimp on ring terminal to the dedicated

M5 earth bolt on the case of the gauge.

Do not rely on the mounting bolts to provide a reliable earth path.

If a height stand is used then it must also be earthed via its own dedicated earth wire.

All earth wires should be kept as short as practical.

Shielded Cables

Use shielded cable for all signal connections.

Ensure that all cable shields are correctly clamped and electrically connected to their

connectors and metal connector shells at both ends.

Page 18 of 68

Proton Products InteliSENS PD30 Instruction Manual (Issue 1a)

Ensure that the shields of cables connecting to the end user’s equipment are clamped to

earth at their destination.

Optional CDI4 interface display unit installation

The CDI4 interface display unit is a recommended optional accessory with the following features:

Menu based user interface for configuring the gauge and displaying measurements and error

messages.

Two versions of the CDI4 interface display are available: one version that mounts directly on

the gauge body and one version that can be connected remotely via a CAN-bus extension

cable.

The remote CDI4 interface display unit can also power DC powered gauges through a CAN-

bus port connected power supply.

Installing a CDI4 display unit to PD30 gauge head:

1

Unscrew the four screws and remove the CDI4

port blanking plate.

Store the blanking plate and four countersunk

screws for future use.

2

Align the CDI4 connector mating key with

the port socket and insert.

Secure the CDI4 unit with four spring

washers and M4 cap head screws.

Installing a remote CDI4 interface display unit:

1. Connect the remote CDI4 interface display unit to the CAN/POWER connector using a CAN-

bus extension cable.

2. Connect an optional PSU-CAN mains power supply unit to the second CAN-bus port on the

remote CDI4 interface display unit.

Page 19 of 68

Proton Products InteliSENS PD30 Instruction Manual (Issue 1a)

DC Power supply

Specification

Minimum

Typical

Maximum

Units

Power supply voltage*

15

24

30

VDC

Power consumption (with optional CDI4 display unit)

30

W

*If a long power supply cable with a significant voltage drop is used, then ensure that the voltage at

the gauge connector does not fall below the minimum value.

Power may be supplied to the gauge via the following optional accessories:

Remote CDI4 interface display unit connected to the “CAN / POWER” connector.

PSU-CAN Power supply unit connected to the “CAN / POWER” connector.

PSU-UNI Power supply unit connected to the “INTERFACE” connector.

PSU-BOB Power supply unit and break out box connected to the “INTERFACE” connector.

Alternatively, power may be directly supplied to the gauge via either of the following connectors:

“CAN / POWER” connector.

“INTERFACE” connector.

“CAN / POWER” Connector

Connector type: DB9 male (plug)

Pin

Designation

Description

Notes

3

REG.GND

Power supply ground (0 V)

9

+24V

+24 V power supply

S

Shield

Ensure that the cable shield is connected to this

via the plug shield connection.

“INTERFACE” Connector

Connector type: DB25 female (socket)

Pin

Designation

Description

Notes

24

REG.GND

Power supply ground (0 V)

25

+24V

+24 V power supply

S

Shield

Ensure that the cable shield is connected to this

via the plug shield connection.

Powering on the gauge

The gauge has no power switch; as soon as power is applied it will power up, perform self tests and

then commence measurement.

Page 20 of 68

Proton Products InteliSENS PD30 Instruction Manual (Issue 1a)

Power indications

PWR

LED status

Indication

Continuous red

Gauge is powered on

Power

Extinguished

Gauge is powered off

If an optional CDI4 interface display is attached to the gauge, then correct power up is indicated by

the display of the welcome screen followed by the home page.

Powering off the gauge

The gauge has no power switch; it may be powered off by switching off or disconnecting the power

supply to the unit.

CONFIGURATION VIA CDI4

Power on screen

When the gauge is powered on, the Proton welcome

screen will be displayed momentarily.

Table of contents

Other Proton Laundry Accessories manuals