Proton HOGEN GC4800 Maintenance and service guide

PD-0100-0063 Rev A CONFIDENTIAL –Do not copy Page 1 of 11

HOGEN®GC4800

External Desiccant Dryer Accessory

Installation / Maintenance

Manual

GC 4800 Desiccant Holder

Installation and Maintenance Manual

PD-0100-0063 Rev A CONFIDENTIAL –Do not copy Page 2 of 11

SIC 3569-901 Gas Generating Equipment

NAICS 333-999-8556 Gas Generating Equipment

November 2011

Proton OnSite

10 Technology Drive

Wallingford, CT 06492

Phone 203.949.8697 • Fax 203.949.8016

www.protononsite.com

© 2011 Proton Energy Systems, Inc. d/b/a Proton OnSite

All rights not expressly granted herein are reserved.

Information in this document is provided in connection with Proton Energy Systems Inc. d/b/a Proton OnSite

(“Proton”) products and services. No license, express or implied, by estoppel or otherwise, to any intellectual property

rights is granted by this document. Except as provided in Proton Terms and Conditions of Sale for such products and

services, Proton assumes no liability whatsoever, and Proton disclaims any express or implied warranty, whether

written or oral, relating to sale and/or use of Proton products or services including liability or warranties relating to

fitness for a particular purpose, merchantability, or infringement of any patent, copyright or other intellectual property

right. Proton products are not intended for use in medical, life saving, or life sustaining applications.

Proton may make changes to specifications and product descriptions at any time, without notice.

This document as well as any software, processes or procedures described in it is furnished under license and may

only be used or copied in accordance with the terms of the license. The information in this document is furnished for

informational use only, is subject to change without notice, and should not be construed as a commitment by Proton.

Proton assumes no responsibility or liability for any errors or inaccuracies that may appear in this document or any

software that may be provided in association with this document.

Except as permitted by such license, no part of this document may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means without the express written consent of Proton.

®

Proton

,

Proton OnSite

,

Proton Energy Systems

, the Proton design,

StableFlow

,

StableFlow Hydrogen Control

System

and design,

HOGEN,

and

FuelGen

are trademarks of Proton Energy Systems, Inc.

Any other brands and/or names used herein are the property of their respective owners.

GC 4800 Desiccant Holder

Installation and Maintenance Manual

PD-0100-0063 Rev A CONFIDENTIAL –Do not copy Page 3 of 11

Key definitions, acronyms, and abbreviations that may be used in this

document

µS/cm –MicroSiemen per centimeter, a measure of water conductivity

Bar –14.5 PSI or 100 KPa (KiloPascals or Newton/cm), a unit of system pressure. All pressures are at gauge

pressure unless otherwise specified.

cc –Cubic centimeter

CPI –Chemical Process Instrumentation

FPT –Female Pipe Thread

FuelGen® - Registered TM of Proton Energy Systems, Inc. for hydrogen systems, comprised of a hydrogen

generator, hydrogen storage container, hydrogen dispensers and parts and accessories

HCS –H Series Control System

HGMS –Hydrogen Gas Management Subsystem

HOGEN® - Registered TM of Proton Energy Systems Inc. for packaged water electrolysis based hydrogen

generators

kVA –Kilovolt -ampere

kW –Kilowatt

L/m –Liters per minute flow (for hydrogen, calculated at a standardized temperature & pressure)

LAN –Local Area Network

LFL –Lower Flammability Limit

NEC –National Electric Code, NFPA 70

NFPA –National Fire Protection Association, a Standards Organization

Nm3/h –Normal cubic meter per hour (International Normal conditions are 1.01325 bar and 0 Celsius)

NPT –National Pipe Thread

NRTL –Nationally Recognized Testing Laboratory

P&ID –Piping and Instrumentation Diagram (Fluid Schematic)

PEM - Proton Exchange Membrane

PPE –Personal Protective Equipment

PPM –Parts per Million

PSI –Pounds force per square inch (lbf /in2=6894.7 Pa), a unit of pressure. All pressures are at gauge pressure

unless otherwise specified.

SCFH –Standard cubic foot per hour (US Standard conditions for air are 1 atmosphere and 70°F)

Standard atmosphere = 1.01325 bara = 14.696 psia

TCU –Thermal Control Unit

TVSS –Transient Voltage Surge Suppressor

VAC –Volts Alternating Current

VDC –Volts Direct Current

WOMS –Water/Oxygen Management Subsystem

- Notes contain helpful suggestions or references.

- Indicates a potentially hazardous situation, which, if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe practices. This could result in equipment damage or

loss of data.

- Indicates a potentially hazardous situation, which, if not avoided, could result in death or serious injury.

The reader is in a situation that could cause bodily injury.

GC 4800 Desiccant Holder

Installation and Maintenance Manual

PD-0100-0063 Rev A CONFIDENTIAL –Do not copy Page 4 of 11

1INTRODUCTION

The purpose of this manual is to provide an overview of the installation and maintenance of the

external desiccant dryer that accompanied your hydrogen generator. This manual is meant to

supplement the Installation and Operation Manual that was included with the hydrogen

generator.

IT IS THE CUSTOMER’S RESPONSIBILITY TO CONSULT WITH THE

LOCAL AUTHORITY HAVING JURISDICTION (AHJ) REGARDING LOCAL

CODE REQUIREMENTS FOR INSTALLATION AND OPERATION OF THIS

EQUIPMENT.

DO NOT USE THIS EQUIPMENT IN A MANNER NOT SPECIFIED BY

PROTON.

Figure 1 - TBD

This manual attempts to answer most of the frequently asked questions regarding the operation

of the unit. PROTON technical staff is also available to answer questions and support the

successful deployment of this equipment. Please call (203) 949-8697 and ask for technical

and serial number of your unit available.

PROTON offers a full range of installation and training services. Contact PROTON

Customer Service at 203.949.8697 or your local service provider/supplier for more

information.

It is the customer’s responsibility to organize a backup hydrogen supply to bridge critical

times during maintenance and service.

GC 4800 Desiccant Holder

Installation and Maintenance Manual

PD-0100-0063 Rev A CONFIDENTIAL –Do not copy Page 5 of 11

2GENERAL DESCRIPTION

The desiccant dryer is the second component that comprises the GC4800 hydrogen

generator system. The purpose of the dryer is to receive the product gas from hydrogen

generator, pass it through a desiccant column, further reducing the moisture content of

the product gas stream to less than one ppmv water content. The hydrogen generator

portion of the GC4800 is capable of producing gas of this quality, but may produce

output with as much as five ppmv moisture content.

The desiccant cartridge holder is only to be supplied hydrogen from a HOGEN

hydrogen generator. Any other use is prohibited.

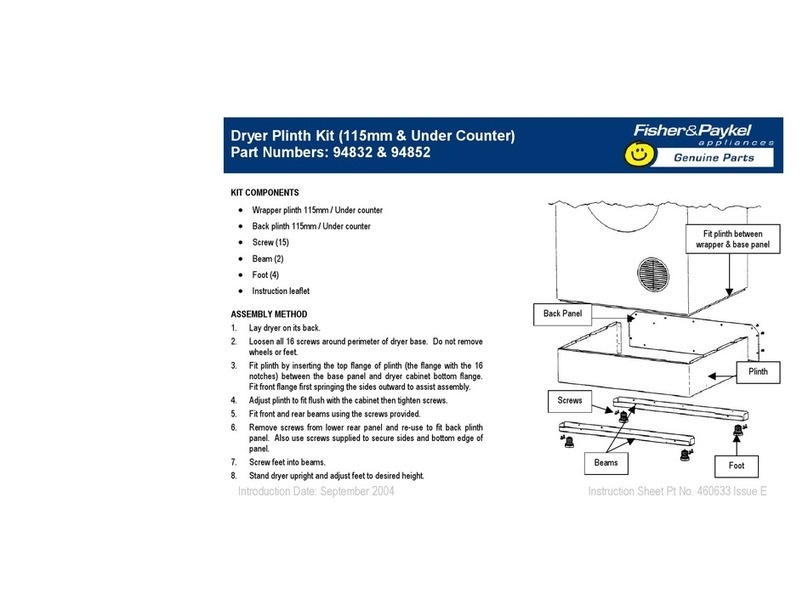

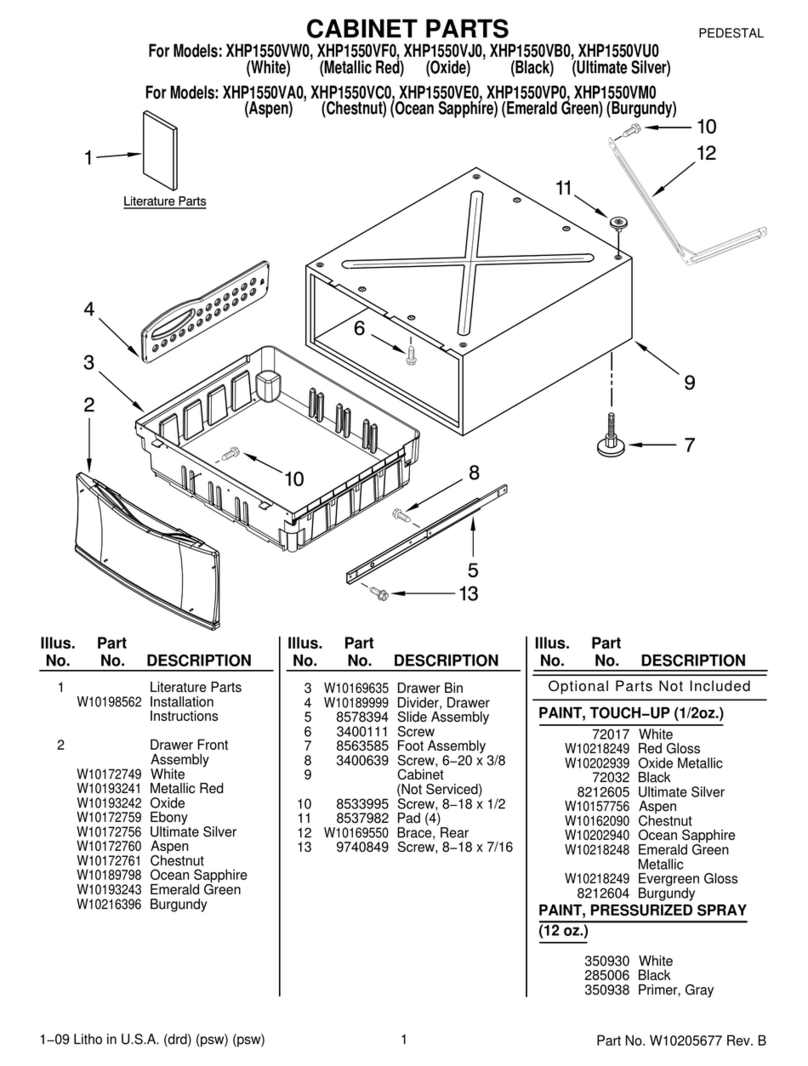

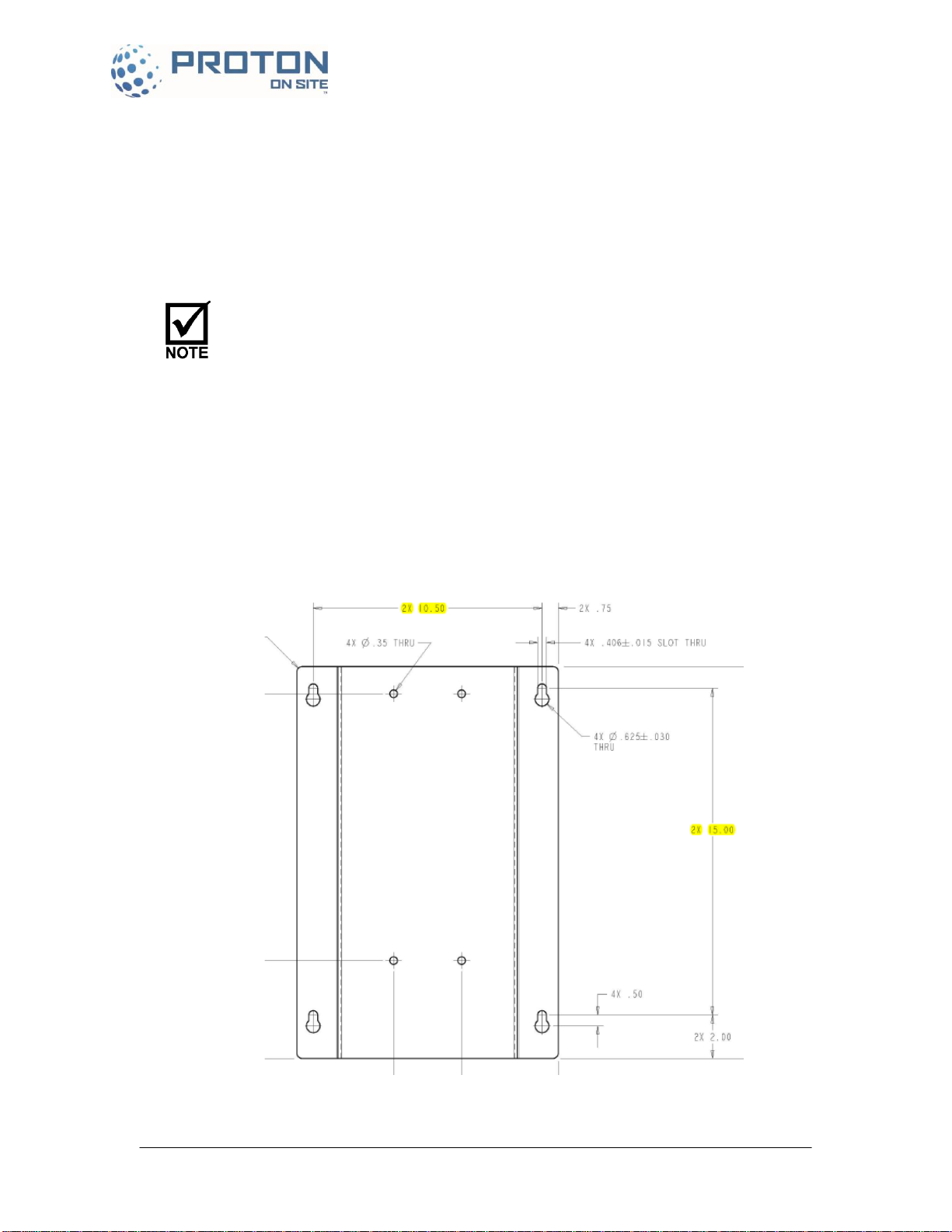

3INSTALLATION OF DESICCANT HOLDER ASSEMBLY

The desiccant cartridge assembly should be securely mounted to a wall or structure

capable of supporting the weight of the assembly, 35 lbs (15.9 kg). The unit should be

located in close proximity, within 10 feet (3 meters), to the hydrogen generator and

within a space that has the same ventilation requirements outlined in the Installation and

Operation Manual for the hydrogen generator. The desiccant cartridge assembly shall not

be directly mounted to the hydrogen generator. The mounting pattern for the mounting

Panel is shown in the following Figure 2.

Figure 2 Mounting Panel Layout

GC 4800 Desiccant Holder

Installation and Maintenance Manual

PD-0100-0063 Rev A CONFIDENTIAL –Do not copy Page 6 of 11

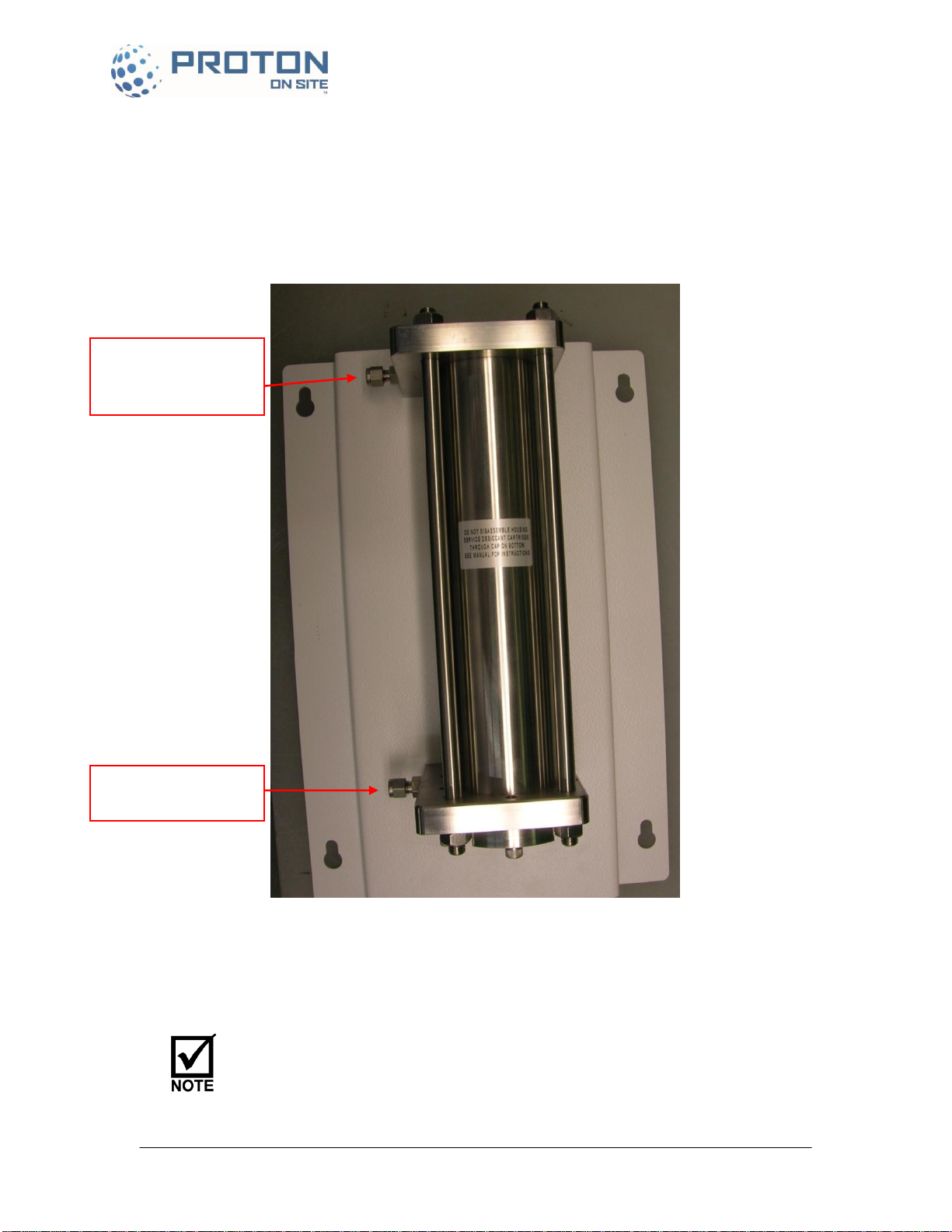

3.1 Hydrogen Gas Connections

On the Desiccant cartridge holder, there are two ¼” compression fittings. The fitting on

the lower block is the inlet and receives gas from the hydrogen generator. The fitting on

the top block is the product out and is to be connected to the process or hydrogen

distribution system, see Figure 3.

Figure 3 Desiccant Holder Connections

If the GC4800 system is to be used in conjunction with a crossover manifold or any sort

of back-up supply for uninterrupted gas flow, a ASME stamped pressure relief valve set

to no greater than 275 psig must be installed in the line and properly vented to protect

against an over pressurization of the desiccant cartridge holder.

The HOGEN hydrogen generator has its own integrated ASME stamped pressure

relief device installed.

Outlet, ¼”

Swagelok

Compression

Inlet, ¼” Swagelok

Compression

GC 4800 Desiccant Holder

Installation and Maintenance Manual

PD-0100-0063 Rev A CONFIDENTIAL –Do not copy Page 7 of 11

3.2 Desiccant Cartridge Installation

DO NOT DISSASSEMBLE THE HOLDER ASSEMBLY. DO NOT

LOOSEN THE NUTS SECURING THE TIE RODS. SERVICE

DESICCANT CARTRIDGE BY REMOVING THE APPROPRIATE

FASTENERS OUTLINED IN THIS SECTION.

1. The service cap is located n the bottom of the desiccant holder. The cap is

secured in place with 6 screws, Figure 4. Using a ¼” hex drive. Remove the six

(6) screws.

Figure 4 Cartridge Holder Bottom with Serviceable Screws

2. With the cap removed, prepare the desiccant cartridge, Part Number: 02-3001-

0040, for installation by removing the peel back lids on both ends of the cartridge,

Figure 5. Do not remove the ends from the cartridge until it is ready to be used

within the desiccant holder.

Remove Only

These Screws

GC 4800 Desiccant Holder

Installation and Maintenance Manual

PD-0100-0063 Rev A CONFIDENTIAL –Do not copy Page 8 of 11

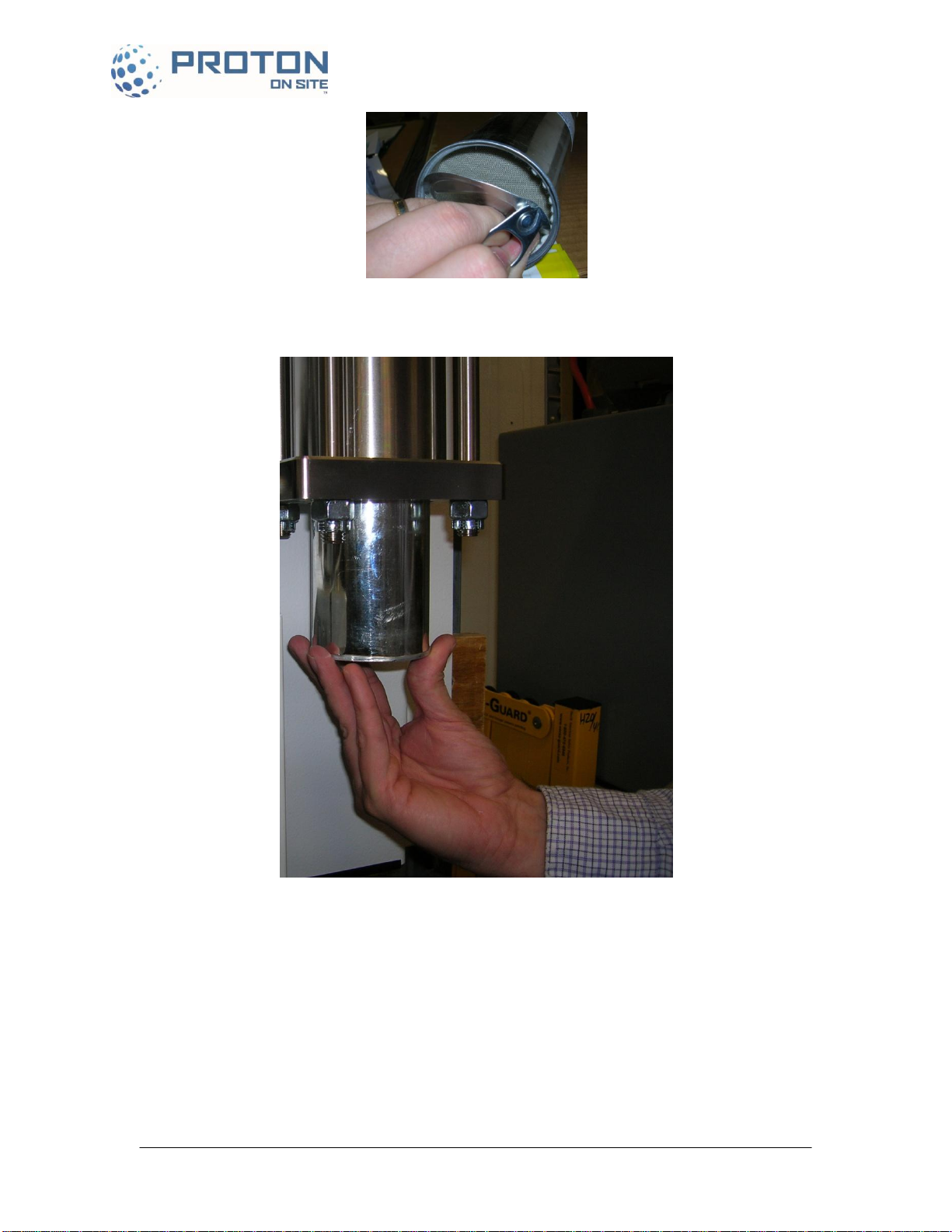

Figure 5 Removal of Cartridge Seal Prior to Installation

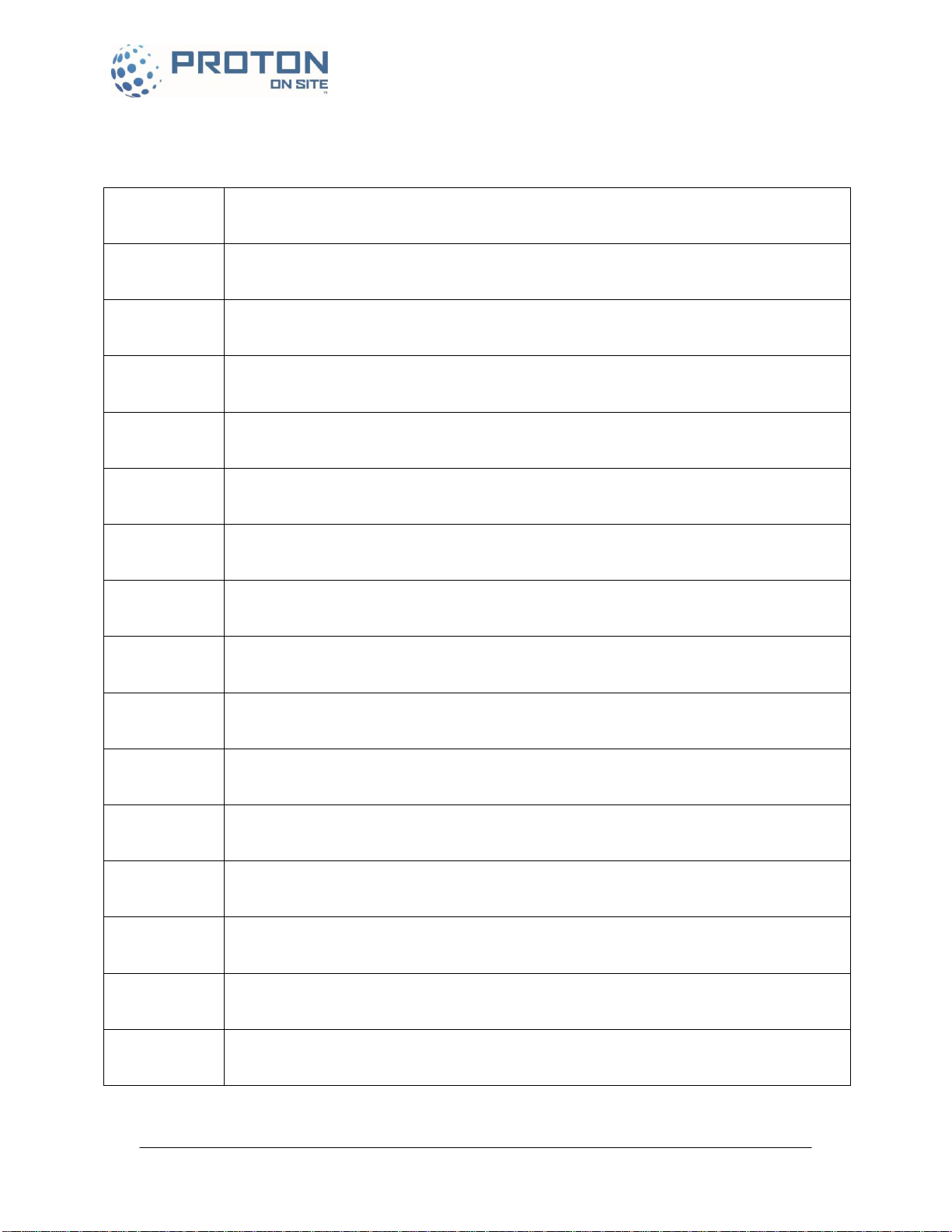

3. Slide the desiccant cartridge up into the desiccant holder assembly, Figure 6.

Figure 6 Installation of Desiccant Cartridge

4. Push the cartridge all the way up into the holder as far as it will go.

5. Install the desiccant cartridge support ring with the spring and bottom cap as

shown in Figure 7.

GC 4800 Desiccant Holder

Installation and Maintenance Manual

PD-0100-0063 Rev A CONFIDENTIAL –Do not copy Page 9 of 11

Figure 7 Installation of Support Ring, Spring and Cap

6. While holding the cap install the six (6) hex head screws finger tight, Figure 8.

Figure 8 Installation of Socket Head cap Screws

7. Using a ¼” hex drive, tighten the six screws up to 1 full turn or until tightened.

8. The unit is now ready to be used.

Cartridge Support Ring

O-Ring

Spring

Cap

GC 4800 Desiccant Holder

Installation and Maintenance Manual

PD-0100-0063 Rev A CONFIDENTIAL –Do not copy Page 10 of 11

4MAINTENANCE

When connected to a GC4800 hydrogen generator under normal operating conditions, the

operational life of the desiccant cartridge should be one year if handled as described in this

manual. However, the desiccant cartridge should be changed out if there is any reason to

suspect that the cartridge is no longer removing moisture to adequate levels regardless of the

operational duration.

Replacement desiccant cartridges can be purchased by contacting Proton OnSite Customer

Service and ordering Part Number 02-3001-0040.

Please follow the instructions outlined in Section 3.1 of this manual for changing the desiccant

cartridge.

GC 4800 Desiccant Holder

Installation and Maintenance Manual

PD-0100-0063 Rev A CONFIDENTIAL –Do not copy Page 11 of 11

NOTES

Table of contents

Other Proton Laundry Accessories manuals