Provia ASPECT User manual

INSTALLATION INSTRUCTIONS

3-LITE VINYL PATIO DOOR

END ACTIVE, UNASSEMBLED

(ASPECT™ AND ENDURE™)

Contact the local recycling waste management center for waste disposal in the area. Always

check local waste requirements and carefully dispose of waste in accordance with Federal

and other regulations.

Homes built before 1978 may contain lead paint. All replacement installations must comply

with the U.S. EPA’s Lead-Based Paint Renovation, Repair, and Painting Program (RRP Rule).

Read more about the RRP Rule and lead-safe work practices, on the U.S. EPA’s website at:

www.epa.gov/lead

* Find QR Codes inside for additional information,

helpful installation tips, and videos.

ATTENTION!

YOU CAN ALSO SCAN

THE PACKAGING QR CODE

TO ACCESS THIS DOCUMENT

Printed instructions included

with each product will be

phased out in the

near future

1

• Tape Measure

• Pencil

• Shims

• Drill & Drill Bits

• Utility Knife

• Hammer or Mallet

• Flat-Head Screwdriver

• Phillips Screwdriver

• Level

• High Quality Silicone Caulking in accordance with

ASTM C 920, Class 25 & Caulking Gun.

•AAMA approved Low-Expanding Window Insulation

Foam in accordance with ASTM C, 1620.

•6" or 9" Adhesive Flashing Tape in accordance with

ASTM D-779 (new construction application)

GETTING STARTED

TOOLS & MATERIALS YOU WILL NEED

REMEMBER: ALWAYS USE THE APPROPRIATE PERSONAL PROTECTIVE EQUIPMENT.

Read these instructions carefully before starting installation. Product warranty does not cover damages

resulting from improper installation.

IMPORTANT NOTES BEFORE YOU BEGIN

• Inspect your package for any visible damages to the product. In addition, double check your paperwork

with label on product(s) and verify all information is a match. Open packaging to confirm style, color, handing

and that order was shipped complete. Double check size of new unit by comparing it for fit to opening. If

damages or irregularities are found, please document with pictures and call Customer Service, 1-800-669-4711.

• If you have ordered optional items, verify that they are included in packaging contents. This includes checking

for multiple packages (For example, 1 of 2 and 2 of 2).

2

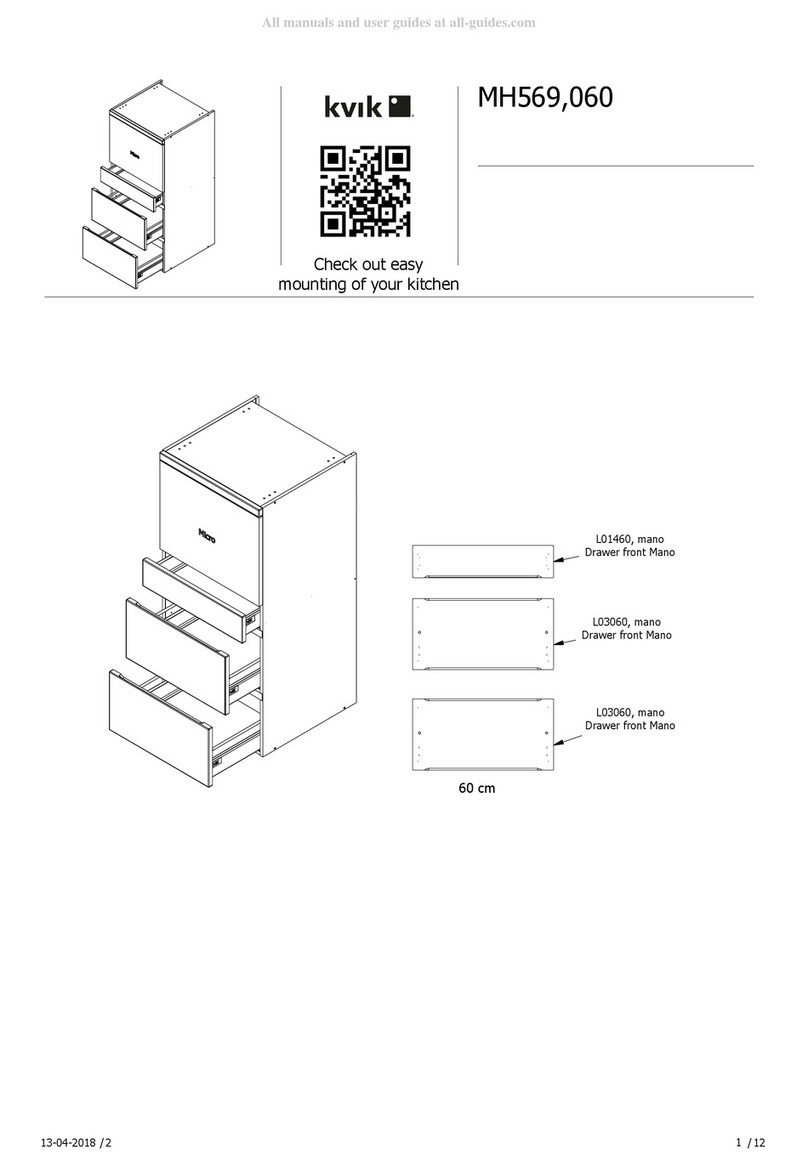

ASPECT™AND ENDURE™

3-LITE END ACTIVE PATIO DOOR ASSEMBLY CONTENTS

NOTE: Please refer to chart below for the required assembly contents of an Aspect or Endure patio door.

The patio frame will arrive from the factory unassembled with a few pre-assembled components to allow for

proper handing of the patio unit as ordered.

Main Frame

Assembly

Profiles

Sash and

Screen

(2) Exterior Vinyl

Jamb Cover

(2" x 80")

(1) Header Assembly

(1) Sill Assembly with Sill

Dust Cover factory installed

(1) Handle Set

(Aeris/ Endure Handle

Set shown)

(1) Mortise

Handle Set Keeper

(Taped to Active Sash)

(1) Active Sash (1) Fixed Sash

with interlock on

each stile

(1) Screen

Accessory

Parts

Optional

Installation

Accessories

(Refer to the

separate and

included instruction

document if

applicable)

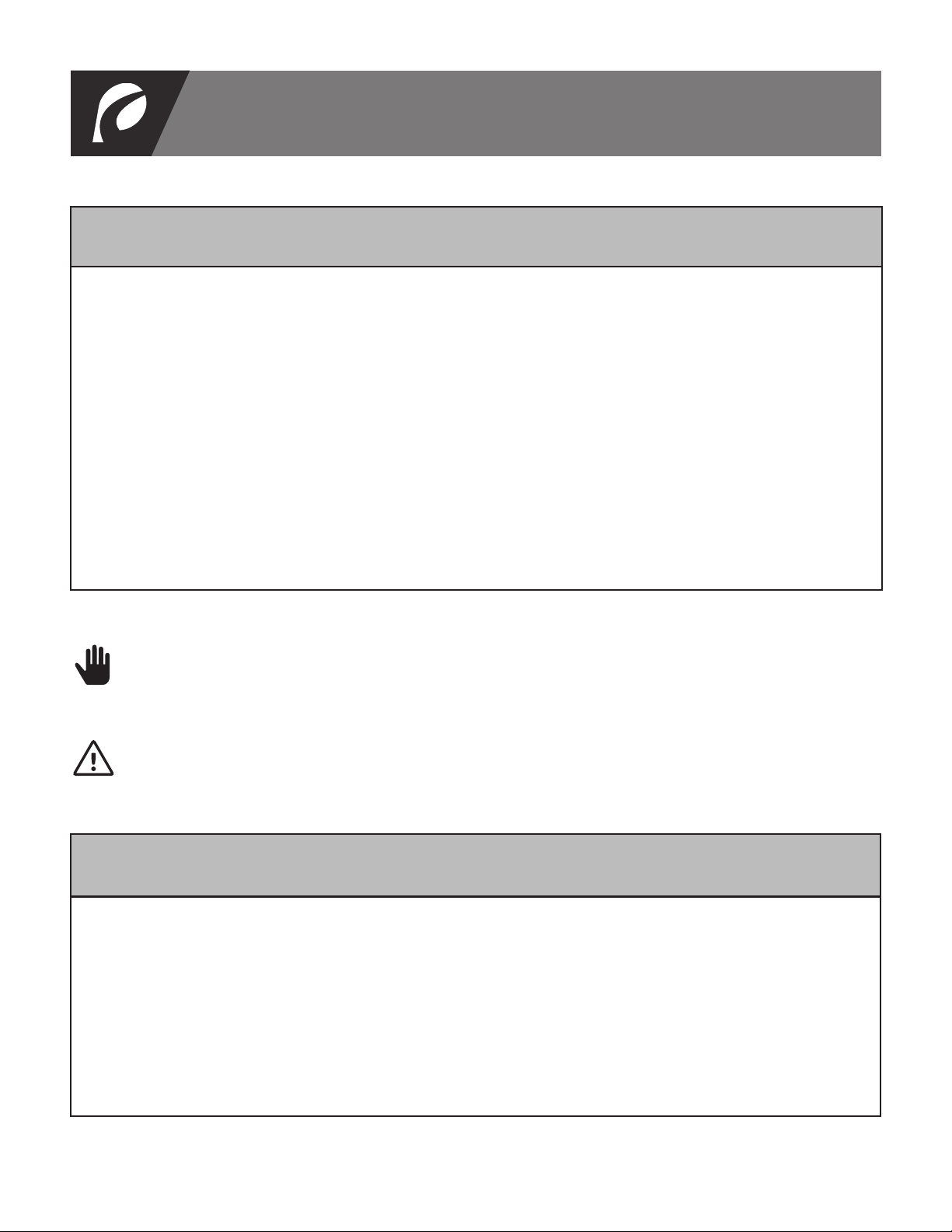

5917

Brickmold

5907

Brickmold

w/ Nail Fin

5940

Nail Fin

(Partial Jamb)

5956

Nail Fin

5945

Nail Fin

(Full Jamb)

5938

Stucco

Flange

(1) Fixed Jamb

Assembly

5927

Frame

Adapter

5907 5917 5956

5928

5892 Interior Trim5840

5945

5940 5938 5927

5907 5917 5956

5928

5892 Interior Trim5840

5945

5940 5938 5927

5907 5917 5956

5928

5892 Interior Trim5840

5945

5940 5938 5927

5907 5917 5956

5928

5892 Interior Trim5840

5945

5940 5938 5927

5907 5917 5956

5928

5892 Interior Trim5840

5945

5940 5938 5927

5907 5917 5956

5928

5892 Interior Trim5840

5945

5940 5938 5927

5907 5917 5956

5928

5892 Interior Trim5840

5945

5940 5938 5927

(1) Fixed Jamb

Assembly

(3) Interior Vinyl

Groove Cover

(Ships installed on frame)

(1) Fixed Sash

with interlock on

(1) stile

3

ASPECT™AND ENDURE™

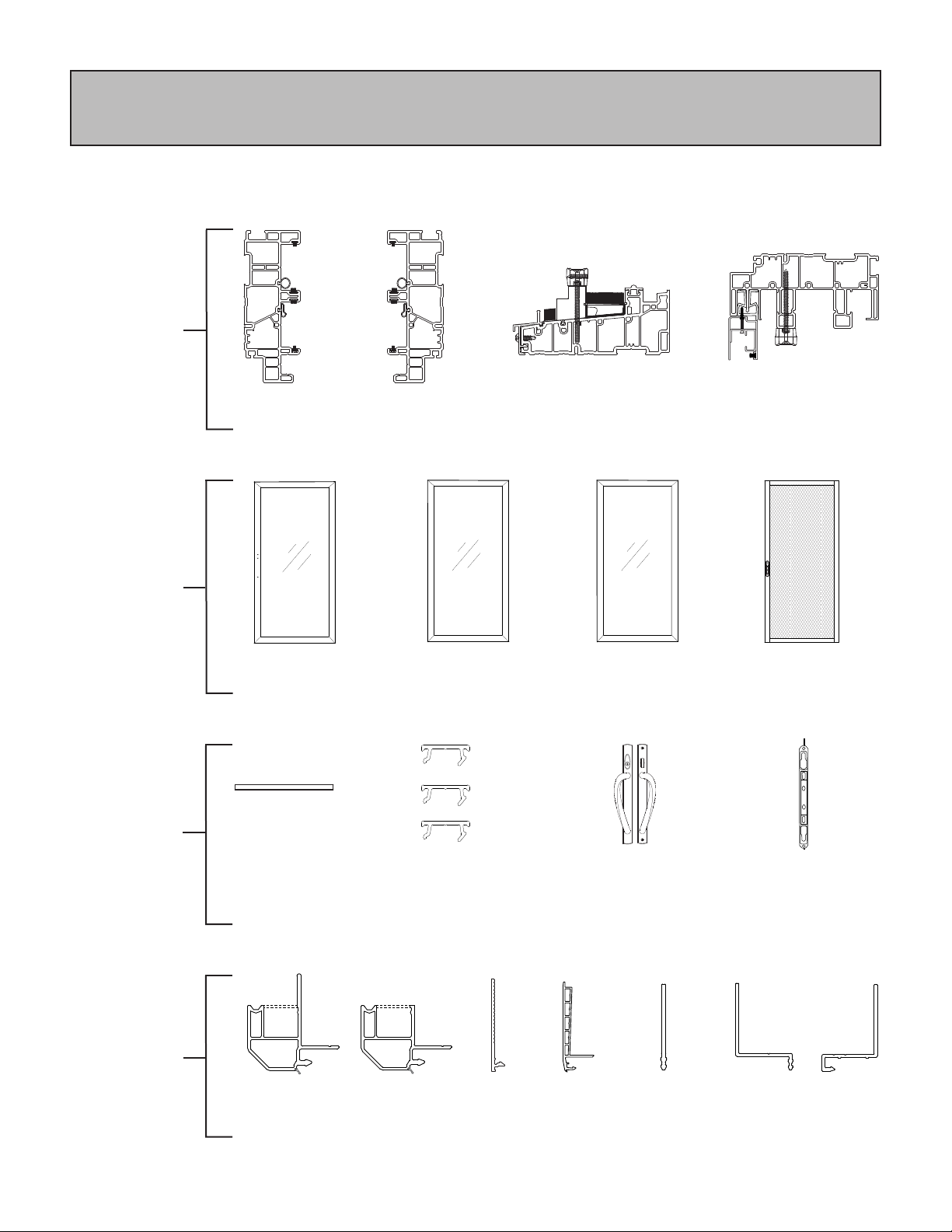

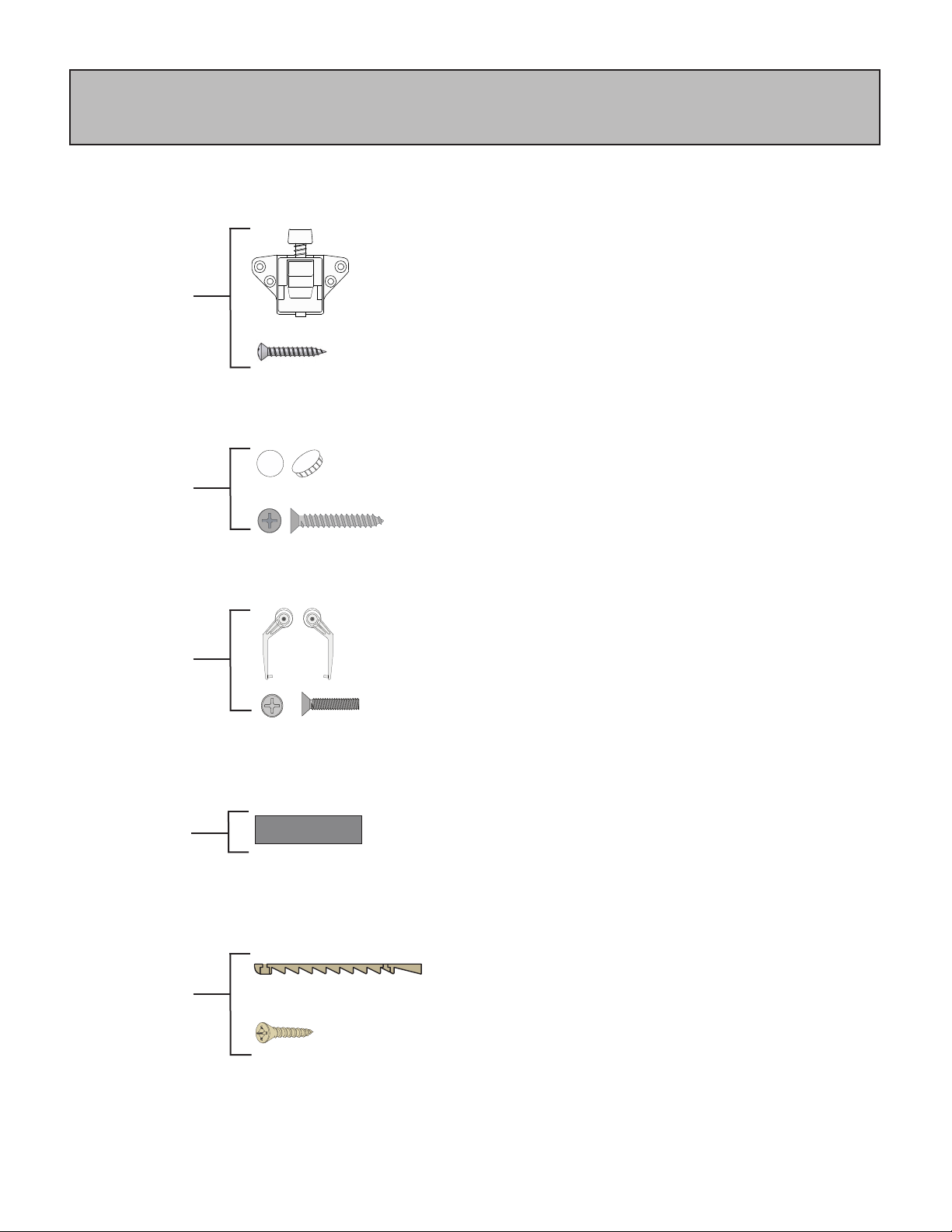

3-LITE END ASSEMBLY INSTALLATION PACK CONTENTS

NOTE: The individual installation packs are labeled and numbered. Please refer to the chart below for the

appropriate pack contents and for the installation location.

3⁄8" Hole Plugs (Color Matched), Part #: S-HG-698-CC

#8 x 3" Phillips Square Screws, Part #: S-HS-350-00

#2 Phillips Square Combo Bit, Part #: S-ST-347

Foam Plugs, Part #: S-HG-521-01

#8 x 1" Phillips Pan Head Screws, Part #: S-HS-345-00

Head Weatherstrip Block, Part #: S-HG-524-13

#8 x 11⁄4" Phillips Pan Head Screws, Part #: S-HS-342-13

Sash Stop (Bumper), Part #: S-HG-532-13

#8 x 11⁄4" Phillips Pan Head Screws, Part #: S-HS-342-13

(1) Installation

Pack #2

S-DH-020S-CC

(Jambs & Header)

(2) Installation

Pack #3

S-DH-023S-CC

(Fixed Sashes)

(2) Installation

Pack #4

S-DH-024S

(Header Block)

(1) Installation

Pack #5

S-DH-025S

(Header Bumper)

Parts

The individual installation packs are labeled, numbered

and are all packed inside one main bag. Open up the

main parts bag and refer to the appropriate pack contents

for each installation location referenced below.

3-Lite End Active

Installation Pack

S-DH-042S-CC

(16)

(16)

(1)

(4)

(4)

(1)

(2)

(1)

(2)

(1)

#8 x 2” Phillips Square Stainless Steel Screws,

Part #: S-HS-344-00

(2) Installation

Pack #1

S-HS-344S-CC

(Frame Assembly)

(10)

Screw Caps, Part #: S-HS-311-CC

(4)

4

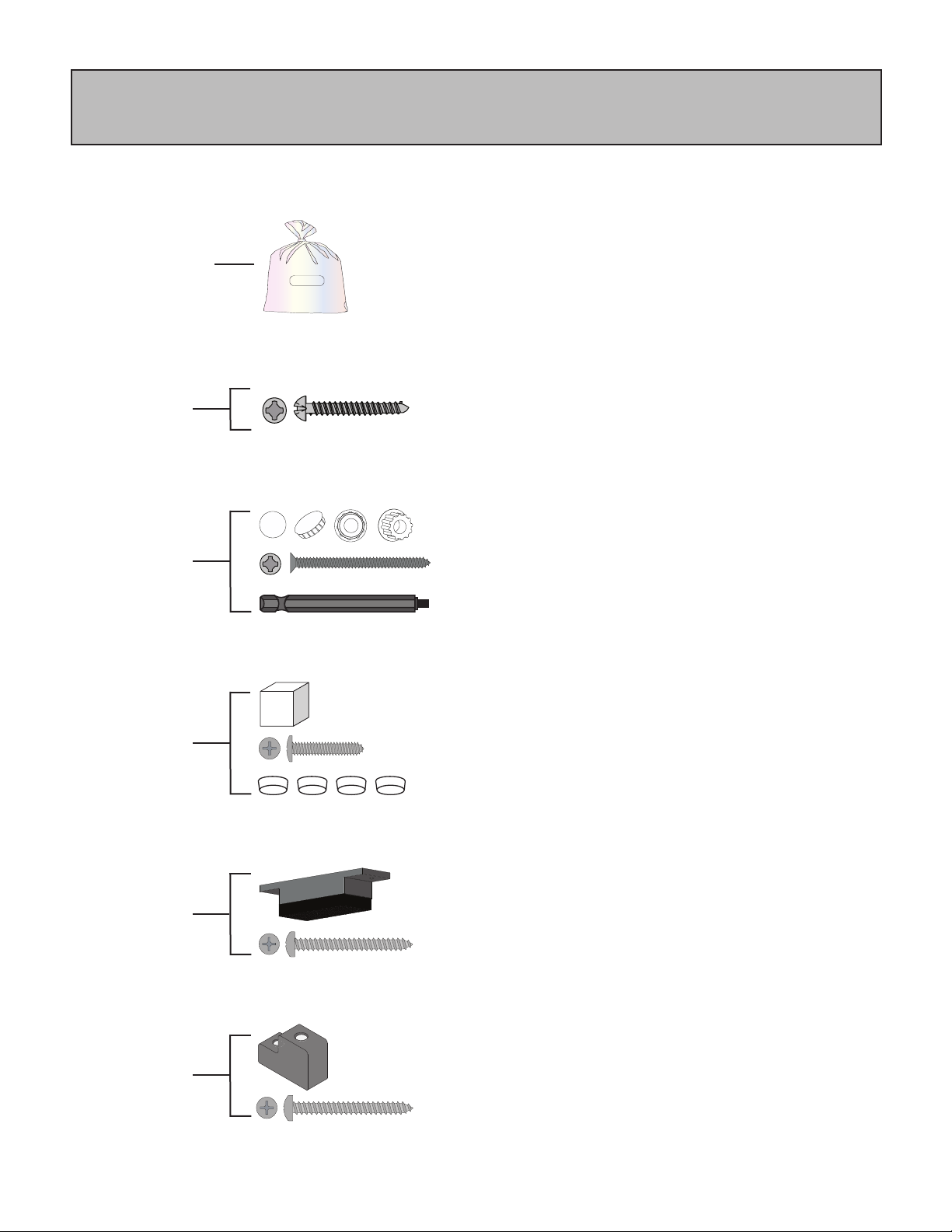

(1) Installation

Pack #10

S-DH-010S

(Screen)

Screen Wheel Brackets,

Part #: S-HG-366P-00 (Right Hand)

Part #: S-HG-367P-00 (Left Hand)

#6-32 x 7⁄8" Phillips Flat Head Screws, Part #: S-HS-360-00

(1)

(1)

(2)

AccuVent Bolt Plate (Color Matched), Part #: S-HG-573-CC

#8 x 1 Combo Vinyl Hold (Color Matched),

Part #: S-HS-340-CC

(1)

(2)

(1) AccuVent™

Bolt Plate Kit

S-HG-573S-CC

(Standard on Endure,

Optional on Aspect)

Active Sash Secondary Lock (Foot Lock) (Color Matched),

Part #: S-HG-353-CC

#8 x 3⁄4” Phillips Oval Head Screws (Color Matched),

Part #: S-HS-414-CC

3-Lite Shims, Part #: S-HG-542-13

(1) Installation

Pack #6

S-DH-026S-CC

(Standard on Aspect,

Optional on Endure)

(1) Installation

Pack #14

S-HG-54S-13

(Sill of Fixed Sash)

(1)

(4)

(4)

ASPECT™AND ENDURE™

3-LITE END ASSEMBLY INSTALLATION PACK CONTENTS

NOTE: The individual installation packs are labeled and numbered. Please refer to the chart below for the

appropriate pack contents and for the installation location.

(1) Installation

Pack #8

S-DH-028S-CC

(Screen Mullion)

NOT USED with

END ACTIVE

Screw Cap Cover (Color Matched), Part #: S-HG-534-CC

#8 x 1" Phillips Flat Head Screws, Part#: S-HS-351-00

(5)

(5)

5

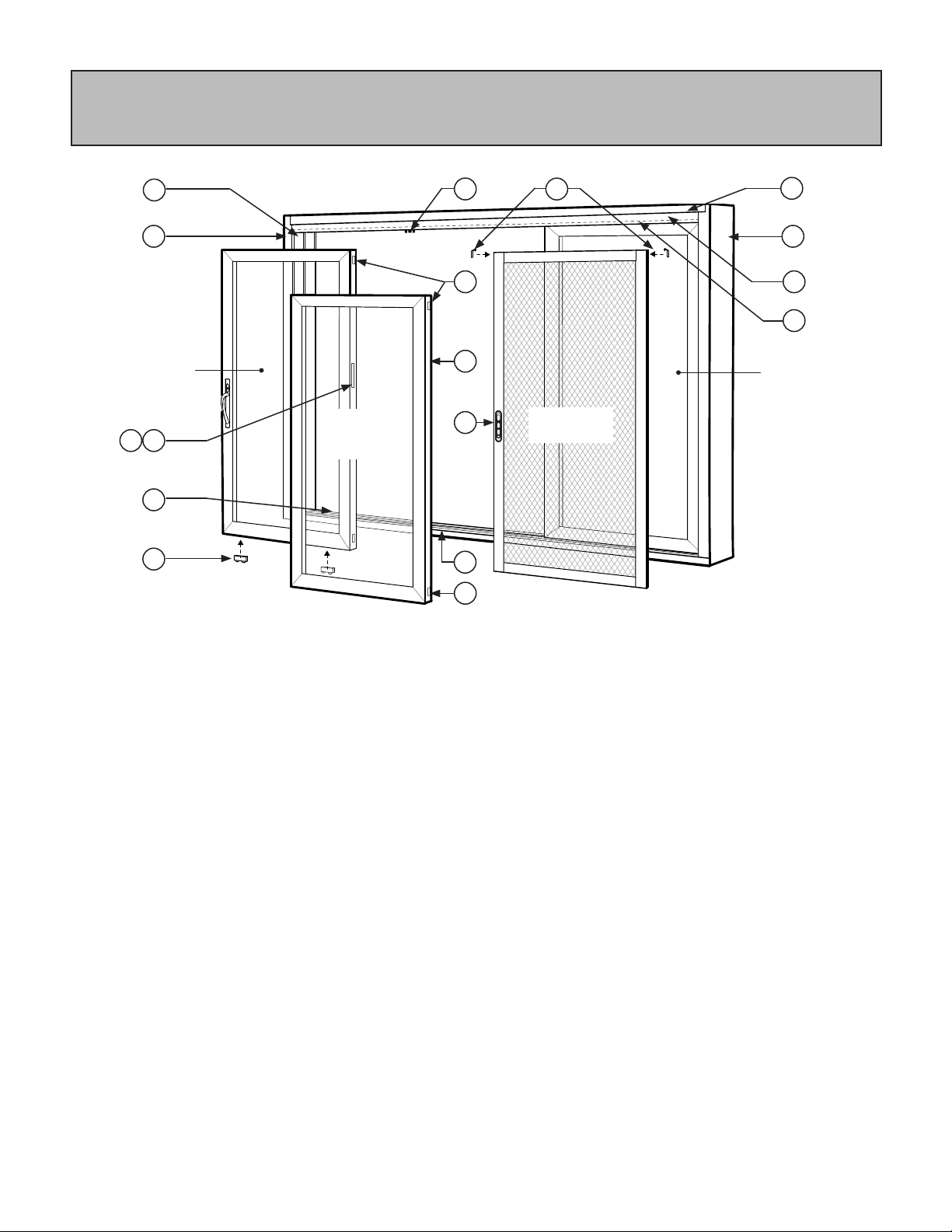

RE-ORDER REFERENCE - PRODUCT PART # IDENTIFICATION

NOTE: Parts listed may be a subassembly or part of a subassembly.

SCREEN PARTS:

O. LH Common Patio Screen Handle - S-DH-071

(RH Common Patio Screen Handle - S-DH-068)

P. LH Wheel Bracket Assembly - S-HG-367P-00 and

RH Wheel Bracket Assembly - S-HG-366P-00

(See page 19 for Detail) (**See note this page)

SASH PARTS - (2) Fixed, (1) End Active:

I. Tandem Wheel Patio Door - S-HG-355-00

with Shim - S-HG-529-01

J. Sash Groove Cover - S-VE-7023-CC

K. Sliding Cap - S-HG-530-CC

L. AccuVent Latch Trim Plate - S-HG-570-CC

(See page 18 for Detail) (*See note this page)

M. AccuVent Latch - S-HG-571-00

(See page 18 for Detail) (*See note this page)

N. Foot Lock Keeper (Optional) - S-HG-354-CC

(Foot Lock - S-HG-353-CC, located on interior

of active sash. (See page 18 for Detail)

NOTES:

* For re-order of all AccuVent™parts, please order the

AccuVent Latch Repair Kit, S-HG-571S-CC.

**For re-order of Screen Wheel Bracket Assembly,

please order Pack #10, S-DH-010S.

***For assistance on all re-orders, please contact your

Dealer or our Customer Service Team at

1-800-669-4711.

FRAME PARTS:

A. Header - S-VE-7002-CC

B. Sill - S-VE-7000-CC

C. RH Jamb - S-VE-7004R-CC

D. LH Jamb - S-VE-7004L-CC

E. Outer Cover - S-AE-6206-CC

(See page 19 for Detail)

F. Common Screen Inner Track - S-AE-6207-32

(See page 19 for Detail)

G. Jamb Covers (Ea. Side) - S-VE-0714-CC

H. AccuVent™Bolt Plate - S-HG-573S-CC

(See page 18 for Detail) (*See note this page)

End

Active Sash

(Interior Track)

Fixed

Center Sash

(Exterior Track)

Screen

(Screen Track)

Fixed

End Sash

(Interior Track)

A

B

C D

GH

E

F

I

ML

N

(Hidden)

K

P

O

J

(Hidden)

K

6

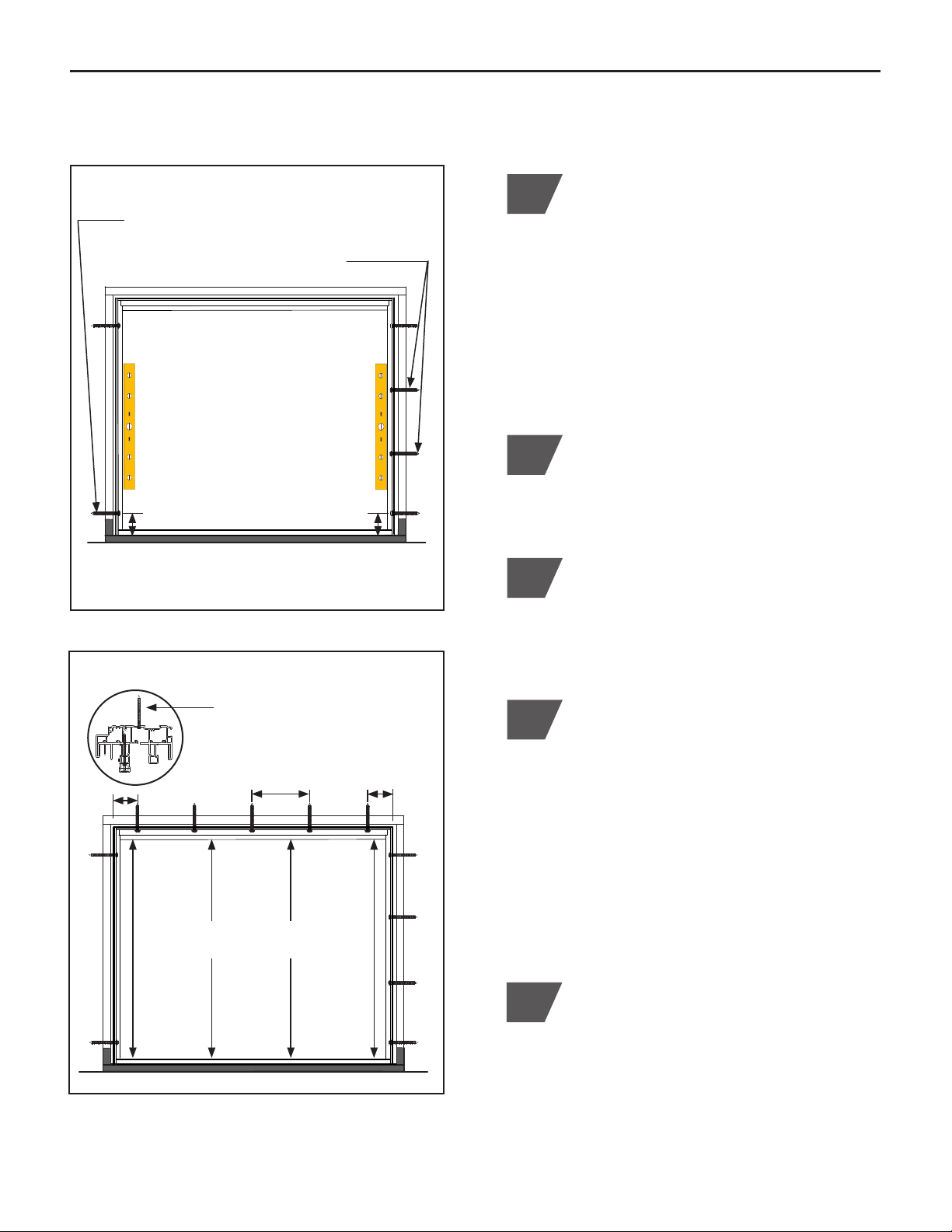

A. ASSEMBLE FRAME

ProVia®understands there are various methods and conditions affecting the installation of a patio

unit. We feel the most critical steps to follow are securing and shimming as instructed in this

document.

FIELD MULLED PATIO UNIT:

Refer to Section R, Field Mulling, page 22. Units must be mulled together before setting into the

opening. For units requiring heavy reinforcement, refer to included instruction.

INSTALLATION ACCESSORY:

If the patio unit is ordered with an installation accessory, refer to the included document,

'Installation Instruction Vinyl Patio Door Installation Accessories and New Construction Flashing'.

The QR code for this instruction can also be found at the end of this instruction document. Nail fin

or installation accessory must be installed on patio unit before installing into the opening.

IMPORTANT INFORMATION

Check to be sure each top and bottom factory

mounted jamb-side gasket is in place.

(Figure A.1)

2

Carefully lay (4) main frame assembly pieces

on a level and well supported area with the

exterior side up. Be sure the interior side is

fully protected from damage. Align each jamb

side with header and sill. Check to be sure

the jamb side screen bumpers are located at

top and facing to the exterior.

3

Secure each jamb side frame to the frame

header and sill using (5) #8 x 2” Phillips head

screws in each top and bottom location

(Pack #1). Make sure the top and bottom

factory mounted jamb gaskets are well

compressed. (Figure A.1)

4

(Figure A.1)

Frame Assembly Isometric

(Assemble with Exterior Side facing up)

Sill

Assembly

Secure each jamb to header and sill

using (5) #8 x 2" screws, each corner

Check each top and bottom jamb gasket

Header

Assembly

Jamb-Side

Assembly

Unpack and inspect all new patio door

assembly components for any material

damages. Check glass, screen, and all

operational hardware.

1

If unit was ordered with a sidelite, transom, or

optional installation accessory, field install at

this time.

5

7

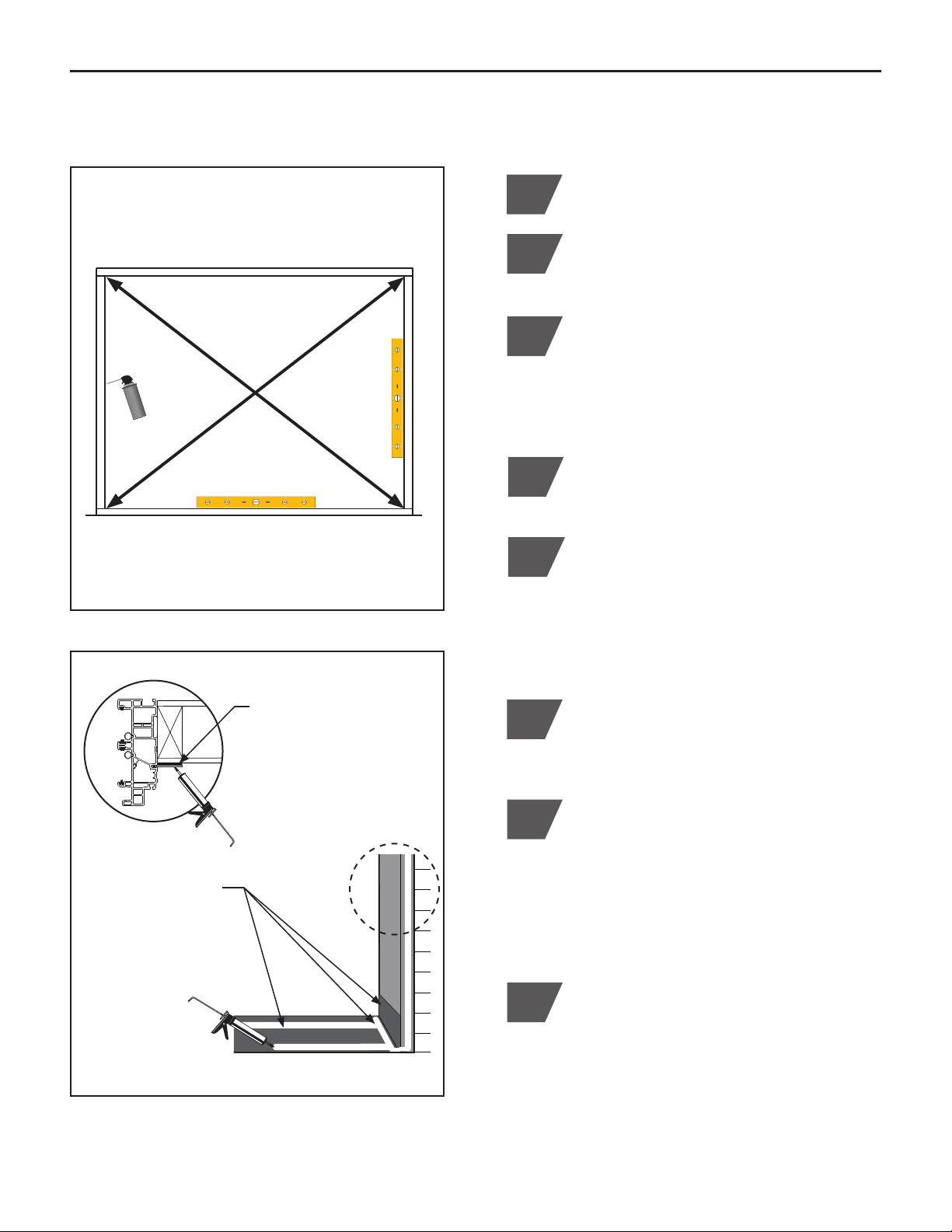

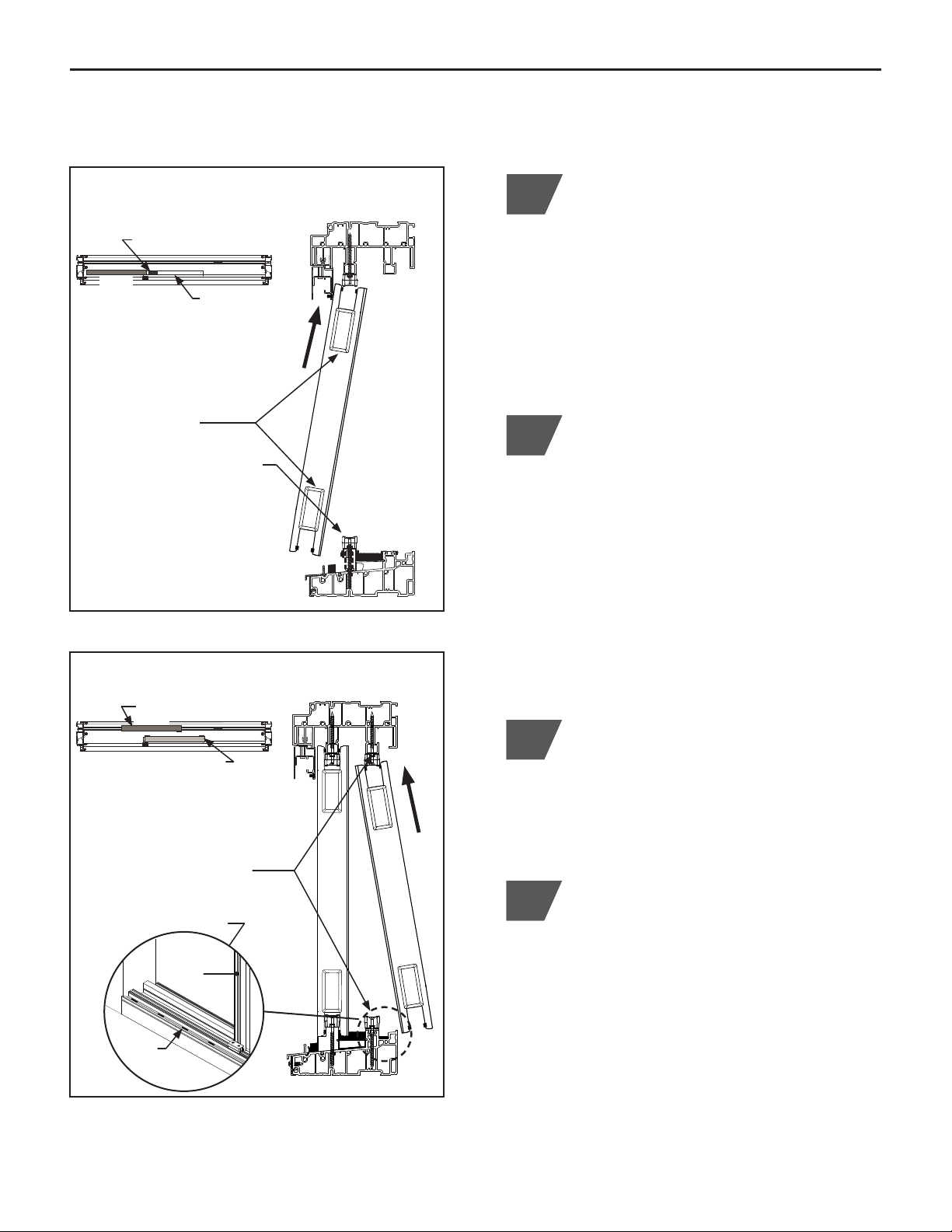

1Clean rough opening of all dirt, debris, and

obstructions.

B. PREPARE OPENING

5Verify opening width and height. Opening

should be large enough to accommodate

patio door with shims and insulation. The

recommended opening size is 1⁄4" - 1⁄2"

greater per side (or 1⁄2" - 1" greater than in

total width) and 1⁄4" - 1⁄2" greater than in total

height.

!

6

(Figure B.1)

(Figure B.2)

Fill all voids found with AAMA approved

low-expanding window insulation foam that

complies with ASTM C 1620. (Figure B.1)

2

Check for level and flat sill. Verify the

structural integrity of the opening to ensure

a proper installation. If sill is not straight

and level, place wood shims between sub-

floor and sill to correct minor leveling and

margin adjustments. (Figure B.1)

3

Opening

7

Exterior View

Fill any and all voids in opening with low

expanding foam

Check sill for level, flat and for proper

structural support

Exterior View

Apply flashing to sill

then apply (2) straight

beads of caulking

along length of sill and

to each corner of sill

as shown

ONLY if frame assembly

is ordered nail fin or

brickmold, apply a bead of

caulking to face of exterior

sheathing to seal against

Apply (2) generous beads of premium

caulking compound in a STRAIGHT LINE,

on top of flashing and along entire length

of rough opening sill. Place first bead of

caulking to the exterior leading edge of sill.

Place second bead towards interior (to bed

flat surface of threshold). Apply caulking in

each corner of sill as shown. (Figure B.2)

Install flashing/pan system to sill area

in accordance with local building codes

and best practices. Replace drip cap if

necessary. (Figure B.2)

If nail fin or brickmold option is used, apply

a bead of caulking to each vertical and

header face of exterior sheathing to seal. To

complete seal, apply bead of caulk from sill

to exterior sheathing, as shown. (Figure B.2)

8

Check opening for square. Measure

diagonally from corner to corner each side

to determine. (Figure B.1)

4

8

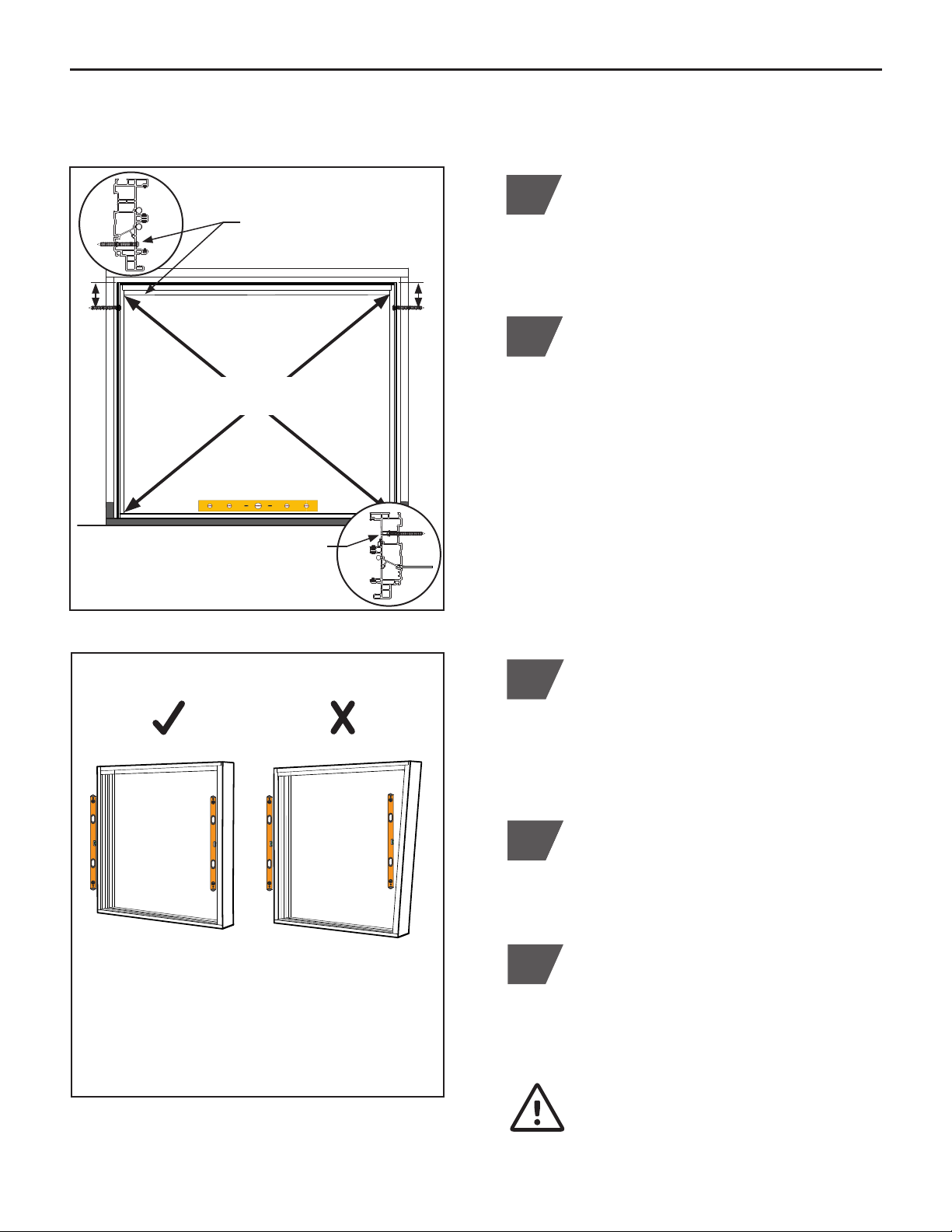

C. INSTALL FRAME

(Figure C.1)

Exterior View

122

1Place assembled patio frame into the

opening, sill first. Center and square frame

in opening. Leave enough space for proper

shimming and insulation.

Install (1) #8 x 3" screw

into top of EXTERIOR jamb

pocket, each side

Install (1) #8" x 3" installation screw (Pack #2)

into the top EXTERIOR jamb pocket of each

fixed sash side, minimum 4" to 6" down from

top corner. Locate screw on score line. DO

NOT over tighten screw causing frame to

pull! (Figure C.1)

NOTE: If using vinyl installation accessory

5940, 5945, or 5956 nail fin, each jamb side

must be secured through the INTERIOR

jamb pocket. Pre-drill a 3⁄8" hole and install

screw into the top of the interior jamb pocket,

minimum 6" down from top corner. Secure to

second vinyl wall of frame. (Figure C.1)

(Figure C.2)

3Check for overall square of patio frame by

measuring diagonally from corner to corner,

each side. Recommended tolerance for the

diagonal measurement is 1⁄8". Adjust top

jamb screws as needed. (Figure C.1)

Level sill if needed. If sill is not straight

and level, it must be shimmed for proper

operation of the patio door.

1214

ONLY if nail fin 5940, 5945, or 5956

is used, install screw into INTERIOR

jamb pocket, second vinyl wall, ea. side

Check sill for level

4"

to

6"

Check frame

for square

CORRECT

Equal vertical

plane alignment

NOT CORRECT

Unequal vertical

plane alignment

Frame Alignment

If frame is bowed, it may be necessary to

shim frame at various locations before

adding installation screws.

5Check plane of the patio frame. Each

vertical jamb side frame should be equal

and parallel to the other. See illustration for

equal and unequal plane. (Figure C.2)

4"

to

6"

9

C. INSTALL FRAME (CONTINUED)

(Figure C.3)

6

Exterior View

8

Check each jamb side frame for straight

and parallel to each other. Adjust jamb side

installation screws as necessary for parallel.

Be sure installation screws do not pull vinyl

frame causing frame to bow. Re-check for

overall square and correct plane alignment.

Install (1) #8 x 3" screw into EXTERIOR jamb

pocket 6" from bottom, each side

Install (2) #8 x 3" screws into EXTERIOR fixed

sash jamb side ONLY

Check each jamb side for straight and parallel

9

For header frame, drill a minimum of (5) 3⁄8"

holes equally spaced at 24" maximum through

the first vinyl wall. Wider units will require

more than 5 screws. Place each end screw

hole a minimum of 4" to 6" in from corner.

Install (1) #8 x 3" screw (Pack #2) into each

pre-drilled header screw hole location. DO

NOT over tighten screws causing frame to

pull. (Figure C.4)

NOTE: DO NOT install screw hole plugs at this

time. Plugs will be installed after installation is

fully completed.

Exterior View

(Figure C.4)

Header

Drill and install #8 x 3" screws

in header, 6" in from each

corner and equally spaced

10

Check frame opening height in (4) locations,

each jamb side and center. All (4)

measurements to be equal. Adjust header

installation screws as necessary to achieve

equal measurements. Be sure installation

screws do not pull vinyl frame causing frame

to bow. Header and sill must be parallel for

proper operation of active sash and screen.

(Figure C.4)

Install (1) #8 x 3" installation screw (Pack #2)

into the bottom EXTERIOR jamb pocket of

each jamb side, minimum 4" to 6" up from

the bottom corner. Locate screw on vinyl

score line. DO NOT over tighten screws.

(Figure C.3)

NOTE: If installation accessory 5940,

5945, or 5956 nail fin, secure through the

INTERIOR jamb pocket. Pre-drill a 3⁄8" hole

and install screws as noted above. Secure to

second vinyl wall of frame.

4" to 6"

4" to 6"24" max.

4" to 6"4" to 6"

7

Install (2) #8 x 3" installation screws (Pack #2)

into the EXTERIOR jamb pocket of fixed jamb

side ONLY, equally centered between top and

bottom screws. Locate screw on vinyl score

line. DO NOT over tighten screws. (Fig. C.3)

Frame Only in

Opening

Check frame opening height

in (4) locations for equal

10

Confirm frame is square on the same plane

and not rolled.

12112

C. INSTALL FRAME (CONTINUED)

(Figure C.6)

11 Place shims next to each installation screw

location, each jamb side and header. Be

sure top jamb shims are located 4" to 6"

from top of frame and bottom shims are 4"

to 6" from bottom of frame. Be sure header

shims are located 4" to 6" from each corner. If

spacing between side jamb or header shims

is greater than 12" to 18", additional shims

may be needed to maintain margins and

stabilize frame. Use shims to adjust straight

and parallel as needed. (Figure C.6)

NOTE: To allow for vinyl expansion, DO NOT

place shims at top header, bottom sill, or

header corner locations as shown. Shimming

in these locations will cause frame distortion.

IMPORTANT! CORRECT shimming

application; stack wedge shaped shims

contrasting and plane to plane. See diagram

below. DO NOT use single wedge shims.

This will cause the frame to roll. (Figure C.5)

IMPORTANT! Be careful to NOT over

shim. Improper shimming may roll,

bow, and change margins, jeopardizing

operational performance.

Exterior View

(Figure C.5)

CORRECT

Flat shims or wedge

shims stacked to

create a flat plane will

result straight frame

NOT CORRECT

A wedge shim will

cause frame to roll

resulting in rolled and

bowed frame

SHIMMING APPLICATIONS

Place stacked shims next to each header and

fixed jamb side screw locations

DO NOT place shims at top

and bottom jamb locations, each side

To prevent water infiltration, DO NOT

install screws through sill.

4" to 6" 4" to 6"

11

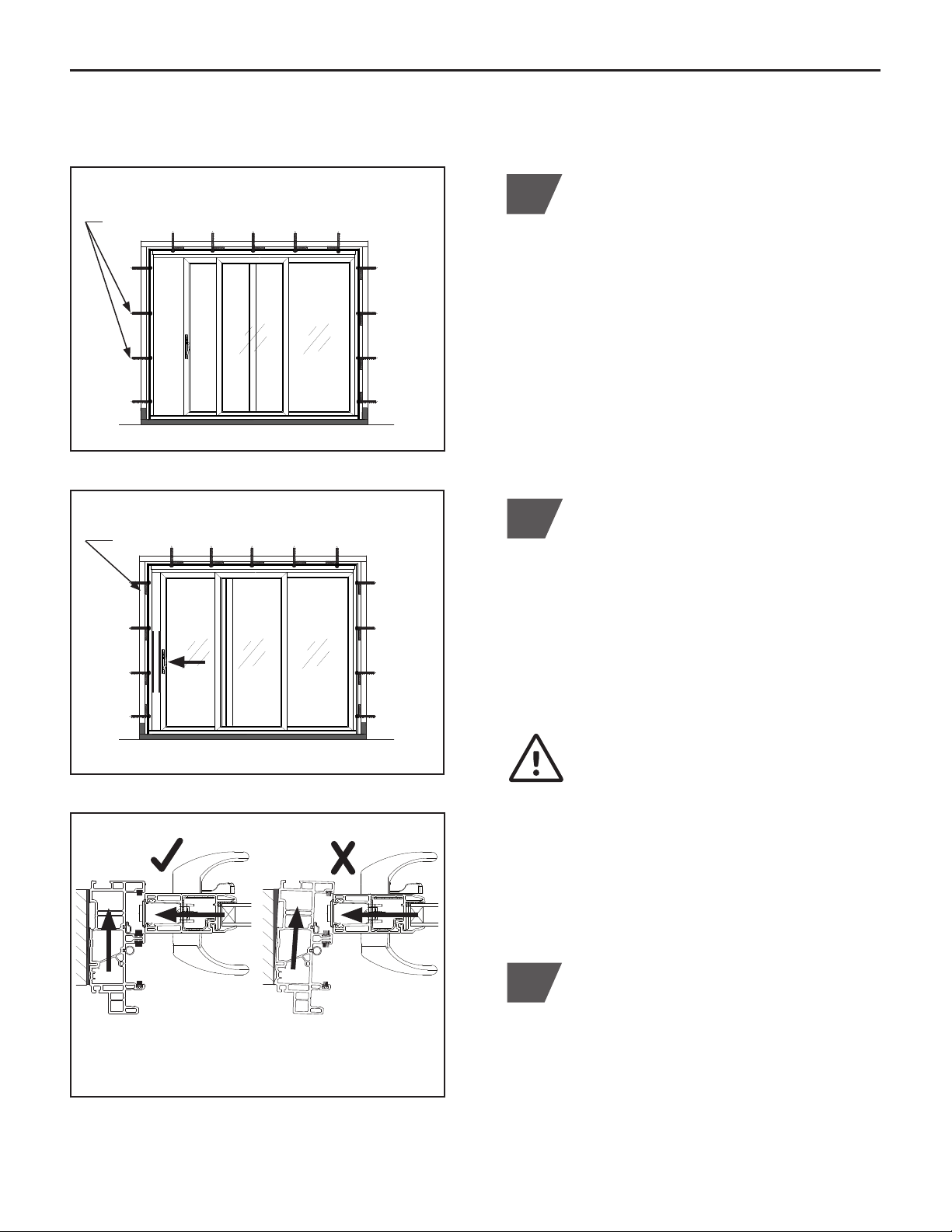

D. INSTALL FIXED SASHES

4

Section View

(Figure D.1)

Locate the fixed center sash (sash with an

interlock on each stile). Orient sash with

interlocks facing the interior and weep holes

located to the bottom exterior. From the

exterior active sash side, insert top of center

sash into the outside header track and away

from the anchor blocks. Align bottom of

sash with the sill adapter. Slide sash onto

adapter and over top and bottom anchor

block. Align fixed center sash flush with end

of sill adapter. (Figure D.1)

12

1411 The slide caps located at the top and

bottom of each fixed sash stile is shipped

in the open position. Check to be sure

caps have remained open. In addition,

check to be sure the weather strip within

each interlock has remained in place and

continues to remain in place throughout the

installation.

Interior

Side

Sill Plan View

Active End Side

Insert

Fixed Center Sash

anchor block

From the exterior active

end, insert fixed center

sash before anchor blocks

Open slide caps

Slide sash onto sill adapter

and engage top and bottom

anchor blocks

Section View

(Figure D.2)

Sill Plan View

Fixed End Sash

Insert

Fixed Center Sash

Sill adapter

Insert fixed end sash into inside

header track and before anchor

blocks

Slide sash over top and bottom

anchor blocks to engage

Place (4) shims into bottom of

interior track (Step 3)

Interior

Fixed

Center

Sash

Shims

3Insert (4) self-adhesive shims (Pack #14)

into inside bottom sill track of the fixed end

sash side, evenly spaced and width of the

sash. Refer to detail located in Figure D.2.

Locate the fixed end sash (sash with a

single interlock and no lock prep). From the

interior, orient the fixed end sash with the

single interlock facing outward, positioned

between the center fixed sash interlocks,

and away from anchor blocks. Lift to insert

top of sash into the inside header track then

lowering onto bottom sill roller rail. Slide

sash over top and bottom anchor blocks and

self-adhesives shims, leaving sash open to

complete the following step. (Figure D.2)

Fixed Center Sash

Fixed End Sash

12

5

9Slide top and bottom caps closed on each

fixed sash.

Ea. side of fixed center sash,

insert (1) foam plug into bottom

cavity of stile

8On each side of the fixed center sash, insert

(1) foam plug (Pack #3) into the open TOP

cavity of stile. (Figure D.5)

Caulk ea. side of sill adapter up to

sash and all sides of plug up to sash

On the jamb side of the fixed end sash,

insert (2) foam plugs (Pack #3), side-by-side,

into the open BOTTOM cavity. (Figure D.3)

6Slide fixed end sash tight into jamb pocket,

engaging the fixed center sash interlock.

Check square of frame to sash.

REMINDER: Check to be sure the weather

strip on interlocks have remained in place.

D. INSTALL FIXED SASHES (CONTINUED)

Interior View

(Figure D.3)

On the jamb side of the fixed end sash,

insert (2) foam plugs into bottom open cavity

Slide sash tight into jamb pocket

Exterior View

Exterior View

(Figure D.4)

(Figure D.5)

Bottom

cap

Sill

adapt.

On each side of the fixed center sash,

insert (1) foam plug (Pack #3) into the open

BOTTOM cavity of stile. For each inserted

plug, apply caulking to each side of the sill

adapter up to sash and all sides of the foam

plug up to sash to form a complete seal, as

shown in Detail. (Figure D.4)

NOTE: Check to be sure sash has remained

aligned and flush with end of sill adapter.

7

Ea. side of fixed center sash,

insert (1) foam plug into top

cavity of stile

13

1Check the active sash and fixed center

sash interlock rails to be sure weather strip,

on exterior side, has not slid up or down.

Properly re-seat if needed.

3Note the location of the adjustment screws

located on bottom sash rollers to adjust each

side of active sash as necessary for equal

height, squareness, and margin. Active

sash should fully and evenly enter jamb

pocket. Turn adjustment screw clockwise to

raise sash and counter-clockwise to lower

sash. Unweight sash to assist with upward

adjustment. (Figure E.1)

From interior of home, insert top of the

active sash into the interior header track.

Lift and lower sash onto the sill rolling rail.

(Figure E.1)

2

E. INSTALL END ACTIVE SASH

Section View

Exterior Interior

(Figure E.1)

Insert top of active sash into header track,

lift and lower onto sill rail

Use adjustment screw on bottom sash roller

for height adjustment

D. INSTALL FIXED SASHES (CONTINUED)

Interior View

Install (1) #8 x 1" screw into (1) factory prepped

screw hole at top of each fixed sash

*DO NOT install the remaining (3) screws

in each fixed sash

(Figure D.6)

For each fixed sash, install ONLY (1) #8 x 1"

Phillips pan head screw (Pack #3) into (1)

factory prepped screw hole located at the top

of the fixed sash. This will secure door to top

anchor block. (Figure D.6)

NOTE: DO NOT install the (3) remaining

screws in each fixed sash factory prepped

screw hole locations. This will allow for

adjustment with active sash once installed.

14111

Verify frame opening height in (4) locations,

each side and center sash interlocks, as

previously performed in Section C, Step 10.

Adjust frame header as necessary for equal

measurements. Frame header may need

to be pushed up or pulled down to achieve

equal measurements.

NOTE: THIS STEP IS CRITICAL for the

AccuVent™and screen to operate properly.

14110

14

F. INSTALL REMAINING FIXED SASH SCREWS

12

Interior View

(Figure F.1)

Install (1) #8 x 1" Phillips pan head screw

(Pack #3) into (3) remaining factory prepped

top and bottom screw hole locations of each

fixed sash. (Figure F.1)

Install (1) #8 x 1" Phillips pan head screw into (3)

remaining factory prepped top and bottom screw

hole locations of each fixed sash

1Re-check for equal height measurements

and alignment with active sash. Check for

equal spacing of fixed sashes and closed

active sash. If fixed center sash requires

adjustment, remove screw from Section D,

Step 11.

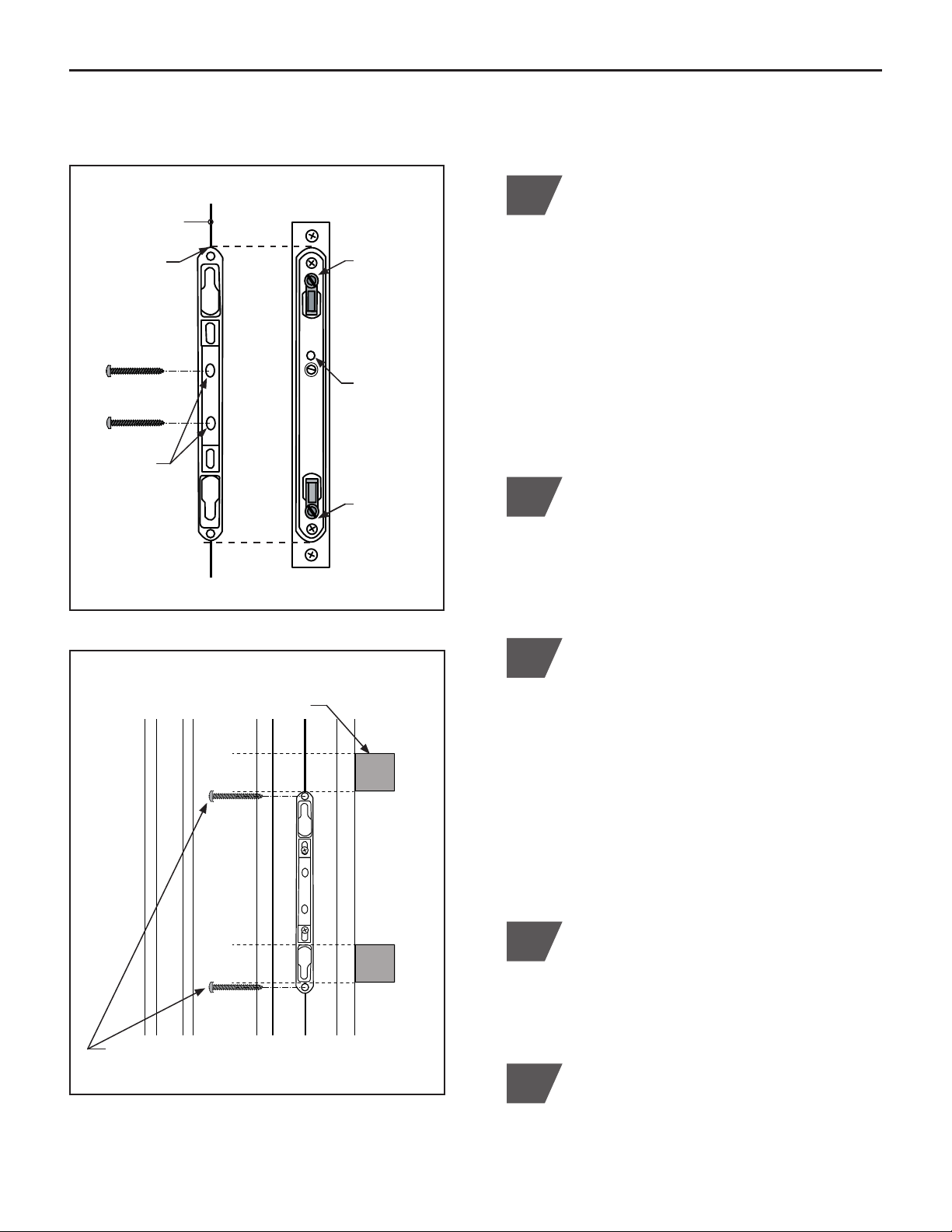

G. INSTALL MULTI-POINT HANDLE SET

2Position handle set into factory prepped

holes. Align spindle with lock knob on inside

handle. Confirm hand grip curves towards

the glass. (Figure G.1)

3Use (2) #8-32 (included) to install the

exterior and interior handle set assemblies

to the active sash. (Figure G.1)

Install exterior and interior

handle set using

(2) #8-32 Phillips

mounting screws,

included

DO NOT USE a power

screwdriver to install

the handle set kit,

doing so will cause

damage and VOID THE

WARRANTY *DO NOT

OVER TIGHTEN screws

1Fasten handles to each plate using (2)

#10-32 mounting screws provided. Place

gasket in base of exterior plate. (Figure G.1)

(Figure G.1)

Active Sash The primary handle set installation

instructions is located inside hardware

box. Refer to included instructions for

the complete hardware installation.

15

H. INSTALL ACTIVE SASH JAMB SIDE SCREWS AND SHIMS

Slide active sash to almost closed, check

alignment and margin of the sash strike edge

to frame. Shim active sash side frame at

each installation screw to adjust frame as

needed. Be sure top and bottom shims are

4" to 6" away from corners. Additional shims

maybe needed for proper frame alignment.

(Figure H.2) FLAT SHIMS MUST BE

USED. Be careful to NOT over shim

causing frame to roll or bow. (Figure H.3)

2

Re-check sash operation. Sash must slide in

and out of jamb pocket smoothly for proper

operation and lock function. If not, continue

to adjust shims, screws, and the adjustment

screw located on bottom sash rollers to

further align as needed.

3

IMPORTANT! CORRECT sash operation.

If jamb side frame becomes rolled

during installation, the active sash will

conflict with the frame resulting in poor

operation. The jamb side frame must

be straight and parallel to active sash.

Refer to Figure H.3 for an illustration of

proper frame to sash alignment.

(Figure H.3)

1Install (2) #8" x 3" installation screws (Pack

#2) into the EXTERIOR jamb pocket of

the active sash side, locate (2) screws

in center and evenly spaced. DO NOT

tighten screws. Screws can be used for

frame alignment and adjustment in Step 2.

(Figure H.1)

NOTE: If using installation accessory 5940,

5945, or 5956 nail fin, secure through

the INTERIOR jamb pocket. Pre-drill a

3⁄8" hole and install screws into the interior

jamb pocket.

Secure to second vinyl wall of

frame.

CORRECT

Sash slides in and out

of pocket with ease

NOT CORRECT

Sash is difficult to operate,

requires adjustments

Exterior View

Slide sash almost closed to check alignment/margin

Shim to each active sash side screw, use shims to

adjust frame alignment, margin to frame

(Figure H.2)

(Figure H.1)

Exterior View

Install (2) remaining installation screws into active

sash side jamb, centered and evenly spaced

SASH OPERATION

(Figure H.3)

16

1Slide active sash almost closed, leaving

enough room to align keeper with lock body.

Mark jamb pocket with the location of top

and bottom keeper as aligned with lock

body. (Figure I.1)

Tip: Place (2) strips of double-sided tape

on back of keeper. Locate keeper onto lock

body and lock in place. Close sash tight to

adhere keeper to jamb pocket. Unlock the

lock body and open sash. Install keeper as

directed below.

2

3

Center keeper on jamb pocket score line

between marks made. Install (1) #10 x 1"

screw in each elongated screw hole

locations. This will allow for a slight up and

down adjustment if needed. (Figure I.1)

4

Close active sash, locking and unlocking

handle. If needed, adjust the latch bolt and

keeper positions until sash latches securely

without sash movement or excessive

latching effort. To adjust latch bolt position,

open sash and engage the anti-slam button

to allow the latch bolt to lock. Use a flat

head screwdriver to loosen or tighten latch

bolt as needed. Test function of the lock.

Repeat step if lock is still too tight or too

loose. (Figure I.1)

After final adjustments are completed,

install (1) #8 x 3" screw (Pack #2) at top

and bottom of the keeper to secure in place.

(Figure I.2)

(Figure I.1)

Vinyl score line

Align keeper

with lock body

and mark top

and bottom

location

Latch bolt

adjustment

Anti-slam

button

Latch bolt

adjustment

Keeper Lock Body

I. INSTALL KEEPER

(Figure I.2)

Keeper in Jamb Pocket

After adjusted, install (1) #8 x 3" screw in the

top and bottom keeper screw hole location

To secure,

install (1) #10 x

1" screw in each

elongated screw

hole location

5Place shims immediately above each top

and bottom keeper screw location.

(Figure I.2)

Place shims above top and bottom

screw location

Interior

Side

Exterior

Side

17

J. INSTALL HEAD WEATHER STRIP BLOCKS & INSECT STOPS

1Locate weather strip blocks directly above

each interlock. With active door open, insert

both blocks into center channel of frame

header. Slide first block past active side

interlock using the second block. Use a thin

long screwdriver to push second block into

position over active sash side interlock. Close

active sash. Slide first block into position over

fixed end sash interlock.

(Figure J.1)

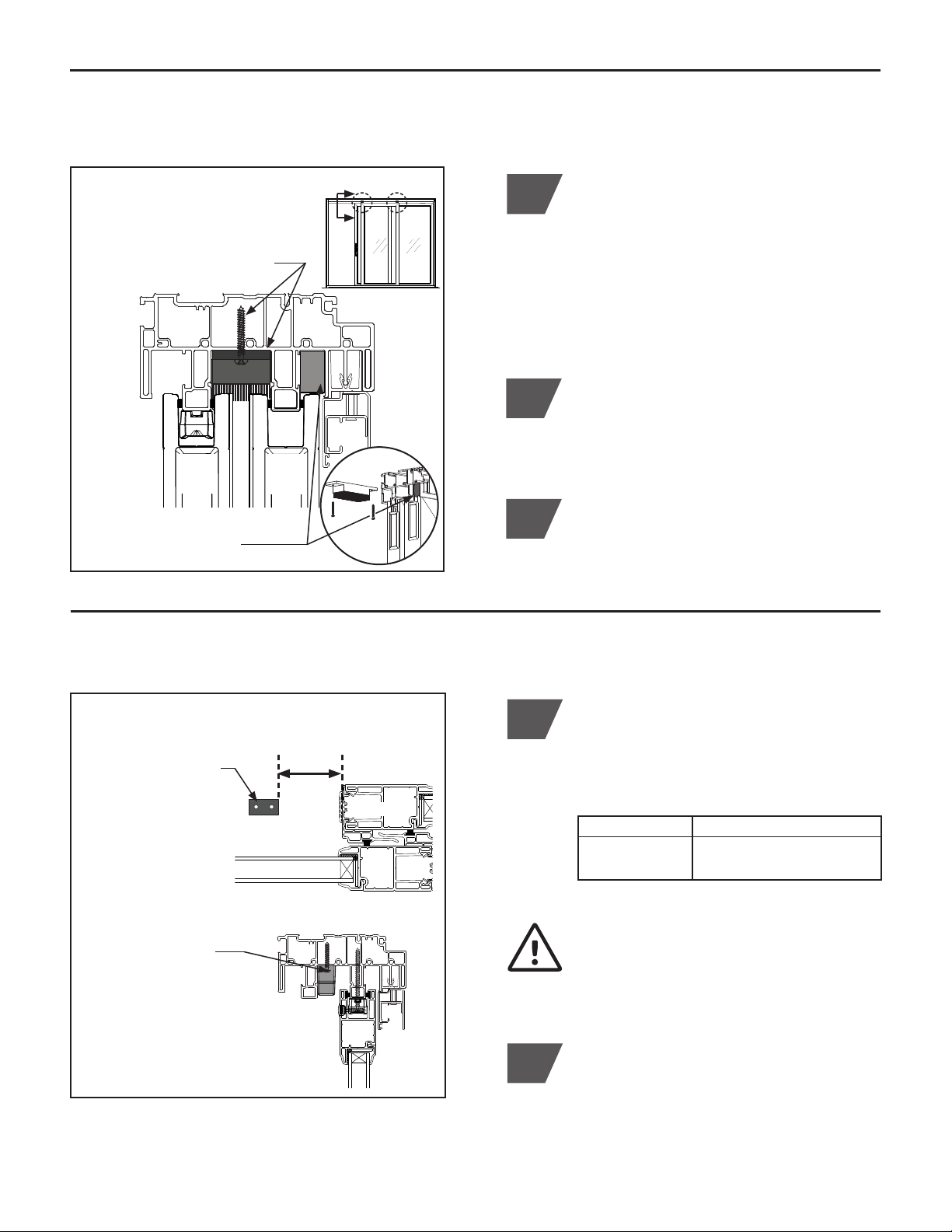

K. INSTALL SASH STOP

1Place sash stopper (Pack #5) on the active

sash header track, behind active sash.

Locate the sash stopper per the appropriate

dimension provided in chart below and per

the illustration in (Figure K.1).

Sash Type Dimension ‘A’

Without Blinds 23⁄4" from edge of fixed sash

With Blinds 4" from edge of fixed sash

IMPORTANT! To avoid a pinch hazard

between exterior handle set and fixed

sash, do not allow less than the above

dimensions.

2Install sash stopper with (2) #8 x 11⁄4" Phillips

pan head screws (Pack #5).

Install (2) #8 x 11⁄4"

Phillips pan head

screws

(Figure K.1)

Sash Plan View

Dim.

'A'

Header Section

Place sash stopper

on the active sash

header track, locate

at the distance

provided in chart

2Secure each head weather strip block using

(2) #8 x 11⁄4" Phillips pan head screws (Pack

#4). For active sash side, close sash to

access the opposite screw hole. DO NOT

over tighten screws. (Figure J.1)

3Insert (1) foam plug (Pack #3) in the open

cavity between the fixed center sash and

screen track, each side of sash and as shown.

Foam plug must align with edge of fixed center

sash, as shown in Detail. (Figure J.1)

Head Weather Strip Block Section

End

Active

Sash

Fixed

Center

Sash

Insert (1) foam stop (plug) in

open cavity, each side

Locate weather strip blocks above

each interlock, secure using (2)

#8 x 11⁄4" screws each block

Sash Stop Location

Fixed End

Fixed Center

18

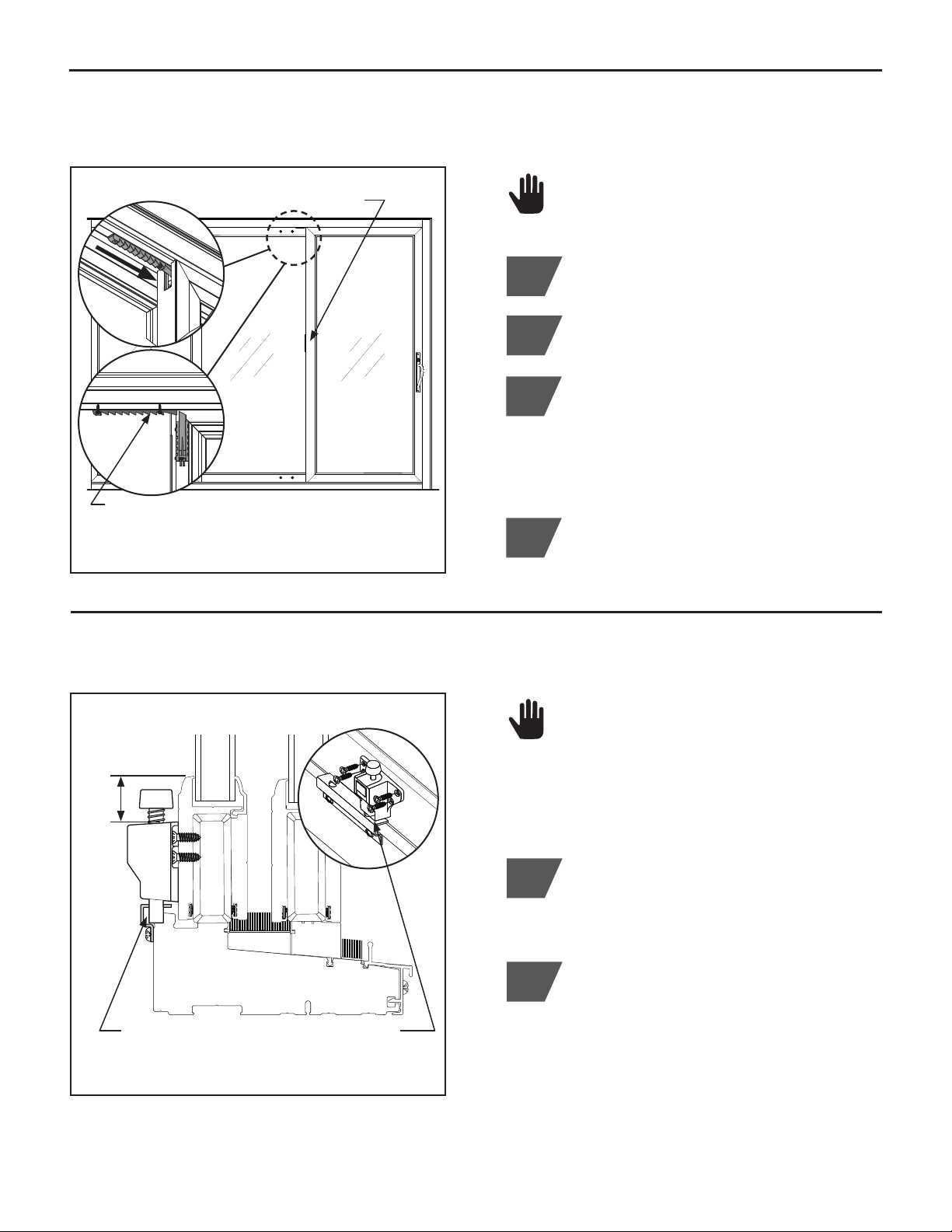

1Close active sash and lock handle.

2Flip AccuVent lever down into locked

position. (Figure L.1)

3Locate the AccuVent bolt plate (AccuVent

Bolt Plate Kit) on the active sash header

track. Slide plate into the stile opening of the

active sash, next to the AccuVent bolt, as

shown in Figure L.1. Provide a 1⁄8" clearance

between bolt plate and bolt. (Figure L.1)

4Pre-drill a 3⁄32" or 7⁄64" hole and install (2)

#8 x 1" screws (AccuVent Bolt Plate Kit).

DO NOT over-tighten screws. (Figure L.1)

L. INSTALL ACCUVENT™VENTING SYSTEM BOLT PLATE

(Figure L.1)

Interior View

Flip AccuVent lever down

Locate AccuVent bolt plate, slide plate into

opening of active sash, leave 1⁄8" clearance,

install with (2) #8 x 1" screws

AccuVent is a standard feature on all

Endure™and an optional feature on all

Aspect™.

M. INSTALL FOOT LOCK

Foot lock is a standard feature on all

Aspect™ and an optional feature on all

Endure™.

Foot lock keeper is factory mounted.

1Close active sash and lock handle.

Align foot lock (Pack #6) over the first hole

of keeper, closest to the latch side. Locate

and install foot lock body a minimum of 15⁄16"

below top of sash rail, as shown. Check to

be sure bolt will engage keeper. Secure to

sash using (4) #8 x 3⁄4" Phillips oval head

screws (Pack #6). (Figure M.1)

2

(Figure M.1)

Foot Lock Section View

15⁄16"

Latch

Side

Align foot lock over first hole of keeper,

locate a minimum of 15⁄16" below top of sash rail,

secure using (4) #8 x 3⁄4" screws

Top of sash rail

19

N. INSERT SCREEN

3

Lift screen into the top screen track

assembly and between wheel brackets.

Place screen with the weather strip to the

interior side. (Figure N.2)

4

Lift and position bottom of screen onto

screen glide rail. (Figure N.2)

5

Insert the left and right wheel bracket tabs

into groove located at the top of screen

frame. (Figure N.3)

Install each wheel bracket using a #2

Phillips head screwdriver to install (1)

#6-32 x 7⁄8" Phillips flat head screw

(Pack #10). (Figure N.3)

NOTE: DO NOT use excessive torque on

the bracket screws.

1Insert Left and Right screen wheel brackets

into the inner track of the top screen track

assembly (Pack #10). Brackets are labeled

and identified by outside looking in. Insert

rollers into the open space located at the

ends of the inner screen track and the jamb.

BE SURE each wheel bracket is positioned

correctly. (Figure N.1)

Insert Left and Right

wheel brackets into

end of inner track

2

(Figure N.1)

(Figure N.2)

(Figure N.3)

Screen Track Section

Outer screen cover

Inner screen track

Section View

Lift screen into the

top of track, between

wheel brackets

*Be sure screen

weather strip is to the

interior side

Position bottom of

screen onto glide rail

Screen Track Section

Insert wheel bracket tab

into screen groove

Install each wheel bracket

with (1) #6 x 7⁄8" screw

This manual suits for next models

1

Table of contents