PSG Dover Mouvex B200 Flow Control User manual

INSTRUCTIONS 1401-X00 e

Section 1401

Effective October 2018

Replaces February 2017

Original instructions

B200 Flow Control

SCREW COMPRESSORS

INSTALLATION

OPERATION

MAINTENANCE

SAFETY

STORAGE

Your distributor :

Z.I. La Plaine des Isles - F 89000 AUXERRE - FRANCE

Tel. : +33 (0)3.86.49.86.30 - Fax : +33 (0)3.86.49.87.17

WARRANTY :

B200 Flow Control compressors are covered 36 months by warranty within the limits mentioned in our General Sales

Conditions. In case of a use other than that mentioned in the Instructions manual, and without preliminary agreement of

MOUVEX, warranty will be canceled.

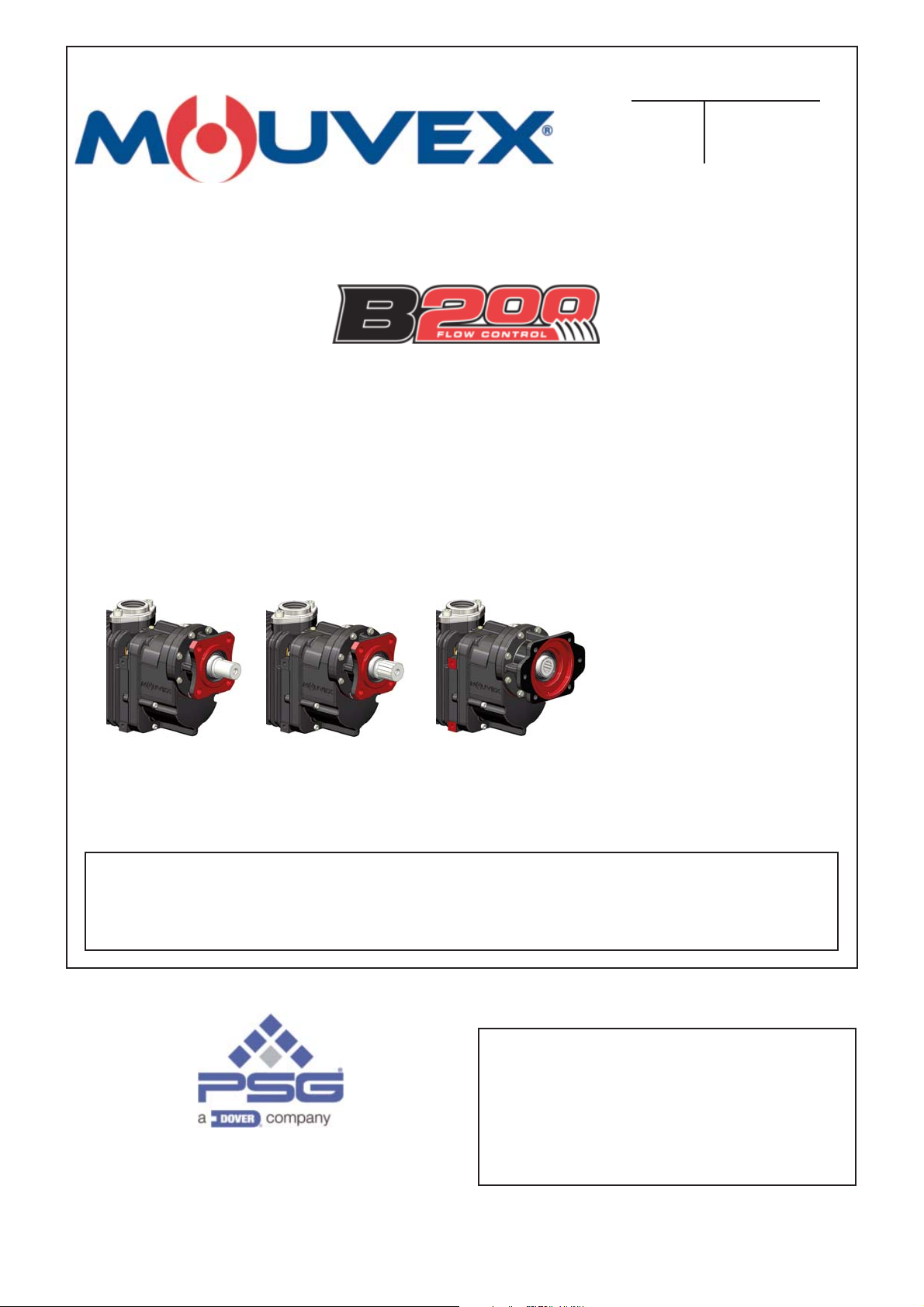

12R/10L PF12R/10L PS 12R/10L HY

2/22

NT 1401-X00 10 18 B200 Flow Control e

MOUVEX TRUCK SCREW COMPRESSOR

SAFETY, STORAGE, INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

MODEL : B200 Flow Control

REMARKS :

MOUVEX truck screw-type compressors MUST be installed in sys-

tems designed by qualified personnel. The installation MUST be in

compliance with local standards, national regulations and rules of

safety.

This manual is designed to permit installation and commis-

sioning of MOUVEX truck screw-type compressors and MUST

accompany the compressor.

Maintenance of MOUVEX screw-type compressors must ONLY

be carried out by qualified technicians. This maintenance must

meet local and national standards as well as all safety regula-

tions. Read this manual, including all instructions and warn-

ings, in full BEFORE any use of MOUVEX compressors.

Reading and the removal of the labels on the MOUVEX com-

pressor apply to approval.

1. OVERALL DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . .4

2. GENERAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1 Principle of operation . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.2 Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . .7

2.3 Operating ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3. INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.1 B200 PF with truck power take-off . . . . . . . . . . . . . . .10

3.2 B200 PS with drive shaft . . . . . . . . . . . . . . . . . . . . . .12

3.3 B200 HY with hydraulic motor . . . . . . . . . . . . . . . . . .13

3.4 Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4. USE OF COMPRESSOR . . . . . . . . . . . . . . . . . . . . . . . . . .17

4.1 Lubricant recommendations . . . . . . . . . . . . . . . . . . . .17

4.2 Filling of lubricant . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

5. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

5.1 Maintenance schedules . . . . . . . . . . . . . . . . . . . . . . .18

5.2 Compressor oil change . . . . . . . . . . . . . . . . . . . . . . . .18

5.3 Inlet shaft replacement . . . . . . . . . . . . . . . . . . . . . . . .19

5.4 Warranty claims . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

6. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . .20

7. STORAGE CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . .20

7.1 Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

7.2 BSC2 oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

8. SCRAPPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

9. COMPRESSORS FORM INFORMATION . . . . . . . . . . . . .21

10. CERTIFICATE OF CONFORMITY . . . . . . . . . . . . . . . . .22

TABLE OF CONTENTS Page

ADDITIONAL DOCUMENTATION

The table below gives the list of instructions in addition

to this central instruction :

B200

application

Spare parts

list

Torque limiter NT 1401-AB00

Air cooler NT 1401-AD00

12R/10L PL 1401-X01

Definition of safety symbols

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the product, or in the manual,

look for one of the following signal words and be alert to the

potential for personal injury, death or major property damage.

Warns of hazards that WILL cause serious personal injury,

death or major property damage.

Warns of hazards that CAN cause serious personal injury,

death or major property damage.

Warns of hazards that CAN cause personal injury or property

damage.

NOTICE

Indicates special instructions which are very important and

must be followed.

DANGER

WARNING

CAUTION

SAFETY CHECK LIST

1. Before operating the compressor, ensure the vessel to which the

compressor is connected is certified to withstand the pressure and

/or vacuum produced.

2. Verify adequately sized relief valves have been fitted to protect the

vessel. Do not use solvents or inflammable products for cleaning

the pipelines and the accessories.

3. Gas/air mixtures which are potentially volatile/explosive must not be

introduced or allowed to be introduced into the compressor.

4. All pressure vessel and piping connected to the compressor must

be isolated and in a safe operating condition.

5. Operators should wear ear protection when operating truck mount-

ed compressors.

6. There are components within the compressor of sufficient weight

to cause injury if mishandled. Use proper lifting devices as neces-

sary.

7. Where necessary, this equipment should be grounded to control

static electricity.

8. The temperature of the air leaving the compressor is elevated

above ambient due to air compression. Check that the elevated

temperatures do not adversely affect the product and any material

used in design of the system. Attach clearly marked warning signs

to warn of potentially hot surfaces on the compressor, piping and

accessories which will burn if touched.

9. Mounting of the compressor must be correctly engineered and the

compressor must be properly secured. Refer to the Compressor

Mounting section of this manual.

NOTICE :

MOUVEX COMPRESSORS ARE DESIGNED TO PRODUCE COM-

PRESSED AIR. NOT TO PUMP LIQUIDS, LIQUEFIED GASSES OR

POWDERS THOUGH THE COMPRESSOR. TO DO SO WOULD VOID

THE WARRANTY.

LIFTING POINTS :

The compressor can be picked up from underneath to be

transported.

Discharge flanges threads can be used to install a lifting lug

in order to transport the compressor.

WARNING

IT IS IMPERATIVE TO APPLY THE

TRUCK PARKING BRAKE AND TO

BLOCK THE WHEELS BEFORE ANY

INTERVENTION DUE TO RISKS OF

SERIOUS BODILY INJURIES OR PRO-

PERTY DAMAGE.

Hazardous machinery

can cause severe

personal injury or

property damage.

WARNING

COMPRESSING GASES INTO A VES-

SEL CONTAINING FLAMMABLE OR

EXPLOSIVE GASES OR COMPRESSING

FLAMMABLE OR EXPLOSIVE GASES,

CAN CAUSE PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

Hazardous fluids

can cause fire,

serious personal injury

or property damage.

WARNING

FAILURE TO INSTALL ADEQUATELY

SIZED PRESSURE RELIEF VALVE(S)

CAN CAUSE PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

Hazardous pressure

can cause

personal injury

or property damage.

CAUTION

COMPRESSOR, PIPING AND ACCES-

SORIES WILL BECOME HOT DURING

OPERATION AND CAN CAUSE SERIOUS

PERSONAL INJURY.

Extreme heat can

cause injury or

property damage.

WARNING

CONTENTS OF THE COMPRESSOR,

TANK, PIPING, AND FILTERS COULD

BE HAZARDOUS TO HEALTH.

TAKE ALL NECESSARY PRECAUTIONS

WHEN PERFORMING COMPRESSOR

SERVICE OR MAINTENANCE.

Hazardous or toxic

fluids can cause

serious injury.

WARNING

THE NOISE EMITTED BY WORKING

MOUVEX SCREW COMPRESSOR

CAN BE HIGHER THAN 80 DBA.

THE END USERS MUST USE, WHEN

NECESSARY THE APPROPRIATE

EAR PROTECTIONS. FAILURE TO

WEAR HEAR PROTECTIONS IN

AREAS WHERE THE NOISE IS

HIGHER THAN 80 DBA CAN LEAD TO

PERMANENT BODY DAMAGE.

A loud noise can

cause permanent

body damage.

3/22

NT 1401-X00 10 18 B200 Flow Control e

SAFETY DATA

4/22

NT 1401-X00 10 18 B200 Flow Control e

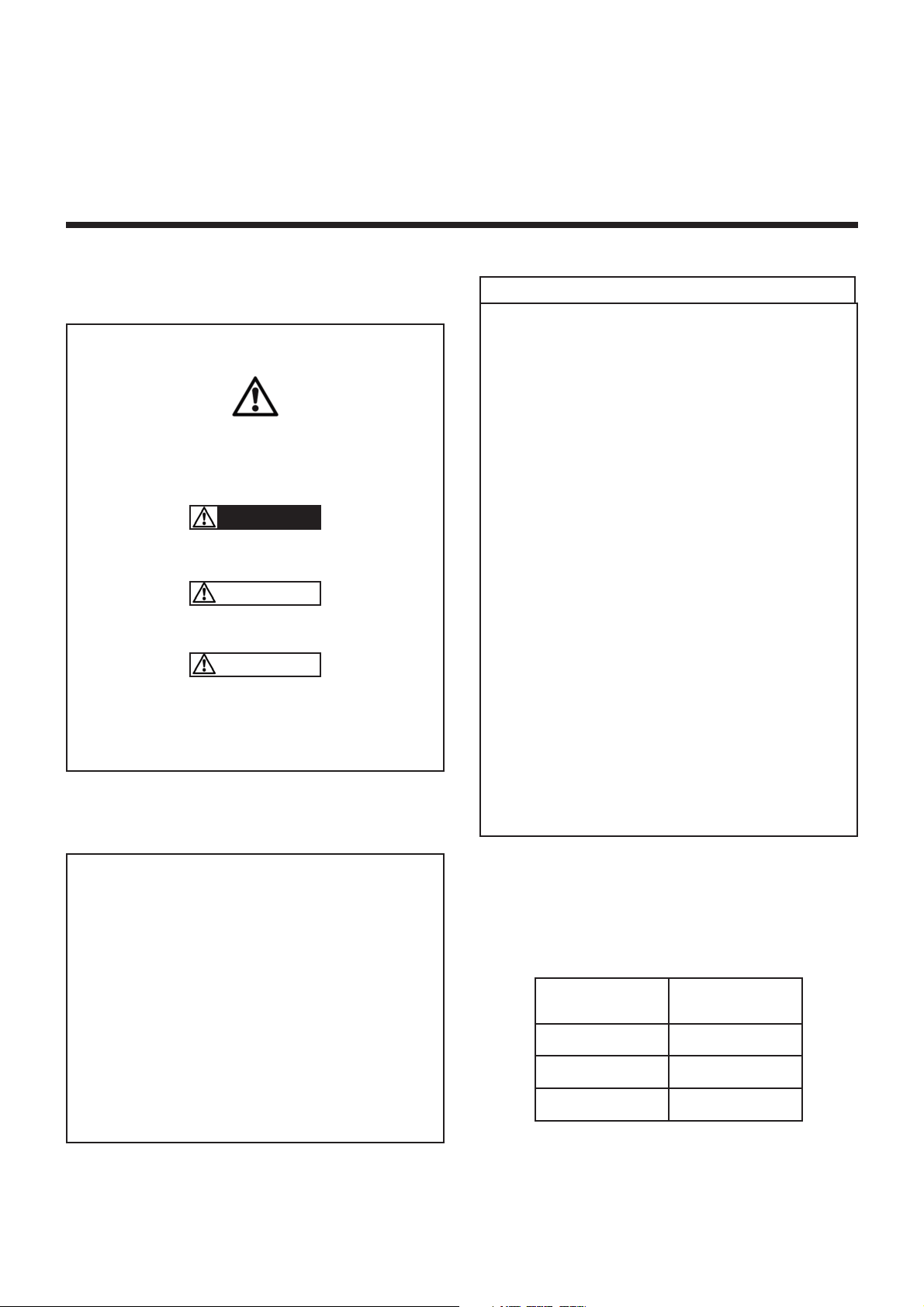

1. OVERALL DIMENSIONS

Identification plate

4 holes Ø 12,5

Swivel cover

Drain plugs

Breather plug

Plug : speed measure

Oil gauge

Oil fill plug

Flange 1,5”

BSP

Splines B8x32x36 DIN 5462

2 holes M10x15

2x 3 holes M10x15

Direction of rotation

MALE SPLINED SHAFT VERSION = PF

MALE KEYED SHAFT VERSION = PS

B200 12R/10L

PS & PF

Weight : 26,3 kg

Serial number

stamped on the body

5/22

NT 1401-X00 10 18 B200 Flow Control e

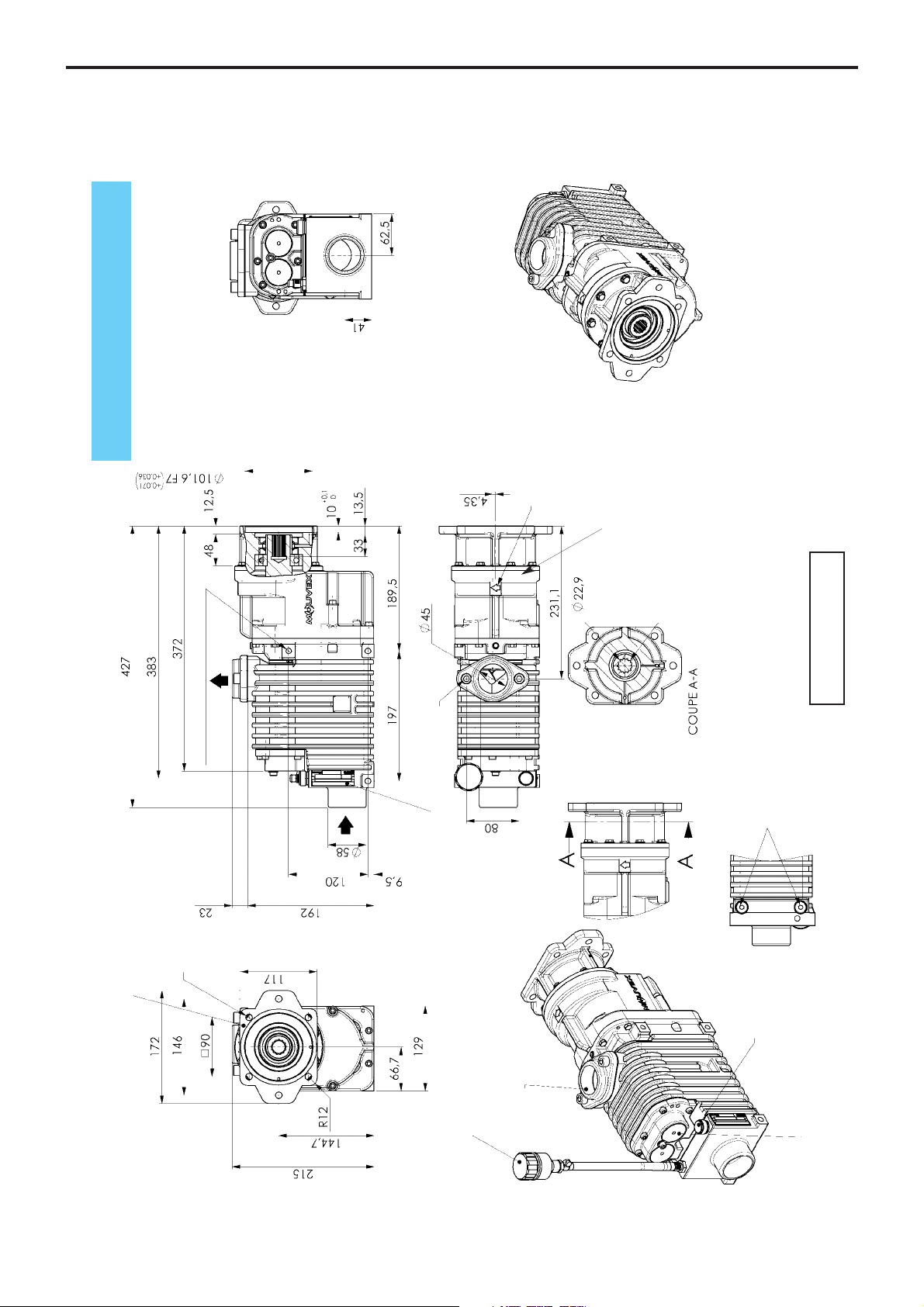

1. OVERALL DIMENSIONS (continued)

Identification plate

6 holes Ø 10,2

Swivel cover

Drain plugs

Breather plug

Plug : speed measure

Oil gauge

Oil fill plug

Flange

1,5” BSP

2 holes M10x15

2x 3 holes M10x15

Direction of rotation

B200 12R/10L

HY

Splines ANSI B92-1a

7/8” SAE_16/32 13 teeth

Weight : 26,8 kg

FEMALE SPLINED SHAFT VERSION

FOR HYDRAULIC DRIVE = HY

Serial number

stamped on the body

6/22

NT 1401-X00 10 18 B200 Flow Control e

1. OVERALL DIMENSIONS (continued)

SILENCER DN 40

CHECK AND RELIEF VALVE

7/22

NT 1401-X00 10 18 B200 Flow Control e

2. GENERAL DATA

2.1 Principle of operation

The male screw and the female screw mesh and rotate

in opposite directions inside the casing fitted with inlet

and discharge ports.

Rotation generates a volume increase on the inner face

between threads and grooves, which corresponds to

inlet, and a volume reduction on the upper face, which

corresponds to compression.

On the discharge port side, a set of gears synchronizes

the male screw and the female screw. Thus, the screws

are not in contact. The discharged air does not enter in

contact with any friction part and remains clean and free

from particles.

On the drive shaft side, the female screw or the male screw

according to the inlet shaft direction rotation is driven by

a set of step-up gears.

Oil circulates, lubricating gears and ball bearings.

On the non-drive end side, the ball bearings are lubrica-

ted permanently with grease.

Sealing is provided between lubricated parts and the

compression stage by means of labyrinth seals.

These seals do not enter in contact with the shaft and

are not subject to wear.

Thanks to their rugged design, B200 compressors have a

long service life.

B200 compressors need very limited maintenance,

which reduce vehicle downtime.

B200 versions 12R (1200 rpm) or 10L (1000 rpm) were

defined so as to drive it directly through on the PTO or

with a drive shaft. Thanks to this system, the installation

is lighter and saves space on the side of the vehicle for

other accessories.

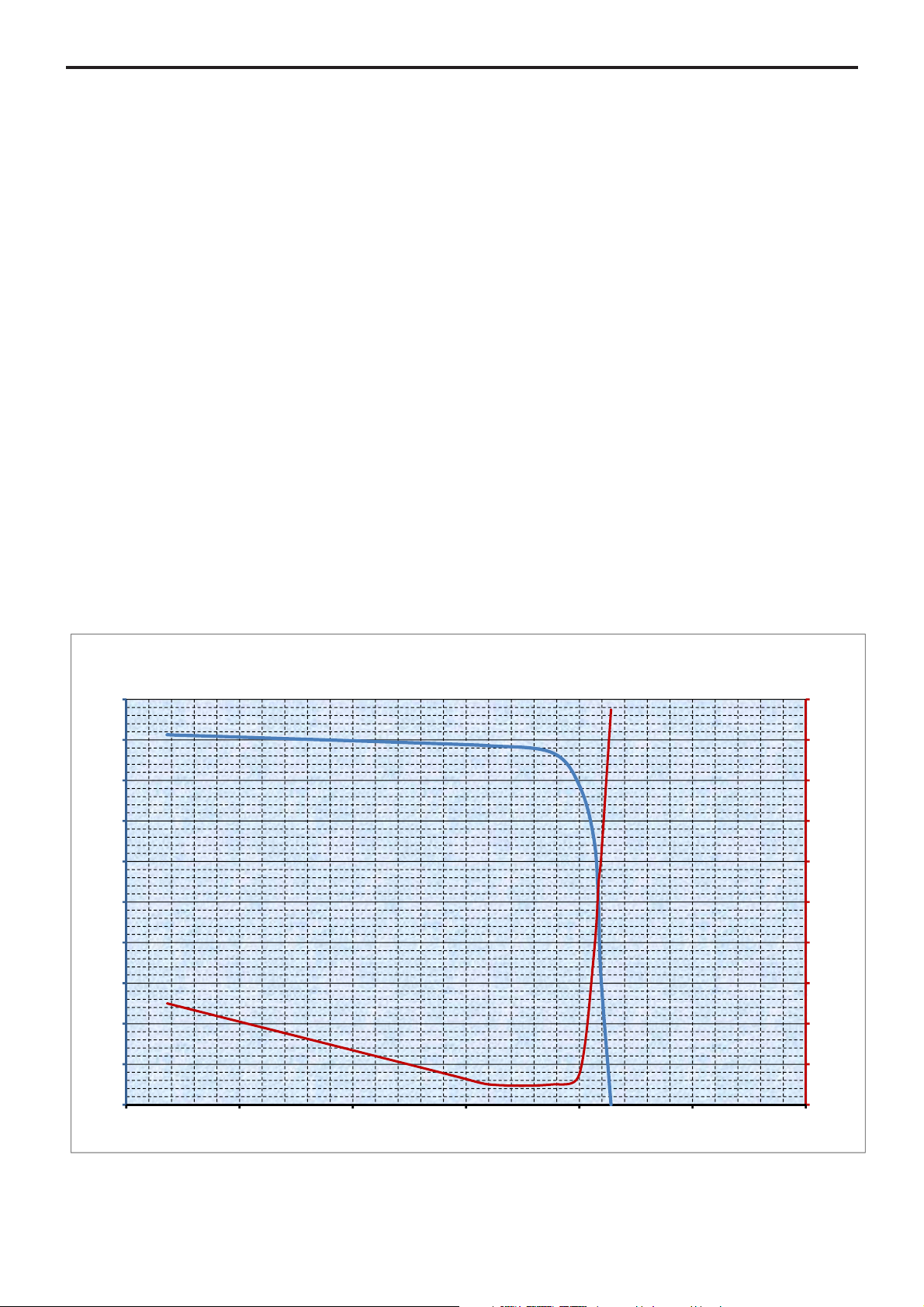

2.2 Technical characteristics

The operating characteristics indicate the requirements

to be met, on the B200 compressors, in order for the

equipment to benefit from the associated warranty.

The operating characteristics for the B200 are given in

the indicative operation conditions : ambient temperature

and air inlet temperature 20°C, atmospheric pressure :

1013 mbars.

Speed :

B200 1 2 3 4

12R (rpm) 840 960 1080 1200

10L (rpm) 700 800 900 1000

Maximum discharge

pressure (bar) 2 2 2,5 2,5

Maximum inlet

temperature (°C) 40 40 40 40

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

180

190

200

0 0,5 1 1,5 2 2,5

EXHAUST PRESSURE (bar)

SUCTION FLOW RATE (m3/h)

0

2

4

6

8

10

12

14

16

POWER (kW)

Suction : 1 atm , 20°C Flow measurement : ISO 5167-2

Characteristics of compressor :

8/22

NT 1401-X00 10 18 B200 Flow Control e

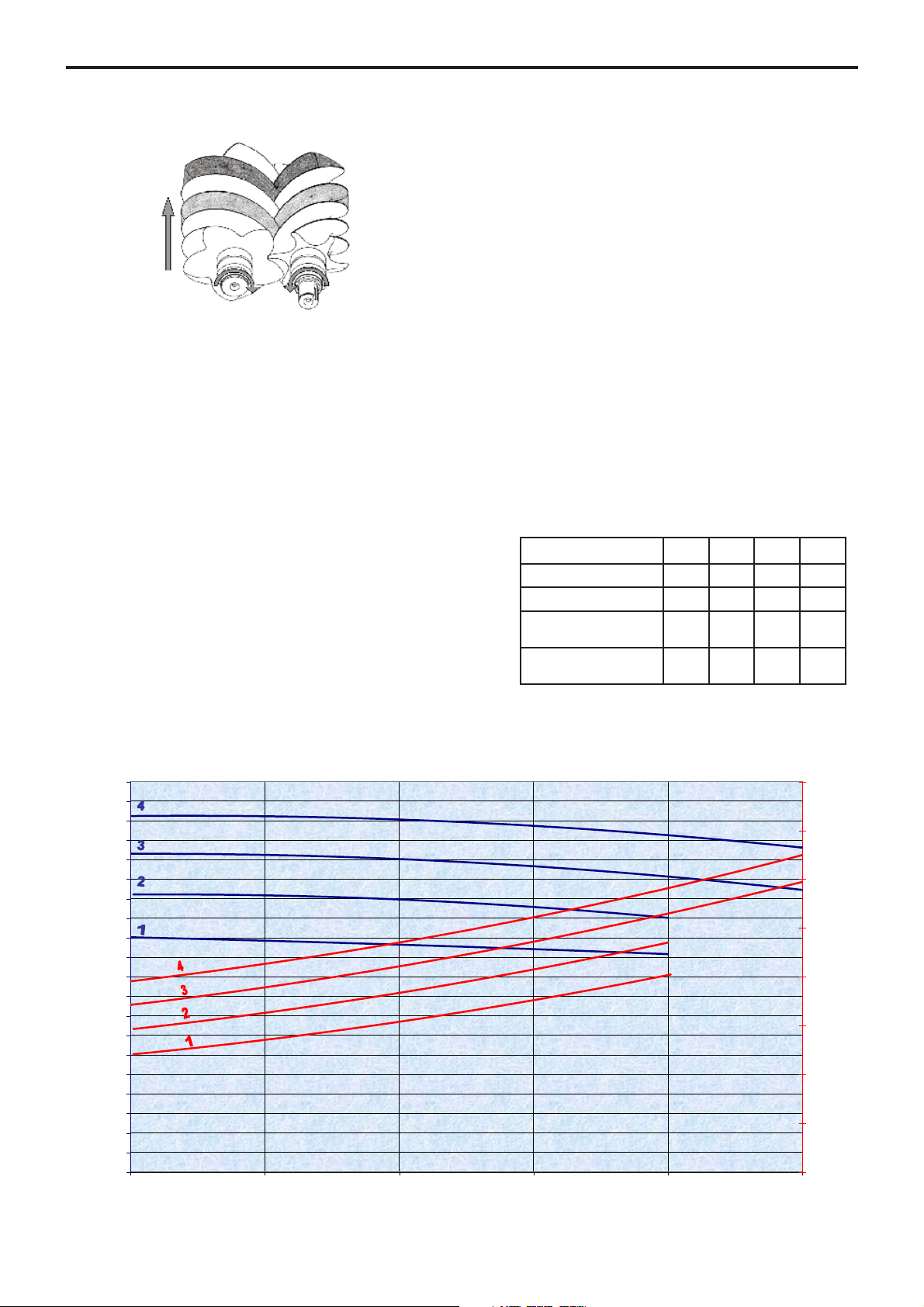

2.3 Operating ranges

The operating ranges specified in the § TECHNICAL

CHARACTERISTICS give the conditions that must be

respected on mounting and packaging of the B200 com-

pressors, in order to be able to benefit from the guaran-

tees for these pieces of equipment.

The MOUVEX relief valve is designed in order to release

any potential overflow. A speed reduction is therefore

needless otherwise to increase the machine temperature.

We recommend to set a single working point corres-

ponding to the maximum speed of the compressor,

which allows an optimal cooling. This operating

point (otherwise the range) must be absolutely fixed

by the Motor management in order to avoid any use

outside theses limits. See § MOTOR MANAGEMENT.

MAXIMUM ACCEPTABLE DISCHARGE PRESSURE

(see § TECHNICAL CHARACTERISTICS)

The Check Relief Valve (CRV) is available with the setting

2 bar, 2,3 bar and 2,5 bar.

It is necessary to select the required value depending on

the limits of the tank, the position of the CRV and the value

of the pressure losses so that the maximum pressure at

the compressor is controlled.

The CRV is assembled and tested by us, its opening

pressure at full flow (closed discharge valve) may fluc-

tuate slightly based on the following parameters :

• Dimensional dispersion associated to the tolerances

of components.

• When the CRV is cold, it generates a greater pressu-

re of 0,15 bar.

• The opening of valves naturally generates pressure

losses, pressure at full flow is therefore increased.

As a result, a hot CRV can reach in full flow a pressure

greater than its value of calibration in the range of 0,35

bar maximum. A 2,5 bar CRV is therefore likely to reach

2,85 bar in full flow.

The operating mode with a closed valve (no unloading flow)

is therefore allowed only intermittently (less than 1 min),

whatever the type of relief valve used. In this case, the full

flow goes out and generates an unnecessary pressure rise.

The result is an overheating of the compressor and poten-

tially irreversible damages not covered by our warranty.

2. GENERAL DATA (continued)

81,0

83,0

85,0

87,0

89,0

91,0

93,0

95,0

97,0

99,0

101,0

0

20

40

60

80

100

120

140

160

180

200

0,00 0,50 1,00 1,50 2,00 2,50 3,00

Pression acoustique à/Acoustic pressure at 1 m (dBA)

Débit Disponible B200 /Available B200 Flow rate ( m3/h)

Pression entrée CRV double/Double CRV inlet pressure (bar)

B200 Flow Control 20 bar : Débit et pression acoustique/Flow rate and acoustic pressure

Aspiration Compresseur/Compressor suction 1 atm 20°C

Mesure débit selon/ Flow measurement : ISO 5162-2

Mesure bruit/ Noise measurement : 1m de la CRV; 1.5 m du compresseur/ 1 m from the CRV; 1.m from the compressor

9/22

NT 1401-X00 10 18 B200 Flow Control e

2. GENERAL DATA (continued)

81,0

83,0

85,0

87,0

89,0

91,0

93,0

95,0

97,0

99,0

101,0

0

20

40

60

80

100

120

140

160

180

200

0,00 0,50 1,00 1,50 2,00 2,50 3,00

Pression acoustique à/Acoustic pressure at 1m(dBA)

Débit Disponible B200 /Available B200 Flow rate (m3/h)

Pression entrée CRV double/Double CRV inlet pressure (bar)

B200 Flow Control 2,3 bar : Débit et pression acoustique/Flow rate and acoustic pressure

Aspiration Compresseur/Compressor suction 1atm 20°C

Mesure débit selon/ Flow measurement :ISO 5162-2

Mesure bruit/ Noise measurement :1m de la CRV; 1.5 mdu compresseur/ 1mfrom the CRV; 1.m from the compressor

81,0

83,0

85,0

87,0

89,0

91,0

93,0

95,0

97,0

99,0

101,0

0

20

40

60

80

100

120

140

160

180

200

0,00 0,50 1,00 1,50 2,00 2,50 3,00

Pression acoustique à/Acoustic pressure at 1 m (dBA)

Débit Disponible B200 /Available B200 Flow rate ( m3/h)

Pression entrée CRV double/Double CRV inlet pressure (bar)

B200 Flow Control 2,5 bar : Débit et pression acoustique/Flow rate and acoustic pressure

Aspiration Compresseur/Compressor suction 1 atm 20°C

Mesure débit selon/ Flow measurement : ISO 5162-2

Mesure bruit/ Noise measurement : 1m de la CRV; 1.5 m du compresseur/ 1 m from the CRV; 1.m from the compressor

10/22

NT 1401-X00 10 18 B200 Flow Control e

3. INSTALLATION

3.1 B200 PF with truck power take-off

3.1.1 Installation of the compressor

The B200 PF compressors have a male splined shaft

DIN 5462 / ISO 14 and a mounting flange ISO 7653-D

that allows them to be installed directly on declutchable

power take-offs.

Power Take Off specifications :

• Must allow a gravity torque of 50 Nm and be able to

accept a working torque of 124 Nm along all the

unloading duration.

Tank builders :

• MERCEDES :

- Original model in aluminium type NA 131 2C com-

patible, in compliance with the dispensation delive-

red by MERCEDES.

- Every other model in cast iron or aluminium in

compliance with the specifications above.

• DAF / IVECO / MAN / RVI / SCANIA :

- Every original or not original model, whatever the

material : cast iron or aluminium, in compliance

with the specifications above.

• VOLVO :

- Original model in aluminium type PTR DM compa-

tible for the range FH/FM in compliance with the

dispensation delivered by VOLVO.

- Every other model in cast iron or aluminium in

compliance with the specifications above.

Not allowed :

• Power take off with double outlet

Installation and operating conditions :

• The use of the discharge flexible supplied by

MOUVEX, fitted in accordance with the B200

Instructions.

• The use of the fixation kit supplied by MOUVEX,

fitted in accordance with the B200 Instructions.

• No extra bracket required to fix the B200.

• B200 must be fitted, operated and serviced in a pro-

per installation in accordance with the B200

Instructions, with the PTO Manufacturer and Truck

Builder Instructions.

Installation is done with screws or studs, minimum grade

8.8.

The B200 PF is provided with a mounting kit that includes

a metallic PTO seal, and 4 specific nuts and washers

that it is essential to use.

If this is possible, tighten the 4 nuts to 37 Nm for all the

PTOs. Don’t put any grease on the studs.

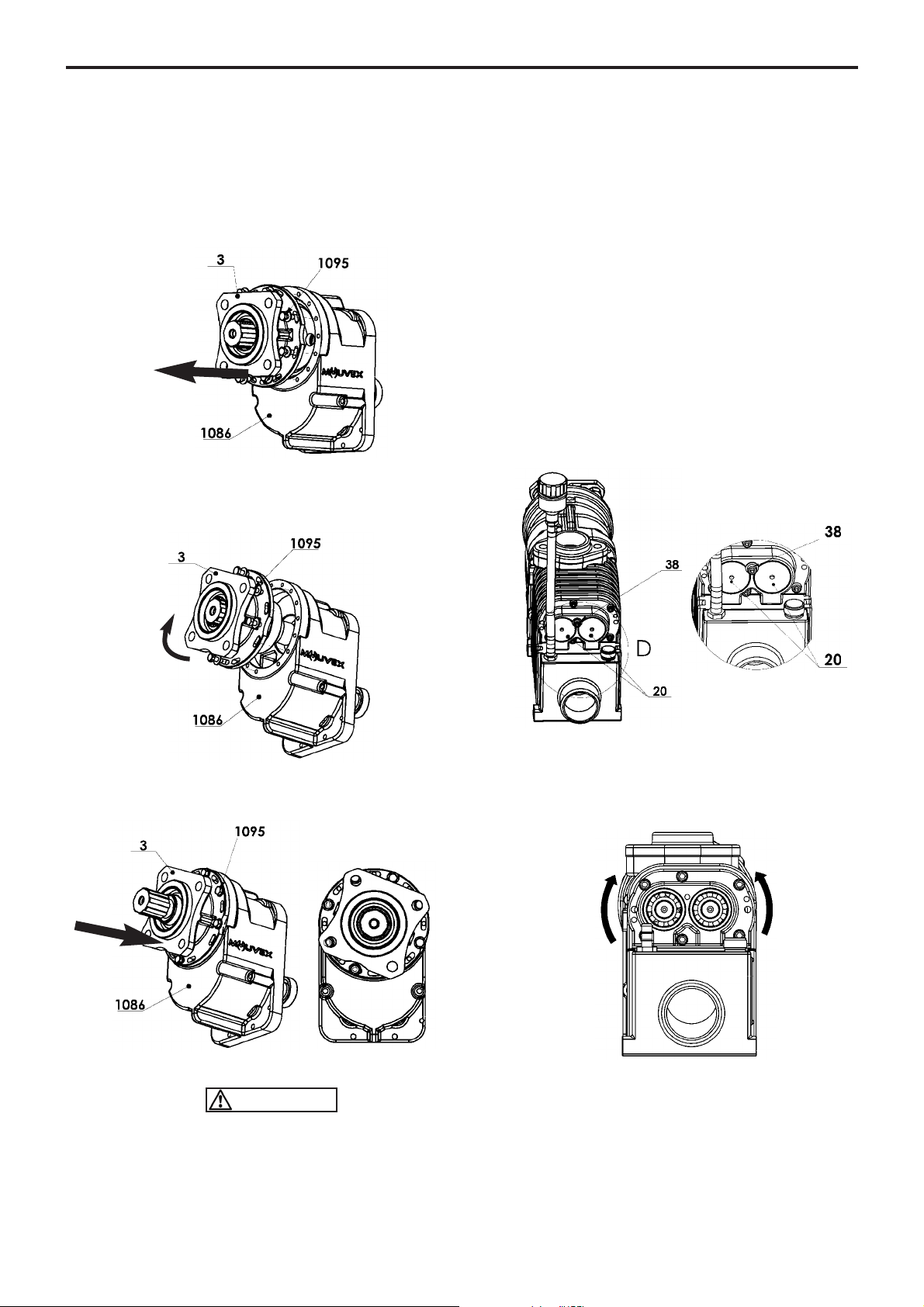

The compressor can be mounted in slightly tilted posi-

tion, but should remain within the angular values defined

on the figures below.

The tapped holes in step-up casing 1086 and the ope-

nings on cover 3can be used to obtain a suitable incli-

nation, whatever the inclination of the PTO flange.

To obtain only a slight inclination of the PTO flange, it is

possible to bring the compressor back in a horizontal

position, taking care to proceed as follows :

• Loosen the 8 screws 1095 without removing them.

• Put the compressor in the desired position.

• Tighten the screws 1095.

Initial position

WARNING

11/22

NT 1401-X00 10 18 B200 Flow Control e

To obtain a strong inclination of the PTO flange, it is pos-

sible to bring the inclination of the compressor to an

angle lower than 10°, taking care to proceed as follows

:

• Loosen and remove the 8 screws 1095.

• Remove the screws 1095 and the cover 3.

• Turn the cover 3in order to offset the ports and posi-

tion them over the next set of tapped holes on the

casing 1086.

• Engage the cover 3in the desired position.

• Tighten the 8 screws 1095.

Final position

Screws 1095 must be :

• equipped with their lock washers, notches on the

side of the screw head,

• sealed with Loctite®* thread locking 243 or equivalent,

• tightened at 13 Nm.

3.1.2 Adjustment of the drive speed

For compressors that are secured by flange on the power

take-off or on the hydraulic motor, the compressor drive

speed can only be measured indirectly on the male or

female screw of the compressor, using a tachometer

with a maximum capacity of 20 000 rpm.

A contact tachometer of the Multimetrix®RPM82 type is

perfectly well suited for measuring the speed on the

screws of the B200 compressor.

Since the male and female screws do not rotate at the

same speed, refer to the tables in the paragraphs below

in order to establish the correspondence between the

drive shaft speeds and the speed of the screw on which

the measurement is performed :

- Measure on the male screw : .......Table 1

- Measure on the female screw : ....Table 2

To access the rotating screws, unscrew screw 38 and

remove plugs 20.

In order to check that the compressor is rotating in

the right direction, check that the male and female

screws rotate in the directions specified on the dra-

wing below, whatever the drive variant (B200 12R

and B200 10L) :

The B200 compressors fitted with a check valve can

withstand a short operating time (less than 30 seconds)

in the opposite direction, as required for checking the

rotation direction.

NOTICE :

Prolonged operation in a direction different from the direc-

tion indicated on the drawing below may cause serious

damage to the compressor and would cancel the warranty.

CAUTION

3. INSTALLATION (continued)

* Loctite®is a registered trademark.

12/22

NT 1401-X00 10 18 B200 Flow Control e

Reversing the rotation direction requires that the com-

pressor be returned to the factory.

Speed pick-up on the male screw :

Table 1

Male screw and drive shaft speed correspondence

Speed pick-up on the female screw :

Table 2

Female screw and drive shaft speed correspondence

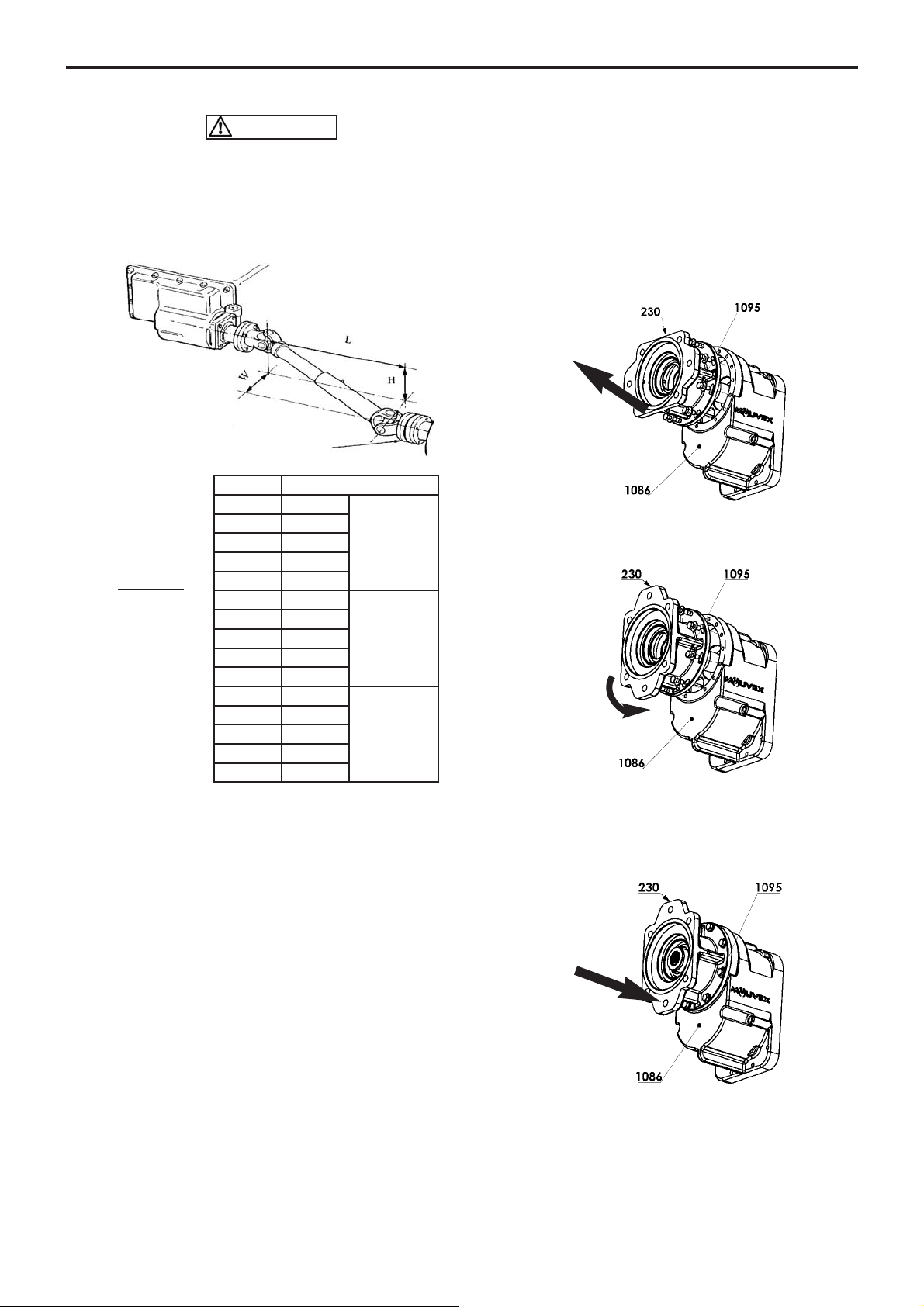

3.2 B200 PS with drive shaft

3.2.1 Installation of the compressor

• Mount the compressor in a position where it is protec-

ted from dirt, debris and road spray. The mounting

location should allow for regular inspection, cleaning

and maintenance.

• The B200 compressor mounting points are located on

the sides of the body.

Installation is performed by means of screws, minimum

grade 8.8.

3.2.2 Recommended drive conditions

The drive shaft must be sized so as to be able to accept

the loads above and also the starting torque.

Operating torque at full speed

It is the responsibility of the installer to check that his

design protects the transmission if the compressor blocks.

Compressors B200 12R PS and B200 10L PS must

be protected by a 400 Nm torque limiter, in order to

protect the truck's transmission if the compressor is

jammed. MOUVEX may not be held liable for any

damages resulting from such jamming if the torque

limiter has not been installed.

Comply strictly with the following instructions :

• The drive shaft slides perfectly well during rotation.

Square slip joints are forbidden.

• Drive shaft length should be as short as possible and

the drive shaft MUST be balanced.

Direction of rotation

Fixation points

Female

screw

Male screw

Inlet shaft speed

(rpm)

Female screw speed

(rpm)

B200 12R

850 11 600

1 000 13 640

1 100 15 000

1 200 16 365

B200 10L

700 11 450

800 13 095

900 14 730

1 000 16 365

Inlet shaft speed

(rpm)

Male screw speed

(rpm)

B200 12R

850 13 910

1 000 16 365

1 100 18 000

1 200 19 640

B200 10L

700 13 750

800 15 710

900 17 675

1 000 19 640

B200 Pressure

1,5 bar 2,0 bar 2,5 bar

Torque 12R (Nm) 83 93 103

Torque 10L (Nm) 100 111 124

WARNING

DRIVES SHAFTS MUST BE GUARDED

IF EXPOSED. OPERATION WITHOUT

GUARDS CAN CAUSE SERIOUS PER-

SONAL INJURY, MAJOR PROPERTY

DAMAGE OR DEATH.

Do not operate

without guard

in place.

3. INSTALLATION (continued)

13/22

NT 1401-X00 10 18 B200 Flow Control e

The non balancing of the drive shafts can lead to

mechanical ruptures that are susceptible of causing

important property damage and/or serious injuries.

• The drive shaft and compressor shaft MUST be parallel

within 1° and have a maximum of 10°compound misali-

gnment. See Table :

• Universal joints MUST be in phase, with the drive shaft

slip joint at mid-position. Use an even number of uni-

versal joints.

• Make sure that the compressor rotates in the direction

of the arrow on the body.

The B200 compressors fitted with a check valve can

withstand a short operating time (less than 30

seconds) in the opposite direction, as required for

checking the rotation direction.

NOTICE :

Prolonged operation in a direction different from the

direction indicated on the drawing below may cause

serious damage to the compressor and would cancel the

warranty.

3.3 B200 HY with hydraulic motor

The B200 HY compressors have a female splined shaft

ANSI B92-1a that allows to flange directly on hydraulic

motor epuipped with a shaft 13T 718 SAE 16/32 and a

mounting flange SAE B 2 or 4 holes.

3.3.1 Hydraulic motor assembly

It is possible to change the orientation of the lantern 230,

taking care to proceed as follows :

• Loosen and remove the 8 screws 1095.

• Rotate the lantern 230 so as to offset the ports and

move them over the set of tapped holes on casing

1086 that approach the desired position.

• Make sure that at least one of the 2 collectors is loca-

ted in the lower part of the lantern 230, otherwise turn

the lantern 230 by 180°.

• Engage the lantern 230.

• Tighten the 8 screws 1095.

AUniversal joint angle

0,017 1°

VERY GOOD

0,035 2°

0,052 3°

0,070 4°

0,087 5°

0,105 6°

GOOD

0,125 7°

0,141 8°

0,158 9°

0,176 10°

0,194 11°

LIMIT

VALUES

0,213 12°

0,231 13°

0,249 14°

0,268 15°

_________

A = √H² + W²

L

If H = Zero, A = W / L

If W = Zero, A = H / L

CAUTION

3. INSTALLATION (continued)

14/22

NT 1401-X00 10 18 B200 Flow Control e

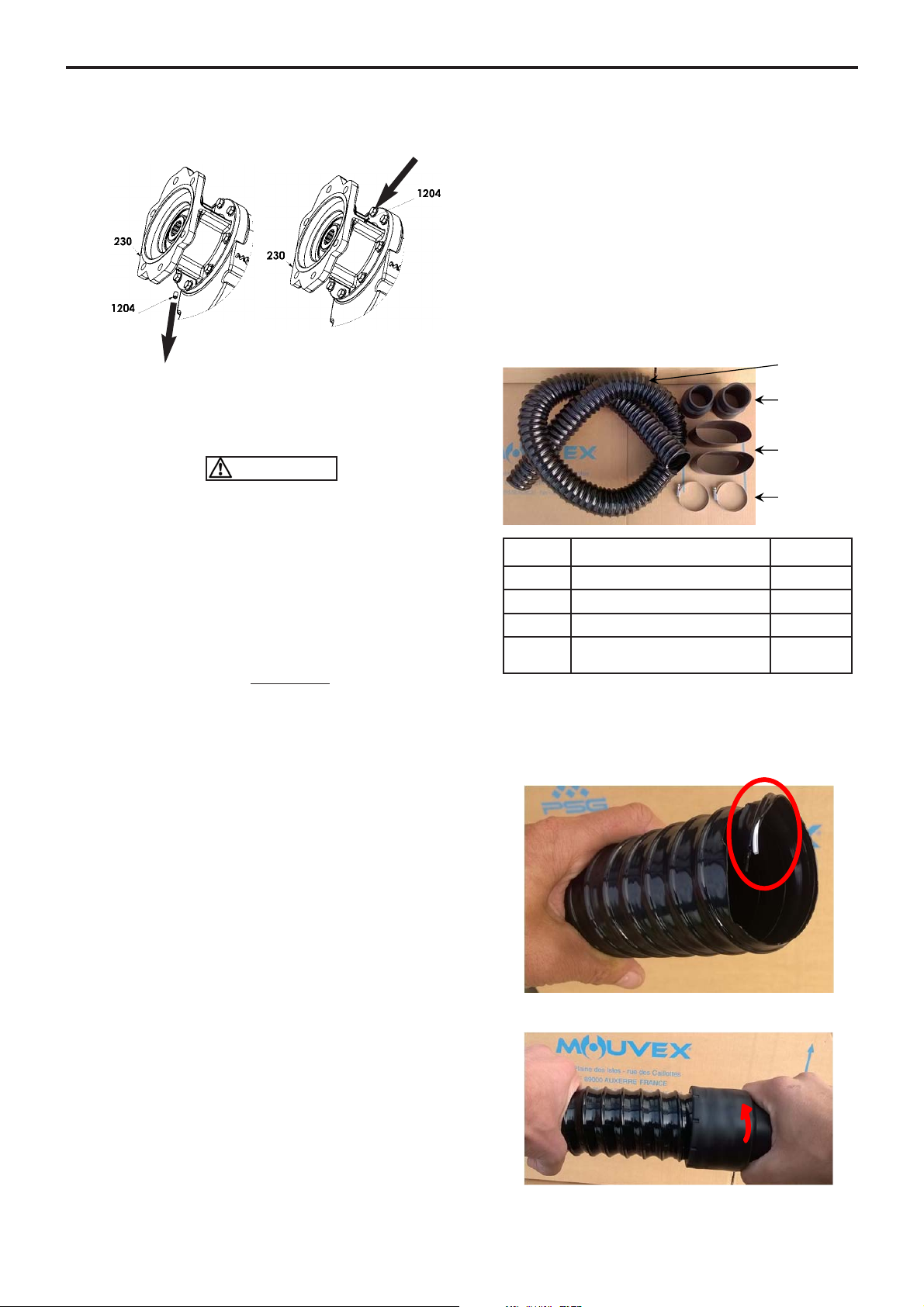

• Install the screwing plug 1204 in the highest collector

on the lantern 230.

• Check that the rotation direction of the motor and the

compressor are correct.

• Lubricate the motor shaft and the female splined shaft

1091 to facilitate subsequent disassembly.

Screws 1095 must be :

• equipped with their lock washers, notches on the

side of the screw head,

• sealed with Loctite®* thread locking 243 or equivalent,

• tightened at 13 Nm.

3.3.2 Adjustment of the drive speed

See § ADJUSTMENT OF THE DRIVE SPEED.

3.3.3 Motor management

The Motor management is mandatory, it has to ensure 2

missions :

• To secure the operating range : The operating point

(otherwise the range) must be set to avoid any ope-

ration outside the range. If a risk remains (need to

switch in complement a gear box button) an infor-

mation sticker shall be affixed in the cabin.

• To ensure a smooth start-up : The start-up of the

PTO must be carried out gradually without genera-

ting a peak of torque to avoid damaging the

Compressor. This is particularly sensitive for the

B200 PF which is equipped with a shaft groove.

It is in particular to ensure that the parameter

‘’TRANSMISSION INPUT SPEED’’ (N° 10.520 on

MERCEDES) is set to a value less than 10.

Otherwise, that will generate in a medium term a

breakage of the B200 shaft.

3.4 Piping

3.4.1 Inlet

The suction side of the compressor MUST be fitted with

an adequately sized air filter, which MUST be protected

from water, road spray, or other debris. This filter is avai-

lable from MOUVEX. Use of wrong filter will void warran-

ty. The compressor filter must be connected by means of

a hose capable of operating in vacuum and of a sufficient

length to absorb the relative movements of the compressor

relative to the chassis. The compressor is delivered with

an inlet connection kit which is installed as follows :

Composition of the kit :

Assembling procedure :

• To cut the hose to the length requested.

• To fold back the end of the wire inside.

• To screw home the humps at the 2 ends.

164

884

152A

165-166

Item Description Quantity

152A Heat shrinkable sleeve 2

164 Hose 1

165-166 Clamp 2

884 Hump 1XØ50

1XØ57

CAUTION

3. INSTALLATION (continued)

* Loctite®is a registered trademark.

• Result :

• To pass a heat-shrinkable sleeve on an end and to

center it on the end of the hump. To retract gradually by

means of a heat gun. Attention not to point the gun

towards the hose not covered, risk of perforation.

To proceed in the same way at the other end.

• To check the hose is perfectly clean inside, and to remove

the protections caps on the compressor.

• To assemble the unit on the compressor inlet port and

to tighten the clamp : cast solid end.

Example :

• To proceed in the same way with the air filter.

• To then suspend the hose while taking care to protect

it from any friction and the potentially hot bodies such

as muffler.

The inlet filter should be positioned to draw in clean, cool

air, and should be mounted away from any engine heat

and exhaust.

The compressor inlet suction air must be filtered in order

to eliminate particles bigger than 5 µm.

The maximum pressure drop at suction must be lower

than 75 mbar.

A restriction indicator system must permit changing the

suction filter when it creates a pressure drop greater

than 75 mbar.

The maximum acceptable temperature at suction as a

function of equipment operating conditions is given in

the § TECHNICAL CHARACTERISTICS.

3.4.2 Outlet

The flange supplied must be equipped with its gasket,

screw tightened at 44 Nm.

Piping MUST be at least as large as the compressor

suction and discharge connections.

All the connections located between the compressor and

the trailer hose connection point must be absolutely

waterproof. For that reason, they must be welded.

The B200 PF compressors directly flanged onto the

power take-off must be fitted with the metallic discharge

hose delivered with the equipment. This woven stainless

steel hose is designed to avoid having any stresses

applied on the compressor flange and the rigid pipes of

the systems, as induced by the relative movements of

the compressor with respect to the chassis.

For the B200 PF, it should cancel the stresses on the

flange, as induced by the movement of the compressor,

and respect the rules below :

• install a 90° elbow between the flange and the hose.

• support the stainless steel hose correctly at its end part.

• the hose output pins should be mounted in the same

horizontal plane. Make sure that the installation allows

a compressor displacement of ± 5 cm to be obtained.

• on the same horizontal plane, if the output pins are

not parallel, the bending radius must be as large as

possible, and in any case at least equal to 50 cm.

Make sure that the installation allows a compressor

displacement of ± 5 cm to be obtained.

==

5 cm

5 cm

15/22

NT 1401-X00 10 18 B200 Flow Control e

3. INSTALLATION (continued)

16/22

NT 1401-X00 10 18 B200 Flow Control e

Top view

Installation rules : Discharge line

All the connections must be welded and be the object

of a waterproof quality control.

During installation, position a pressure gage on the com-

pressor output, so as to measure the operating pressure.

The measurement should be done at the discharge flange

level and should not exceed 2,5 bar over the allowable

operating range of the compressor.

It is mandatory to protect the compressor with the Check

relief valve supplied by MOUVEX. The check valve pre-

vents any air from returning in the compressor when it is

no longer in operation.

The safety valve protects the compressor against possi-

ble overpressure. The maximum set point of the valve is

2,5 bar. If there is a drop in pressure between the pres-

sure relief valve and the compressor, reduce the pres-

sure relief valve setting by the value of the pressure

drop. It is the installor responsability to check that the

relief valve is compliant with the compressor performance

for the application speed.

The compressor is delivered with a check and relief valve

allowing 3 settings capabilities : 2 bar, 2,3 bar or 2,5 bar.

It will have to be selected depending of the installation limits

and by making sure the maximum pressure of 2,5 bar of

the compressor is never exceeded. Be careful in particular

with the pressure drop located between the check relief

valve and the compressor especially if an air cooler and

a silencer are used.

It is forbidden to insert a damping valve in the pipe lin-

king the compressor to the tank hose connector in order

to avoid any risk of water entering.

Ensure that ALL components are capable of operation at

the maximum system pressure limits and that all vessels

are adequately protected by SEPARATE relief valves.

3.4.3 Oil breather

Compressor B200 is fitted with an oil breather which is

mounted on a hose for easier installation.

In case of the inclination of the compressor, it is essen-

tial to position the breather on the highest tapped hole.

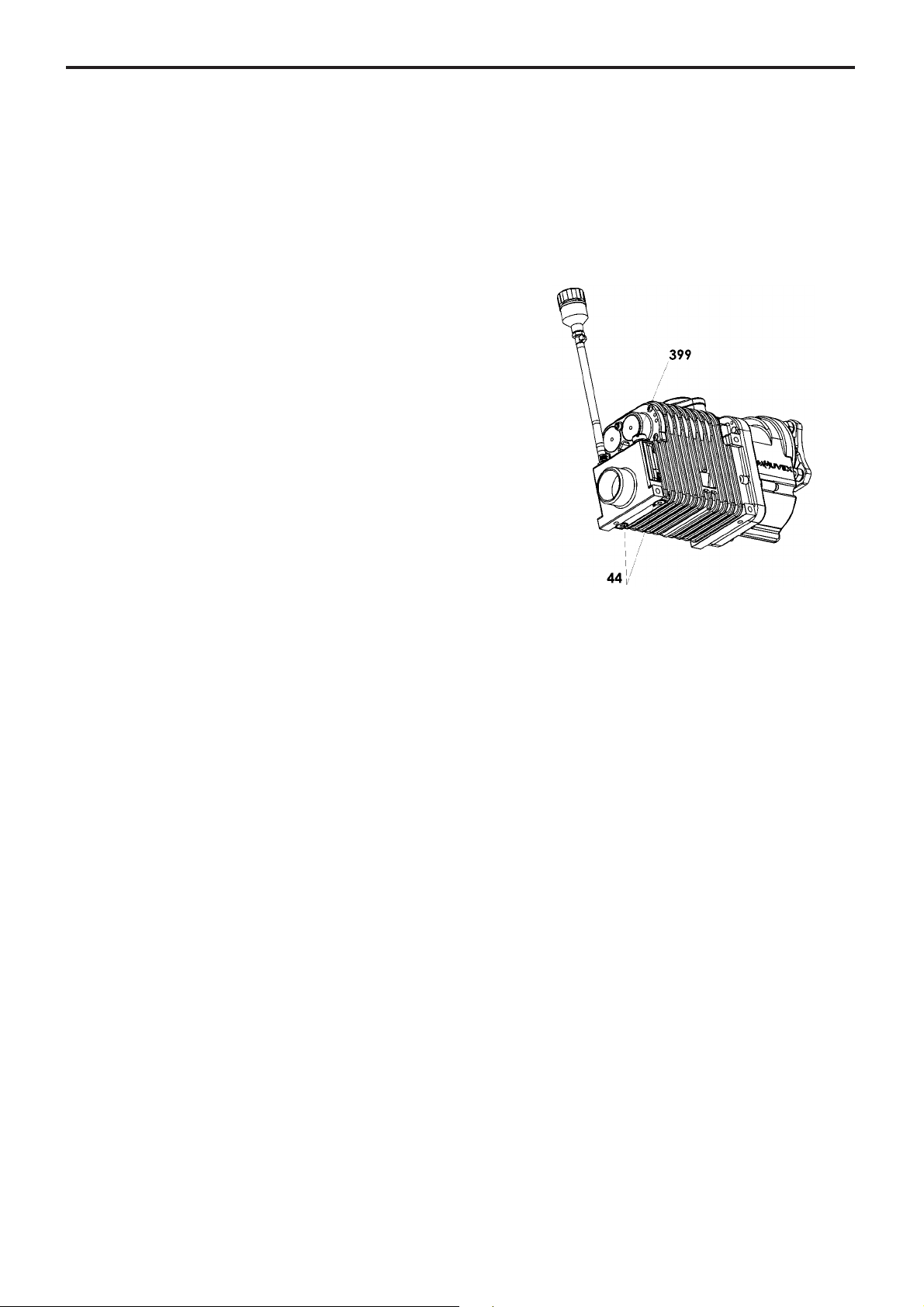

Invert the positions of the oil gage 399 and the breather

assembly, as appropriate.

Position the breather plug in a clear area, to avoid any oil

condensation.

Do not crush the hose when positioning the breather, so

as to allow any oil vapors to be evacuated.

The hose mustn’t be shortened,, keeps imperatively its

original length.

The breather must be placed above the compressor,

preferably with the connecting hose running up towards

the breather.

1

1

1111

1

1

CRV

Option

silencer

Hose (B200PF)

Oil breather

}

R mini 50 cm

WARNING

FAILURE TO INSTALL ADEQUATELY

SIZED PRESSURE RELIEF VALVE(S)

CAN CAUSE PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

Hazardous pressure

can cause

personal injury

or property damage.

CAUTION

OPERATING A COMPRESSOR ABOVE

ITS MAXIMUM OPERATING PRESSURE

CAN CAUSE SUBSTANTIAL PROPERTY

DAMAGE OR SERIOUS BODILY INJU-

RIES.

Extreme heat can

cause injury or

property damage.

3. INSTALLATION (continued)

17/22

NT 1401-X00 10 18 B200 Flow Control e

4. USE OF COMPRESSOR

4.1 Lubricant recommendations

The MOUVEX screw compressor operates with MOUVEX

BSC2 oil.

It is imperative to change the BSC2 oil every year or 500

operation hours.

The BSC2 oil covers operation from -30°C to +40°C.

4.2 Filling of lubricant

Our compressors are delivered without oil. The use

of a compressor with an oil level different from 1,2 l

± 10% can lead to important property damage and

serious injuries.

Before starting the system, fill the casing with oil so that

the oil level is set between the min and max value of the

gauge.

4.3 Operation

• The compressor must be started with the discharge

valves open.

• The operator should remain nearby the equipment

throughout the use to ensure the proper functioning

of the system.

• Check the compressor drive shaft rotation direction :

- B200 12R PS and B200 10L PS : The drive shaft

rotation direction must match with the arrow on the

body of the compressor.

- B200 12R PF and B200 10L PF : Refer to § DIRECT

INSTALLATION TRUCK POWER TAKE-OFF.

4.3.3 Start-up procedure for manual gear box

• Start the engine and run with standard speed.

• Depress clutch and engage the PTO.

• Release the clutch SLOWLY.

• Set engine speed to give the correct compressor speed.

4.3.4 Shutting down procedure for manual gear

box

• Depress the clutch and disengage the PTO.

• Reduce engine speed to idle.

ALWAYS DISENGAGE THE DRIVE BEFORE SLOWING ENGINE

DOWN.

• Release the clutch.

NOTICE :

Prolonged operation in a direction other than the

direction of the arrow on the body can cause serious

damages to the compressor and would cancel the

warranty.

• Avoid if possible stopping or starting the compressor

with the tank under pressure.

• At commissioning, check that the combinations of

rotation speed and discharge pressure of the com-

pressors are in conformity with those indicated in §

TECHNICAL CHARACTERISTICS.

During operation, the temperature of the surface of

a compressor and nearby parts can be in the region

of 200°C. The compressor and the parts located

nearby are thus susceptible of provoking serious

burns and property damage. Be careful to not

approach elements that are sensitive to heat and

affix plates informing users that the compressor is

hot, to prevent any risk of burns.

PTO

ON SLOWLY

PTO

OFF

CAUTION

CAUTION CAUTION

18/22

NT 1401-X00 10 18 B200 Flow Control e

5. MAINTENANCE

5.1 Maintenance schedules

After every cleaning of the truck

Always run the compressor for 15 minutes to remove

any water that inadvertently gets into the piping. DO

NOT fog or introduce anti-corrosive liquids into the com-

pressor to prevent corrosion : Use of liquids in the com-

pressor will cause failure.

Weekly

1. The compressor should be run for at least 15 minutes

to prevent moisture from collecting inside. This will

reduce the risk of corrosion damage to the compres-

sor and other equipment in the piping.

2. Inspect and clean air filter. Inspect DAILY if operating

in dirty or severe environment. Check the condition of

the inlet filter hose for splits and tears. Replace or

repair as necessary.

3. Inspect compressor, system piping and components.

Clean or repair as necessary.

4. Check power transmission line.

5. Check the air filter restriction indicator. When the indica-

tor turns red, replace the filter cartridge. Before repla-

cing the cartridge with a new one, clean the inside of

the filter's body with a clean damp cloth.

Per manufacturer’ s recommendations

Lubricate the universal seal (for B200 PS models).

Monthly

1. Check the relief valve(s) for wear and proper settings.

Replace or adjust as necessary.

2. Check that the check valve works properly, replace as

necessary.

3. Check the oil level and complete if necessary.

Yearly :

1. Check tightness of the 4 mounting nuts on the B200 PTO.

5.2 Compressor oil change

Oil recommendations : See § LUBRICANT RECOMMEN-

DATIONS.

Depending on the inclination of the compressor, remove

the lowest drain plug 44.

Put plug 44 back into place and remove filling plug 399

and fill the compressor with new oil, as recommended in

§ LUBRICANT RECOMMENDATIONS.

19/22

NT 1401-X00 10 18 B200 Flow Control e

5. MAINTENANCE (continued)

5.3 Inlet shaft replacement

The B200 PF inlet shaft has a groove that breaks the

shaft in case of excess torque, as required to protect the

gear box and the PTO.

Before replacing the inlet shaft, it is essential to make sure

that the compressor is not damaged :

• Loosen and remove the 8 screws 1095.

• Remove the wheel, complete with the remaining part

of the shaft.

• Rotate the wheel 6 manually and check that it can

rotate freely and without any hard point over a com-

plete rotation.

• Inspect the screws on the discharge part and make

sure that there are not any marks of contact between

the screws, or due to the presence of any foreign

bodies.

The compressor is to replace if :

• wheel 6does not rotate.

• wheel 6cannot rotate easily.

• marks can be seen on the screws.

• Engage the bearing of shaft kit 1071 in the housing of

casing 1086.

• Check the state of the lip seals 1089 and the O’ring

40. Make sure that they are not damaged.

• Engage the lantern 230 in the desired position.

• Tighten the 8 screws 1095.

For the installation of the compressor on the power take-

off, refer to § DIRECT INSTALLATION ON B200 PF TRUCK

POWER TAKE-OFF.

Screws 1095 must be :

• equipped with their lock washers, notches on the

side of the screw head,

• sealed with Loctite®* thread locking 243 or equivalent,

• tightened at 13 Nm.

5.4 Warranty claims

The compressor oil is considered as wear part.

No failure connected with wear part damage will be

accepted under warranty conditions.

The following situations will void warranty for all compo-

nents of the compressor :

• Installation not in accordance with the CL 1401-001

Control check list installation B200 FC.

• No MOUVEX Check relief valve.

• Tampering with the setting of the relief valve.

• Presence of foreign body inside the compressor body.

• Traces of damage representative of abnormal use of

the compressor.

• Use of non genuine parts.

• If the compressor is repaired by a repairer who is not

a MOUVEX-approved repairer.

• Construction of the package not validated by our

Design Office.

• Use of an oil other than BSC2.

• Presence of a dumping valve on the pipe linking the

compressor to the tank hose connector.

• Motor management not fixed, allowing the operator a

using outside the working range.

Before returning your equipment to the factory, you must

first obtain an Equipment return approval (RMA) from our

After Sales Department.

A Compressors form information shall be filled by the

installer or distributor and send to MOUVEX in order to

claim for a warranty.

WARNING

CAUTION

* Loctite®is a registered trademark.

20/22

NT 1401-X00 10 18 B200 Flow Control e

7.1 Compressor

The equipment must be systematically stored in an area

sheltered from bad weather.

The equipment must bear its original protective compo-

nents until it is installed in its final application.

If installation is interrupted, put back in place the original

protective components or equivalent components.

7.2 BSC2 oil

In its unopened original container in a dry, frost-free and

light-free place.

The maximum shelf life is approx. 60 months.

7. STORAGE CONDITIONS

The compressor must be scrapped in compliance with the

regulations in force.

During this operation, particular care must be paid to the drai-

nage stages of the compressor.

8. SCRAPPING

Problem Possible origin Possible solution

1. Pressure issue

Too much pressure drop. Tocheck pipes diameter.

Relief valvedamaged. Tocheck the opening point.

Noreturn valvedamaged. Tocheck the proper operating of the Noreturn

valve.

2. Flow rate issue

Wrong Compressor speed. Toadjust the speed by taking care of the range

allowed.

Relief valvedamaged. Tocheck the opening point.

3.Abnormal hightemperature

Air filter clogged. Toclean the cartridgeor to replace it.

Air pressure too much high. Tosee problems 1. /2.

Outside temperature too much high. Torespect the maximum external temperature

allowed.

Lack of oil. Tocheck the oil level.

Compressor speed too much low.Toadjust the speed by taking care of the range

allowed.

4. Inlet pressure drop > 75mbar

(Clogging indicator red)

Air filter clogged. Toclean the cartridgeor to replace it.

Air inlet hose folded. Tocheck the air inlet hose.

5. Compressor doesn’toperate

Torque limiter damaged. Toreplace the torque limiter.

Transmission damaged. Toconsult your Service point.

6. Torque limiter damaged

Screw Compressor damaged. Toconsult your Service point.

Wrong motor /transmission management. Toconsult your Truck dealer.

Oil too much viscous. Tobe in compliance with the MOUVEX

Instructions.

7.Oil leak

Too much oil. Tocheck the oil level.

Oil breather clogged. Toclean the oil breather.

8. Vibrations

Wrong motor speed. Toincrease the speed by taking care of the

rangeallowed.

Transmission damaged. Tocheck the driving shaft.

Lack of rigidity of the chassis. Tobe in compliance with the Truck

Manufacturer Instructions.

6. TROUBLESHOOTING

CAUTION :

OBSERVE ALL SAFETY WARNINGS CONTAINED IN THIS MANUAL.

Table of contents

Popular Air Compressor manuals by other brands

Certa

Certa CTAICOMWISA quick start guide

Iwata

Iwata Silver JET IS50 Operating instructions manual

Parkside

Parkside PKO 270 A1 Operating and safety instructions

Black & Decker

Black & Decker 641915-00 instruction manual

California Air Tools

California Air Tools 20040DC owner's manual

EINHELL

EINHELL EURO 4000/1 operating instructions