Puch Magnum II MKII User manual

Dear

Puch

Owner

This

is

your

riding, maintenance

and

warranty guide. By following the instructions

described in this booklet,

we

at

Puch know you will enjoy many miles

of

pleasurable

Moped Riding.

Should a need

ever

exist for parts

or

service, simply contact your Puch dealer.

He

also

hasavailablefor

your

purchaseaServiceManualunder

the

partNr

.

907

.2.

71

.894.5 0180

Thank you for joining the Puch family, please ride safely and have fun.

P.O.

BOX

7777

Greenwich, Ct. 06830

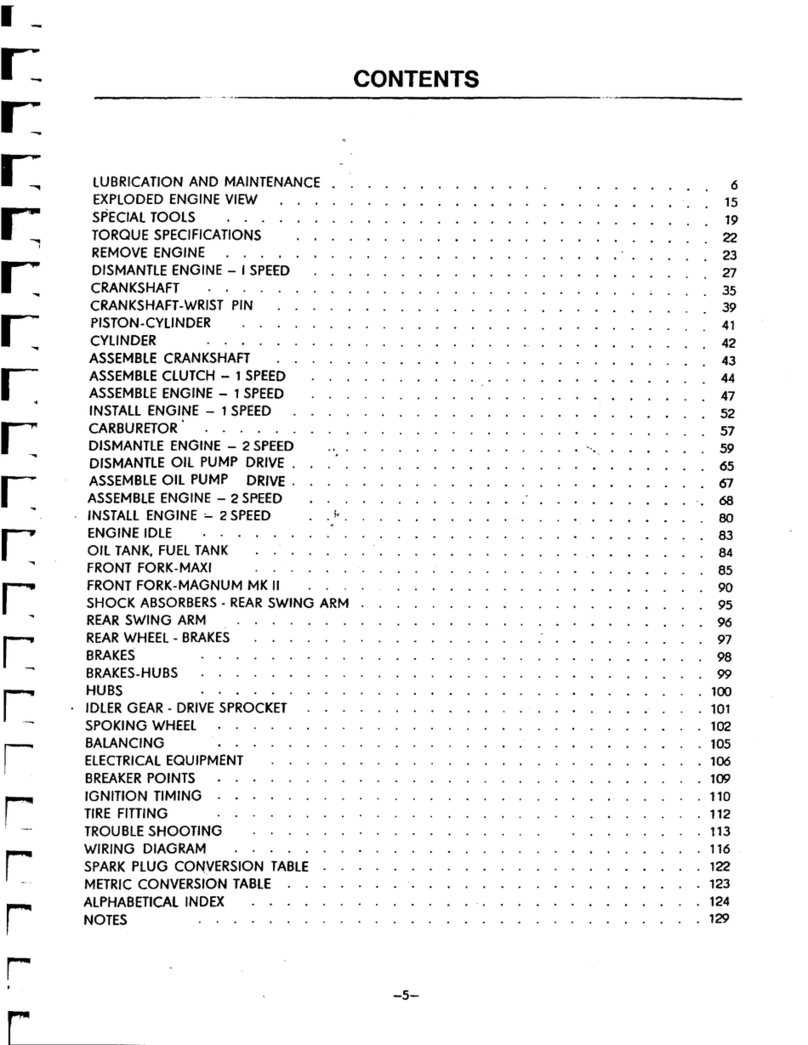

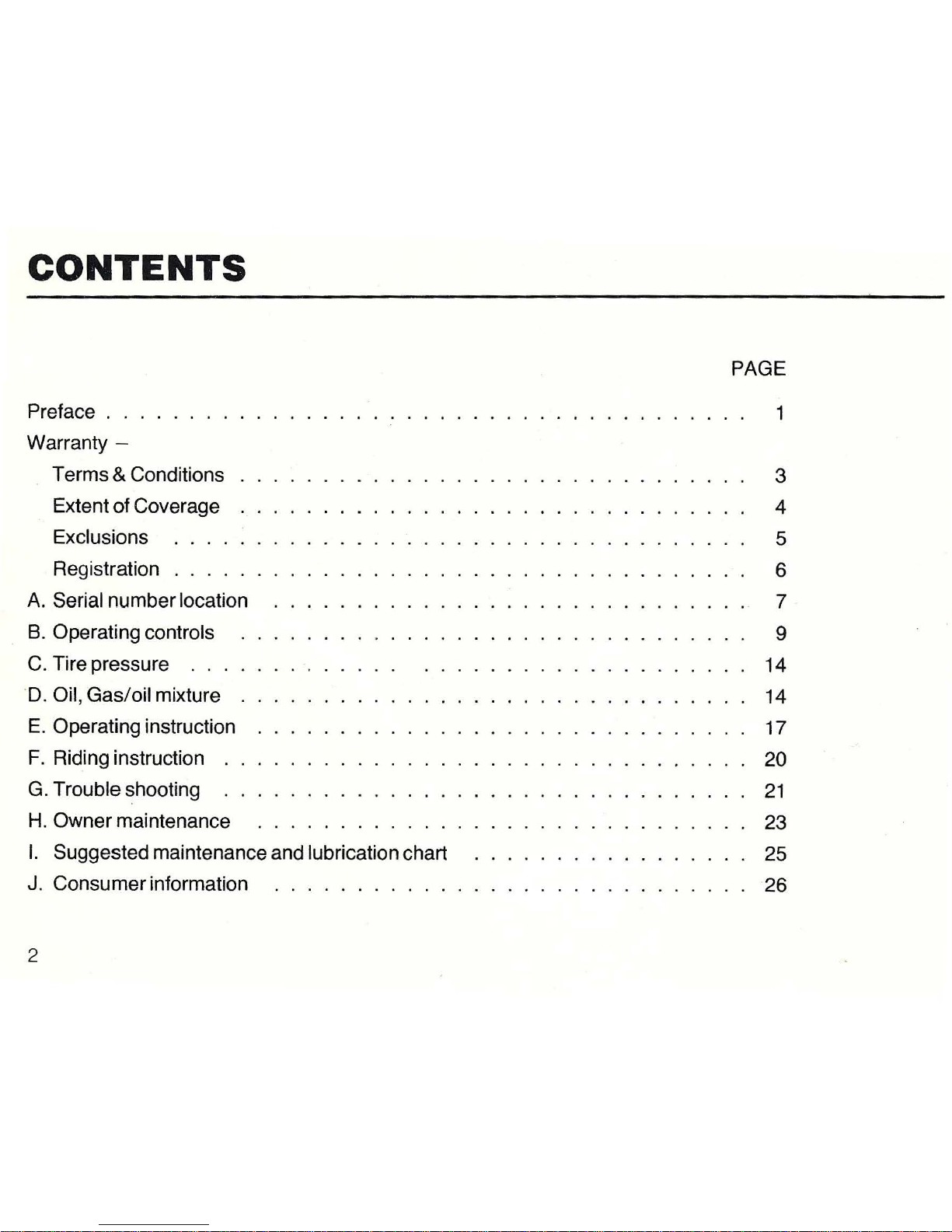

CONTENTS

Preface . .

..

.

..

.

Warranty-

Terms& Conditions

Extent

of

Coverage

Exclusions

Registration . . . .

A. Serial

number

location

B. Operating controls

C. Tire pressure . . . .

D . Oil,

Gas/oil

mixture .

E. Operating instruction

F. Riding instruction

..

G. Trouble shooting

H.

Owner

maintenance

I.

Suggested maintenanceand lubrication chart

J.

Consumer

information

2

PAGE

3

4

5

6

7

9

14

14

17

20

21

23

25

26

THE

WARRANTY-

Terms

&

Conditions

Subject to the terms set forth below, the

Puch

motorized bicycle is warranteed

to

be

free from defects

in

material

and

workmanship for a period of 6 months from the date

of original consumer purchase. While under this warranty, Steyr Daimler Puch of

America, hereafter SDPA, will, at its descretion, replace or repair without charge, any

product or part which

an

authorized service representative determines is defective

in

material or workmanship.

This warranty applies to the original consumer purchaser only.

This warranty gives the original consumer purchaser specific legal rights. The original

consumer purchaser may also have other rights which vary from state

to

state

3

EXTENT

OF

WARRANTY

COVERAGE

The warranty will not

be

extended to any machine that

has

been subject to mis-use,

negligence, alteration, use

of

non-authorized spare parts, improper maintenance

(including improper fuel mix ratio, lack of oil, or use

of

poor quality oil) or modification

of

assemby. Additionally, this warranty will not apply if the machine

is

damaged

by

fire,

flood, accident, acts of God or any other cause

of

a similar nature beyond SDPA's

control.

Under

no

circumstances will SDPA be liable for damages due to loss of use, loss of

business or profits or for any other incidental or consequential damages. Some states

do

not allow the exclusion or limitation or incidential

or

consequential damages,

so

the above limitation may not apply.

This warranty will

be

null

and

void

if:

1.

Any part of the serial numbers are removed, defaced

or

altered;

2.

If

any unauthorized modification or alteration

is

made;

3.

If

any unauthorized or non-standardized spare part

is

installed;

4.

If

any maintenance or repair

is

perfomed dur

in

g

the

warranty period

by

anyone

other than

an

authorized

Puch

Dealer.

4

EXCLUSIONS:

Normal wear parts are excluded from this warranty.

Normal wear parts include:

Tires, tubes, spark plugs, brake linings, clutch hub, chains, spokes, sprockets,

ignition points, condenser, brake cables, throttle cable, air filter.

Routine maintenance.

No

one

has

the authority

to

orally change the terms, conditions or exclusions of this

warranty

or

make any representations or express warranties other than those

contained here.

SDPA

is

proud

and

confident

of

its dealers

and

products,

and

wants to assure that

each new

Puch

owner receives full satisfaction.

In

the event satisfaction

is

not

obtained

at

the dealer level however, the original consumer

is

invited to contact

SDPA directly

at

P.O

.

Box

7777, Greenwich, Connecticut 06830

5

l

WARRANTY

REGISTRATION

The Warranty Registration form should

be

completed

by

the dealer

and

the consumer

purchaser

at

the

time of sale.

Part 1 shall

be

kept

by

the selling dealer.

Part 2 should

be

kept

by

the original purchaser

in

his/her possession.

ANY CLAIM MADE UNDER THIS WARRANTY MUST

BE

ACCOMPANIED

BY

PART

2 OF THE WARRANTY REGISTRATION FORM.

Part 3 which

is

self-addressed

and

stamped, must

be

mailed

to

Steyr Daimler

Puch

of

America Corporation,

P.O.

Box 7777, Greenwich, Connecticut 06830 not later than

ten

(1

0)

days after purchase of vehicle.

All

information

on

the

Form

must

be

written legibly. The serial numbers

on

the

Registration

Form

must agree with those

on

the Moped.

6

A)

SERIAL

NUMBER

LOCATION

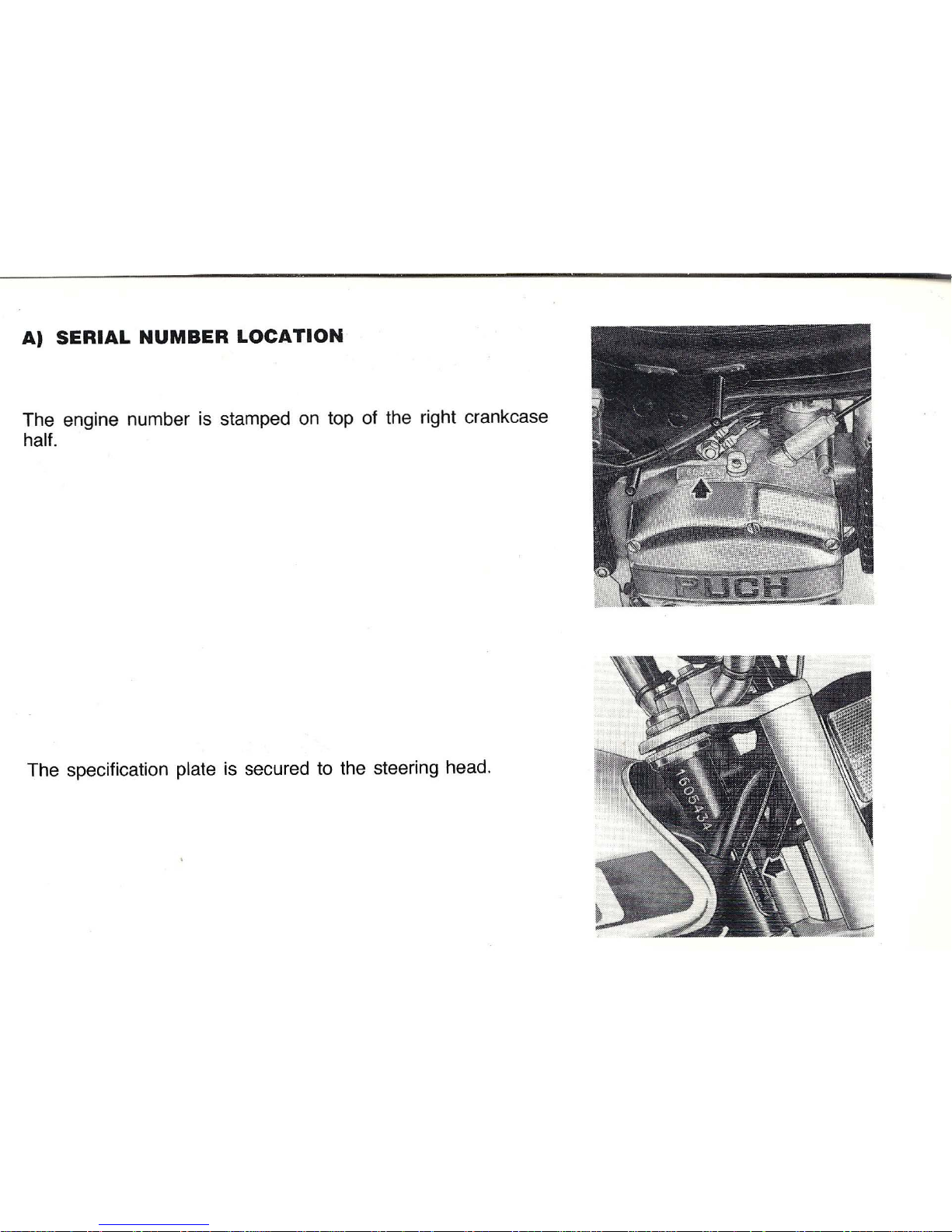

The engine number is stamped on top of the right crankcase

half.

The specification plate is secured to the steering head.

l

8

0

c=::2

IMPORTANT!

Write down

key-number

at

once.

This saves time,

money

and

annoyance

if

the

keys are lost.

The frame serial number

is

stamped

on

the steering head, just

above of the vehicle identification number plate.

My

key number

is

______________

<(Z

__

1Q

__

J(

___

--

---

--

-----

----------------

·

--

B)

OPERATING

CONTROLS

The positions of the controls are shown

in

the enclosed technical

data sheet.

Following some operating controls described

in

detail:

Locking

and

unlocking

your

moped

To

lock, move

the

handlebar

to

the right. Insert key into lock.

Turn key to the left, push

in

and

turn key to the right.

Remove

key.

Unlock

in

reverse order.

Fuel

tank

filler

cap

TO

open, turn filler

cap

counter clockwise.

9

10

Fuel

valve

The fuel valve

is

located

on

the left side of the fuel tank.

The positions are clearly indicated

on

the tank.

In

the

event

you

should

run

out of fuel, the reserve position

should give

you

adequate range

to

get

you

to a filling station.

Always turn the fuel valve

to

the "Off" position when the moped

is

not

in

use.

Carburetor

1)

The primer

is

operated

by

depressing the black rod extending

through the left engine cover.

2)

The choke is operated

by

depressing the metal thrust pin

which extends upward toward the opening in the left

engine cover.

Air

pump

and

tools

The air pump is located

on

the left side of the luggage carrier.

The tool kit is stored behind the cover

in

the rear of the seat.

Brake

levers

The brake control levers are mounted

on

the handlebar.

Left (1) lever controls the rear wheel brake.

Right

(2)

lever controls the front wheel brake.

11

12

Starting

lever

The starting lever

is

located

on

the left side of the handlebar

and

is

used for starting the engine.

Please refer to operating procedure

on

page

17.

Light

and

ignition

switch

The Magnum MK

II

has a two step combination key switch

located

on

the right top side of the instrument panel.

A key

is

needed for switching.

Fully

to

the left -ignition

and

lights off

Step 1 to the right -ignition.

on

Step 2

to

the right -ignition and lights

on

Horn

button/Light

switch

and

horn

button

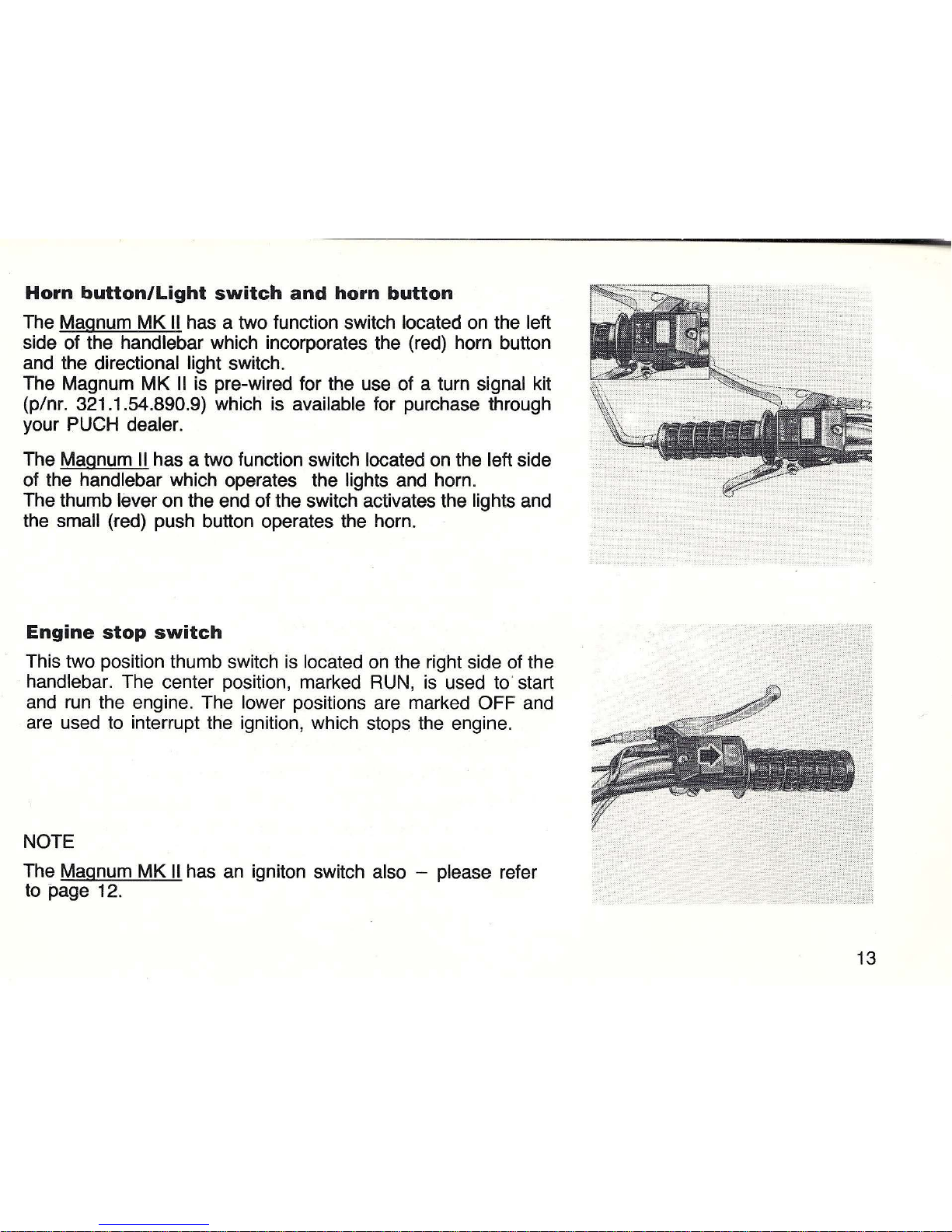

The Magnum

MK

II

has a two function switch located on the left

side of the handlebar which incorporates the (red) horn button

and the directional light switch.

The Magnum

MK

II

is pre-wired for the use of a turn signal kit

(p/nr. 321.1.54.890.9) which is available for purchase through

your PUCH dealer.

The Magnum

II

has a two function switch located on the left side

of the handlebar which operates the lights and horn.

The thumb lever on the end of the switch activates the lights and

the small (red) push button operates the horn.

Engine

stop

switch

This two position thumb switch is located

on

the right side of the

handlebar. The center position, marked RUN, is used to·start

and

run

the engine. The lower positions are marked OFF and

are used to interrupt the ignition, which stops the engine.

NOTE

The Magnum

MK

II

has

an

igniton switch also -please refer

to page 12.

13

14

C)

TIRE

PRESSURE

Recommended ti(e pressure

Front 26 psi

(1

.8

bar)

Rear 32 psi (2.25 bar)

D)

OIL,

GAS/OIL

MIXTURE

Checking

transmission

oil

level

The oil level control screw

(1)

on

the 2-speed automatic,

is

located

on

the clutch cover. The oil filler hole (2) is trough the top

of the right crankcase half. The drain plug (3) is located

on

the

lower portion of the right crankcase half.

91/2

fl.

oz

. (280

cc)

of ATF "TYPE

F"

is

used for refill.

CAUTION

The moped must

be

upright when filling oil. Do not overfill. Leave

oil level control screw removed until excessive ATF drains off.

Oil change after the first 300 miles of operation is highly recom-

mended.

-------

--

---

--

-----

--------

---

-

--

Filling

up

with

two

stroke

mixture

Gas/oil mixture

on

model without

oil

pump-

Magnum

II

The

Magnum

II

engine must

be

run

with a gas/oil mixture

(regular gas). The recommended mixing ratio

is

50:

1when using

speci

al

Maxi Mix two stroke moped

oil.

If

another

oil

is

used

please refer to the fuel mixing chart.

NOTE:

DO

NOT

USE

UNLEADED GASOLINE r

50

: 1 OIL MIXING TABLE WI

TH

PUGH

MAXI MIX

To

5 gallons gasoline

add

12

fl.

oz. (355 cc)

oil

To

1 gallon gasoline

add

2,4

fl.

oz.

(71

cc) oil

To

1 quart gasoline add

,6

fl.

oz

. (18

cc)

oil

NOTE

To

reduce carbon build-up within the engine

and

exhaust system,

we

strongly recommend

the

use of the special 2 stroke

MAXI

MIX oil,

50

: 1 ratio. However

as

an

emergency measure,

a regular 2 stroke

oil

can

be

mixed in a

25

: 1 ratio

as

shown

below.

25

: 1 OIL MIXING TABLE WITH REGULAR TWO STROKE OIL

To

5 gallons of gasoline

add

24

fl.

oz

.

(71

0 cc) oil

To

1 gallon

of

gasoline

add

4,8

fl.

oz.

(142 cc) oil

To

1 quart of gasoline

add

1

,2

fl.

oz.

(36 cc)

oil

15

16

Us\ng

cup

to

measun~

gasl

o\\

m\x\ng

ra\\o

MAGNUM

n lwithout

oi1

pump)

When measuring

oil

for the gas/oil mixture, use

one

cupful

of

Maxi Mix

to

one gallon

of

fuel.

NOTE: When using other grades of 2 stroke oil, please refer

to

previous page.

MAGNUM MK

II

only (with

oil

pump)

Use

pure regular grade gasoline only. Check

oil

level

in

the

oil

tank each time

you

refuel your machine.

CAUTION

If oil level

in

oil

tank drops to half, top off with Maxi Mix.

Should

you

notice that

no

oil

is

passing through

oil

feeder hose,

although sufficient

oil

is

in

tank, stop engine. Drain gas

and

refuel

with gas/oil mixture. See

Oil

Mixing Table

on

page

15.

WARNING

NEVER REFUEL WITH THE ENGINE RUNNING!

DO

NOT SMOKE

OR

ALLOW OPEN FLAMES

OR

SPARKS

IN

THE AREA, WHERE YOUR MOPED

IS

REFUELED

AND/OR WHERE GASOLINE

IS

STORED!

E)

OPERATING

INSTRUCTION

1. Prop the moped

on

its stand.

2. Unlock fork.

3. Magnum MK

II

only. Turn

on

ignition -

1st

step to the right

on

the switch.

4.·Turn fuel valve

to

the

ON

position.

5.

Be

sure that the engine stop switch

is

in

the

RUN

position.

6.

If

engine

is

cold, depress the choke and depress

the

primer

button on the carburetor until fuel drips from carburetor.

CAUTION:

After completing step 6

do

not open the throttle

control,

as

this will deactivate the choke. After the engine

has

started

and

warming

up,

open throttle gently to the full

position briefly. This will disengage choke. Avoid racing

engine.

7. Keep both hands

on

the handlebar with the weight

of

the

moped centered

on

the

front wheel. Apply the front brake

and

fully depress the starting lever located

on

the left side of the

handlebar. Position the pedal approx. parallel

to

the chain

guard. While holding the starter lever, push the pedal to start

engine.

8. Alternate starting method:

The moped may also

be

started

by

pedalling

as

a bicycle.

When momentum has been gained, pull the start lever

and

gently open the throttle. Release the start lever after the

engine starts.

1

17

18

Throttle

The speed of the moped is controlled with a twist grip on the

rightsideofthe handlebar. To accelerate twistthe throttle towards

you; to decelerate release slowly.

NOTE: Depending on engine RPM, cluch will engage or disen-

gage automatically. Shifting into or from

2.

gear, depending on

engine RPM and road speed, will occur automatically also.

Braking

To slow down, release the throttle control and apply equal pull

to both brake levers. Application of both brakes at the same time

is essential to prevent premature brake wear and/or loss of

vehicle control.

CAUTION:

Be alert when riding on wet or sandy surfaces. Loss

oftractionbetweentireandroad can occurundertheseconditions.

Be careful when braking, turning or accelerating under adverse

conditions.

To

stop

and

park

Release the throttle and simultaneously apply both brakes to stop.

Switch off engine with stop switch..

Magnum MK

II

only. Turn off ignition

and

remove key.

Close fuel valve.

Rest moped

on

stand

and

lock.

Securing

your

moped

Please refer to page

9.

A high security locking device

is

recommended. See your Puch

dealer for advice.

WARNING

After the engine has been

run

, the exhaust pipe and muffler

will become hot, avoid contact with them.

1

19

Table of contents

Other Puch Motorcycle manuals