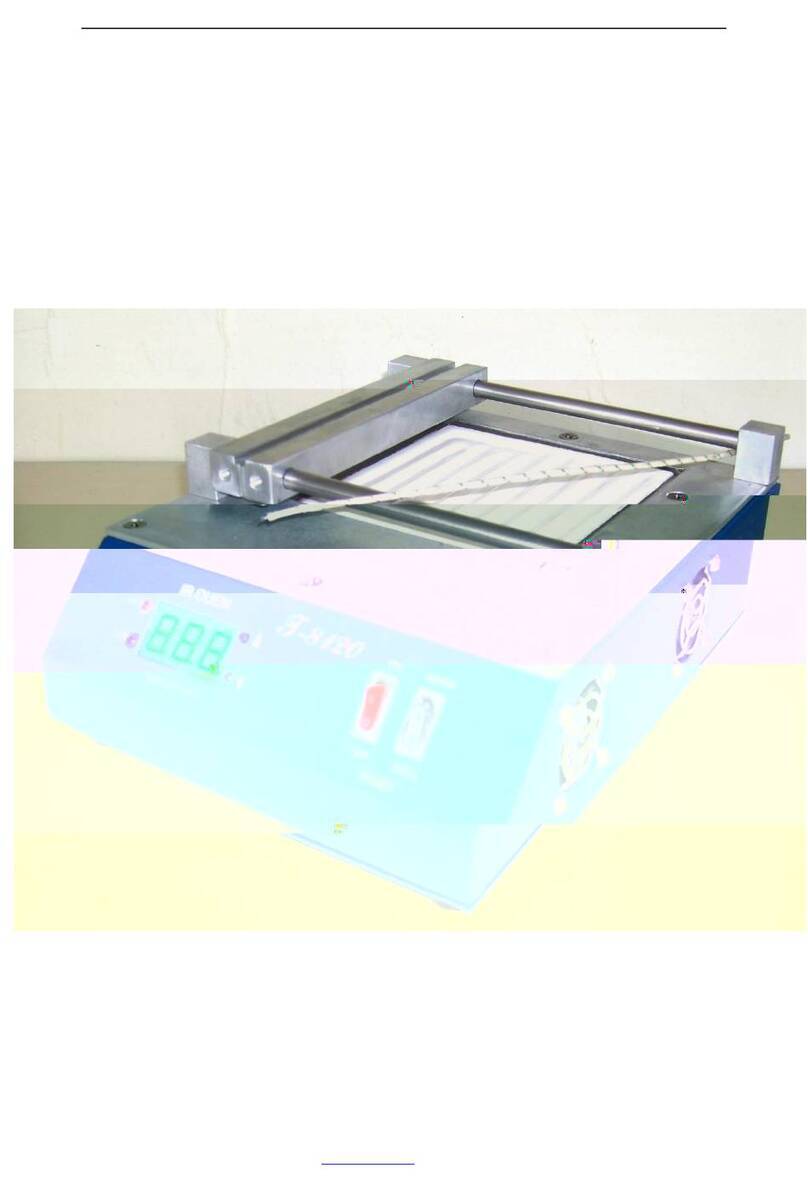

Puhui T-961 User manual

Mini SMT Reflow Oven User Manual

Http://www.tech168.cn 2/9

Features:

1. This machine selects IR and hot air heating technology controlling,

equipped with special design wind wheel, speed stability and uniform

temperature, suit for uninterrupted soldering the LED and BGAcomponents.

2. This machine is equipped with the crawler-type and six temperature zone

heating systems, and each temperature zone uses independent PID

controlling and up-down heating type, can make the inside temperature

more accurate and well-proportioned, just take about 7 minutes can let it

heat up to the working temperature from the room temperature.

3. Intelligent temperature wave heating type, oversized capacity wave

selection, have eight temperature waves can satisfy various welding

technological requirements.

4. Use programmable technology, preset the temperature wave memory

storage function, can complete the whole welding process automatically

according to your presetting wave.

5. Adopt the thermocouple temperature measurement and add the

compensation circuit, make the temperature measurement more accurate,

the wave more perfect.

6. Use PID intelligent temperature control technology; make the temperature

control more accurately. Adopt the imported large current solid-state relay

non-contact output can effectively avoid the IC or circuit board damage due

to the rapid or uninterrupted warming up, make the whole welding process

more scientific safety.

7. Transmission system adopt imported frequency conversion motor, PID

closed-loop speed, smooth operation, speed adjustable range

0-290mm/min.

8. Adopt independent wheel structure and special stainless steel strut,

durable wear-resisting runs smoothly, speed precision can reach ±10mm/min.

9. Independent cooling zone, to ensure the PCB board of low temperature

when the required.

10. Friendly human-machine operation interface, perfect LCD display, no

need to connect with the PC, can watch the whole repairing process very

clearly.

11. Ergonomic design, practical and easily operated. Good build quality but at

the same time light weight and a small footprint allows the T-961 to be easily

bench positioned, transported or stored.

Mini SMT Reflow Oven User Manual

Http://www.tech168.cn 3/9

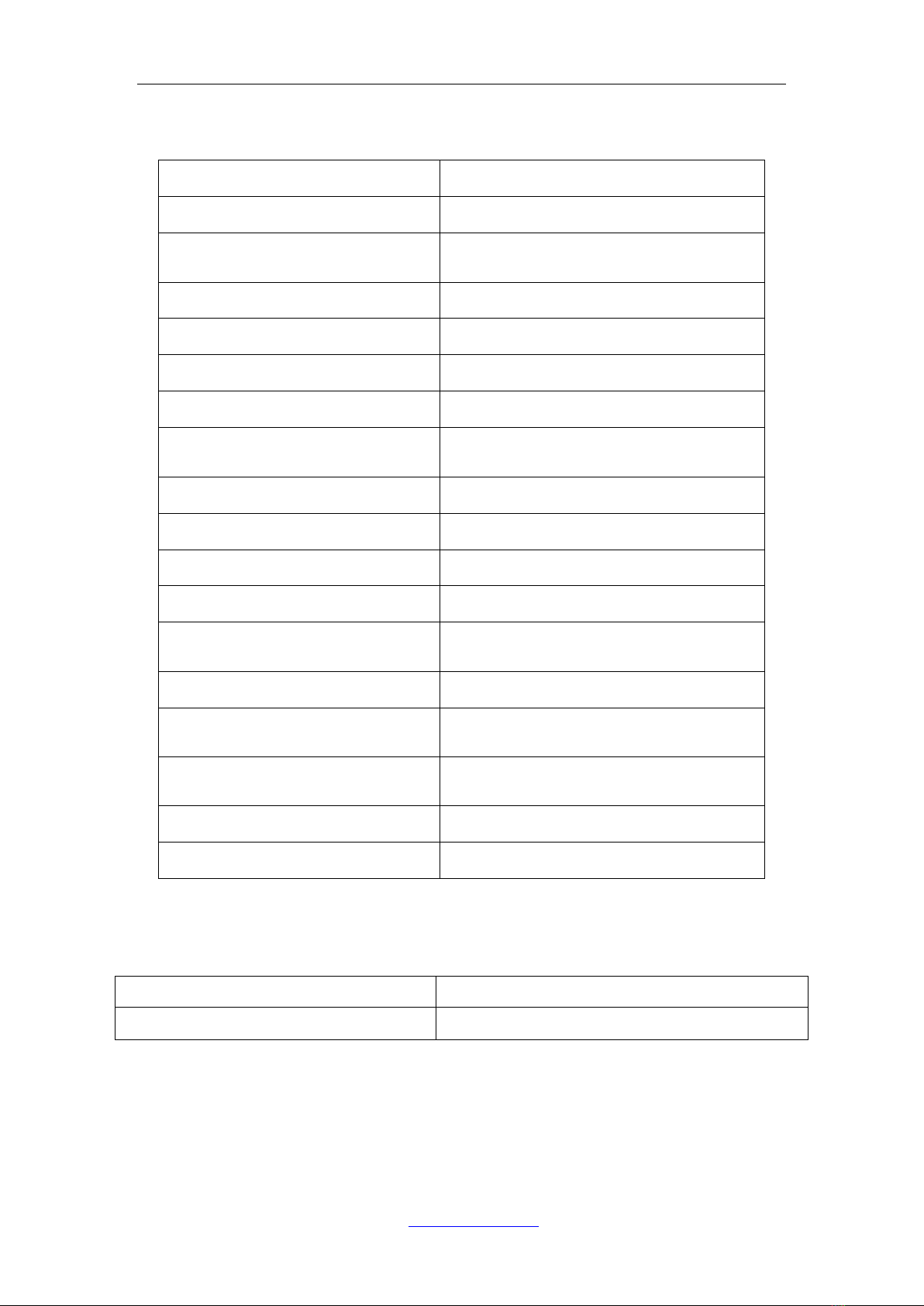

Technical parameters

Model

T-961

The heating zone quantity

upper3/down3

The length of the heating

zone

730mm

The heating type

IR and hot air heating

The cooling zone quantity

1

Maximum width of PCB board

230mm

The operation direction

left→right

Delivery options

Net transmission +chain

transmission

The speed of conveyer belt

0-290mm/min

The power supply

220V 50/60Hz

Peak power

3.5KW

Heating up time

Around 7mins

Temperature control range

Room temperature~300℃

Temperature control mode

PID closed-loop control

Temperature control accuracy

±1℃

PCB temperature distribution

deviation

±2℃

Overall dimensions

1000×466×445mm

Machine weight

70KG

Main parts

Complete machine

1

User manual

1

Mini SMT Reflow Oven User Manual

Http://www.tech168.cn 4/9

Operating Instructions

1. Enter into the setting interface when starts the machine.(temperature zones

from left to right 1/upper 3/upper 5/upper , 2/down 4/down6/down;face the

swift of machine,(temperature zones from left to right1/upper 3/upper 5/upper ,

2/down 4/down6/down).

2. Rotate Param button slowly to move the white cursor, when button move

counterclockwise,white cursor up. When white cursor refers to the parameters

need changed, slowly rotate value key to change parameter, when rotating

value key clockwise ,the parameter bigger,when rotating value key

counterclockwise, the parameter shrunk. The SPD is belt transmission speed

setting, PRFV is wave number set.

3. After the parameters changed, press the value button for long time, until the

screen reads “successfully”,parameters saved successfully.

4. Press param button long time to enter work interface, the oven start to run

the wave.

5. Press param button long time to return to setting interface to re-set other

waves.

6. After the wave set, only need to change the wave number of PRFV then

select the wave.

7. Six small red switch, control the six tempreture zone lamp.

Attentions:

1. Each temperature wave purposes as follows:

Wave 1 & 2: use the same with soldering the less lead paste, like 85Sn/15Pb

70Sn/30Pb

Wave 3 &4: use the same with soldering the more lead paste, like 63Sn/37Pb

60Sn/40Pb.

Wave 5&6: use the same with soldering high-melting-point Warm prompt: the

machine after shutdown, if you want to restart, the interval of at least 5 s

Wave 7&8: use the same with soldering lead-free solder in melting point, like

Sn/Ag2.5/Cu.8/Sb.5;Sn/Bi3.0/Ag3.0

According to the chips size and welding technological requirements, select the

Mini SMT Reflow Oven User Manual

Http://www.tech168.cn 5/9

proper wave.

2. There are lot kinds of solder paste, every company chooses is also not

identical. For these reasons, we design this product can set eight waves, each

wave has three sections, each section of the heating time and temperature all

can alter. You can reset the heating waves according to the solder required

heating temperature and time.

Warm prompt: the machine after shutdown, if you want to restart,

the interval at least 5 s

Foundation for wave set

1. The reflow soldering theory and the temperature wave

When the PCB board goes into heat up area (dry area), the solvent and gas in

the solder paste will evaporate. At the same time, the flux can wet the pad and

the component tip and foot. The solder paste melts, caves in and covers the

pad, leading to the pad and component pins insulate the oxygen. PCB board

goes into heat preservation area. PCB board and components get full

preheating. In case of damaging the PCB and components when it goes into

the welding area and the temperature heats up quickly. When PCB board goes

into the welding area, the temperature heats up and the solder paste melts.

When PCB board goes in to cooling area, the liquid solder paste the soldering

points solidify. The reflow process is finished.

The temperature is the key to welding quality. The actual and the setting

temperature warming slope and the peak temperature should be accordant.

Before the temperature reaches 160℃, please control the heat up speed in

about 1℃/S. If heat up too quickly, the PCB board and the components will be

damaged, and the PCB board may be out of shape. On the other side, the flux

volatilizes too fast. And it is easy to make soldering tin ball. Set the peak

temperature 20℃-40℃higher than the solder paste melting point. Set the

reflow time 10S-60S. If the peak temperature is low or the reflow time is short,

it will affect the welding quality, and serious is causing the solder paste does

not melt. If the peak temperature is high or the reflow time is long, the metal

power will be oxidized and affect the welding quality and serious is causing the

component and PCB board damaged.

2. The set of the temperature wave

Set the wave according to the solder paste and the above foundation. Different

solder paste, choose and set different waves. In addition, the temperature

Mini SMT Reflow Oven User Manual

Http://www.tech168.cn 6/9

wave has related to the PCB, the density and size of components. Generally

lead-free welding temperature should be higher 40℃than melting point.

Temperature Area Set

1. Set the temperature and belt speed to initial value (usually the manufacturer

supply when adjust)

2. To the cooling oven, should be preheated for 20-30 minutes.

3. When the temperature is stable, let PCB board pass heat reflow system.

Under this set, the solder paste can reach the reflow critical point. If there is no

reflow, to operate as step 4. If the reflow is too fast, please keep correct

proportion to increase or reduce the temperature. And let the PCB pass the

system again until reach the reflow critical point. Then turn to step 4, only when

there is reflow that is good.

4. If there is no reflow, please reduce the belt speed. For example, now the belt

speed is 500mm/min, please adjust it to about 460mm/min. Usually, reduce the

speed 10% can increase the temperature about 30F. Another way is that, do

not adjust the speed, and increase the temperature properly. The increase

range standard is the temperature wave. Adjust the temperature on the basis

difference between PCB actual and standard temperature. The adjust range is

about 5℃.When adjust the temperature, it cannot exceed the PCB and

component bearing capacity.

5. Let the PCB board pass the reflow system in the new speed or new set

temperature. If there is no reflow, back to step 4 to adjust again. Or carry out

the step 6 for temperature fine-turning.

6. The heat temperature wave is adjustable according to the PCB board. You

can adjust the transmission belt speed to adjust the temperature. Reduce the

belt spend can increase the product heat temperature. On the contrary, you

can reduce the product heat temperature.

7. Attention: if there is components on the PCB, the PCB pass the reflow and it

reflow not very completely, suggest you adjust then reflow again. Usually this

cannot damage the components.

8. From low to high when set temperature. If the heat range is over the reflow

temperature too high, should increase the transmission speed or reduce the

set temperature. The detailed operation is opposite to step 4.

Equipment Installation

Mini SMT Reflow Oven User Manual

Http://www.tech168.cn 7/9

1. Set up field.

1.1. Please do the work in the clean environment condition.

1.2. Do not put the machine near the electromagnetism interfering resource.

1.3. Do not put the oven exits and entrances face towards to the fan and the

window.

2. Power supply

Please use system 220V. Ensure the machine contacts the earth well and

requested professional electrician operation.

3. Adjust the reflow oven height.

By adjust the machine leg to adjust the height. The way is follow: use

industrial or alcohol gradienter to measure. Then adjust the machine leg to

adjust the dryer on all sides till it is completely horizontal.

4. Caution:

4.1. The working environment should be clean. So the welder quality is

good.

4.2. Do not use and store the machine out of door, high temperature and

humid condition.

4.3. During operation take care of the high temperature, avoid scald.

4.4. When overhaul the machine, please cut off the power supply to avoid

electric shock or cause short circuit.

4.5. If move the machine after overhaul, must check all the parts, especially

the net-belt position. Cannot make it be lock or fall off.

4.6. Ensure the machine is stable, not lean or instable. Adjust the leg under

the machine to keep the transmission horizontal. Or the PCB will shift in the

transmit process.

4.7. Do not put too big and big absorbed heat components into the oven

avoiding damage the net-net and affect the temperature.

4.8. Put lubricating oil into the transmission chain every 7 days.

4.9. Do not put the inflammable and explosive dangerous goods near the

reflow oven.

4.10. Do not reach hands into the reflow oven when the machine is in normal

working condition.

Daily Maintenance

1. Keep the electrical control cabinet clean.

Mini SMT Reflow Oven User Manual

Http://www.tech168.cn 8/9

2. Check if the fan shaft sleeve is in good condition.

3. Check if the fan and the electro-motor rotate without abnormal noise.

4. Check if the fan works smoothly.

5. Check if there are no foreign matters in the air passage.

6. Check if the transmission net-belt is in good condition.

7. Check if the electrical chest and electrical equipment work without abnormal

noise.

8. Check if the transmission parts are in good condition and work without

abnormal noise.

9. Before turning on the machine, please check that the supply voltage is

stable and in the range of rated voltage to ensure that all the parts can work

safely and normally. Before running the reflow program, check that all the

parameters have no difference with your ideal ones. Before turning off the

machine, turn off the heater switches first,and do not turn off the transmission

motor switch until the air inside the heating chamber is completely cool。

10. Lubricate the driving rolls every two months.

11.Due to the long time and high temperature working environment,the motor

bearings should be lubricated twice a week or more, to ensure that the

transmission mechanism works normally.

12. Power supply must be firmly grounded.

Routine maintenance

1. Keep the oven clean, and make sure there is no foreign matter blocking the inlet and

the outlet.

2. Make sure the cooling fans work well.

If you set the heating temperature parameters to high values and the oven often works

for a long time, you should oil the driving gears with high-temperature greases termly .

1) Driving motor

Chain block

Flywheel

Motor fastening

bolts

Motor shaft

wheel

Driving chain

Mini SMT Reflow Oven User Manual

Http://www.tech168.cn 9/9

2) Driving rolls and Diamond bearing seat

Toolkits list

Name

Model

Number

Solid wrench

24

1pc

Allen wrench

2、3、4、5、6、8

1set

Cross head screwdriver

75*5

1

Mesh belt

8

Jackscrew

M4*10

2 pcs

Fuse

10X38 20A

1pc

Driving shaft

Driving rolls

Diamond

bearing seat

Table of contents

Other Puhui Oven manuals