Puhui T-980 User manual

LED SMT Reflow Oven T-980 User Manual

Https://www.te168.com 2/11

Features:

1. T-980 selects the IR and hot air heating technology controlling, equipped with

special design wind wheel, speed stability and uniform temperature, suit for

uninterrupted soldering the LED and BGA components.

2. Equipped with the crawler-type and 8 temperature-zone heating systems, each

temperature zone uses independent PID controlling and up-down heating type, can

make the inside temperature more accurate and well-proportioned, just take about

20 minutes can let it heat up to the working temperature from the room temperature.

3. Intelligent temperature wave heating type, oversized capacity wave selection,

have eight temperature waves can satisfy various welding technological

requirements.

4. Programmable technology, preset the temperature wave memory storage function,

can complete the whole welding process automatically.

5. Adopts the thermocouple temperature measurement , adds the compensation

circuit, makes the temperature measurement more accurate, the wave more perfect.

6. Uses PID intelligent temperature control technology; makes the temperature

control more accurately. Adopts the imported large current solid-state relay

non-contact output can effectively avoid the IC or circuit board damage due to the

rapid or uninterrupted warming up, make the whole welding process more scientific

safety.

7. The transmission system adopts stepping motor and stepping motor driver, which

runs stably with adjustable speed range of 0-600mm / min,2mm/s-12mm/s.

8. Adopts independent wheel structure and special stainless steel strut, durable

wear-resisting runs smoothly, speed precision can reach ±10mm/min.

9. Independent cooling zone, to ensure the PCB in low temperature when out of the

oven.

10.Adopts advanced touch screen control technology, which integrates machine

operation,function display and monitoring, making the working state display more

intuitive, heating process more clear, and operation more convenient.Facilitate

product upgrading.

11.Ergonomic design, practical and easily operated.

Good build quality.Technology - based concept is constant.

12. Preheating modes:

(1) Sequential preheating: switch on heating zones in turn.

(Advantages: small instantaneous power, low machine load, available for 220V .

Disadvantages: long preheating time);

(2) Synchronous preheating: switch on heating zones at the same time

(Advantages: short preheating time.

Disadvantages: power is too large, recommended to use 380V industrial

electricity).

LED SMT Reflow Oven T-980 User Manual

Https://www.te168.com 3/11

Technical parameters

Model

T-980

The heating zone quantity

Upper5/down3

The length of the heating zone

1160mm

The heating type

IR and hot air heating

The cooling zone quantity

1

Maximum width of PCB

400mm

The operation direction

left→right

Delivery options

Net transmission+chain transmission

The speed of conveyor belt

0-600mm/min

The power supply

(220/380V) 50/60Hz

Peak power

13.2KW

Average power

7.0KW

Heating up time

Around 20 min

Temperature control range

Room temperature~350℃

Temperature control mode

PID closed-loop control

Temperature control accuracy

±1℃

PCB temperature distribution deviation

±2℃

Overall dimensions

1600mm×734mm×567mm

Net weight

130KG

Main parts

Complete machine

1

Power line(4m)

1

User manual

1

LED SMT Reflow Oven T-980 User Manual

Https://www.te168.com 4/11

Description of the main parts

1. Welding table main body

2.Control panel

3.The instruction of the connecting line

Remove the sealing plate screw of the power wiring cabinet at the back of the

machine, remove the sealing plate, and press the power line on the terminal block in

sequence according to the wiring requirements of L, N and PE. L1, L2 and L3 are

respectively connected to the three phases of three-phase power, N connect neutral

line and PE connect ground line.The wiring diagram as follow:

Start button

Stop button

Exhaust pipe joint

Status indicator lamp

Cooling fan

Emergency stop button

LED SMT Reflow Oven T-980 User Manual

Https://www.te168.com 5/11

When the power cord is connected, power on the circuit breaker.

4.Status indicator lamp

When the status indicator is green, it means that the temperature zone is in heating

state; when the status indicator is red, it means that all the temperature zones are not

in heating state.

Operating Instructions

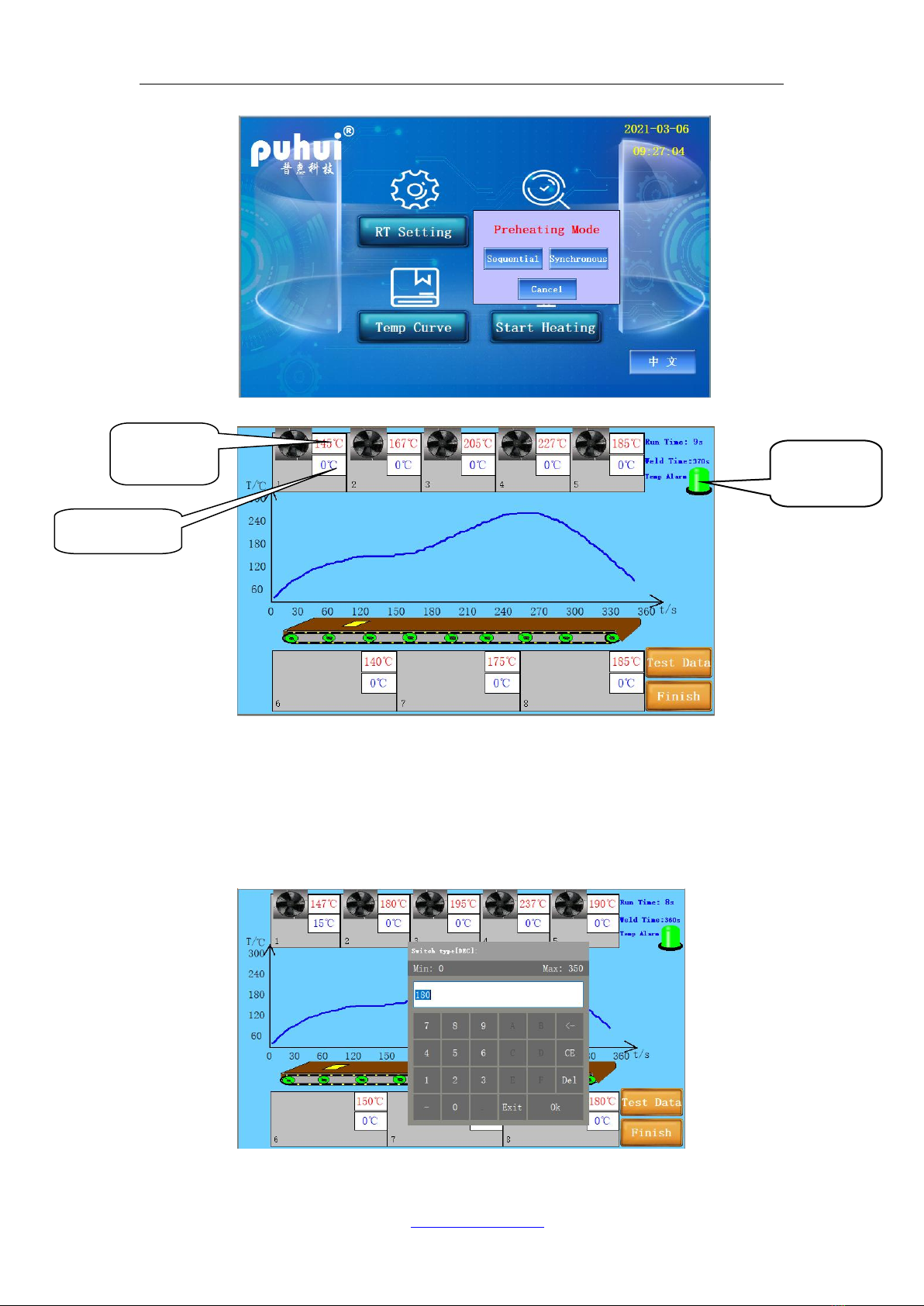

1. Main menu interface.

Click the button to enter the corresponding interface.

2. Room temperature setting interface.

Click the "RT Setting" button to enter the following interface:

Chinese/English

LED SMT Reflow Oven T-980 User Manual

Https://www.te168.com 6/11

To calibrate the temperature of the machine, input the current room temperature in the

dialog box when the internal temperature of the machine is consistent with the room

temperature, click "save" to finish the room temperature calibration, and click the

back button to enter the main menu interface.

3. Click the "Temp Curve" button to enter the following interface:

There are 8 default solder paste welding curves of the machine. Users can select the

appropriate welding curve according to the process requirements of their own solder

paste.click “perform”,pops up preheating mode dialogue,click “sequential”(All

temperature zones will not be started at the same time to avoid excessive starting

current)

or“synchronous”

(All temperature zones start synchronously and run with full

load)to start.Click the return button to enter the main menu interface after selection.

4. On the main interface,click “Start Heating”,pops up “Preheating Mode”

dialogue,click “sequential”

(All temperature zones will not be started at the same time

to avoid excessive starting current)or“synchronous”(All temperature zones start

synchronously and run with full load)to start.The machine runs the selected curve.

Return

LED SMT Reflow Oven T-980 User Manual

Https://www.te168.com 7/11

When the actual operating temperature of the temperature zone exceeds the set

temperature of the temperature zone by 20°C, the temperature alarm indicator will

flash red and green alternately. During the heating process and the normal temperature

control temperature alarm indicator shows green.

The user can modify the parameters of the curve in this interface, including setting the

temperature and running speed of the belts. Click the preset temp dialog box to enter

the following interface:

Modify the parameters directly.

Preset temp

Actual temp

Temp alarm

indicator

LED SMT Reflow Oven T-980 User Manual

Https://www.te168.com 8/11

5. Click the "Time Setting" button to enter the following interface:

By dragging the ruler slider left and right to change the PCB run time, the run speed

of the belt can be changed.

6. Click "Test Data" to enter the following interface:

By clicking the button, you can turn on or turn off a single temperature zone. When

the temperature zone is turned on, the button will display green and the temperature

zone off,button will display red.To end the heating state of the machine, click the

"Finish" button.

6.Special reminder:

①.When welding chip, select appropriate curve according to chip size and welding

process requirements.

②.If the touch screen crashes, the machine will automatically cut off the heating, and

there is no need to worry about the chip burning out of control.

③.The touch screen alarms. The fault is that the single chip computer crashes or the

communication line between the main board and the touch screen is damaged.

④.When the touch screen has been in the state of over temperature alarm (the display

LED SMT Reflow Oven T-980 User Manual

Https://www.te168.com 9/11

interface has an indicator light to indicate), the power should be cut off to prevent

damage to the circuit board and chip;Adjust the temp curve when the temp is stable.

⑤.At present, there are many kinds of solder production and use, and each company

chooses different ones. There are many articles about theoretical analysis and test

analysis.For these reasons, the product launched by our company can preset eight

curves, each curve has 8 sections, and the heating time of each section can be

changed.The user can reset the heating curve according to the required heating

temperature and time of solder.

Foundation for wave set

1. The reflow soldering theory and the temperature wave

When the PCB board goes into heat up area (dry area), the solvent and gas in the

solder paste will evaporate. At the same time, the flux can wet the pad and the

component tip and foot. The solder paste melts, caves in and covers the pad, leading

to the pad and component pins insulate the oxygen. PCB board goes into heat

preservation area. PCB board and components get full preheating. In case of

damaging the PCB and components when it goes into the welding area and the

temperature heats up quickly. When PCB board goes into the welding area, the

temperature heats up and the solder paste melts. When PCB board goes in to

cooling area, the liquid solder paste the soldering points solidify. The reflow

process is finished.

The temperature is the key to welding quality. The actual and the setting

temperature warming slope and the peak temperature should be accordant. Before

the temperature reaches 160℃, please control the heat up speed in about 1℃/S. If

heat up too quickly, the PCB board and the components will be damaged, and the

PCB board may be out of shape. On the other side, the flux volatilizes too fast. And

it is easy to make soldering tin ball. Set the peak temperature 20℃-40℃ higher

than the solder paste melting point. Set the reflow time 10S-60S. If the peak

temperature is low or the reflow time is short, it will affect the welding quality, and

serious is causing the solder paste does not melt. If the peak temperature is high or

the reflow time is long, the metal power will be oxidized and affect the welding

quality and serious is causing the component and PCB board damaged.

2. The set of the temperature wave

Set the wave according to the solder paste and the above foundation. Different

solder paste, choose and set different waves. In addition, the temperature wave has

related to the PCB, the density and size of components. Generally lead-free welding

temperature should be higher 40℃ than melting point.

Temperature Area Set

1. Set the temperature and belt speed based on initial value(usually the manufacturer

supply when adjust)

2. To the cooling oven, should be preheated for 20-30 minutes.

3. When the temperature is stable, let PCB board pass heat reflow system.

Under this set, the solder paste can reach the reflow critical point. If there is

LED SMT Reflow Oven T-980 User Manual

Https://www.te168.com 10/11

no reflow, to operate as step 4. If the reflow is too fast, please keep correct p

roportion to increase or reduce the temperature. And let the PCB pass the syst

em again until reach the reflow critical point. Then turn to step 4, only when

there is reflow that is good.

4. If there is no reflow, please reduce the belt speed. For example, now the belt speed

is 500mm/min, please adjust it to about 460mm/min. Usually, reduce the speed 10%

can increase the reflow temperature about 16℃. Another way is that, do not adjust the

speed, and increase the temperature properly. The increase range based on the

standard temperature wave. Adjust the temperature on the basis difference between

PCB actual and standard curve temperature. The adjust range is about 5℃.When

adjust the temperature, it can not exceed the PCB and component bearing capacity.

5. Let the PCB board pass the reflow system in the new speed or new set temperature.

If there is no reflow, back to step 4 to adjust again. Or carry out the step 6 for

temperature fine-turning.

6. The heat temperature wave is adjustable according to the PCB board. You can

adjust the transmission belt speed to adjust the temperature. Reduce the belt speed can

increase the product heat temperature. On the contrary, you can reduce the product

heat temperature.

7. Attention:the PCB passes the reflow and it reflow not very completely, suggest you

adjust then reflow again. Usually this cannot damage the components.

8. From low to high when set temperature. If the heat range is over the reflow

temperature too high, should increase the transmission speed or reduce the set

temperature. The detailed operation is opposite to step 4.

Equipment Installation

1. Set up field.

1.1. Please do the work in the clean environment condition.

1.2. Do not put the machine near the electromagnetism interfering resource.

1.3. Do not put the oven exits and entrances face towards to the fan and the window.

2. Power supply

Please use five-wire system 380V. Ensure the machine contacts the earth well and

request a professional electrician operation.

3. Adjust the reflow oven height.

By adjust the machine leg to adjust the height. The way is follow: use industrial or

alcohol level to measure. Then adjust the machine leg to adjust the machine on all

sides till it is completely horizontal.

4. Caution:

4.1. The working environment should be clean. So the welder quality is good.

4.2. Do not use and store the machine out of door, high temperature and humid

condition.

4.3. During operation take care of the high temperature, avoid scald.

4.4. When overhaul the machine, please cut off the power supply to avoid electric

shock or cause short circuit. And turn on the machine at room temp as far as possible.

4.5. If move the machine after overhaul, must check all the parts, especially the

LED SMT Reflow Oven T-980 User Manual

Https://www.te168.com 11/11

net-belt position. Cannot make it be lock or fall off.

4.6. Ensure the machine is stable, not lean or unstable. Adjust the leg under the

machine to keep the transmission horizontal. Or the PCB will shift in the transmit

process.

4.7. Do not put too big and big absorbed heat components into the oven avoiding

damage the net-belt and affect the temperature.

4.8. Put lubricating oil into the transmission chain every 7 days.

4.9. Do not put the inflammable and explosive dangerous goods near the reflow

oven.

4.10. Do not reach hands into the reflow oven when the machine is in normal

working condition.

Daily Maintenance

1. Keep the electrical control cabinet clean.

2. Check the fan shaft sleeve is in good condition.

3. Check the fan and the motor have abnormal sound.

4. Be sure the fan does work flexibly.

5. Check the air hole if there are abnormal materials.

6. Check the transmission net-belt is in good condition.

7. Check the electrical chest and electrical equipment have abnormal sound.

8. Check the transmission part if it is in good condition and has abnormal sound.

9. Before turn on the machine, please check the working voltage if it is in the safe

voltage and if it is stable. Ensure all the parts can work safely and normally. At the

same time, when turn on the machine, check the parameters are the same to the last

time turn off. When turn off the machine, do not let the transmission belt in the hot

area, please turn off the temperature and when cool down well and stop the

transmission belt.

10. Lubricate the driving rolls. Put lubricating oil every two months.

11. The motor works in high temperature for long time, please put lubricating oil

twice a week or more, ensure the motor can work normally.

12. Clean the residual goods on the fan blade and motor timely. Or the circuit ages

will lead to short circuit and damage the fan.

13. Be sure the machine contacts the earth when use five-wire system.

Statement: These images and screenshots in this product manual may very

slightly different from the actual purchased product.

Actual products shall prevail.

Table of contents

Other Puhui Oven manuals

Popular Oven manuals by other brands

Hotpoint

Hotpoint FH 103 IX /HA S operating instructions

Culina

Culina UB70NMFS user manual

Siemens

Siemens CS958GD 1 Series User manual and installation instructions

Nectre Fireplaces

Nectre Fireplaces N550 Installation instructions manual

Frigidaire

Frigidaire PLEB27M9E Factory parts catalog

Comfee

Comfee CO-B08AA user manual

AEG

AEG COMPETENCE CB1100-1W operating instructions

Heinner

Heinner HCE-452BK manual

Dacor

Dacor ECD230SCH Use and care guide

Miele

Miele 11 919 480 Operating and installation instructions

Küppersbusch

Küppersbusch EKDG 6800.2M Instructions for use and installation instructions

AEG

AEG SURROUNDCOOK 6000 Series user manual