INLET PRESSURE should fall within the specifications of the

pump.

• High RPM, high temperatures, low vapor pressures or high

viscosity may increase acceleration loss of liquids.

• Optimum pump performance is obtained with +20 PSI (1.4

BAR) inlet pressure. With adequate inlet plumbing, most

pumps will perform with flooded suction.

• After prolonged storage, pump should be purged of air to

facilitate priming. Disconnect the discharge port to allow

liquid to pass through pump and measure flow.

BYPASS TO INLET –care should be exercised when

deciding the method of bypass from control valves.

• It is recommended that the bypass be directed to a baffled

reservoir tank, with at least one baffle between the bypass

line and the inlet line to the pump.

• Although not recommended, bypass liquid may be returned

to the inlet line of the pump if the system is properly

designed to protect your pump.

• A low-pressure, flexible hose should be used from the

bypass connection to the inlet of the pump.

• Caution should be exercised to avoid under sizing the bypass

hose diameter and length.

• Check the pressure in the bypass line to avoid over-

pressurizing.

USING CHEMICALS

Chemicals can be mixed into the fluid and it is necessary to

understand whether these chemicals will damage the pump or

other system components. Another way to put chemicals into

the fluid is with a downstream injector.

An injector works as a result of the difference of pressure

between the inlet side of injector and discharge side. In most

cases, the pressure on the discharge side cannot exceed 1/2 of

the inlet pressure. For example, 1000 PSI into an injector

should allow up to 500-600 PSI spray pressure on discharge

side. There are dual-function nozzles that permit high

pressure, chemical free rinse and low pressure, chemical

spray. These are convenient for the operator and will not harm

a properly designed system.

The advantages of an injector are:

Fewer items touching chemical, the chemical injection rate can

be controlled, and applying chemical at lower pressure

increases chemical use efficiency.

HEATING FLUID

The pumps may sometimes be used with downstream heaters

and precautions need to be taken to protect the system and

persons from harm. Refer to the skilled staff at the equipment

manufacturer for guidance and proper system care. Please be

aware that heated water expands, and additional pressure

release safety devices may be required.

SYSTEM DESIGN

A pump is the heart of every system and proper selection is

critical to equipment function and durability. If a pumping set

with excess flow is chosen, then energy and fluid is wasted.

Equipment effectiveness can decrease if excess pressure

results, and so can pump life.

TYPICAL APPLICATIONS AND THEIR PERFORMANCE

CONSIDERATIONS

PEST SPRAYING

This application can have specific chemical usage requirements

and application pressure limits, so use the included

information as a guide only. Refer to label requirements for

each specific chemical.

LINE LOSS

When choosing a pump for spraying, pressure loss in the hose

must be considered. The pressure is greatest at pump and

decreases over the length of the hose. Typically, these systems

utilize very long hoses, 200-300 ft. is common, and requires a

certain minimum amount of performance to move the flow

through the lengths of hose. For example, a 3 GPM system will

require (lose) 50 PSI per 50 ft. of 3/8” ID hose. A pump with

only 60-70 PSI may not provide the desired performance at the

end of the hose. See reference charts to assist in system

design.

DO NOT return bypass fluids from regulating valve directly

back to inlet of pump. The returned fluid will contain large

amounts of air bubbles that will cause cavitation and damage

in the pump head. Also, the small amount of returned fluid can

heat up rapidly and lead to further cavitation and component

damage. It is recommended to route bypass back to inlet of

filter to allow air bubbles to dissolve and water to cool prior to

entering pump.

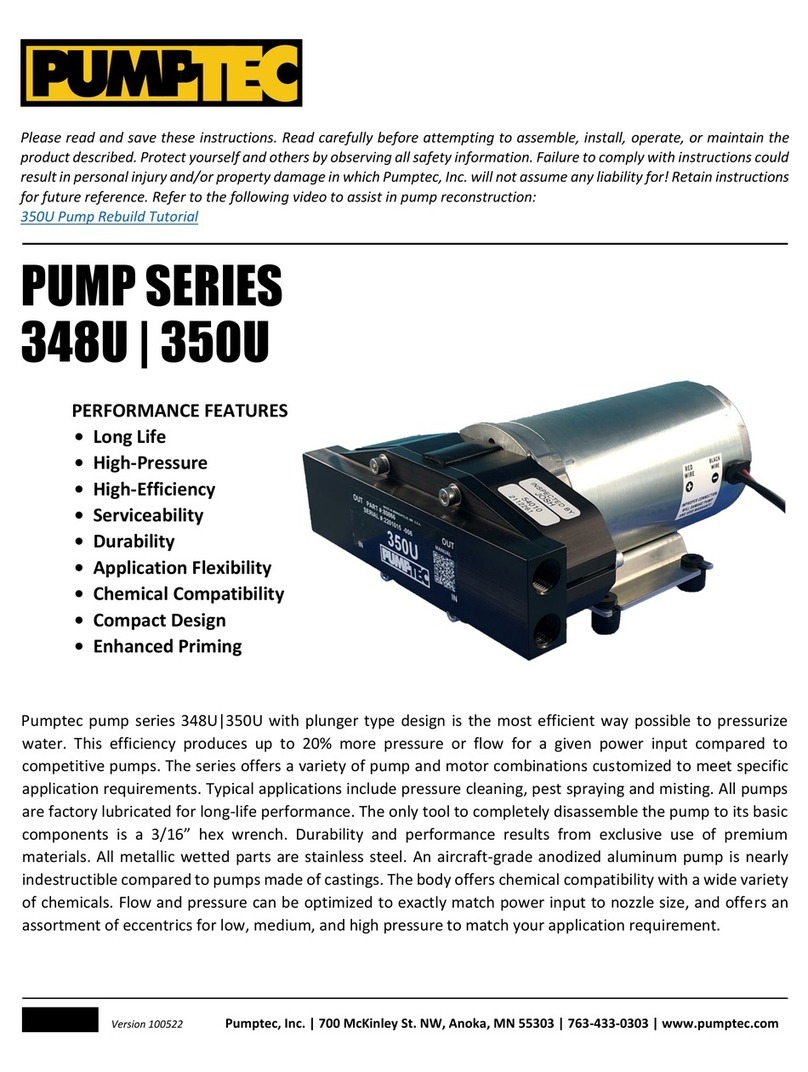

The pumps are shipped assembled to a custom-made motor

based upon your specifications. It is not necessary to order a

motor separately. Communicate your specification

requirements and the supplier will assist with pump options.

Please use the following charts as a guide to understand the

basic system requirements.

NOTE: Nozzle sizes in the performance chart are additive. For

example, 2 pieces of ’02 nozzle equals the performance of 1

piece of ’04.

Nozzles create restriction (pressure) in the system. If unsure of

the nozzle size needed for desired performance, refer to

Nozzle Performance Chart. If you are sure of your nozzle size,

but unsure of which pump set to choose, use the Nozzle

Performance Chart along with the Horsepower Chart to

determine your required pump specification. See next page.