Priming Pump

All suction and discharge valves must be open as well as filter air relief valve when starting the circulat-

ing pump system. Failure to do so could result in severe personal injury.

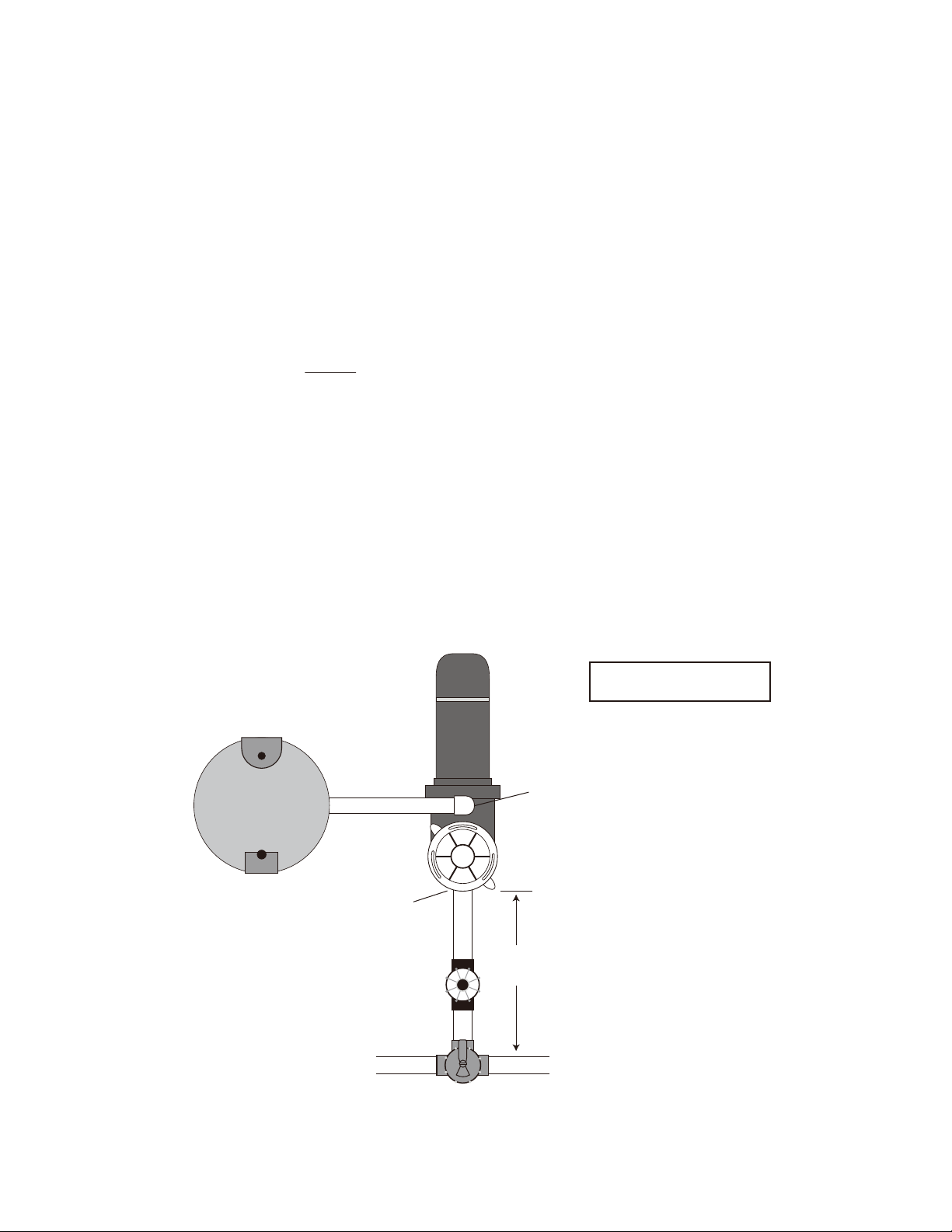

Priming Pump Placed Below Water Level

● The pump will prime itself if it is placed lower than the water level.

Priming Pump Placed Above Water Level - If water level is lower than the pump, then following

these instructions for priming. The suggested installation of the pump is 12” above the pool water

level. The pump should not be installed more than 30” above the pool water level.

● Turn Power off to pool pump

● Make sure pool water is halfway up pool skimmer face

● Open suction valves

● Open discharge valves

● Open filters air release valve

● Unscrew and remove pump lid

● Remove any debris from pump basket

● Clean pool filter if needed

● Clean pool skimmer basket if needed

● Fill pump strainer basket with water from garden hose

● Clean and lubricate strainer cover O-ring each time it is removed. Inspect O-ring and place it

back on the strainer cover.

● Turn the strainer cover clockwise to tighten. NOTE: Tighten the strainer cover by hand only.

NO wrenches.

● Turn on the power to the pump and wait for the pump to prime. This may take up to five (5)

minutes. Priming time depends on the vertical length of the suction lift and the horizontal length

of the suction pipe. If the pump does not prime within five minutes, stop the motor and

determine the cause. Be sure all suction and discharge valves are open when the pump is

running.

● Once the water starts coming out of the pool filter air release close pool filter air release

Helpful Videos for Pool Pump Priming

● Video on How to Prime a Pool Pump -

https://www.inyopools.com/HowToPage/how_to_prime_ a_pool_pump.aspx

● Video on How to Determine Why a Pool Pump Won't Prime -

https://www.inyopools.com/HowToPage/how_to_determine_why_a_pool_pump_won_t_prime.aspx

● Video on How to Identify and Correct Air Leaks -

https://www.inyopools.com/HowToPage/how_to_identify_and_correct_air_leaks.aspx

● Video on How to Correct Swimming Pool Plumbing Issues -

https://www.inyopools.com/blog/how-to-fix-priming-problems-in-your-pool-plumbing/

ATTENTION- Before removing strainer cover:

ATTENTION- Wait five seconds before re-starting the pump. Failure to do so may cause

reverse rotation of the motor and seriously damage the pump.

1. STOP PUMP before proceeding.

2. CLOSE VALVES in suction and outlet pipes

3. RELEASE ALL PRESSURE from pump and piping system using filter manual air relief valve.