Whisper 60 modular Guide

1.0 GENERAL THEORY OF OPERATION

1.1 REVERSE OSMOSIS THEORY

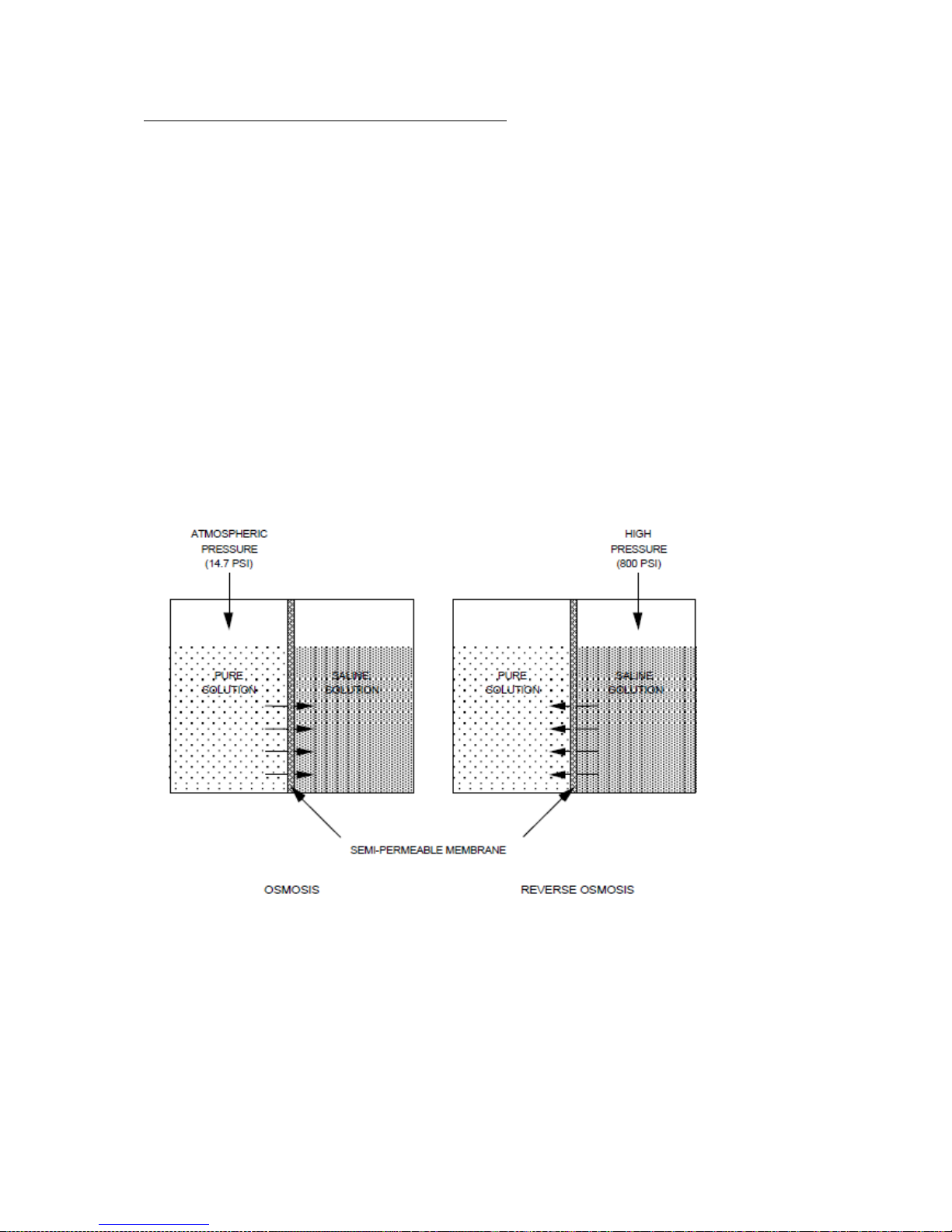

Reverse osmosis, like many other practical scientific methods, developed from processes first

observed in nature. Osmosis is a naturally occurring phenomenon in which a semi-permeable

membrane separates a pure and a concentrated solution (a semi-permeable membrane is defined as

one that preferentially passes a particular substance). Every fluid has an inherent potential that is

directly related to the type and amount of solids in solution. This potential, referred to as osmotic

pressure, increases in proportion to relative concentration of a solution. A concentrated solution,

therefore, has an osmotic pressure that is higher than that of a pure solution. In an osmotic system,

the less concentrated solution will attempt to equalize the concentrations of both solutions by

migrating across the semi-permeable membrane. When enough pure solution migrates across the

membrane such that the inherent potential difference between the solutions in no longer higher than

the osmotic pressure of the membrane, the purer solution will stop flowing. If the pressure on the

concentrated solution is increased to above the osmotic pressure, fluid flow will be reversed. This

condition, called Reverse Osmosis, can be established by artificially pressurizing the more

concentrated solution using a high pressure pump. In this type of system, the concentrated solution

(normally referred to as feed-water) will become more concentrated as pure water flows out of solution

and across the membrane to the permeate side. Discounting the effects of feed-water temperature

and salinity, the operating pressure normally required to produce significant amounts of pure water is

at least twice the osmotic pressure of the membrane being used. Fig. 1.1

Figure 3.0 - Simple (Reverse) Osmosis Process

1.2 APPLICATION OF REVERSE OSMOSIS

Seawater contains many kinds of solids dissolved in solution. The most prevalent is common table salt

(Sodium- Chloride). Other minerals that may be present in solution are substances that usually contain

Various Compounds of Calcium and Sulfate. The sum of all of the solids dissolved in a particular

sample of water is referred to as Total Dissolved Solids or TDS. Seawater normally averages 32,000

ppm (parts per million) TDS although variations of 5000 ppm are common in various parts of the

world. The fundamental goal any desalination process is a significant reduction in the amount of

dissolved solids in water.

2