3

INTRODUCTION

QuattroTecQuaternaryDiaphragmPumpsareconstructedaccordingtothestateoftheartandtheyare

reliable.Imminentdangerbyoperatingerrorormisusecanleadtodamagesofpropertiesand/orpersons.

Thepumpsaretobeappliedfortheintendeduseandinasafety‐relatedproperconditiononly.Noliability

willbeundertakenforanydamagescausedbynon‐compliancewiththeoperatinginstructionsandservice

conditions!Originalsparepartsservesafetypurposes.Theuseofotherpartsmaycanceltheliabilityforthe

consequencesandsecondaryfailuresresultingthereof.

EachpersonworkingontheALMATECair‐operateddiaphragmpumpsconcerninginstallation,start‐up,

handlingormaintenancehastoreadthismanualcompletelyandinanattentivewayandhastofollowall

mentionedproceduresandsafetynotes.

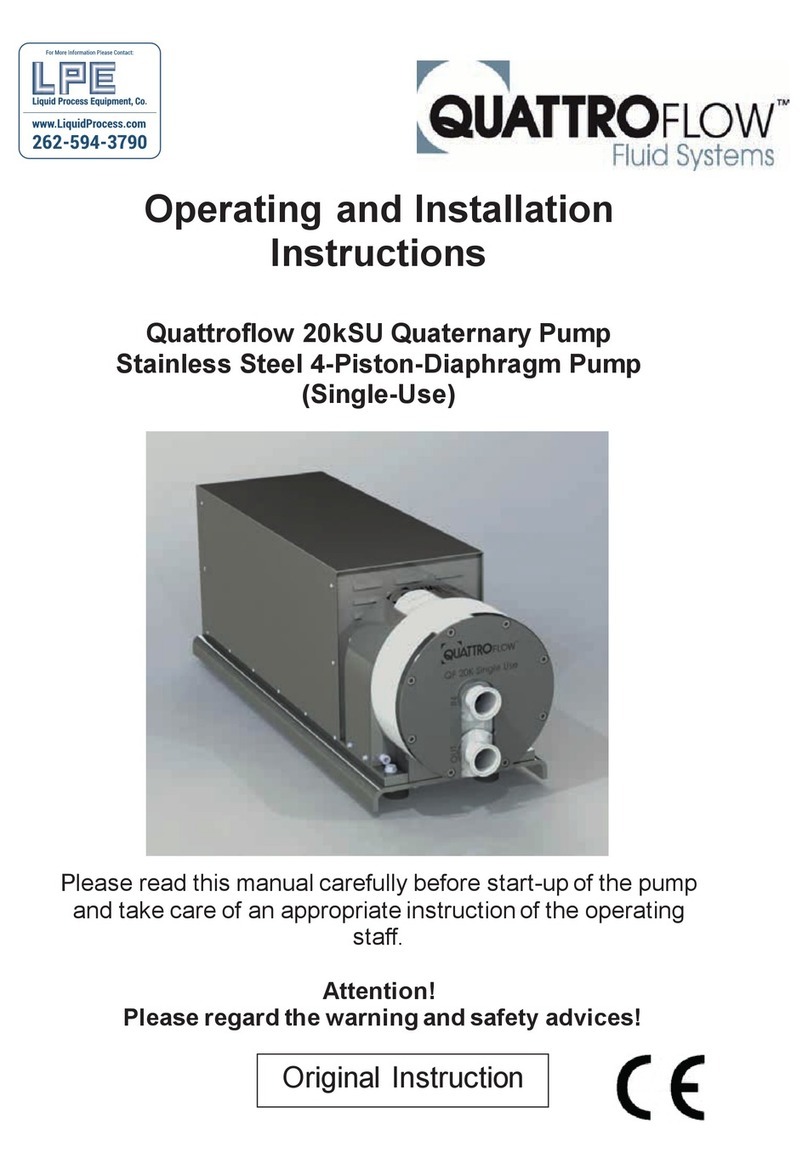

GENERALDESCRIPTIONOFTHEMACHINE,APPROPIATEUSEANDRESIDUALDANGERS

PumpsoftheQuattroTecseriesare4‐pistondiaphragmpumps.Thefoursegmentsofthepumpdiaphragm

oscillatebackandforth.Thisalternatemovementiscreatedbyaconnectorplatethatisarrangedonaball

bearing.Theballbearingsitsonaneccentricshaft.Theconnectorplatedoesnotturn.

TheappropriateuseofaQuattroTecpumpreferstothetransportofaqueousliquidstakingintoaccountthe

operationparametermentionedinthismanualandincomplianceofthegiventermsforcommissioning,

operation,assembly,disassemblyandmaintenance.

Evenifallnecessarysafetymeasuresdescribedinthismanualhavebeenmet,aresidualdangerexistsby

leakagesormechanicaldamages.Atsealingareasorconnectionsliquidcanbereleaseduncontrollablythen.

STORAGE

IngeneraltheQuattroTecpumpisdeliveredoperationalandpackaged.Iftheunitisnotinstalledrightaway,

properstorageconditionsareimportantforatroublefreeoperationlater.Thepumphastobeprotected

fromwetness,coldness,dirtying,UV‐radiationandmechanicalinfluences.Thefollowingstorageconditions

arerecommended:

‐Steadyventilated,dustandvibrationfreestorageroom

‐Ambienttemperaturebetween15°C(59°F)and25°C(77°F)witharelativehumiditybelow65%

‐Preventionofdirectthermalinfluences(sun,heating)

LABELLINGOFTHEPUMP

ALMATECMaschinenbauGmbH–manufactureroftheQuattroTecpumps‐iscertifiedasamodern,quality‐

orientatedenterpriseaccordingtoDINENISO9001:2008and14001:2004.Beforereleasefordispatch,any

pumpoftheQuattroTecserieshastoundergoanextendedfinalcontrol.Theperformancedataregistered

duringthisarearchivedinourrecordsandcanbereadbackatanytime.

AsageneralruleinthecountriesoftheEUonlysuchmachinesareallowedtotakeintooperation,whichare

determinedtomeettheregulationsoftheEUmachinerydirective,theharmonizedstandards,European

standardsandtherespectivenationalstandards.HencetheoperatorhastoverifywhethertheQuattroTec

pumpmanufacturedanddeliveredproperlyaccordingtothecustomer’sordermeetsthementioned

requirements.Thereforemakesure,beforeputtingthepumpintooperation,thatthepumpandtheused

materialsofconstructionaresuitablefortheprovidedapplicationandtheinstallationsite.Tocheckthis,the

exactpumpcodeisrequired.Thiscode,theserialnumberandtheyearofconstructionarenotedonthe

identificationplatesonthepumpitself.