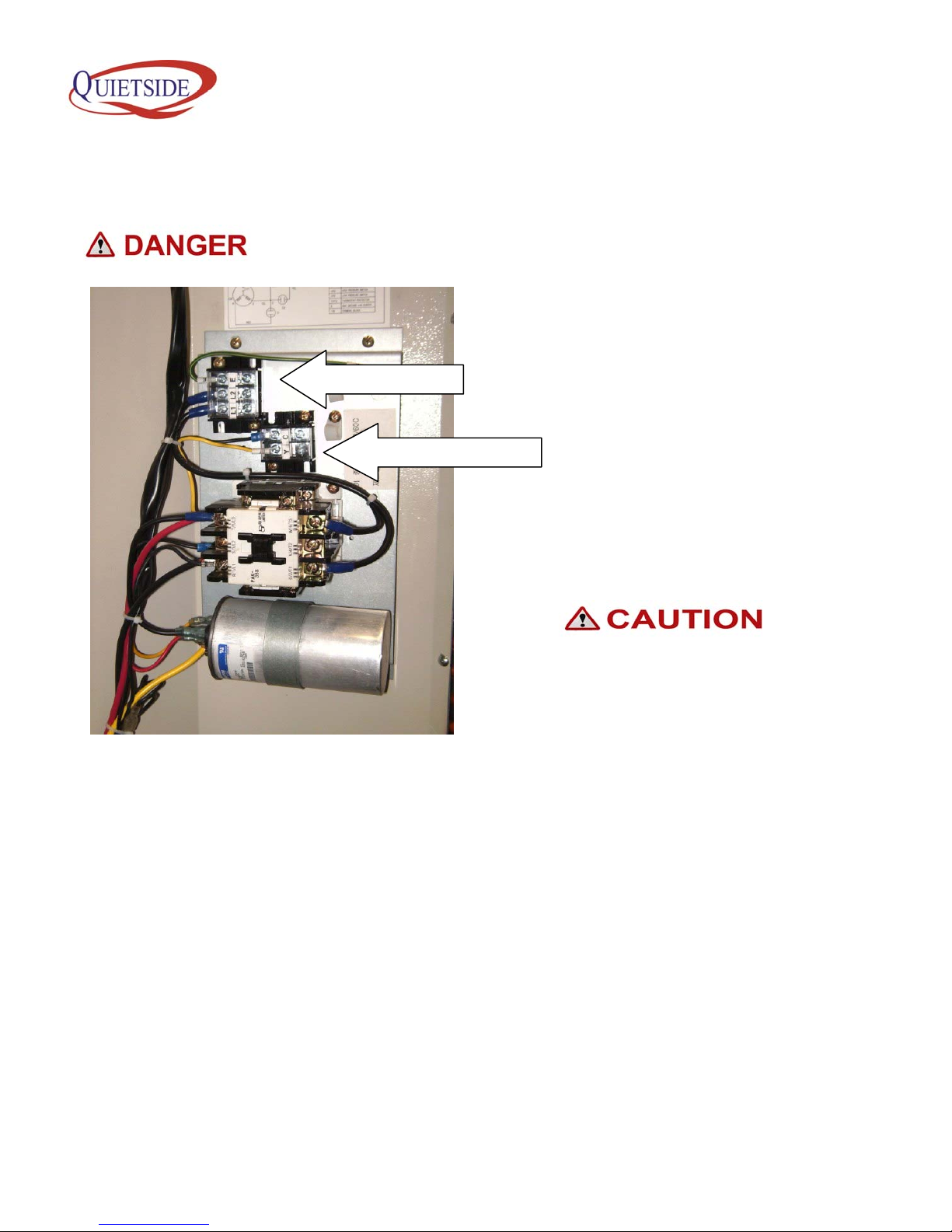

Quietside QSCU-361 Supplement

Other Quietside Air Conditioner manuals

Quietside

Quietside QSFMO-D2 User manual

Quietside

Quietside QSVSI-09A User manual

Quietside

Quietside QSHE-092 User manual

Quietside

Quietside QS36-VJ220 User manual

Quietside

Quietside QSVSI-18A User manual

Quietside

Quietside QSVMI-09A User manual

Quietside

Quietside QSHD-24A User manual

Quietside

Quietside QS09-VJ115 User manual

Quietside

Quietside QSCE-093 User manual

Quietside

Quietside QS09-VP115 User manual

Popular Air Conditioner manuals by other brands

CIAT

CIAT Magister 2 Series Installation, Operation, Commissioning, Maintenance

Bestron

Bestron AAC6000 instruction manual

Frigidaire

Frigidaire FFRE0533S1E0 Use & care guide

Samsung

Samsung AS09HM3N user manual

Frigidaire

Frigidaire CRA073PU11 use & care

Soleus Air

Soleus Air GB-PAC-08E4 operating instructions

McQuay

McQuay MCK020A Technical manual

Webasto

Webasto Frigo Top 25 DS Instructions for use

Frigidaire

Frigidaire FAZ12ES2A installation instructions

Mitsubishi Electric

Mitsubishi Electric MSC-GE20VB operating instructions

Mitsubishi Electric

Mitsubishi Electric PLA-M100EA installation manual

Daikin

Daikin Split Sensira R32 Service manual