2

4. INSTALLATION

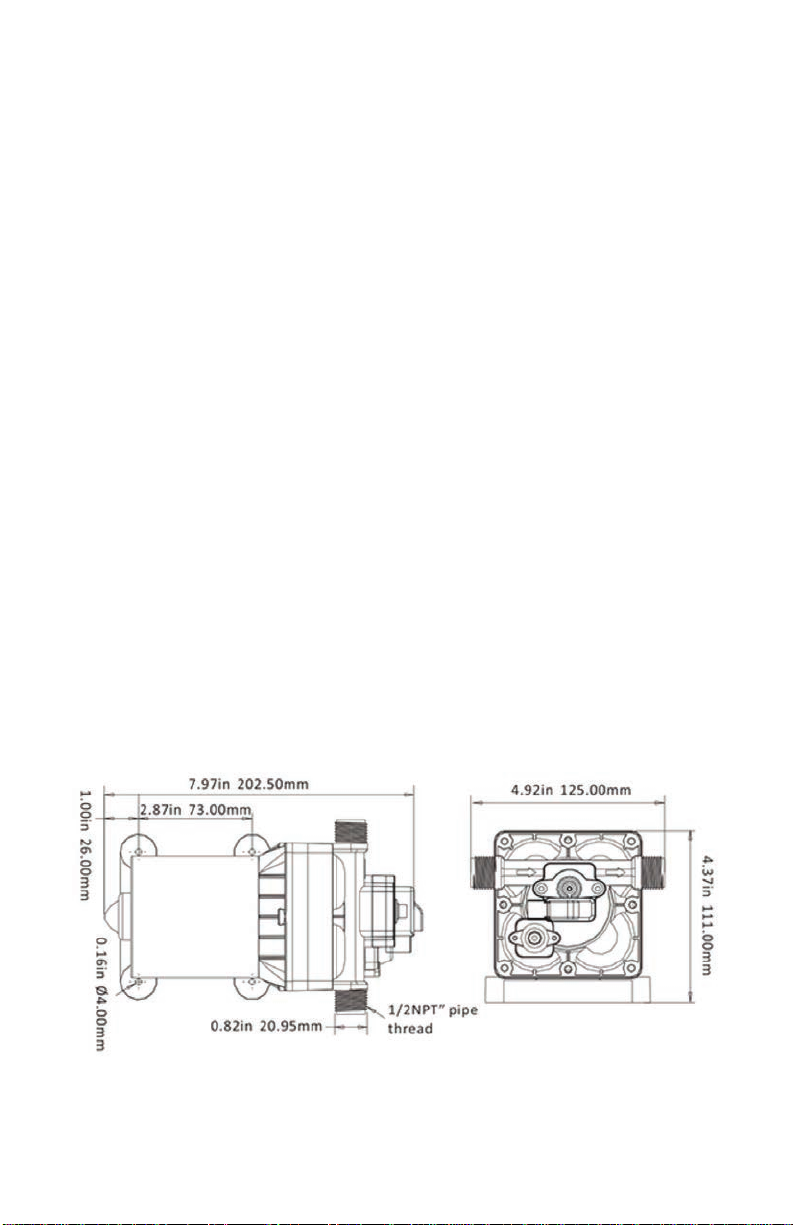

Materials

- 1 diaphragm pump with related accessories

-

strength of twice the inlet collapsing pressure, hose must be mini-

- 4 stainless steel hose clamps and screws

- 4 screws to fasten the pump to the mounting surface

-

- 1 fuse

- 1 screwdriver

- 1 strong, cutting implement for tubing

-

Setup

1. The pump may be mounted in any position. If mounted vertically, the

pump head should be in the down position to avoid leakage into the

motor casing in the event of a malfunction.

2. Secure the feet, but do not compress them. Over-tightening the se-

curing screws may reduce their ability to dissipate noise and vibra-

tion.

3.

mm).

4. Plumb the system using high pressure (2 x pump rating) braided,

5.

avoid any inlet pressure completely.

6.

7. Strainer should be attached to the inlet side.

8.

9. Use clamps at both ends of hose to prevent air leaks into the water

line.

If a check valve is installed in the plumbing, it must have a cracking

pressure of no more than 2 PSI.

11. If applying a sealer or plumbing tape, be careful to not over-tighten,

as they may be sucked into pump.

12. This pump should be wired on its own dedicated circuit. Connect

the positive lead (red) to the positive terminal of the battery and the

negative wire (black) to negative terminal of the battery.

13. In an easily accessible location, install a switch to control electricity

or when the tank is empty.

14. The electrical circuit should be protected with an over-current protec-