2

CONTENTS

1. INTRODUCTION ................................................................................................................................................................... 3

1.1 Scope.......................................................................................................................................................................... 3

2. CAMERA CARE ..................................................................................................................................................................... 3

2.1 Cleaning the Sensor Window.................................................................................................................................... 3

3. SPECIFICATION..................................................................................................................................................................... 4

3.1 Camera Specification................................................................................................................................................. 4

3.2 Specification Table .................................................................................................................................................... 4

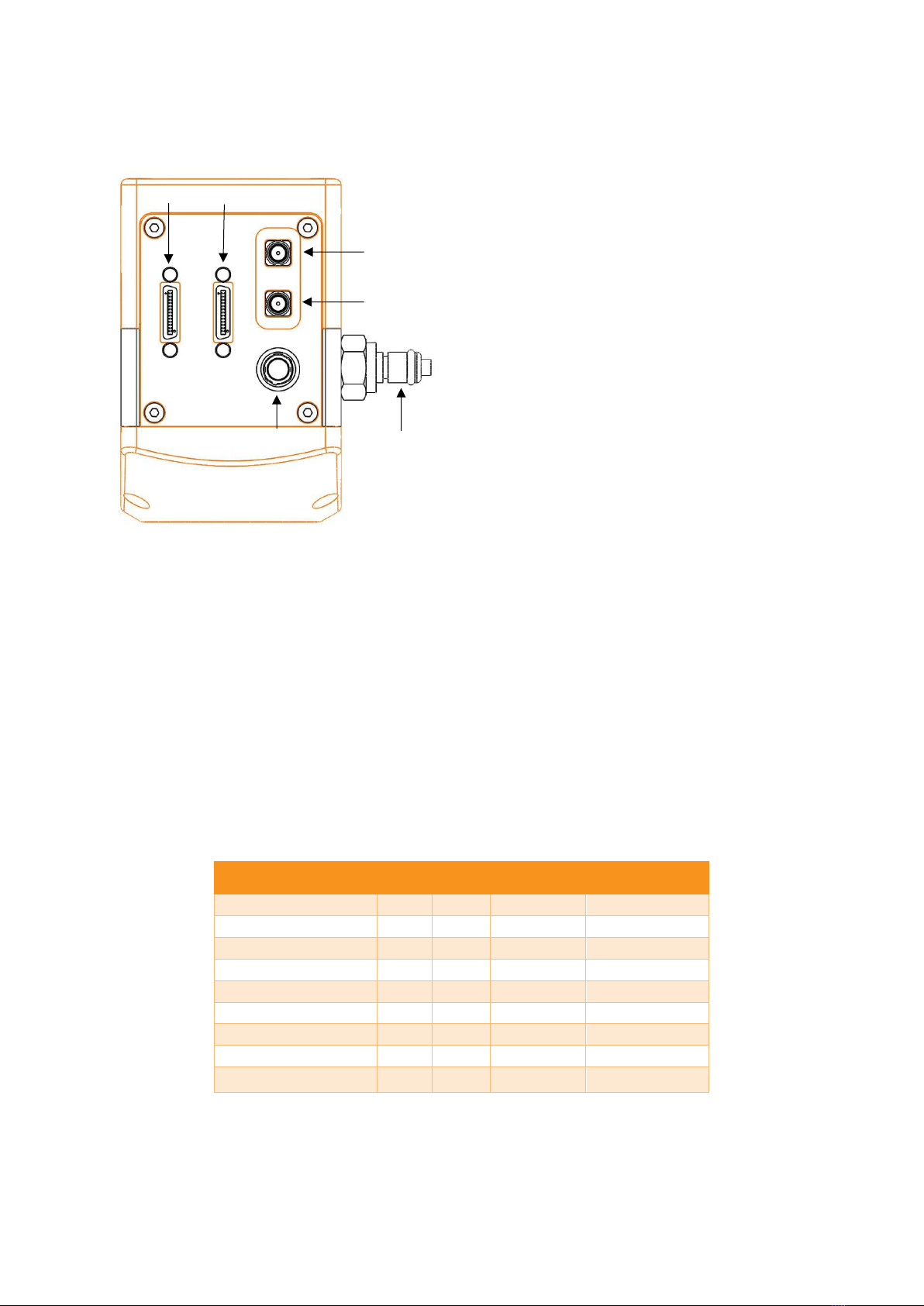

4. MECHANICAL DESIGN ......................................................................................................................................................... 5

4.1 Mechanical Model................................................................................................................................................ 5

4.2 Physical Interface ................................................................................................................................................. 6

4.3 Mounting to Microscope ..................................................................................................................................... 6

4.4 Mounting to a tripod or optical table ................................................................................................................. 6

5. SOFTWARE COMPATIBILITY ................................................................................................................................................ 6

5.1 Compatibility Table .............................................................................................................................................. 6

5.2 XCAP Compatibility............................................................................................................................................... 7

5.3 Micromanager Compatibility............................................................................................................................... 7

5.4 LabView Compatibility ....................................................................................................................................... 7

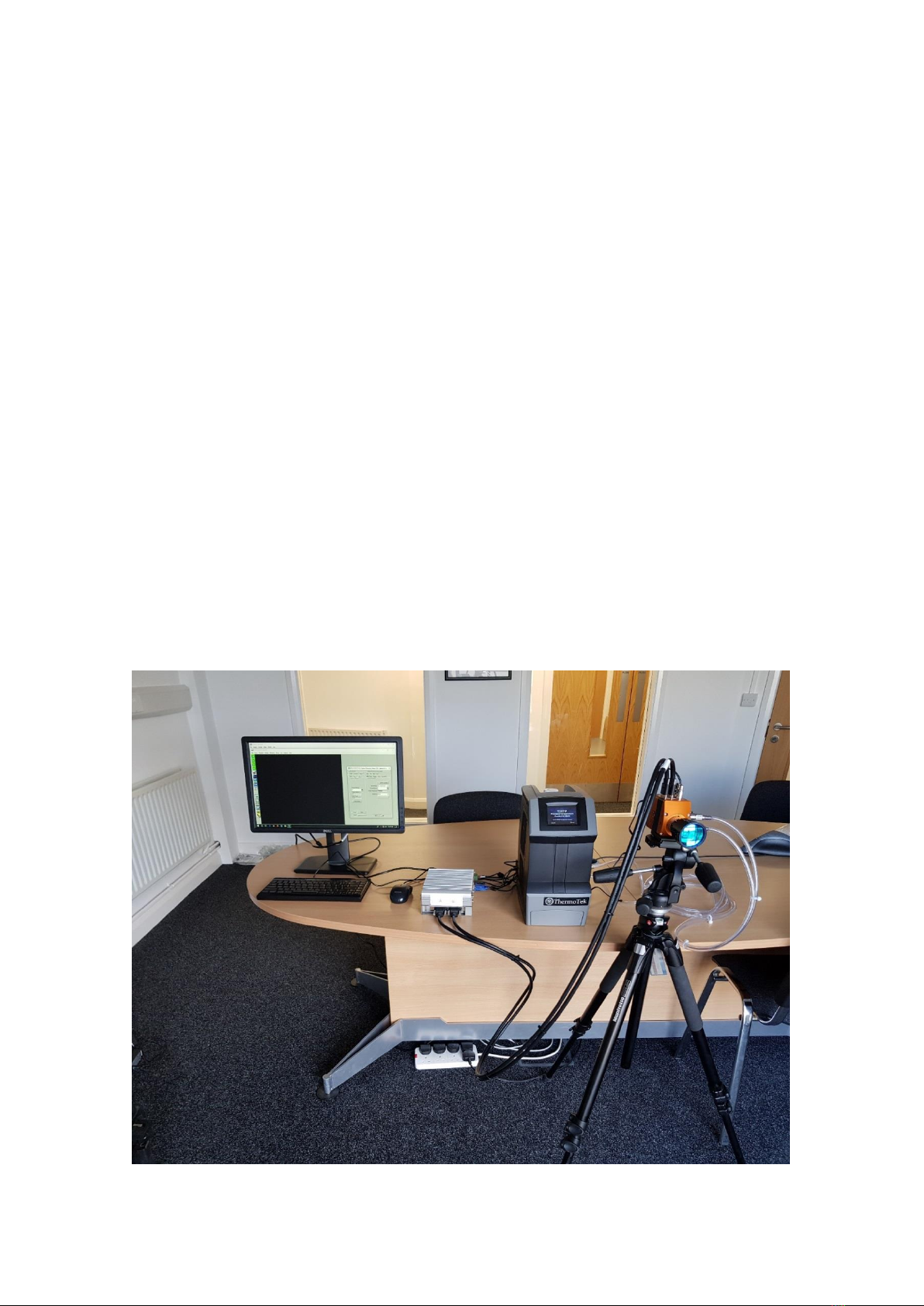

6. CAMERA SETUP.................................................................................................................................................................... 7

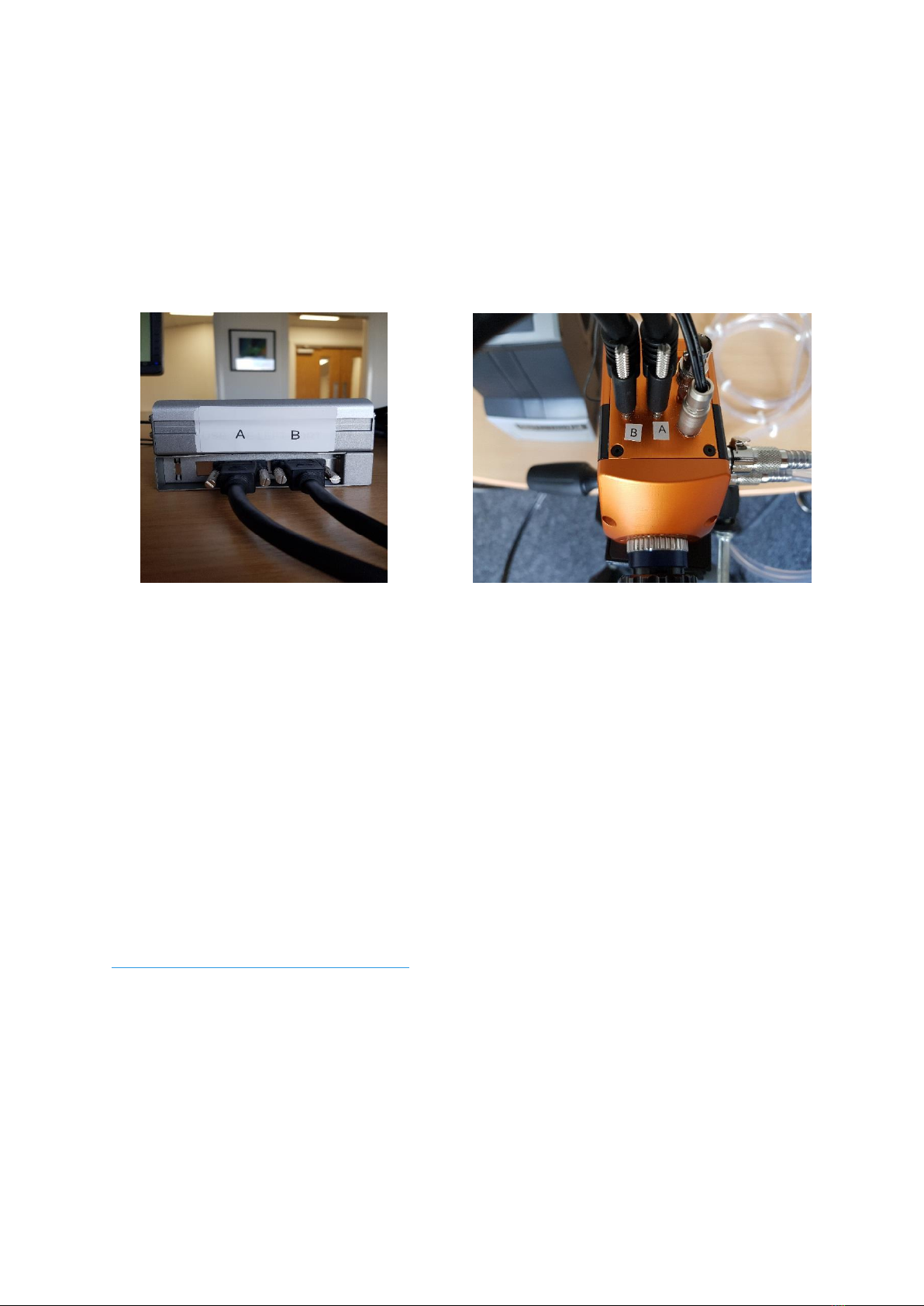

6.1 Connecting Camera to Chiller.............................................................................................................................. 8

6.2 Connecting Camera to Frame Grabber............................................................................................................... 8

7. XCAP IMAGING SOFTWARE................................................................................................................................................. 9

7.1 Computer System Requirements. ....................................................................................................................... 9

7.2 Frame Grabber Requirements............................................................................................................................. 9

7.3 Downloading and Installing XCAP........................................................................................................................ 9

7.4 Opening Camera Configuration......................................................................................................................... 10

7.5 Ensuring the Camera is Connected ................................................................................................................... 11

7.6 Acquiring a Live Image Sequence...................................................................................................................... 12

7.7 Controlling the Camera...................................................................................................................................... 12

7.7.1 Gain, Exposure & Frame Period. .................................................................................................................. 12

7.7.2 Triggering Modes. ......................................................................................................................................... 14

7.7.3 Thermoelectric Cooler (TEC). ....................................................................................................................... 14

7.7.4 Non-Uniformity Correction (NUC)................................................................................................................ 15

7.7.5 Auto Exposure Control (ALC):....................................................................................................................... 16

7.7.6 Auto Exposure ROI Control........................................................................................................................... 17

7.7.7 Miscellaneous Section. ................................................................................................................................. 19

7.7.8 Manufactures Data Information .................................................................................................................. 19

7.7.9 Saving Preset Settings................................................................................................................................... 20

7.7.10 Contrast Modification................................................................................................................................... 21