Page 6

Weekly Check

Check oil level and top-up if necessary.

Check water level of radiator.

Check tyre pressures.

Check battery electrolyte level.

At First 500 Miles (800 km) (Free Service)

Lubrication

Change engine oil and fit new filter.

Change gearbox and rear axle oils.

Oil or grease all lubrication points.

Check steering box level and top up if necessary.

Adjustments

Tighten cylinder head, rocker shaft, sump and manifold

fixings to correct torque.

Check and adjust valve clearances.

Check and adjust fan belt.

Examine and adjust distributor points.

Check and adjust brakes.

Check and adjust clutch.

Check hydraulic system, bleed and top-up the master

cylinder(s) as necessary.

Adjust tyre pressures and check security of wheel nuts.

Check all body, steering, spring and suspension fixings and

steering connections.

Check front wheel bearings.

Balance the road wheels.

Check and adjust door operation.

Road or roller test and adjust carburettor or timing if

required.

General

Top-up the battery, radiator and washer bottle.

Check operation of seat adjustment, all controls, lights,

horn, instruments and windscreen wipers etc.

Check battery connections.

Check for water or oil leaks.

Every 1000 miles (1,600 km)

Lubrication

Top-up engine, gearbox, rear axle and steering box oil

levels.

Top up master cylinder(s) fluid levels if necessary.

Oil or grease all lubrication points.

Adjustments

Check and adjust brakes.

Check and adjust clutch.

Check tyre pressures and security of wheel nuts.

General

Check level of electrolyte in battery.

Every 5,000 miles (8,000 km)

Lubrication

Change engine oil and fit new filter.

Change gearbox oil.

Oil or grease all lubrication points.

Check steering box oil and top-up if necessary.

Clean oil filler cap.

Adjustments

Tighten cylinder head, rocker shaft, sump and manifold

fixings to correct torque.

Check and adjust valve clearances.

Check and adjust fan belt.

Examine and adjust distributor points.

Check air cleaner. (replace every 10,000 miles).

Check and adjust brakes.

Check and adjust clutch.

Check hydraulic system, bleed and top-up the master

cylinder(s) as necessary.

Reposition road wheels and check tyre pressures.

Check front wheel bearings.

Balance the road wheels.

Check and adjust door operation.

Road or roller test and adjust carburettor or timing if

required.

General

Top-up the battery, radiator and washer bottle.

Check operation of seat adjustment, all controls, lights,

horn, instruments and windscreen wipers etc.

Check battery connections.

Check for water or oil leaks.

Every 15,000 miles (24,000 km)

The 15,000 mile service is the same as the 5,000 mile service

with the addition of the following recommendations:

Change rear axle oil.

Re-pack front wheel bearings with grease.

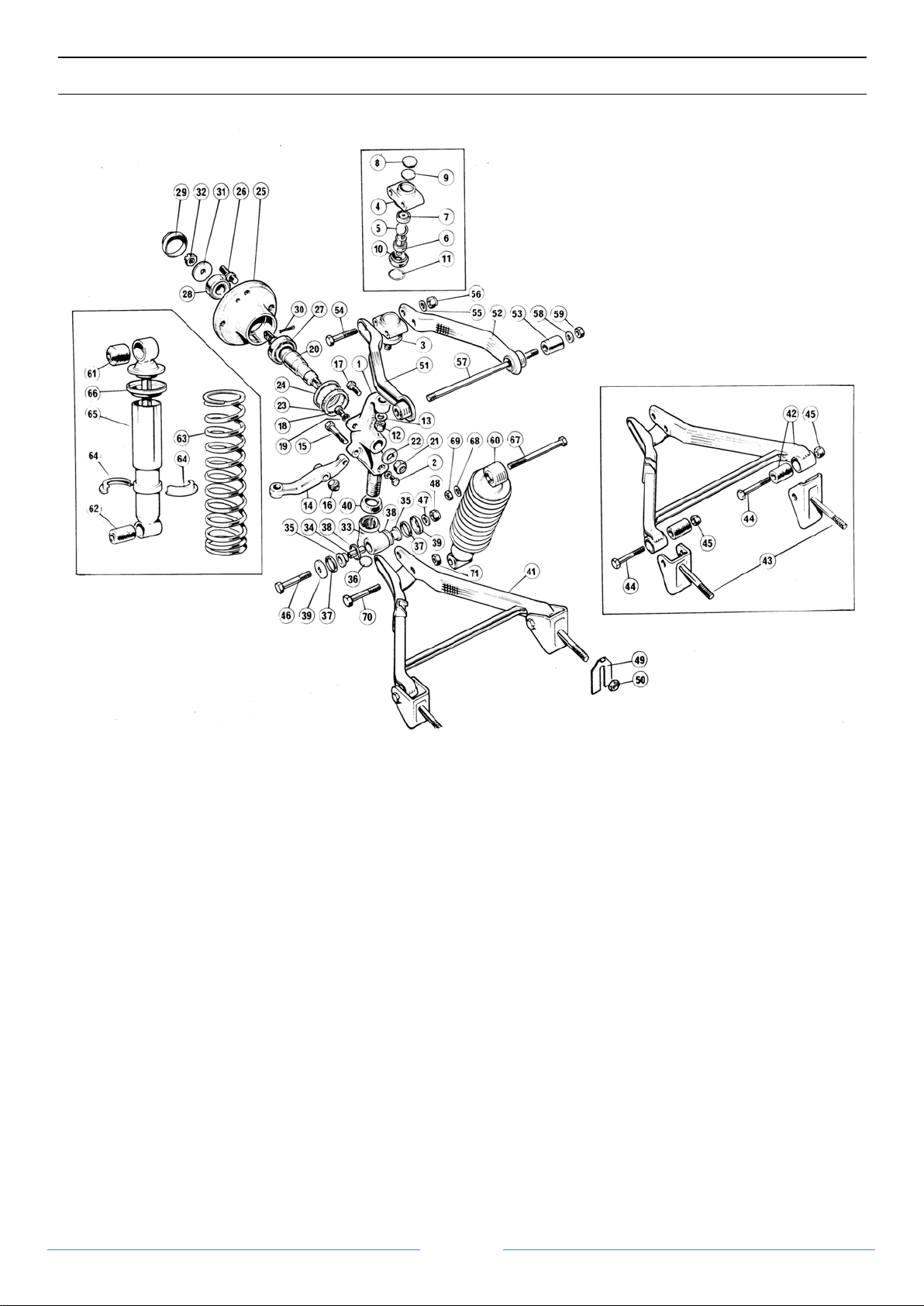

Lubricate front suspension vertical link lower pivot.