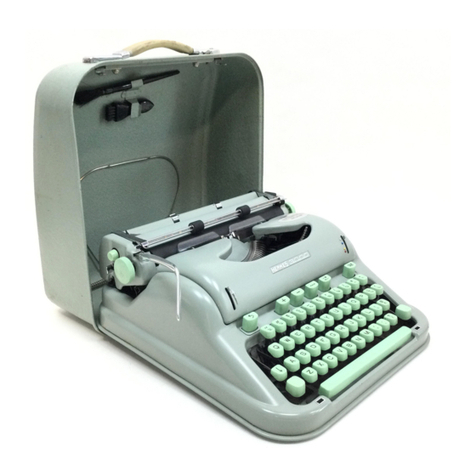

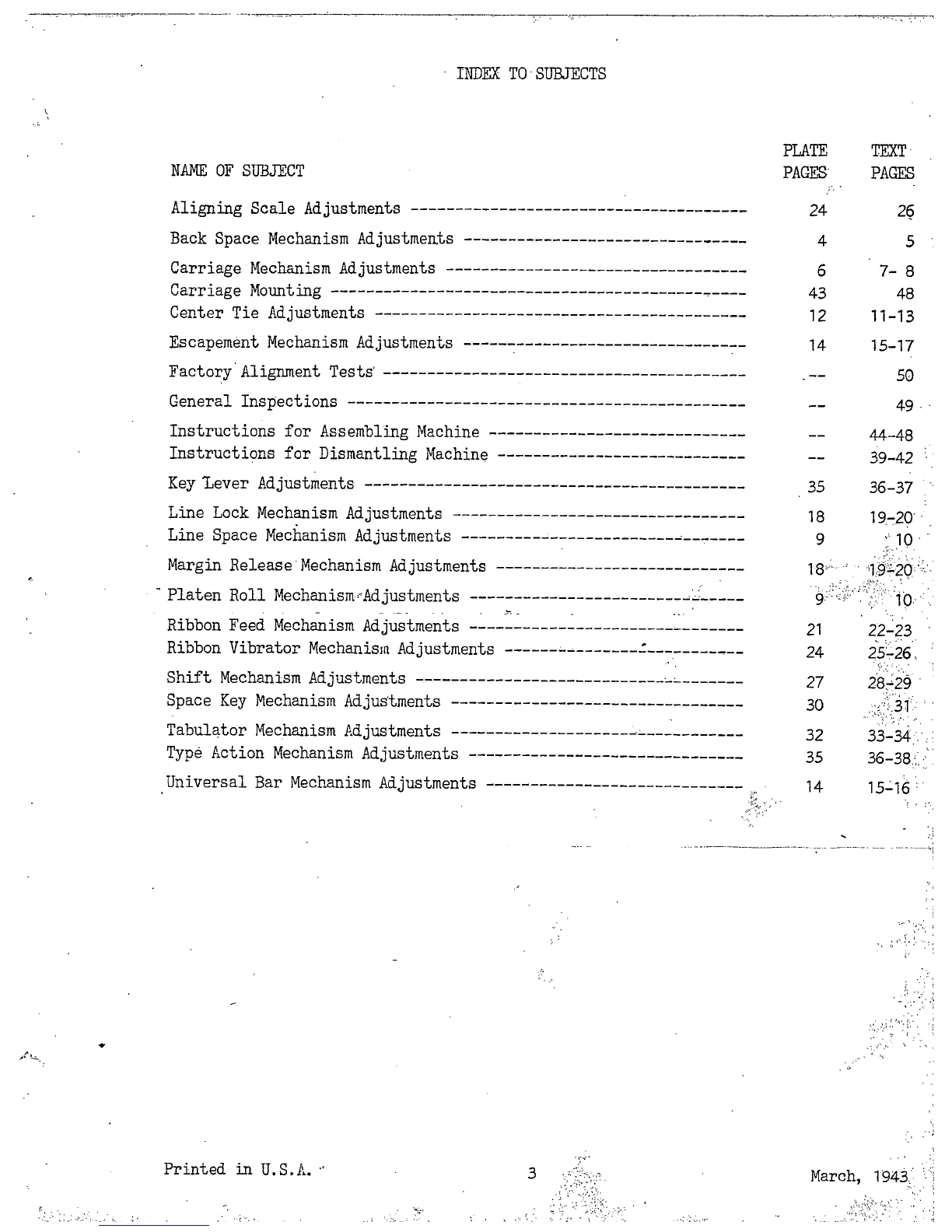

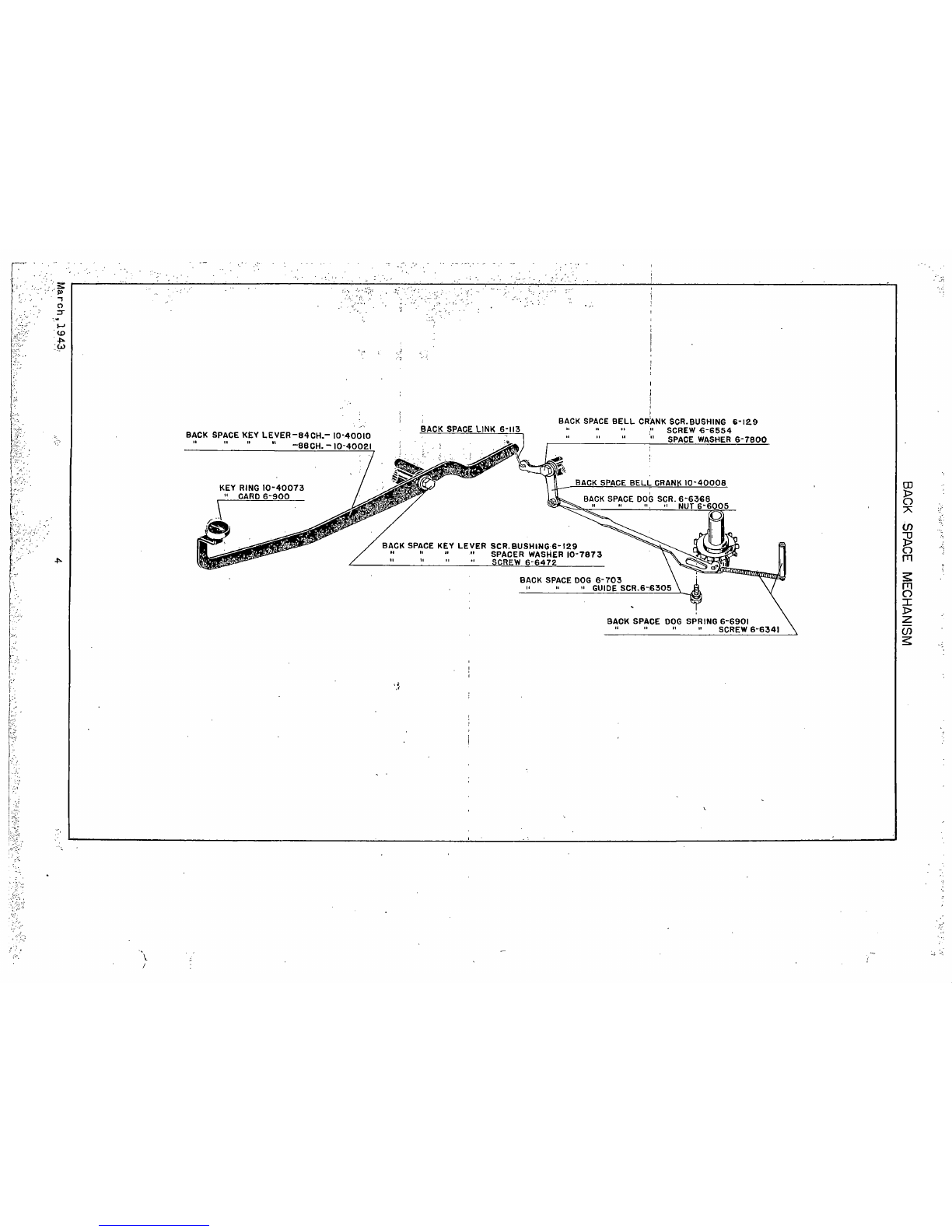

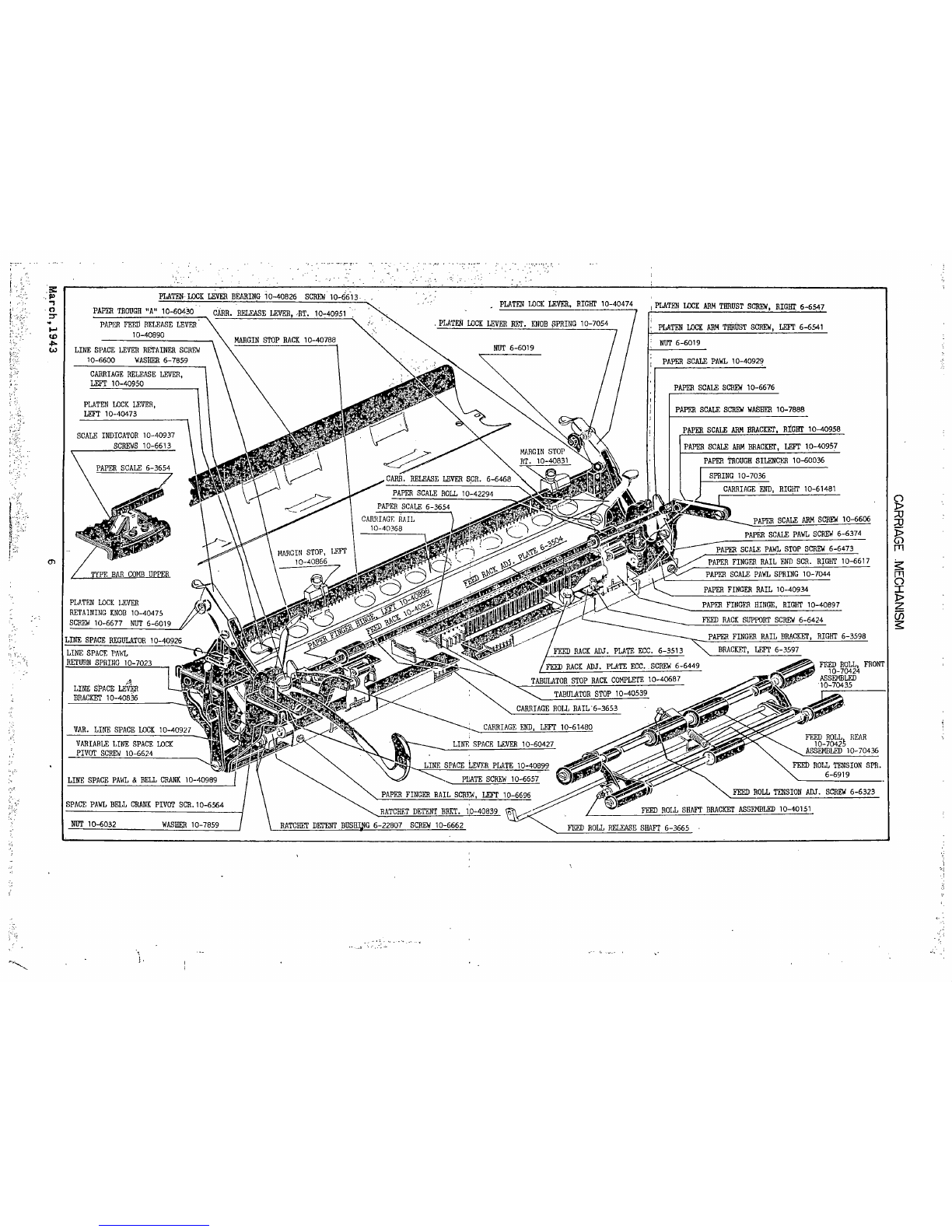

Remington Rand Inc. Noiseless 10 User manual

Popular Typewriter manuals by other brands

IBM

IBM Selectric II operating instructions

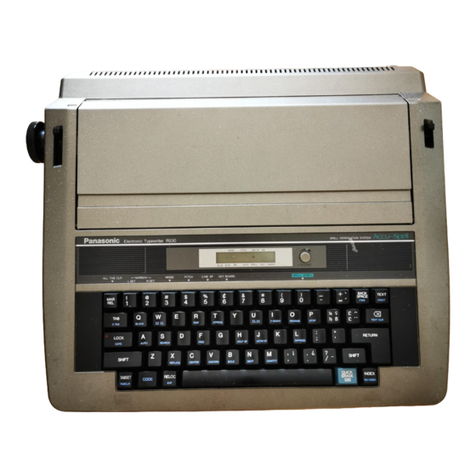

Panasonic

Panasonic KX-R530 - Electronic Typewriter operating instructions

Brother

Brother AX-425 parts reference list

Scheidegger

Scheidegger TYPOMATIC-TMS Instruction handbook

Siemens

Siemens 1000 CA operating instructions

Panasonic

Panasonic KX-E50 Operator's instruction manual