Installation Manual

CA294-03070 rev 00 page 2 of 153

Securing the turnbar..........................................................................................................................54

Electrical cabling ...............................................................................................................................58

Installing the vacuum hoses..............................................................................................................70

Install the floor platform.....................................................................................................................72

Installing the chiller and cooling water hoses....................................................................................72

Install the UPS...................................................................................................................................75

Install the writing head.......................................................................................................................76

Install the HVPS (High Voltage Power Supply).................................................................................77

Install the roof covers ........................................................................................................................79

Install system components................................................................................................................80

Unpacking the ILP, unwinder, utility cabinets, and ink cabinets .......................................................80

Installing the ILP................................................................................................................................81

Installing the ILP web rollers .............................................................................................................97

Installing the unwinder.....................................................................................................................100

Unwinder electrical connections......................................................................................................104

ILP electrical connections................................................................................................................105

Connect the air supply.....................................................................................................................108

Install the ILP vacuum hoses ..........................................................................................................112

Installing the ink cabinets ................................................................................................................113

Adjusting the web guide ..................................................................................................................116

Install the utility cabinet ...................................................................................................................117

Connect the computers ...................................................................................................................121

Install the master console ...............................................................................................................127

Connecting the master computer ....................................................................................................128

Production flow................................................................................................................................130

Install the finishing components ......................................................................................................130

Installing the turnbar stepping plate ................................................................................................130

Install the main power connection and transformer ........................................................................130

Initial power-up ................................................................................................................................131

Emergency stop tests......................................................................................................................136

Threading the web...........................................................................................................................138

Configure the press software ..........................................................................................................139

Install PIP and blankets...................................................................................................................139

Testing and calibrating the press ....................................................................................................139

Customer acceptance test procedure (CATP) ................................................................................145

CATP specification checklist ...........................................................................................................147

Complete the installation.................................................................................................................150

Appendix A: Image placement parameters ..........................................................................................151

Revision history ....................................................................................................................................153

Confidentiality Notice............................................................................................................................153

List of figures

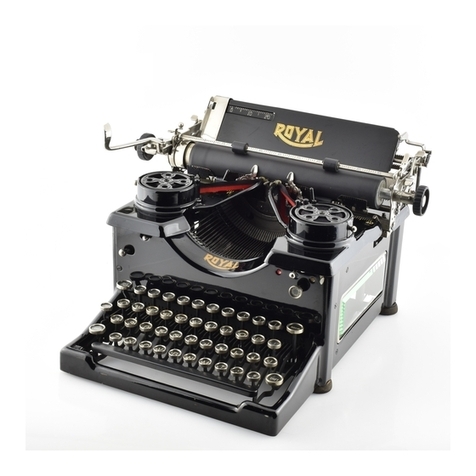

Figure 1 The HP Indigo press w3250 ...................................................................................................6

Figure 2 The alignment jig ..................................................................................................................19

Figure 3 The alignment jigs mounted .................................................................................................19

Figure 4 Sections of the new Parallel jig ............................................................................................20

Figure 5 Mounting the v-section of the Parallel jig..............................................................................21

Figure 6 Mounting the dial bracket on the extension..........................................................................22

Figure 7 Positioning the u-bases ........................................................................................................25

Figure 8 Remounting the u-base slip plates .......................................................................................26

Figure 9 Adjusting the u-base height..................................................................................................27

Figure 10 Placing the foresight on the PE2 u-base ............................................................................28