.I'IOOI'OO

t!aa!aaatoo o

aaaaoaaooaa

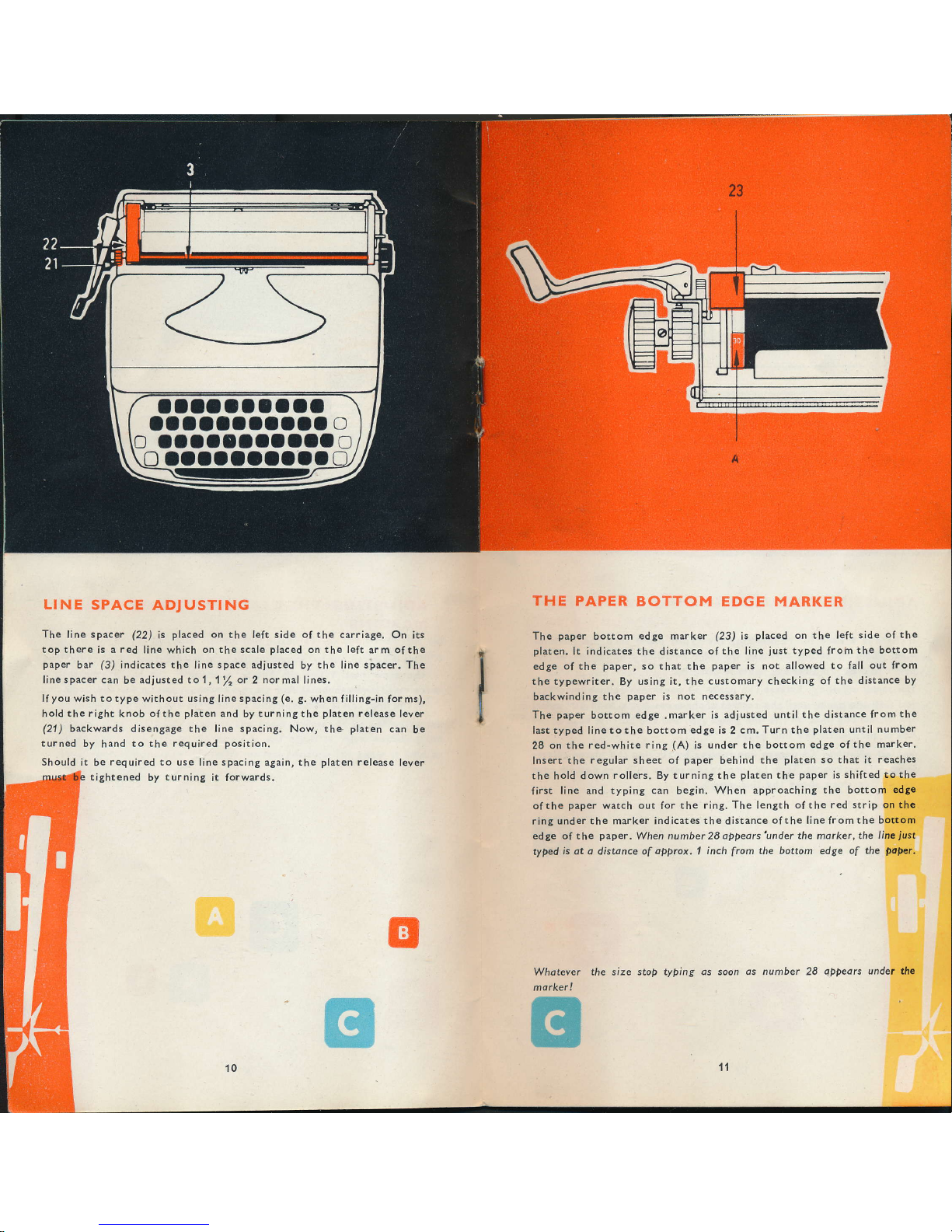

LINE SPACE ADJUSTTNG

The line spacer (22) is placed on the left side of the carriage. On its

top there is a red line which on the scale placed on the left arm ofthe

paper bar (3) indicates the line space adiusted by the line spacer. The

linespacercan beadiusted to1,1lor 2 normal lines.

lfyou wish totype without using line spacing (e. g. when filling-in forms),

hold the right knob ofthe platen and by turning the platen release lever

(21) backwards disengage the line spacing, Now, the platen can be

turned by hand to the required position.

Should it be required to use line spacing again, the platen release lever

tightened by turning it forwards.

THE PAPER BOTTOM EDGE MARKER

The paper bottom edge marker (23) is placed on the left side ofthe

platen, lt indicates the distance ofthe line just typed frotn the bottom

edge of the paper, so that the paper is not allowed to fall out from

the typewriter, By using it, the customary checking of the distance by

backwinding the paper is not necessary.

The paper bottom edge .marker is adjusted until the distance from the

last typed line to the bottom edge is 2 cm. Turn the platen until number

28 on the red-white rine (A) is under the bottom edge ofthe marker.

lnsert the regular sheet of paper behind the platen so that it reaches

the hold down rollers. By turning the platen the paper is shifted to the

first line and typing can begin. When approaching the bottom ed8€

ofthe paper watch out for the ring. The length ofthe red strip on the

ring under the marker indicates rhe distance ofthe line from the bottom

ed ge o{ the paper. When nu mber 28 appedrs'under the mdrker, the line just

typed is ot o disunce of opprox. l inch from the bottom edge of the Paqet.

morker!

E

10

the size stop typing os soon os number 2E qppeorc under the