LabRAM Users Manual –Revised 3/18/11

1 TABLE OF CONTENTS

1TABLE OF CONTENTS 2

2SAFETY INSTRUCTIONS 4

2.1 Types of Notices.................................................................................................. 3

2.2 General Safety Guidelines .................................................................................. 3

3DEFINITIONS 4

4INTRODUCTION TO THE LabRAM 5

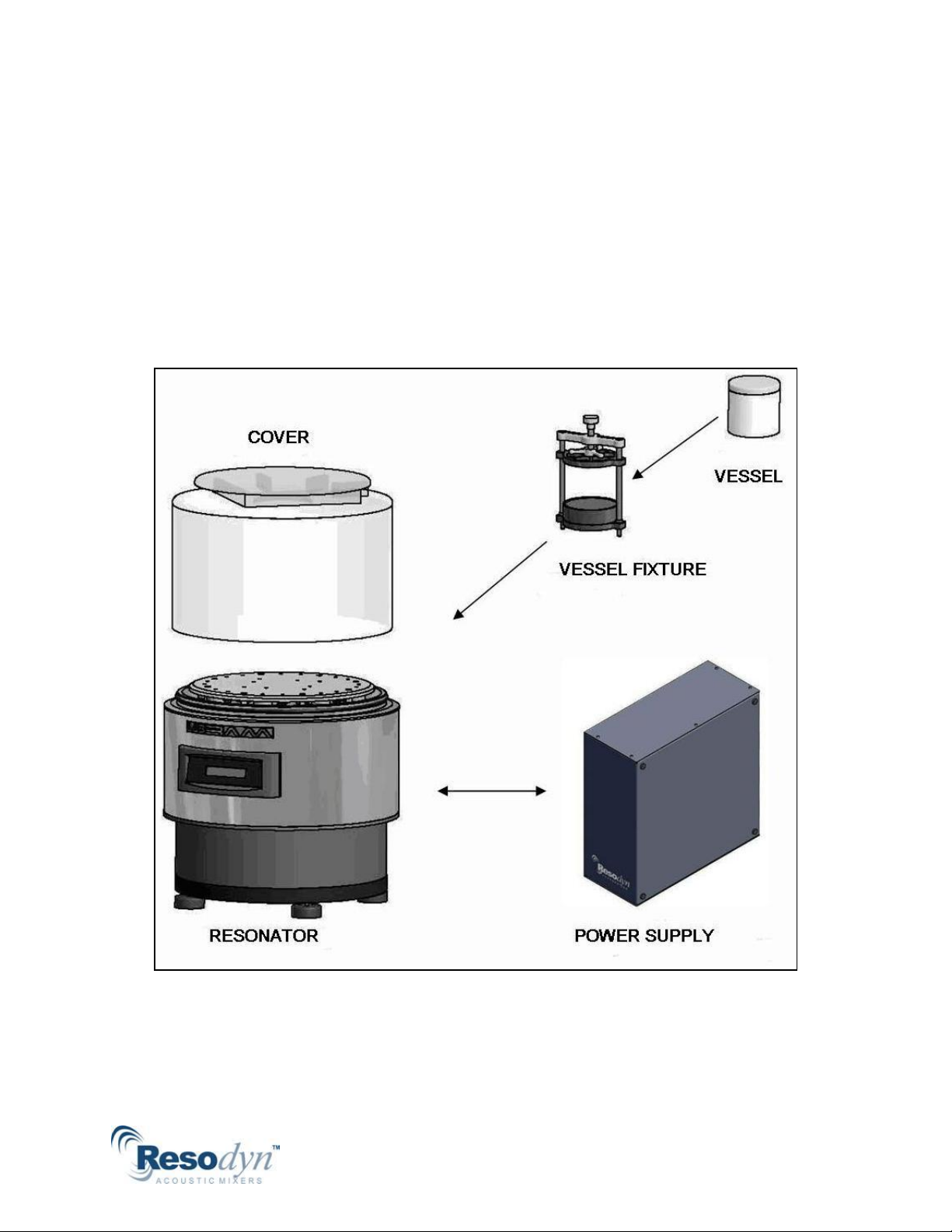

5MAJOR COMPONENTS 6

5.1 Overall Assembly ................................................................................................ 6

5.2 Resonator............................................................................................................ 7

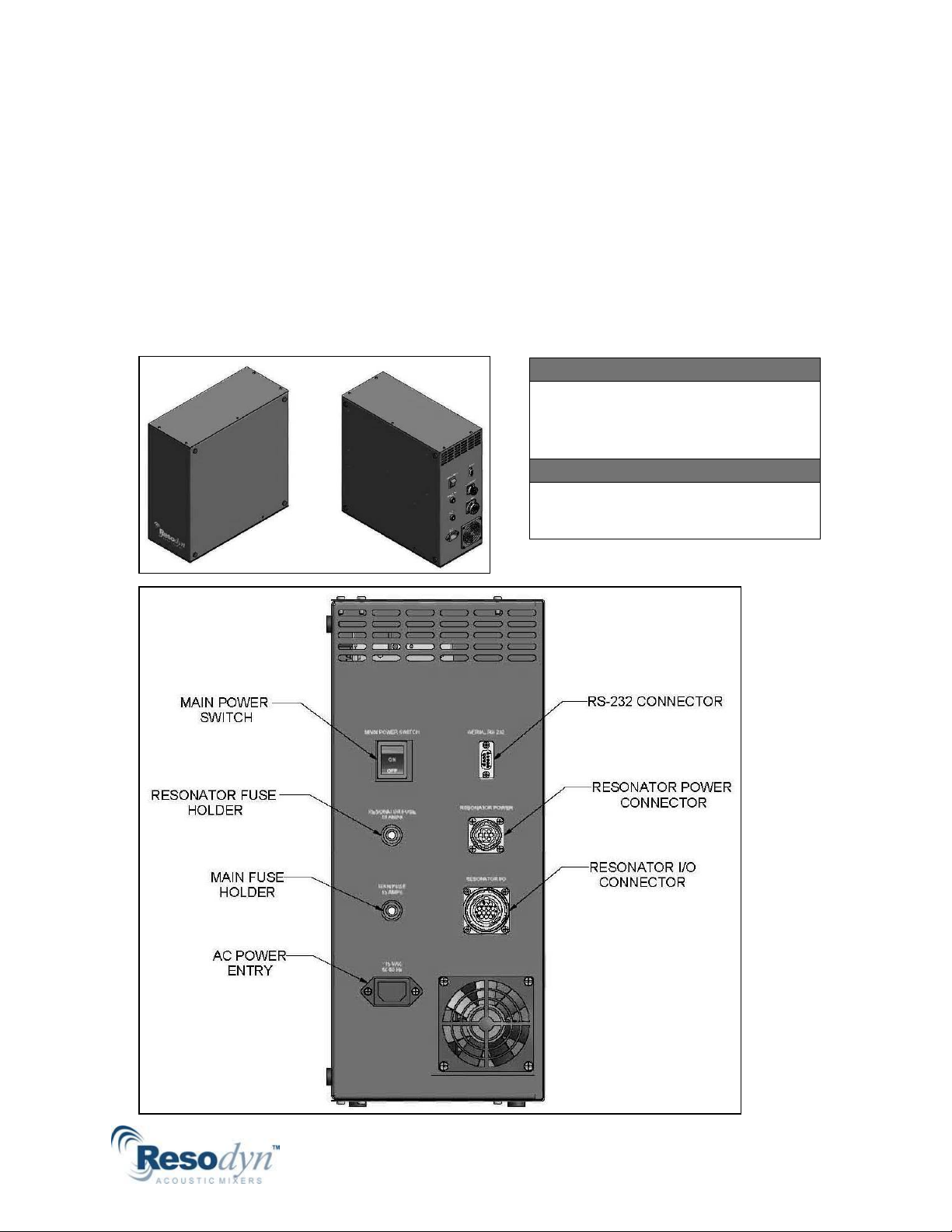

5.3 Power Supply and Control .................................................................................. 9

5.4 Standard Vessel Fixture and Vessels ................................................................ 11

6THEORY OF RAM MIXING 12

7SETUP 14

7.1 Prepare the Resonator...................................................................................... 14

7.2 Position the Power Supply................................................................................ 15

7.3 Connecting the Power Supply to the Resonator .............................................. 16

7.4 Attach the Hold-Down Fixture.......................................................................... 17

7.5 Install Vessel ..................................................................................................... 18

7.6 Install Cover ...................................................................................................... 19

8OPERATION 20

8.1 Turn on Power .................................................................................................. 20

8.2 User Interface Menus ....................................................................................... 21

8.3 Startup and Mixing Procedure.......................................................................... 22

8.4 Automatic Countdown Timer ........................................................................... 24

8.5 Error Handling................................................................................................... 25

9VACUUM OPTION 29

9.1 Introduction to the LabRAM Vacuum Option................................................... 29

9.2 Overall Assembly .............................................................................................. 29

9.3 Vacuum Set Up ................................................................................................. 30

9.4 Vacuum Operation............................................................................................ 32

9.5 Vacuum Maintenance....................................................................................... 33

9.6 Vacuum Technical Specifications...................................................................... 34

10 TROUBLE SHOOTING 34

11 MAINTENANCE 36

11.1 General Cleaning Instructions........................................................................... 36

11.2 Accelerometer Harness .................................................................................... 36

11.3 Driver Harness .................................................................................................. 37

12 TECHNICAL SPECIFICATIONS 38

12.1 General.............................................................................................................. 38

12.2 Resonator Enclosure......................................................................................... 39

12.3 Resonator Top Plate Fixture Mounting ............................................................ 40

12.4 Power and Control Supply ................................................................................ 41

12.5 Materials of Construction and Chemical Compatibility.................................... 42

13 SERVICE PLAN 45

14 ACCESSORIES 46