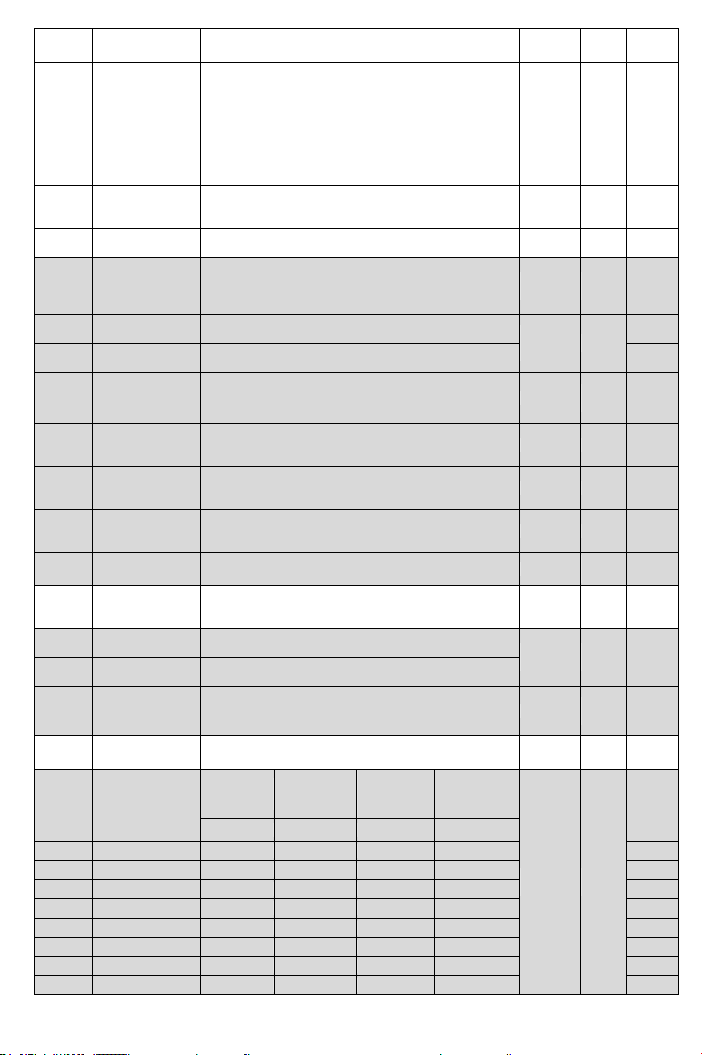

Operation

Selection at

Instantaneous

Power Failure

0: Drive cannot be restarted

1: Drive can be restarted

Auto-Restart

Selection for

Error Trip

Condition

0: Short time interval to auto-restart according to

the setting of F_080 (OC,OE,GF only).

1: Long time interval to auto-restart according to the

setting value of F_080, F_083 (except Fb Lo).

Error Trip

Auto-Restart

Number of time

Set the counting number for drive auto-restart

when errors occur.( OC,OE,GF only)

0: Disable

The setting value is higher and the motor noise is

lower.

0: Ramp to stop

1: Coast to stop

2: Coast to stop + DC braking

Time Interval

before

Auto-Restart

Set the error tripping time interval before drive auto

restarts for F_079 when the drive trips to

stop.( F_079=1)

Pressure Boost

(Water Usage

Detection)

Boost the pressure up to detect if the water is used.

Time Interval of

Pressure Boost

(Water Usage

Detection)

Set the time interval for F_084 to detect if the

water is used.

(0: off)

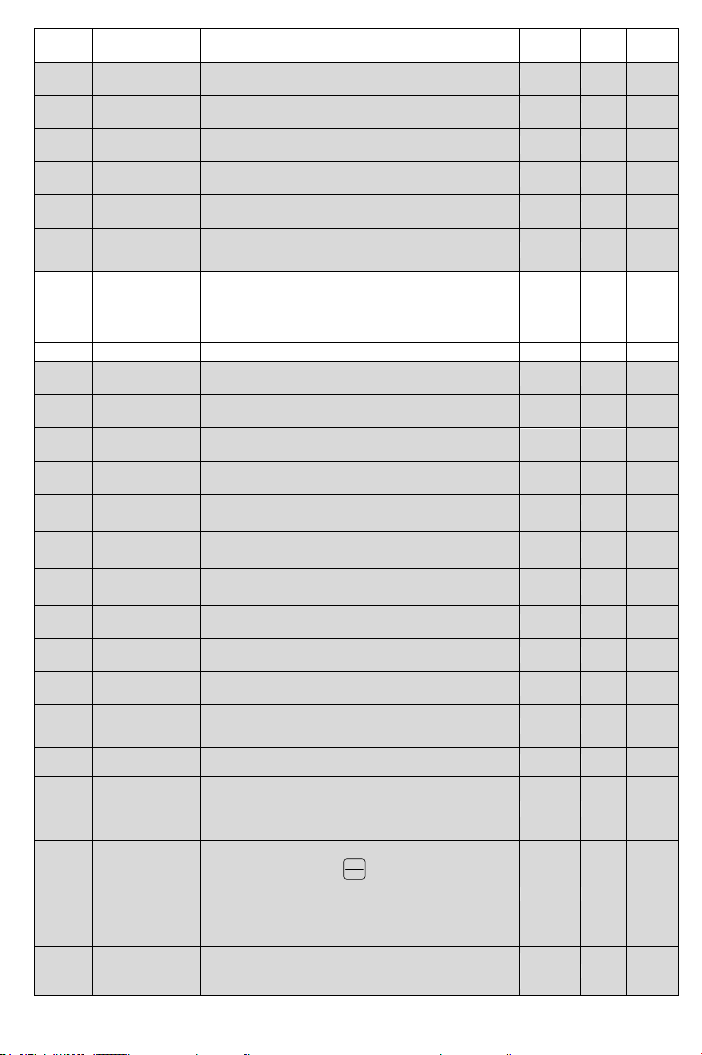

(ON/OFF Mode)

Starting Rate

Setting

In constant pressure control mode and under low

flow condition, setting the starting rate of drive to

activate ON/OFF mode.

Detective time: F_085*(100-F_086)% (0:off)

(ON/OFF Mode)

Pressure Dead

Band Setting

In ON/OFF mode, drive will auto start/stop the

pump in accordance with the setting value.

*Start level=SV(Setting pressure) - F_087

Stop level=SV(Setting pressure) + F_087

Speed Tracing

Current Level

When the current is higher than the “speed tracing

current level”, the output frequency will trace

downward.

0~200% of

drive rated

current

Delay Time

before Speed

Tracing

Set the output delay time before the speed tracing.

V/F Curve in

Speed Tracing

Set the percentage of V/F output voltage at the

speed tracing.

Display the latest 5 error records.

0: Parameters are changeable. Maximum

frequency cannot exceed 120.0Hz.

1: Parameters are locked. Maximum frequency

cannot exceed 120.0Hz.

2: Preserve

3: Preserve

Automatic

Voltage

Regulation

(AVR)

0: Disable

1: Electric thermal protection

2: Current limit overload protection

3: Electric thermal and Current limit overload

protection are enabled.

The value of setting according to the actual power

source.

Analog Input

Signal

Dead Band

When the signal noise is large, appropriately

increase the dead band to stabilize the frequency.

But this will reduce the tuning linearity.