FAST ROTATING BARREL (5 hours per revolution inste d of 7.5 hours)

This type of barrel has the following advantages:

- The phenomenon of periodic internal mainspring adhesion is significantly diminished, thereby increasing performance,

- Provision of an excellent mainspring delta curve with an ideal power reserve/performance and regularity ratio.

NEWLY DEVELOPED GEAR TEETH PROFILE

The entire going train of the watch, the primary transmitter of power throughout the movement, utilizes a special

profile for the teeth of the wheels. Developed specifically for the caliber CRMA1, the wheels use a 20° pressure angle.

This system equalizes any discrepancies that might arise between the centers of each wheel, for instance during thermal

changes and normal use, and promotes an excellent transmission of torque to the balance wheel, thus supporting

excellent chronometric characteristics.

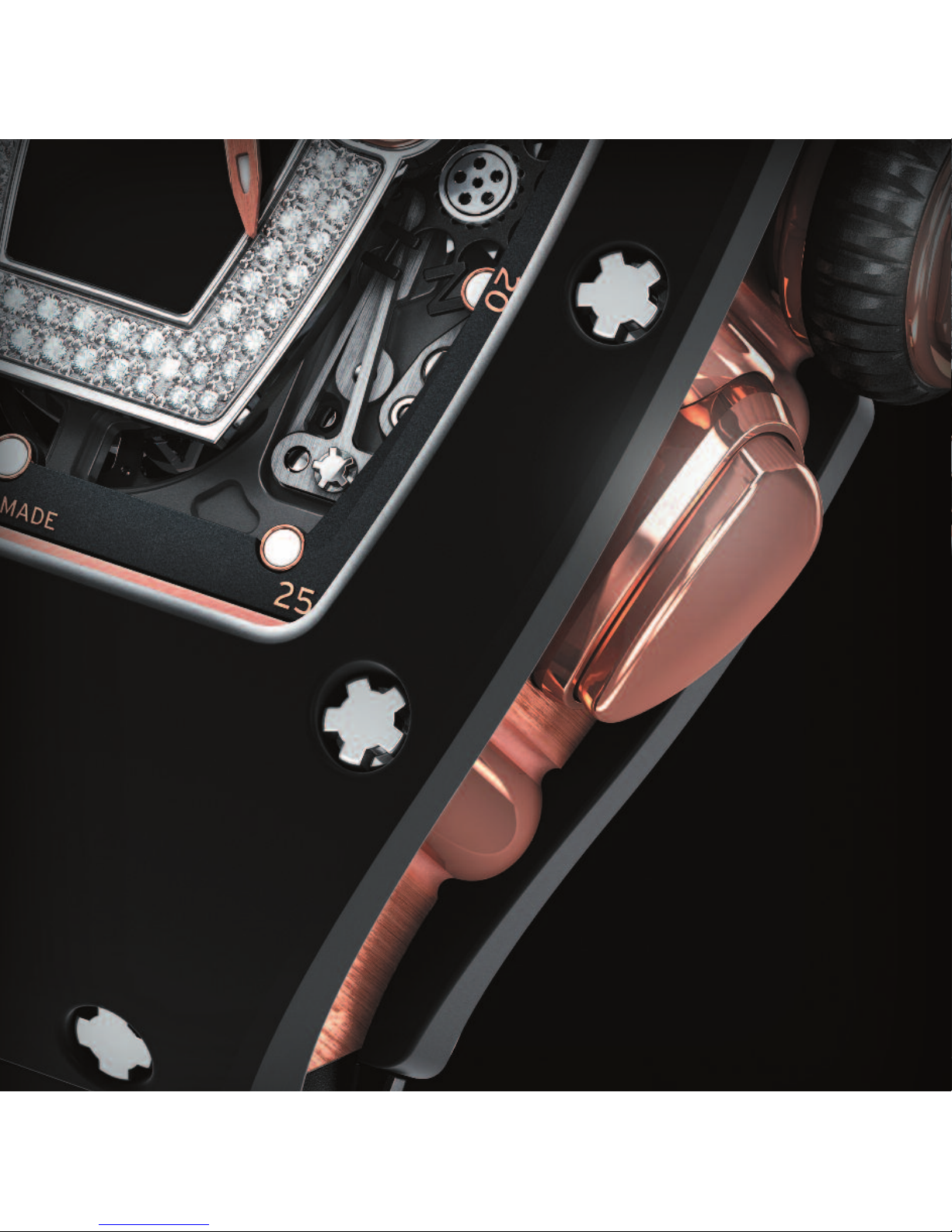

OVERSIZE DATE DISPLAY

Semi-instantaneous, horizontally placed under 12 o’clock, functioning via two skeletonised calendar discs over a white

field. The date can be easily corrected via the pusher located at 10 o’clock.

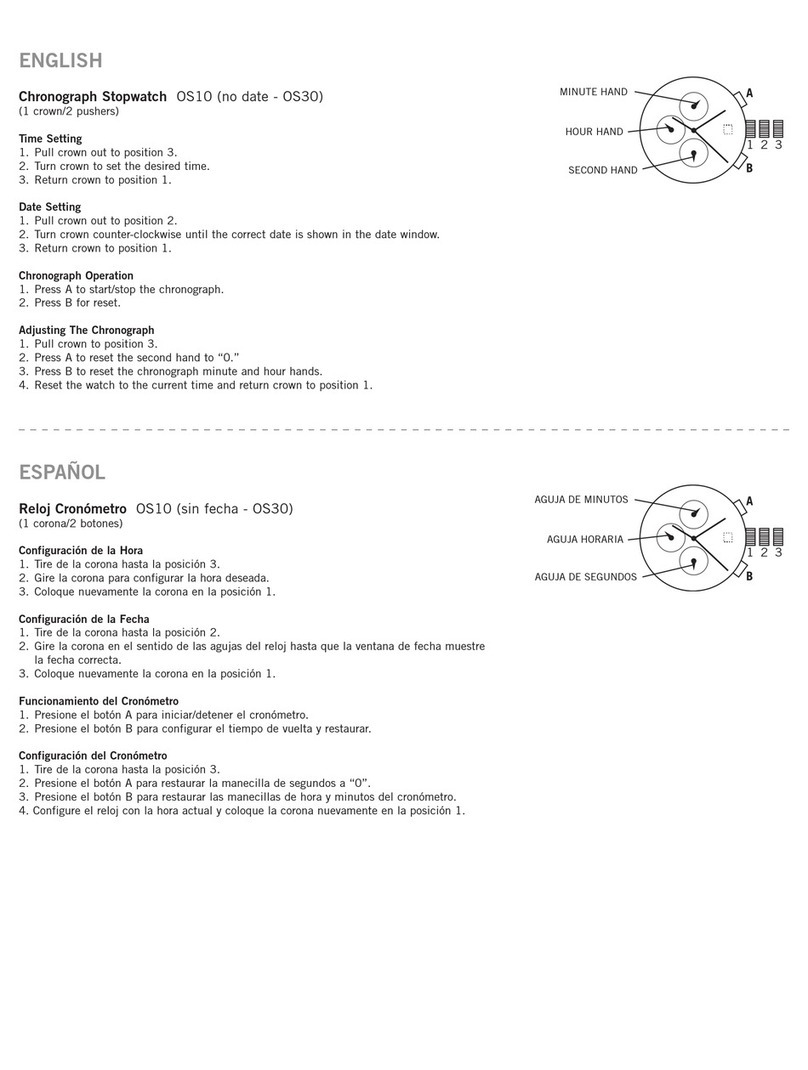

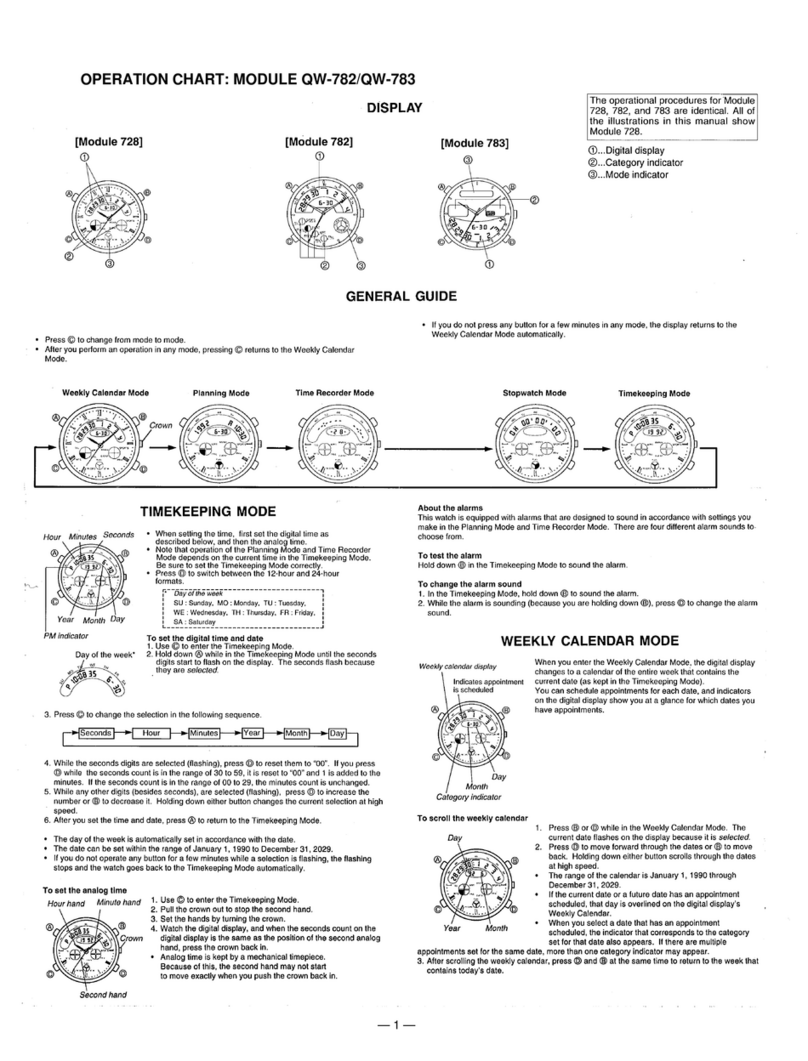

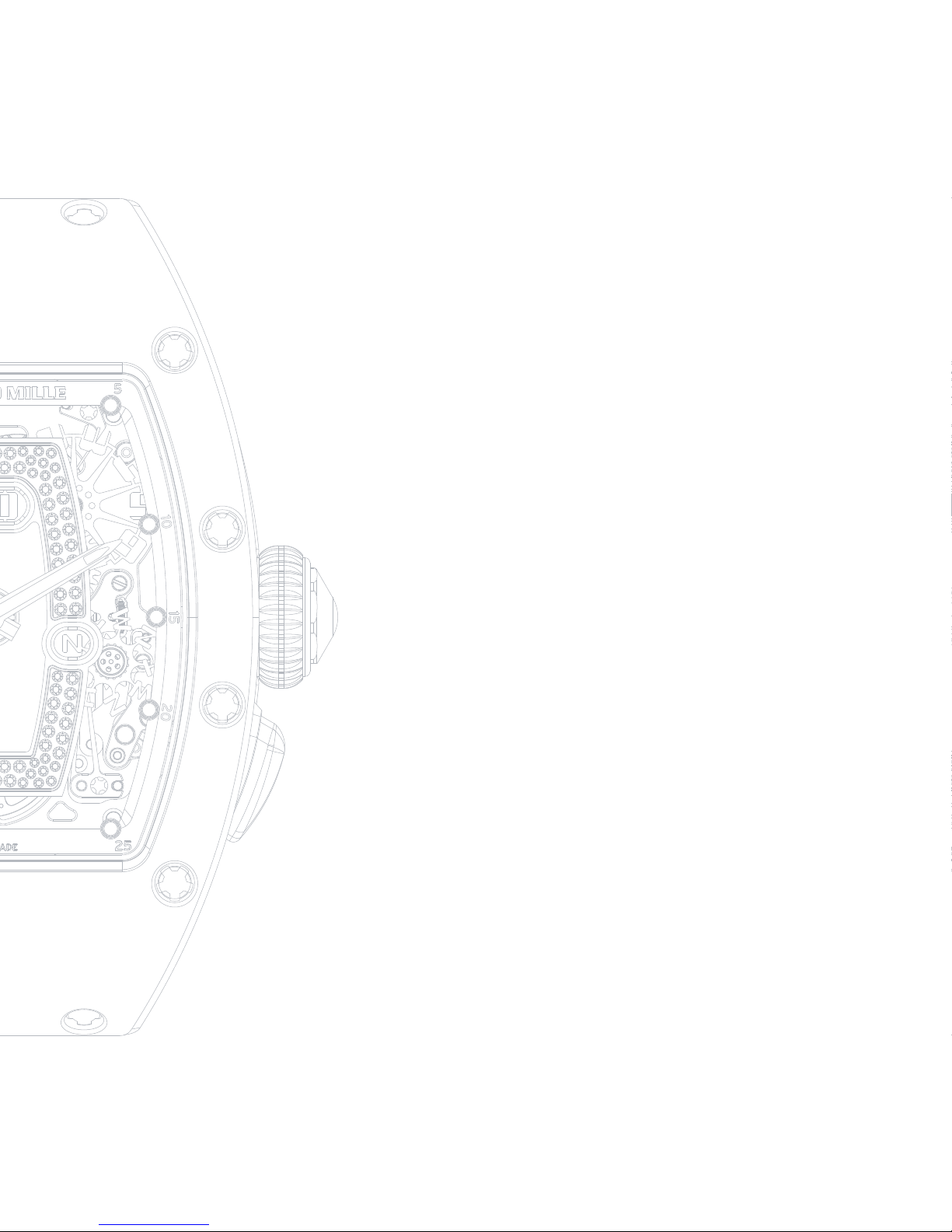

FUNCTION SELECTOR

A push-button located at 4 o’clock allows one to select the winding, neutral and handsetting functions with a simple push

in a manner similar to a car’s gearbox. An aperture located at 4 o’clock shows the function selected: W (Winding) -

N (Neutral) - H (Handsetting).

SPLINE SCREWS IN GRADE 5 TITANIUM FOR THE MOVEMENT

This permits better control of the torque applied to the screws during assembly. These screws are therefore unaffected

by physical manipulation during assembly or disassembly and age well.

OTHER FEATURES

- Movement dimensions: 28.00 x 22.90 mm

- Thickness: 4.82 mm

- Jewels: 25

- Balance: CuBe, 4 arms, 4 setting screws, inertia moment 7.5 mg.cm2, angle of lift 50º

- Frequency: 28,800 vph (4 Hz)

- Balance spring: AK3

- Shock protection: Incabloc 908.22.211.100 (transparent)

- Escapement wheel jewels: Rubifix (transparent)