5.17630 / 5.17640 5.17637 / 5.17638

Components

Pumps for direct connection to mains

water:

No underground shaft required for

function.

Order No. 5.17630 / 5.17640

1 Playground Pump with integrated

connection to mains water in the pillar

Order No. 5.17637 / 5.17638

1 Crank Handle Pump with integrated

connection to mains water in the pillar

Utility Model

20 2020 100 441 Germany

Installation information

Surfacing must be ready to take heavy

duty bolts.

Alternatively, the pumps can be mounted

on the pedestals

Order No. 5.14190 / 5.19003

or foundation anchors

Order No. 5.17505 / 5.17633.

Order No. 5.17630 / 5.17637

Pump must be drained during frost

period; secure or remove handle/crank;

we recommend disassembly.

Order No. 5.17640 / 5.17638

It is absolutely essential to disassemble

the equipment during the period of frost.

Attention:

Exact measurements may vary;

for all installation dimensions refer

to current assembly instructions.

Technical changes reserved.

For use in aggressive environments

such as salt or chlorine water, the

equipment is also available in marine

grade steel (V4A).

Technical information

Order No. 5.17630 Playground Pump

Closed piston suction pump; all top parts

made from hot-dip galvanised grey cast

iron; cylinder housing, air dome cap,

mounting plate, forked lever, plunging

valve, gland flange and connecting

rod are hot-dip galvanised; cylinder

with a liner made of brass alloy and

plastic piston (POM); drive shaft made

of stainless steel, with replaceable brass

bearing, additionally fixed with the gland

flange using the shaft collar; secured

against being extracted by means of a

collar; drive shaft bearing made of brass

with lubricating nipples; pump capacity:

approx. 0.75l per stroke, bore 75mm,

pump lift 170mm the valve combination

for direct connection to mains water, Ø 1

inch, and a shut-off valve with backflow

preventer (type EA) and drainage are

installed in the galvanised pillar made of

steel; thread 1inch; min. 2.5bar water

pressure, max. 6 bar, relief valve prevents

swipe from striking back, water require-

ment approx. 45 l/min

Order No. 5.17640

General pump specification

as with Order No. 5.17630; plus

programmable rinsing device, no connec-

tions to power supply required

Order No. 5.17637

Crank Handle Pump

Closed piston suction pump; pump and

pillar made of stainless steel; cylinder and

crank housing, mounting plate, piston

rod and drive shaft made of stainless

steel; the drive shaft brass bearing is

replaceable, fitted with nipple for lubri-

cation; cylinder with a liner made of brass

alloy and plastic piston (POM); crank ring

made of stainless steel, knob made of

plastic material; the valve combination

for direct connection to mains water, Ø 1

inch, and a shut-off valve with backflow

preventer (type EA) and drainage are

installed in the galvanised pillar made of

steel; external thread 1 inch; min 2.5 bar

water pressure, max. 6 bar;

relief valve prevents swipe from striking

back, water requirement approx. 18 l/min

Order No. 5.17638

general pump specification as with

5.17637; plus programmable rinsing

device; no connection to power supply

required

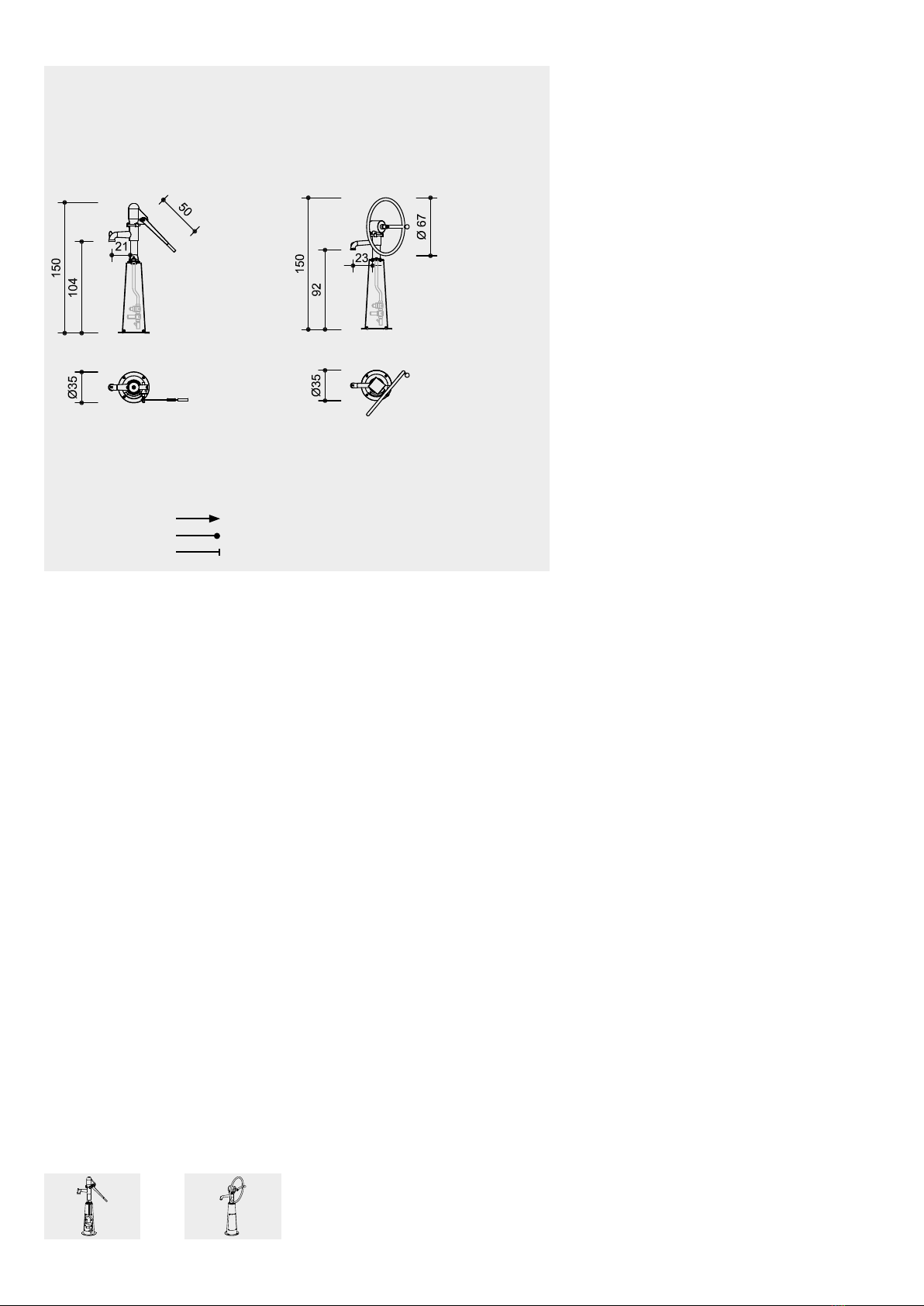

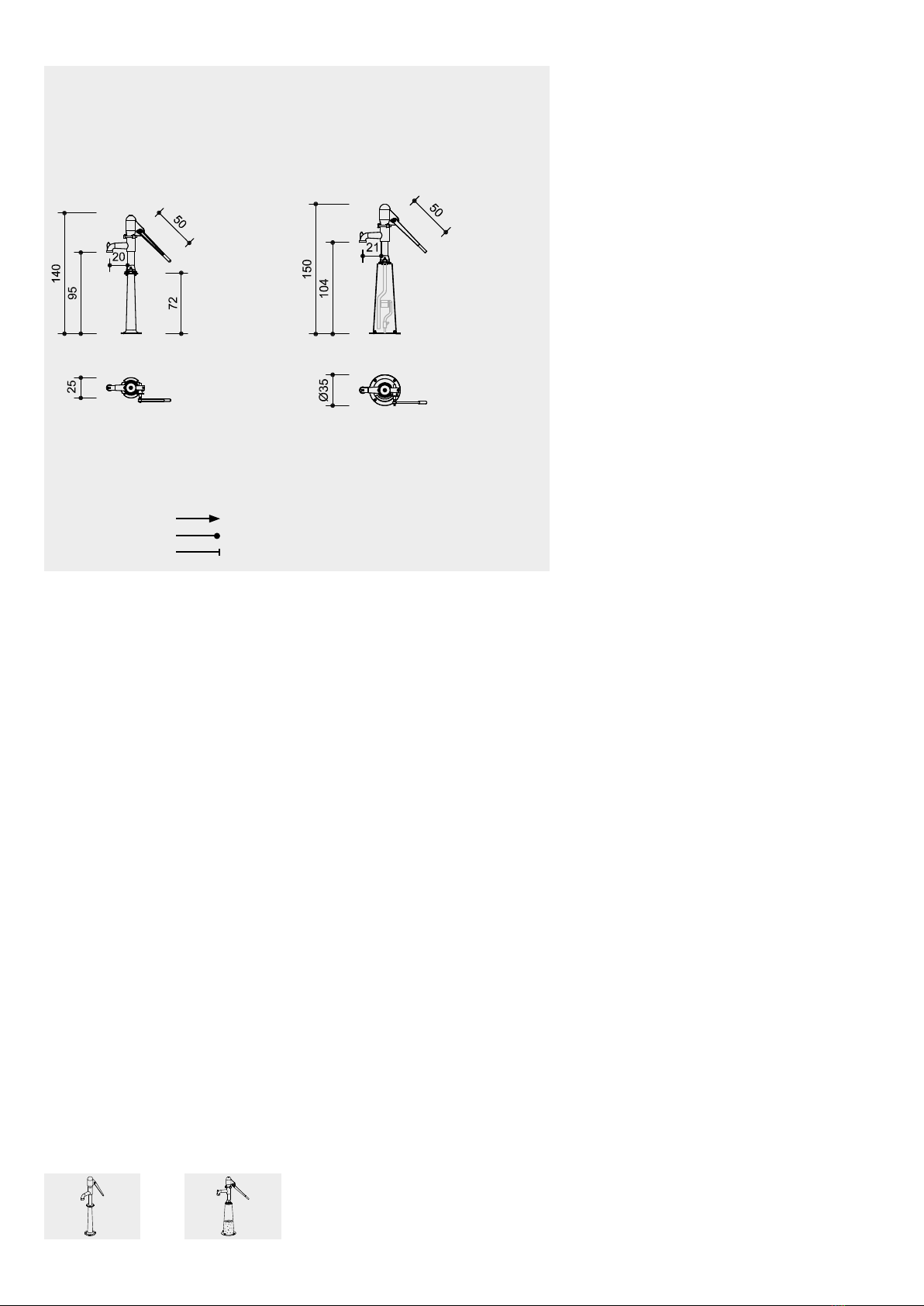

Dimensions

(small deviations possible)

Order No. 5.17630 / 5.17640

Playground Pump

Equipment height 1.50 m

Width with horizontal

pump swipe 0.95 m

Weight 73 kg

Best.-Nr. 5.17637 / 5.17638

Crank Handle Pump

Equipment height 1.50 m

Width 0.35 / 0.67 m

Weight 70 kg

Scale 1:50

Safety check according to DIN EN 1176

Safety distance

Device dimensions

Functional distance

Order No. 5.17630 / 5.17640

Playground Pump with integrated

connection to mains water in the

pillar

Drinking water up to underside of

piston

Order No. 5.17637 / 5.17638

Crank Handle Pump with integra-

ted connection to mains water in

the pillar

Drinking water up to underside of

piston

S P I E L G E R Ä T E G M B H · D - 8 3 1 1 2 F R A S D O R F · P H O N E + 4 9 - 8 0 5 2 - 1 7 9 8 0 · F A X 4 1 8

4