Ricoh PB2030 Operating and maintenance manual

Paper Feed Unit PB2030/2040

Machine Code: D3F1

Installation Procedure

Initial Release: December, 2018

(c) 2018 Ricoh Co., Ltd.

NOTE: THIS UNIT MUST BE INSTALLED BY A CUSTOMER SERVICE

REPRESENTATIVE WHO HAS COMPLETED THE TRAINING COURSES ON THE

BASE MACHINE AND THE UNIT.

Printed in Japan

D3F18610

Symbols and Abbreviations

This manual uses the following symbols and abbreviations:

Symbols:

Screw

Black screw

Connector

Flexible flat cable (FFC)

Hook

Clamp

Clip ring

E-ring

C-ring

Timing belt

Spring

Location of a screw(s) to be tightened or loosened.

Location of a connector(s), clamp(s) or spring(s) to be removed

Direction (Rotating or moving)

Abbreviations:

Abbreviations such as (M1), (S1), or (TH1) after the names of some electrical components indicates

that those components are shown on a Point-to-Point diagram.

Abbreviation Meaning

SEF Short edge feed

LEF Long edge feed

[A] Short edge feed (SEF)

[B] Long edge feed (LEF)

1

Table of Contents

1. Installation Requirements ................................................................................................................... 2

Environment............................................................................................................................................ 2

Machine Level......................................................................................................................................... 3

Minimum Space Requirements .............................................................................................................. 4

Power Requirements.............................................................................................................................. 5

2. Accessory Check ................................................................................................................................ 6

3. Installation Procedure......................................................................................................................... 7

Installing the Single Paper Feed Unit..................................................................................................... 7

Installing the Double Paper Feed Unit ................................................................................................. 12

1.Installation Requirements

2

1. Installation Requirements

Environment

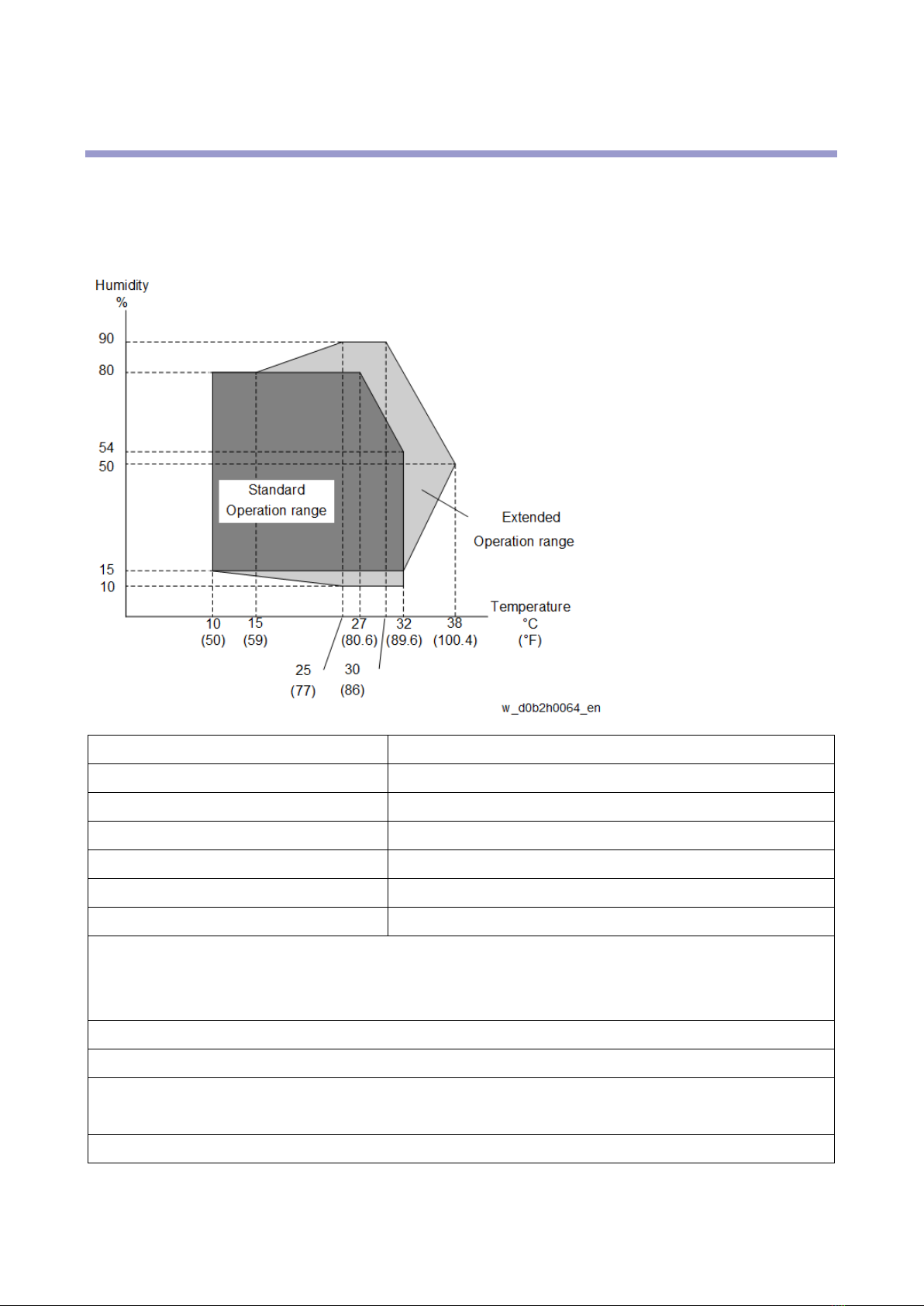

–Temperature and Humidity Chart–

•Standard temperature range: 10 - 32°C (50 - 89.6°F)

•Standard humidity range: 15% to 80% RH

•Extended temperature range: 10 - 38°C (50 - 100.4°F)

•Extended humidity range: 10% to 90% RH

•Ambient illumination: Less than 1,500 lux (do not expose to direct sunlight)

•Ventilation: 3 times/hr/person or more

•Ambient dust: Less than 0.075 mg/m3(2.0 x 10-6 oz/yd3)

•Avoid areas exposed to sudden temperature changes:

1) Areas directly exposed to cool air from an air conditioner.

2) Areas directly exposed to heat from a heater.

•Do not place the machine in areas where it can get exposed to corrosive gases and chemicals.

•Do not install the machine at any location over 2,000 m (6,500 ft.) above sea level.

•Place the machine on a sturdy and level base. (Inclination on any side should be no more than 5

mm.)

•Do not place the machine where it is subjected to strong vibrations.

1.Installation Requirements

3

Machine Level

Front to back: Within 5 mm (0.2") of level

Right to left: Within 5 mm (0.2") of level

1.Installation Requirements

4

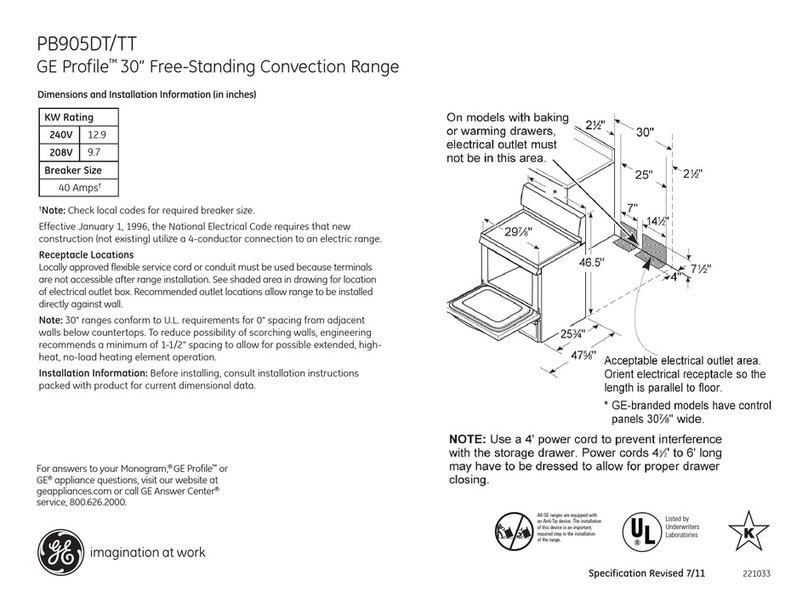

Minimum Space Requirements

Place the machine near a power source, providing clearance as shown:

A (front): 750 mm (30")

B (left): 150 mm (6")

C (rear): 300 mm (12")

D (right): 450 mm (18")

The recommended 750 mm (30") front space is sufficient to allow the paper tray to be pulled out.

Additional front space is required to allow operators to stand at the front of the machine.

1.Installation Requirements

5

Power Requirements

•Make sure that the wall outlet is near the machine and easily accessible. After completing the

installation, make sure the plug is firmly inserted into the outlet.

•Avoid using extension cables.

Input voltage:

EU, AP, CHN 220V - 240V, 50/60Hz, 8A

2.Accessory Check

6

2. Accessory Check

Check the quantity and condition of the accessories against the following list.

No. Description Q’ty

1 Relay harness 1

2 Screws 4

3.Installation Procedure

7

3. Installation Procedure

•Turn off the main power switch of the main machine and unplug the power cord before starting

the installation procedure.

•Two or more people are required to lift the main machine. The main machine is highly unstable

when lifted by one person, possibly resulting in injury or property damage.

•Do not lift the main machine with the paper feed unit installed. The grips may be damaged.

Installing the Single Paper Feed Unit

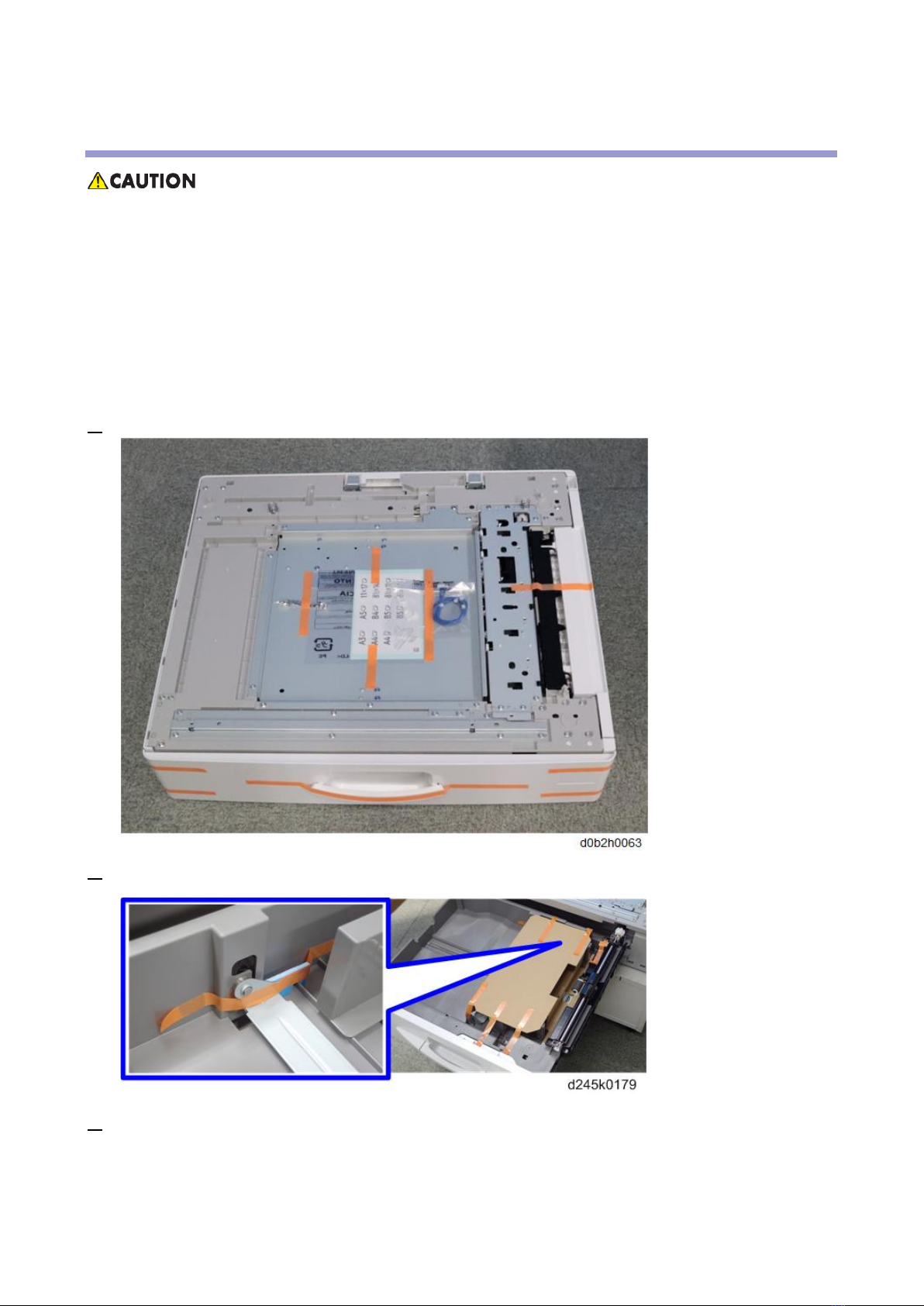

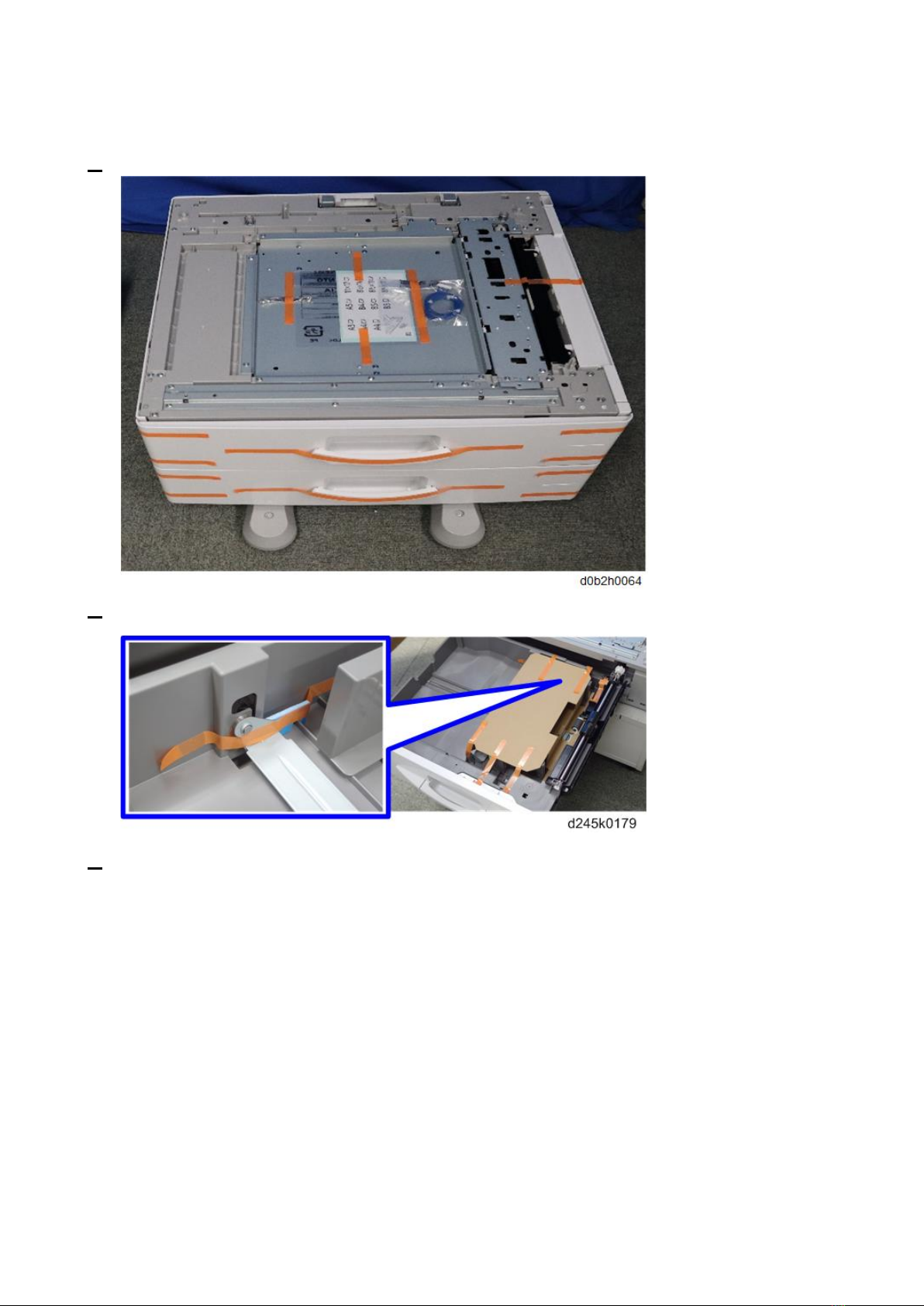

1. Remove all tapes and accessories on the paper feed unit.

2. Pull the tray, and then remove the filament tapes and padding.

3. Lift the main machine and place it on the paper feed unit.

3.Installation Procedure

8

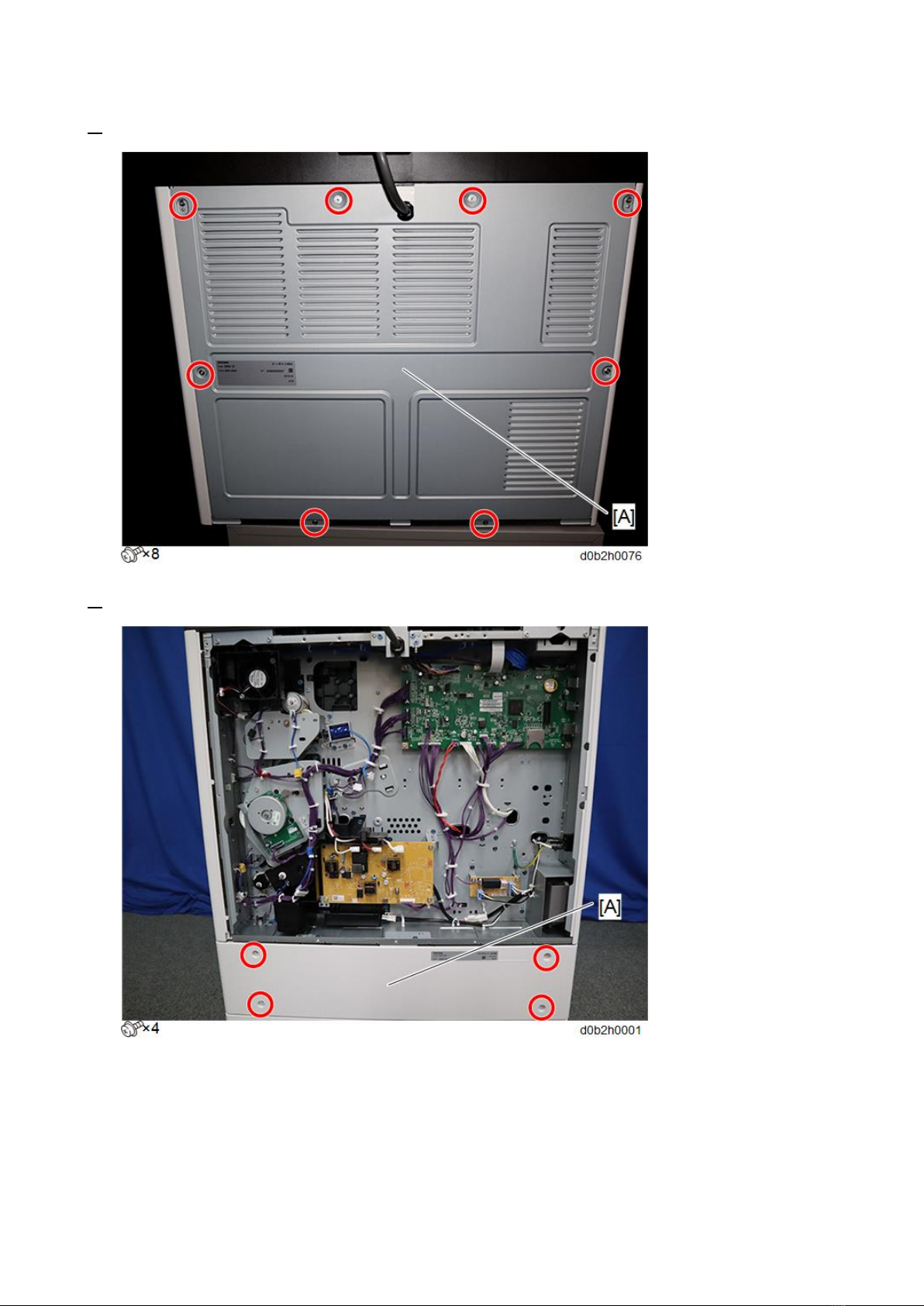

4. Remove the rear cover of the main machine [A].

5. Remove the rear cover [A] of the paper feed unit.

3.Installation Procedure

9

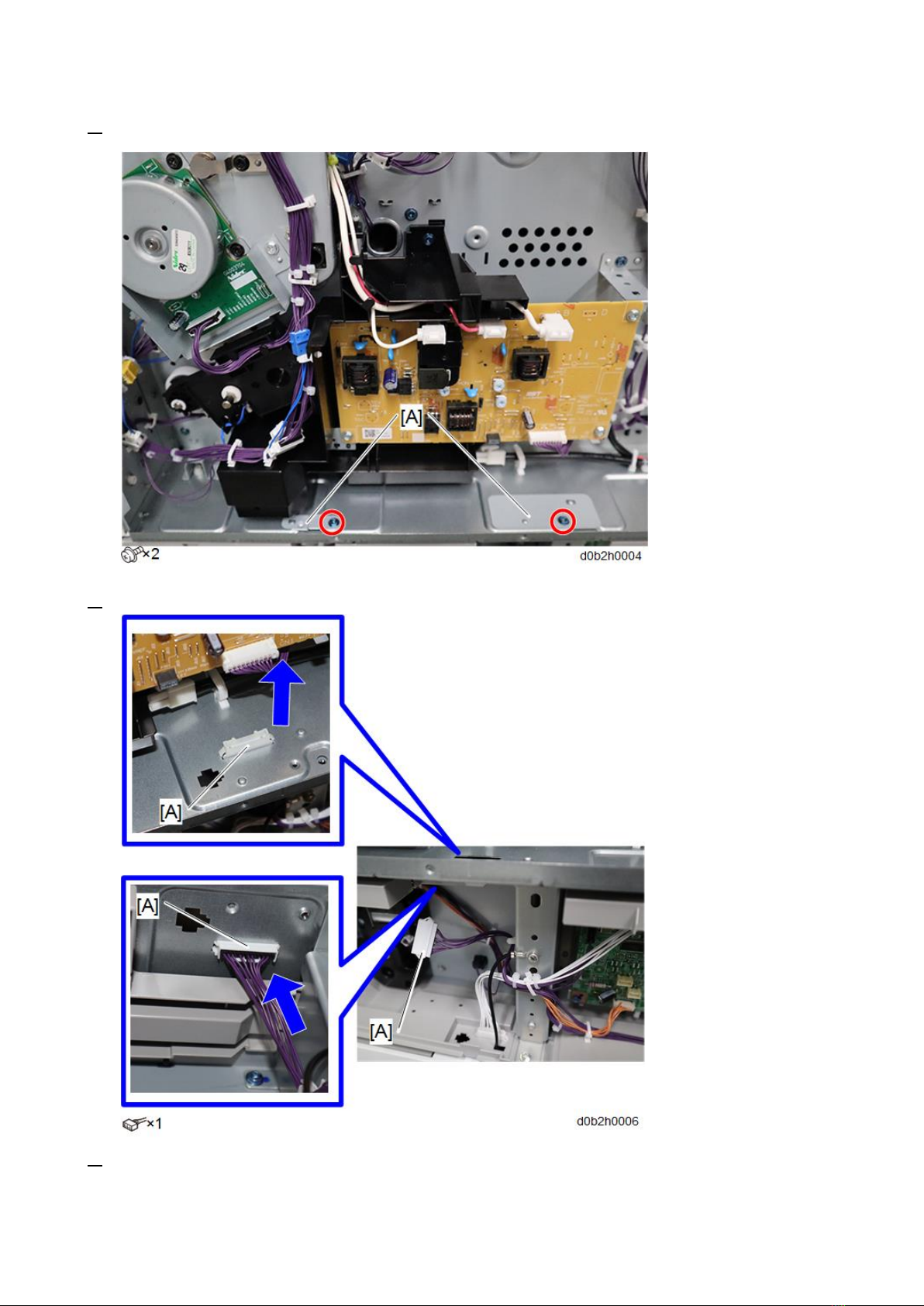

6. Remove the brackets [A] on the bottom of the main machine.

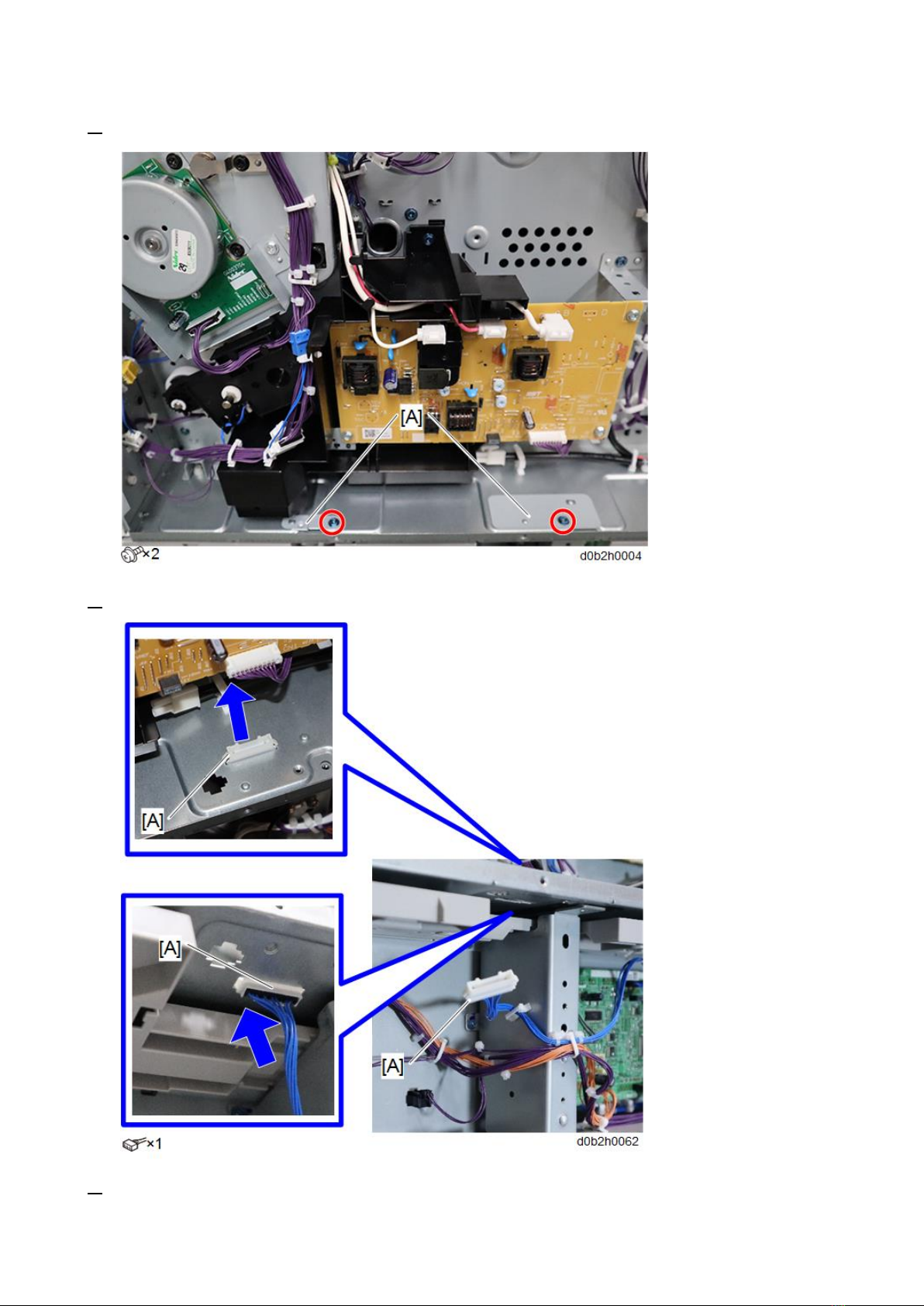

7. Insert the relay harness into the opening [A] of the main machine.

8. Connect the relay harness provided with the paper feed unit to the bottom connector [A] and

3.Installation Procedure

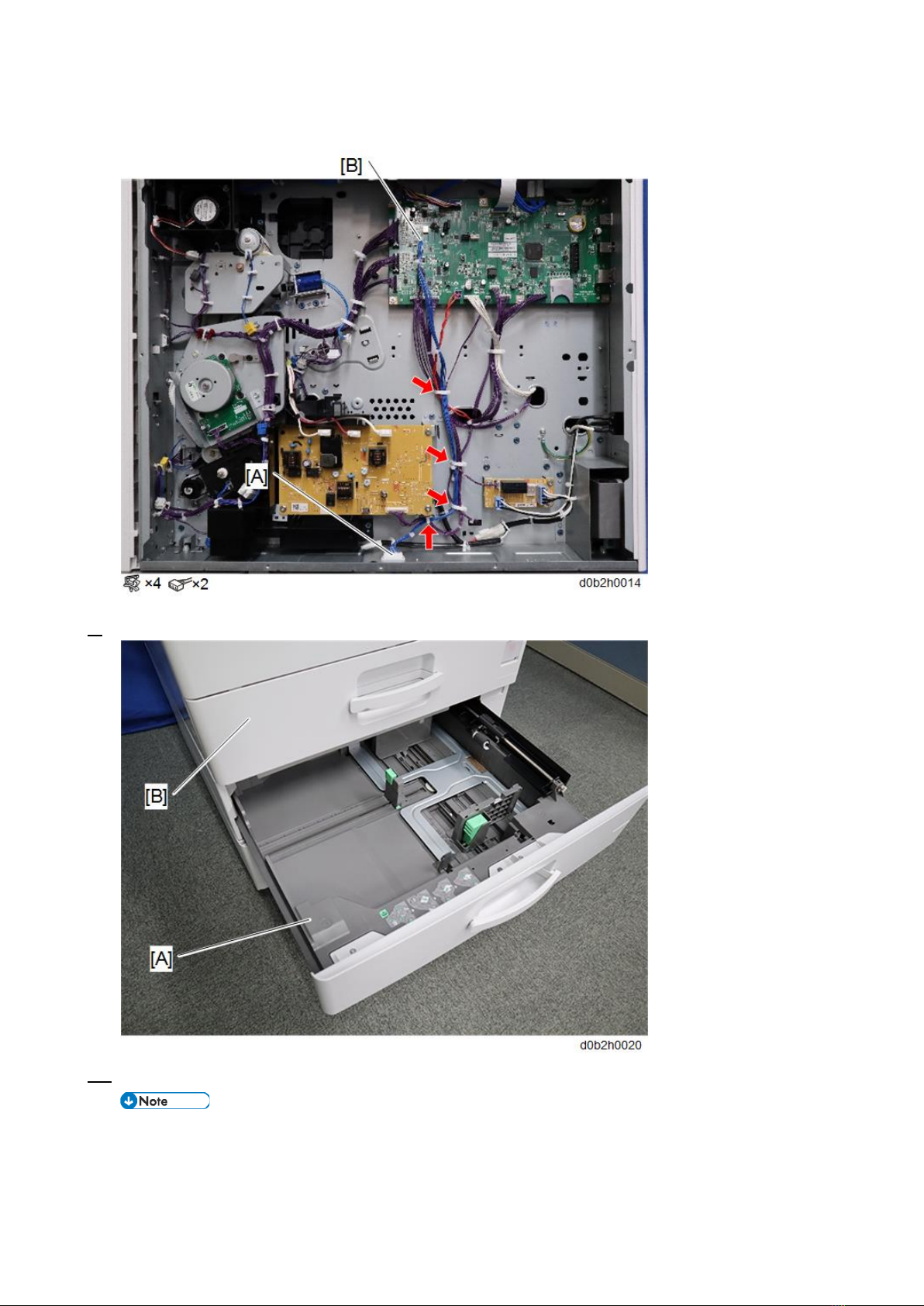

10

CN246 [B] on the MPU (PCB7) board.

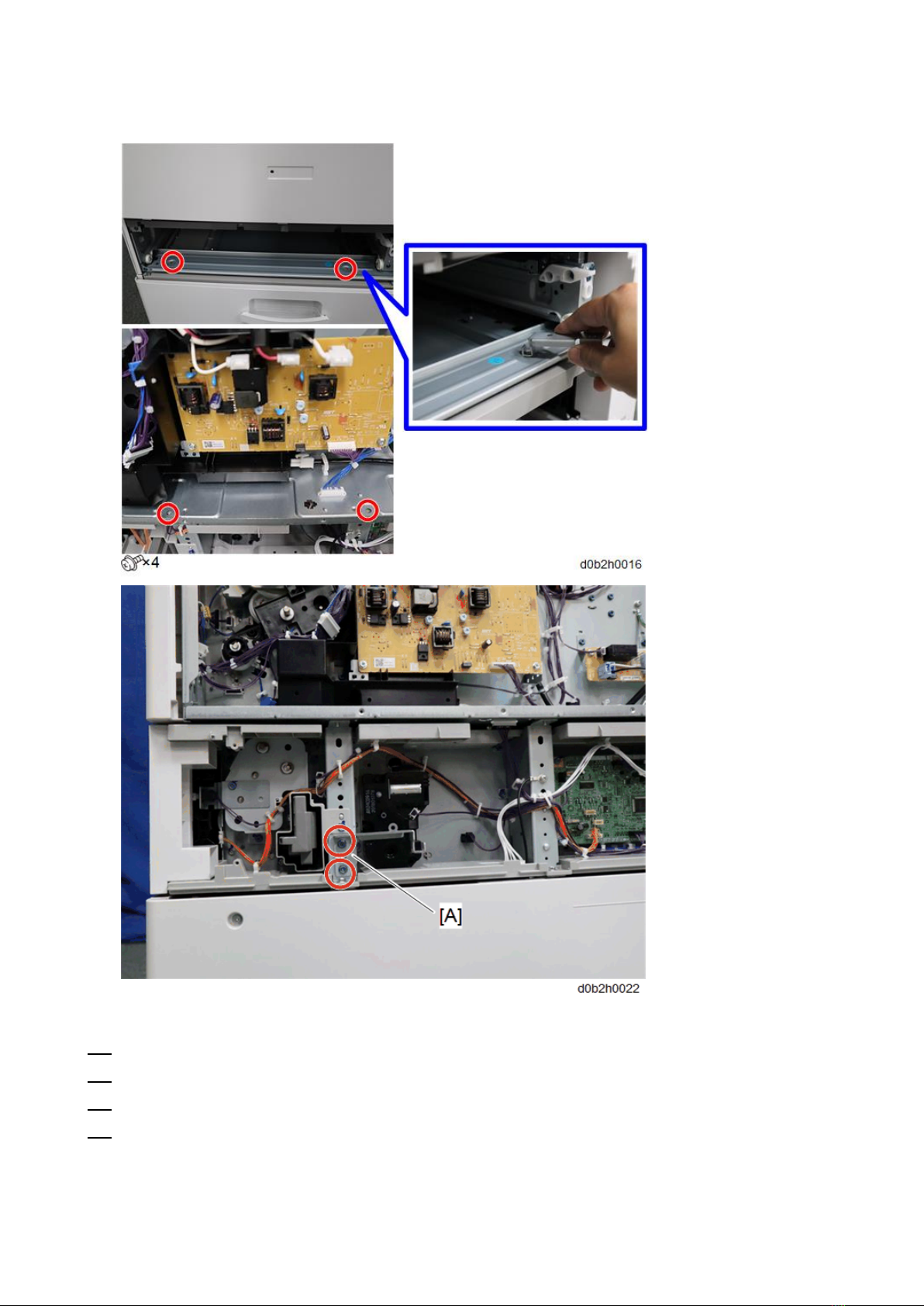

9. Pull out the paper trays [A] and [B].

10. Secure the main machine to the paper feed unit.

Screws (M4 x 6) are provided with the paper feed unit.

Use a stubby driver or the bracket wrench [A] attached to the rear bottom of the paper feed unit.

Reattach the bracket wrench after tightening the screws.

3.Installation Procedure

12

Installing the Double Paper Feed Unit

1. Remove all tapes and accessories on the paper feed unit.

2. Pull the tray, and then remove the filament tapes and paddings.

3. Lift the main machine and place it on the paper feed unit.

3.Installation Procedure

13

4. Remove the rear cover of the main machine [A].

5. Remove the rear cover [A] of the paper feed unit.

3.Installation Procedure

14

6. Remove the brackets [A] on the bottom of the main machine.

7. Insert the relay harness into the opening [A] of the main machine.

8. Connect the relay harness provided with the paper feed unit to the bottom connector [A] and

3.Installation Procedure

15

CN246 [B] on the MPU (PCB7) board.

9. Pull out the paper trays [A] and [B].

10. Secure the main machine to the paper feed unit.

Screws (M4 x 6) are provided with the paper feed unit.

Use a stubby driver or the bracket wrench [A] attached to the rear side of the paper feed unit.

3.Installation Procedure

16

Reattach the bracket wrench after tightening the screws.

11. Reinstall all trays and covers.

12. Load paper into the paper feed unit.

13. Turn on the main power switch of the machine.

14. Adjust the registration of the upper paper feed unit. (Adjustment after Replacement)

•Use SP1-002-005 for the tray bank 2.

Other manuals for PB2030

1

This manual suits for next models

2

Table of contents

Popular Range manuals by other brands

KitchenAid

KitchenAid W10524723A manual

Haier

Haier QCAS70 user manual

Thermador

Thermador Pro Grand PRD364WDGC installation instructions

Thermador

Thermador Professional PRO-HARMONY PRD30 installation manual

Jenn-Air

Jenn-Air Dual Fuel Updraft Slide-In Range installation instructions

Plamen

Plamen Termo Glas Installation and operating instructions

Frigidaire

Frigidaire FFGF3015L M Brochure & specs

Frigidaire

Frigidaire FEF357CGSA owner's guide

GE

GE JGAS24 Use and care & installation guide

Viking

Viking Professional Custom VGCC5366BSS installation guide

Electrolux

Electrolux Frytop EFT7 Series Installation and operating manual

Jenn-Air

Jenn-Air JER8885RAB Use & care guide