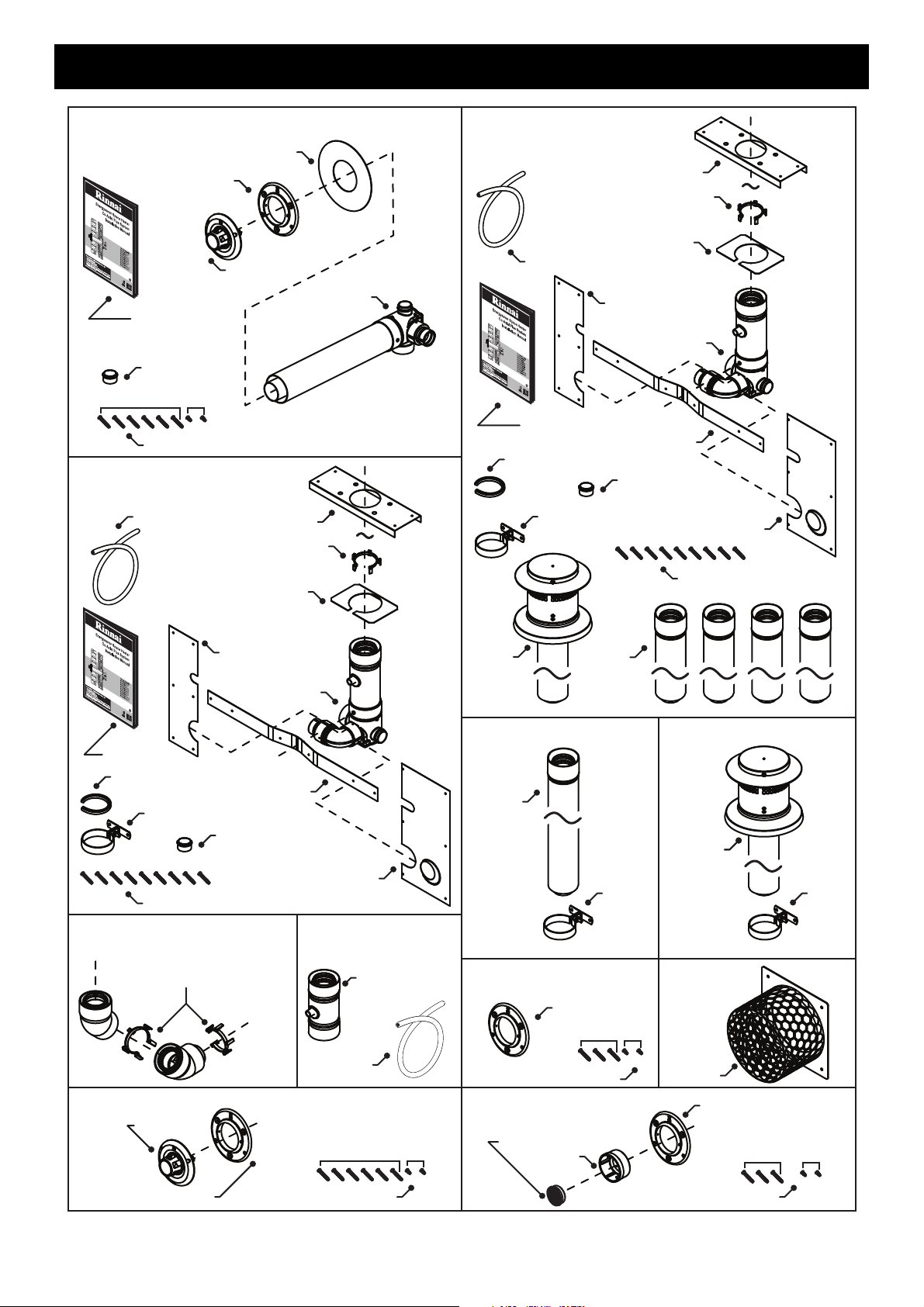

Rinnai Australia 4 ES Flue Installation Manual

REGULATIONS, CLEARANCES & GENERAL INFORMATION

The heater and the flue system shall be installed in accordance with the following:

These components MUST be installed, serviced and removed by an Authorised Person! ONLY the Rinnai flue

system components specified in this manual MUST be used. Componenents NOT specified in this manual,

whether manufactured by Rinnai or otherwise, are NOT compatible and MUST NOT be used!

Rinnai Energysaver space heater when correctly installed with Rinnai approved flue components are room-sealed

appliances and no internal ventilation is required. The Rinnai Energysaver space heater is fan-assisted. Therefore

the fan assisted flue clearance dimensions from AS/NZS 5601 extract shown on this page MUST be used.

The outer plastic section of the Co-Axial Flue complies with temperature hazard requirements and can be installed

with zero clearance to combustible material. Vertical clearances when using a roof terminal (ESROOFCOWL) are

shown in Fig.1. If in doubt contact the Rinnai Australia National Helpline (number on the back page).

• Manufacturer’s Installation Instructions • Current AS/NZS 3000, AS/NZS 3500 & AS 5601

• Local Regulations and Municipal Building Codes • Any other relevant Statutory Regulation

Before commencing an installation, read the installation sections of the ‘Customer and

Installation Manual’ supplied with the heater.

Note that AS/NZS 5601 is referred to in this instruction and was current at the time of printing, but

may have since been superseded. It is the Installer’s responsibility to ensure that requirements

of the current version of AS/NZS 5601 are met.

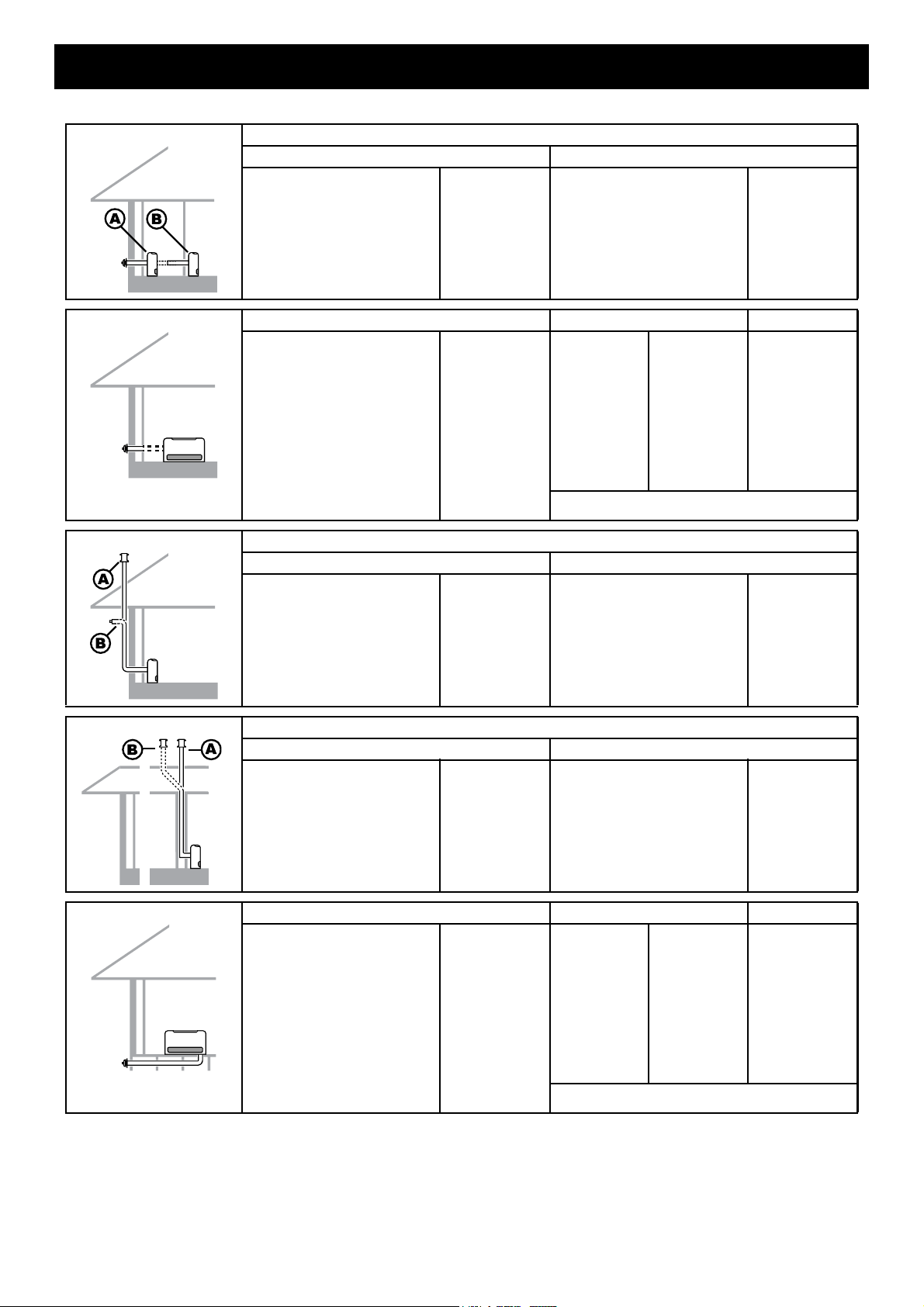

Horizontal Clearances (Extract AS/NZS 5601 Fig. 6.2)

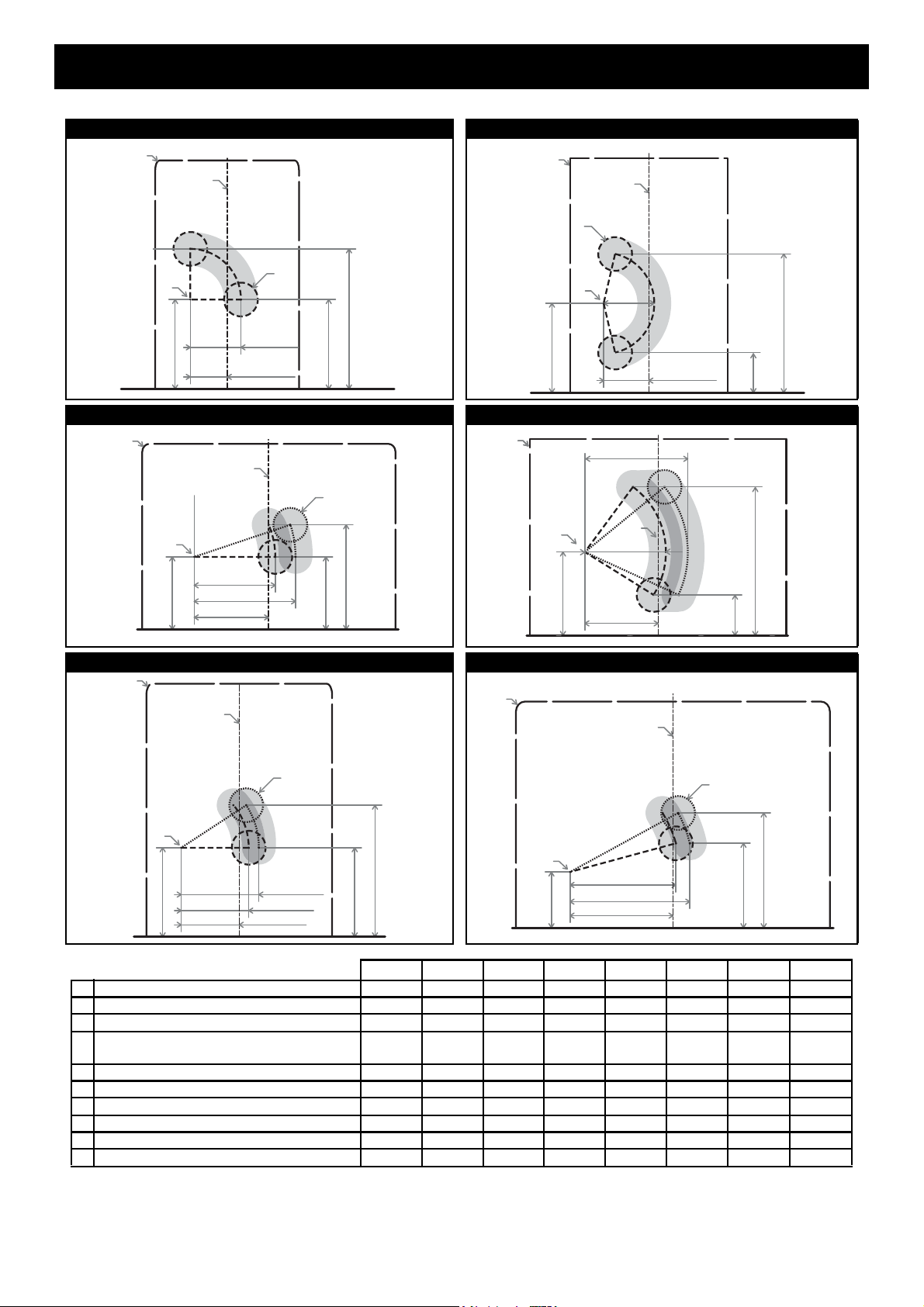

Vertical Clearances Fig.1

Natural draft Fan assisted

Appliances

Appliances

b

meter regulator

meter

flue terminal

Appliances

Appliances

Appliances

Appliances

flue appliances

appliances

Appliances

Appliances

c, j k

2 flue terminal

3 flue terminal cylinder.

flue terminal

Ref. Item

Min. clearances (mm)

NOTES:

appliance certified

appliance s

Flue terminal Fan assisted flue appliance only Gas meter Electricity meter or fuse box Mechanical air inlet

Minimum Clearance 500 mm

ESROOFCOWL

Decktite or lead collar flashing

ESPLATE

ESPIPE900

Flue pipe clip supplied withESPIPE900

Flue pipe clip supplied with ESROOFCOWL