RITZ SIS BUS BAR SYSTEMS User manual

INSTALLATION INSTRUCTIONS

SIS BUS BAR SYSTEMS

GERMANY

HAMBURG • WIRGES • KIRCHAICH • DRESDEN

AUSTRIA

MARCHTRENK |

HUNGARY

KECSKEMÉT |

CHINA

SHANGHAI |

USA

HARTWELL

Installation Instructions for SIS Bus Bar Systems A2MS001EN revision R05

2 / 130

READ THE INSTRUCTIONS PRIOR

TO PERFORMING ANY TASK!

RITZ Instrument Transformers GmbH

Mühlberg 1

97514 Oberaurach-Kirchaich

Germany

Telephone: +49 9549 89-0

Fax: +49 9549 89-11

E-Mail: sis-service@ritz-international.com

Internet: www.ritz-international.com

Checked by: Wolfgang Wessing

Approved by: Stefan Waldheuser

Ritz documentation designation: A2MS001EN

Supersedes RITZ document SA8520-001

©RITZ Instrument Transformers GmbH 2015 - 2020

Installation Instructions for SIS Bus Bar Systems A2MS001EN revision R05

3 / 130

INFORMATIONS ON INSTALLATION

INSTRUCTIONS

These instructions, together with the project

documentation (see other valid documents),

enable you to install the bus bars correctly.

The figures contained in these installation

instructions are for illustration purposes. You

must refer to the project documentation (see

other valid documents) for the actual design.

Staff must carefully read through and understand

these instructions before starting any work.

Adherence to all the safety information and

instructions specified in these instructions is a basic

requirement to ensure safety whilst working.

COPYRIGHT

The local occupational health and safety regulations

and general safety rules for the installation of bus

bars also apply.

The contents of these instructions are protected by

copyright. They may be used within the scope of

installation of the SIS bus bar system. Any other form

of use going beyond this is not permitted without

written permission from RITZ Instrument

Transformers GmbH.

CUSTOMER SERVICE ( KIRCHAICH SITE )

Telephone number: +49 9549 89-0

Installation Instructions for SIS Bus Bar Systems A2MS001EN revision R05

4 / 130

TABLE OF CONTENTS

1THE SIS BUS BAR SYSTEM.............................................................................................................7

1.1 SHORT DESCRIPTION......................................................................................................................7

1.2 OTHER APPLICABLE DOCUMENTS................................................................................................9

1.3 SCOPE OF DELIVERY ......................................................................................................................9

1.4 MEANS OF LABOUR AND TOOLS .................................................................................................10

1.5 TORQUE VALUES...........................................................................................................................10

1.6 RATING PLATE................................................................................................................................10

2SAFETY............................................................................................................................................11

2.1 SYMBOLS.........................................................................................................................................11

2.2 PROPER USE ..................................................................................................................................12

2.3 RESIDUAL RISKS............................................................................................................................13

2.3.1 BASIC HAZARDS WHEN PERFORMING INSTALLATION ............................................................13

2.3.2 ELECTRICITY HAZARDS................................................................................................................17

2.3.3 HAZARDS FROM SUBSTANCES AND CONSUMABLES..............................................................18

2.3.4 RISK OF MATERIAL DAMAGE........................................................................................................19

2.4 RESPONSIBILITY OF THE OWNER...............................................................................................20

2.5 STAFF REQUIREMENTS ................................................................................................................22

2.6 PERSONAL SAFETY CLOTHING AND EQUIPMENT ....................................................................23

2.7 ENVIRONMENTAL PROTECTION..................................................................................................25

3TRANSPORTATION AND STORAGE ............................................................................................27

3.1 SAFETY INSTRUCTIONS ON TRANSPORTATION AND STORAGE ...........................................27

3.2 SYMBOLS ON THE PACKAGING ...................................................................................................28

3.3 TYPE OF DELIVERY........................................................................................................................29

3.4 TRANSPORT INSPECTION.............................................................................................................29

3.5 TRANSPORTATION OF PACKAGES..............................................................................................30

3.6 PACKAGING ....................................................................................................................................31

3.7 UNPACKING.....................................................................................................................................32

3.8 STORAGE ........................................................................................................................................33

3.9 TRANSPORTATION TO THE INSTALLATION LOCATION............................................................34

4INSTALLATION ...............................................................................................................................35

4.1 SAFETY INSTRUCTIONS ON INSTALLATION...............................................................................35

4.2 PREREQUISITES FOR INSTALLATION.........................................................................................39

4.3 PROTECTION FROM CLIMATIC INFLUENCES.............................................................................40

4.4 INSTALLING FIXATION UNITS .......................................................................................................40

4.5 INSTALLING BUS BARS..................................................................................................................45

4.5.1 SPACING BETWEEN BAR ELEMENTS..........................................................................................45

Installation Instructions for SIS Bus Bar Systems A2MS001EN revision R05

5 / 130

4.5.2 TIGHTENING TORQUE VALUES....................................................................................................46

4.5.3 FASTENING BUS BAR ELEMENTS................................................................................................46

4.5.4 SETTING FIXED BEARINGS...........................................................................................................47

4.5.5SETTING SLIDING BEARINGS.......................................................................................................47

4.6 PREPARING THE EARTHING CABLES .........................................................................................47

4.7 INSTALLING CONNECTION SLEEVES..........................................................................................50

4.7.1 INSTALLING INDOOR CONNECTION SLEEVES...........................................................................50

4.7.1.1 PREPARING INDOOR CONNECTION SLEEVES ..........................................................................50

4.7.1.1.1 PREPARATION ON BOTH SIDES...................................................................................................50

4.7.1.1.2 PREPARING THE CONNECTION SLEEVE....................................................................................52

4.7.1.2 ESTABLISHING THE ELECTRICAL CONNECTION.......................................................................54

4.7.1.2.1 INSTALLING FLEXIBLE CONNECTORS AND CONTACT SPRINGS: ALUMINIUM-COPPER.....54

4.7.1.2.2 INSTALLING FLEXIBLE CONNECTORS AND CONTACT SPRINGS: COPPER-COPPER..........64

4.7.1.2.3 INSTALLING FLEXIBLE CONNECTORS AND CONTACT SPRINGS: OTHERS...........................68

4.7.1.2.4 TIGHTENING THE TORQUING.......................................................................................................69

4.7.1.2.5 MARKING THE BOLTED CONNECTIONS......................................................................................70

4.7.1.2.6 CLEANING THE CONTROLLED SYSTEMS...................................................................................70

4.7.1.3 CLOSING INDOOR CONNECTION SLEEVES ...............................................................................72

4.7.1.3.1 ALIGNING THE CONNECTION SLEEVE PIPE...............................................................................72

4.7.1.3.2 SCREWING THE SEALING FLANGE IN PLACE............................................................................73

4.7.1.3.3 EARTHING THE INDOOR CONNECTION SLEEVE.......................................................................74

4.7.2 INSTALLING OUTDOOR CONNECTION SLEEVES ......................................................................75

4.7.2.1 PREPARING OUTDOOR CONNECTION SLEEVES ......................................................................75

4.7.2.1.1 PREPARING THE BELLOWS..........................................................................................................75

4.7.2.1.2 PREPARATION ON BOTH SIDES...................................................................................................78

4.7.2.1.3 PREPARING THE CONNECTION SLEEVE PIPE...........................................................................80

4.7.2.2 ESTABLISHING THE ELECTRICAL CONNECTION.......................................................................81

4.7.2.3 ALIGNING THE CONNECTION SLEEVE PIPE...............................................................................82

4.7.2.4 EARTHING THE OUTDOOR CONNECTION SLEEVE...................................................................83

4.7.2.5 CLOSING THE CONNECTION SLEEVE AND BELLOWS ON BOTH SIDES ................................84

4.8 SETTING UP ELECTRICAL CONNECTIONS ON SWITCHGEARS OR TRANSFORMERS.........86

4.8.1 BUS CONNECTION.........................................................................................................................86

4.8.2 INSTALLATION WITH AL ELAST CONTACT DISCS .....................................................................86

4.8.3 INSTALLATION WITH CONICAL SPRING WASHER.....................................................................87

4.9 EARTHING THE BUS BAR SYSTEM ..............................................................................................88

4.9.1 WHEN EARTHING VIA EARTHING NUT APPLIES........................................................................89

4.9.2 WHEN EARTHING VIA EARTHING NUT DOES NOT APPLY........................................................91

4.9.2.1 REGARDING INDOOR BUS BAR SYSTEMS .................................................................................91

4.9.2.2 REGARDING OUTDOOR BUS BAR SYSTEMS .............................................................................93

4.10 FINAL INSPECTION.........................................................................................................................94

4.10.1 VISUAL INSPECTION AND FILLING OUT THE CHECK LISTS.....................................................94

Installation Instructions for SIS Bus Bar Systems A2MS001EN revision R05

6 / 130

4.10.2 PERFORMING A HIGH-VOLTAGE TEST .......................................................................................95

4.10.2.1 ROUTINE TEST AS PER IEC 60137...............................................................................................95

4.10.2.2 PERFORMING AN AC OR VLF VOLTAGE TEST...........................................................................96

4.10.2.3 PERFORMING A DC VOLTAGE TEST ...........................................................................................96

4.10.3 ATTACHING THE RATING PLATES ...............................................................................................97

5MAINTENANCE ...............................................................................................................................98

5.1 ONSHORE........................................................................................................................................98

5.2 OFFSHORE......................................................................................................................................98

5.3 AFTER A SHUTDOWN OF 3 MONTHS OR MORE ......................................................................100

6DISASSEMBLY AND DISPOSAL .................................................................................................101

6.1 SAFETY FOR DISASSEMBLING AND DISPOSAL.......................................................................101

6.2 DISASSEMBLY ..............................................................................................................................102

6.3 DISPOSAL......................................................................................................................................102

7TECHNICAL DATA........................................................................................................................103

8INDEX.............................................................................................................................................104

APPENDIX ........................................................................................................................................................106

ADRAWINGS....................................................................................................................................108

BTORQUE TABLE............................................................................................................................109

CTEST VOLTAGES ..........................................................................................................................111

DTOOL LIST......................................................................................................................................112

ECHECKING WHETHER EARTHING VIA EARTHING NUT APPLIES...........................................114

FCHECK LIST FOR INSPECTING INSTALLATION OF ONE SIS BUS BAR SYSTEM –EXAMPLE ..

........................................................................................................................................................115

GCHECK LIST FOR STORAGE AND OPENING OF A TRANSPORT BOX –EXAMPLE ..............124

HCHECK LIST FOR ONE INDOOR CONNECTION SLEEVE –EXAMPLE....................................129

ICHECK LIST FOR ONE OUTDOOR CONNECTION SLEEVE –EXAMPLE................................130

THE SIS BUS BAR SYSTEM

Installation Instructions for SIS Bus Bar Systems A2MS001EN revision R05

7 / 130

1THE SIS BUS BAR SYSTEM

1.1 SHORT DESCRIPTION

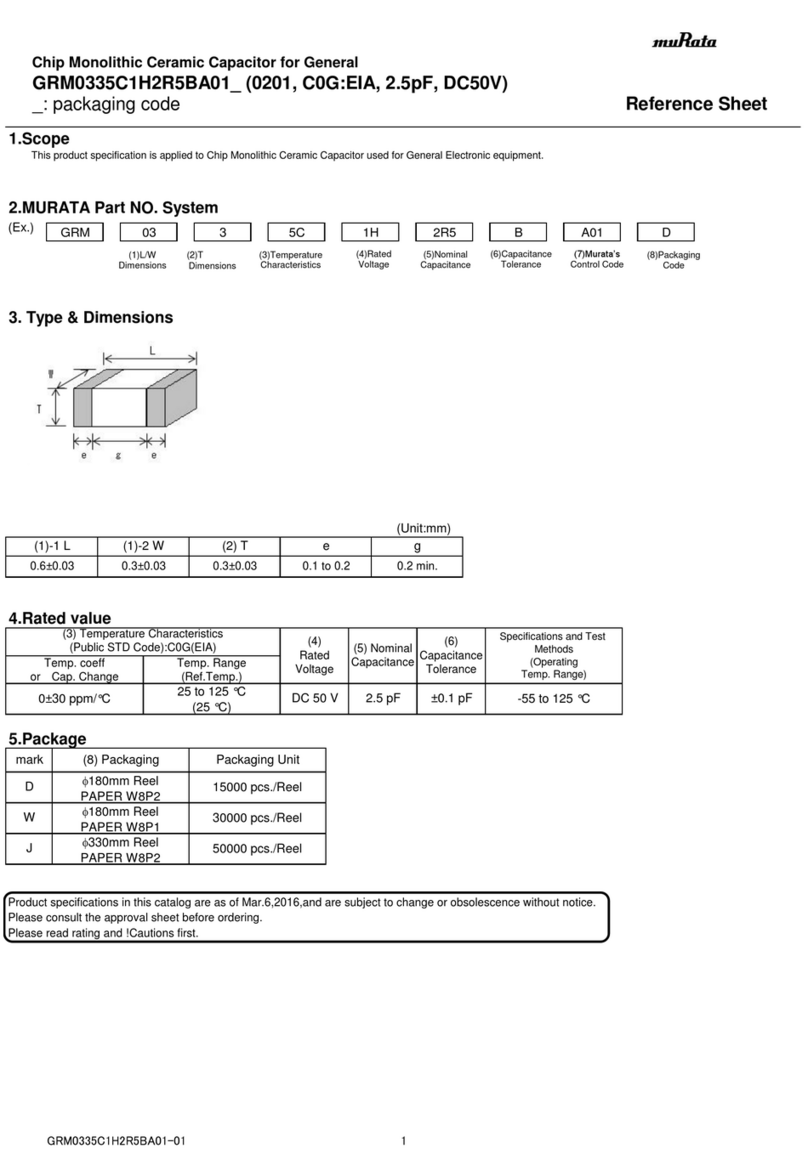

Construction ………….………………….

Fig. 1: Basic illustration of a bus bar

connection in a connection sleeve

The fully insulated bus bars comprise a conductor in the form

of a pipe or round material (E-Al or E-Cu) with solid insulation

made of epoxy resin impregnated paper (RIP).

For reasons of mechanical stability, adherence with transport

dimensions, handling on site and maximum dimensions

dictated by the production facility, bus bar systems typically are

made in sections. In order to ensure a continuous, potential-

free bus bar system, an insulated connection sleeve is installed

over the connection between the non-insulated, controlled bus

bar ends.

1 Contact tube

2Fully insulated bus bar

3 Earth connection

4 Fully insulated indoor connection sleeve

5 Contact spring

6 Flexible connector

Fig. 2: Indoor connection sleeve installed

(example)

The connection of two bus bar elements (Fig. 2/2) inside the

connection sleeve (Fig. 2/1) is established using flexible

connectors (Fig. 2/4) which offset small length tolerances

during installation, and the thermal expansion of the bars

during operation. The contact springs (Fig. 2/3) are installed on

the flexible connectors and touch the inside of the contact tube.

The connection sleeve and the bus bar elements are contact-

proof when operated within the technical specifications.

Fig. 3: Bellows on the outdoor connection

sleeve

Indoor connection sleeves (Fig. 2) are closed with an

aluminium sealing flange (Fig. 2/5) which ensures that the

connection of the connection sleeve on the bar is dust and

splash proof. Outdoor connection sleeves are manufactured

with a stainless steel protective tube. It is secured and sealed

off on the bar with a ring seal unit. A second seal to the bar is

provided by bellows (Fig. 3/2) which are secured to the bus bar

and connection sleeve using hose clamps (Fig. 3/1).

THE SIS BUS BAR SYSTEM

Installation Instructions for SIS Bus Bar Systems A2MS001EN revision R05

8 / 130

Fig. 4: Fixation unit (example)

Bus bars are installed on floors, ceilings or walls on a fixation

design which is specific to the respective order. An individual

fixation unit comprises, for example, brackets (Fig. 4/1), C-

profiles (Fig. 4/2), fixation clamps (Fig. 4/3) and bolted

connections (with T-bolts, conical spring washers and nuts, Fig.

4/4).

In general, an earthing bar or earthing cable has to be laid

parallel to the bus bar, to which all bars, connection sleeves,

and fixation must be connected and, subsequently, to the earth

potential.

Design …………………...…………………

Dimensions and designs are in line with the valid regulations

and standards. The drawing and serial number of the

respective bus bar is punched in at one end of the long side of

the flange connection, or on the face of round or pipe-shaped

connections. The bus bar elements are shown with an item

number in the assembly drawing. The drawing number is

shown underneath the respective item number in the

corresponding bill of material. The same bill of material also

indicates the drawing numbers of the fixation units and the

connection sleeves (for bus bar connections with multiple

parts).

THE SIS BUS BAR SYSTEM

Installation Instructions for SIS Bus Bar Systems A2MS001EN revision R05

9 / 130

1.2 OTHER APPLICABLE

DOCUMENTS

In addition to these instructions, the following supplementary

documents apply:

Bill of material for installation

Installation drawings

–Assembly drawing (complete system with item numbers

and bill of material)

–Subassembly drawings

–Bus bar drawing

–Part drawings

–General detailed drawings

Optional: Specific project documents

Packing list for inspection –packing check list

Tool list

Check list for inspecting installation one SIS bus bar system

Appendix F on page 115

Check list for storing and opening of one transport box

Appendix G on page 124

Check list for one indoor connection sleeve

Appendix H on page 129

Check list for one outdoor connection sleeve

Appendix I on page 130

If special constructions, such as wall penetrations,

transformer protection boxes, tab off boxes etc., are

required for a project, the corresponding installation

instructions or installation drawings are included with

the delivery, as necessary.

1.3 SCOPE OF DELIVERY

The construction of the bus bar system is specific to

the respective project and the individual

subassemblies can be seen in the assembly

drawing.

Refer to the subassembly drawings and part

drawings in the documentation folder for details of

individual subassemblies.

Refer to the bill of material in the documentation

folder for the exact scope of delivery.

Assigning the material ……………..…

All the items listed in the bills of material are

packaged separately with the respective item

numbers and can thus be easily assigned to the

respective positions using the bill of material for

installation.

THE SIS BUS BAR SYSTEM

Installation Instructions for SIS Bus Bar Systems A2MS001EN revision R05

10 / 130

System of bills of material ……………

All the required parts are listed in the bill of material for

installation. You must use the delivery notes (packing check list)

to check that they are complete, and sign to confirm. There are

also bills of material for fixation units, connection sleeves and a

bill of material for other accessories. The bills of material for bus

bar fixations include the bill of material for fixation clamps.

Fig. 5: System of bills of material

1.4 MEANS OF LABOUR AND

TOOLS

Various means of labour and tools are required for

installation of the bus bar system. They are listed in

Appendix ‘Tool List’ on page 112.

1.5 TORQUE VALUES

The torque values appropriate for the applications

are indicated in the installation instructions in the

table of torque values in Appendix B and in the

individual drawings. A calibrated torque spanner

must be used for tightening the bolted connections.

After tightening the bolted connections, they have to

be marked (example in Chapter 4.7.1.2.5

‘Marking the Bolted Connections’ on page 70).

1.6 RATING PLATE

A rating plate is attached to each bus bar.

Alternatively, the rating plate is included separately

with the delivery and can be glued to the bus bar

where it is clearly visible once installation has been

completed.

The serial numbers of the bus bars and connection

sleeves must be noted and entered in the general

drawing before closing the connection sleeves.

SAFETY

Installation Instructions for SIS Bus Bar Systems A2MS001EN revision R05

11 / 130

2SAFETY

2.1 SYMBOLS

The safety instructions and safety information in these

instructions are denoted by symbols. The safety instructions are

prefaced by signal words which express the extent of the risk.

Safety instructions ………………………

DANGER!

This combination of symbol and signal word

indicates an immediately hazardous situation which

may cause serious or even fatal injuries if not

avoided.

WARNING!

This combination of symbol and signal word

indicates a possibly hazardous situation which may

lead to serious or even fatal injuries if not avoided.

CAUTION!

This combination of symbol and signal word

indicates a possibly hazardous situation which may

cause minor or light injuries if not avoided.

NOTICE!

This combination of symbol and signal word

indicates a possibly hazardous situation which may

cause material damage if not avoided.

ENVIRONMENTAL PROTECTION!

This combination of symbol and signal word

indicates possibly hazards for the environment.

Safety instructions in instructions for

actions ………………………………..…….

Safety instructions may relate to certain, individual instructions

for actions. These safety instructions are embedded in the

instruction for action so they do not interrupt the flow of reading

when performing the action. The signal words described above

are used.

Example:

1. Unfasten the bolt.

CAUTION!

Risk of entrapment on the cover!

2. Close the cover carefully.

3. Tighten the bolt.

SAFETY

Installation Instructions for SIS Bus Bar Systems A2MS001EN revision R05

12 / 130

Tips and recommendations ……………

This symbol indicates tips, recommendations and

information for efficient fault-free operation.

Further markings …………………………

The following markings are used in these instructions for

emphasizing instructions for actions, results, lists, cross

references and other elements:

Marking

Explanation

Step-by-step instructions for actions

Results of actions

References to sections of these Instructions

and other applicable documents

Lists without a set order

2.2 PROPER USE

The bus bar system is used exclusively for conveying electrical

current and insulating touch voltage as per the specification

defined in the order documentation.

Proper use also includes adhering to all the information and

specifications in these instructions.

Any use going beyond the proper use or other type of use is

regarded as misuse.

SAFETY

Installation Instructions for SIS Bus Bar Systems A2MS001EN revision R05

13 / 130

WARNING!

Danger arising from misuse!

Misuse of the bus bar system can lead to hazardous

situations.

–Only operate bus bar systems in accordance

with the agreed terms and conditions of

delivery, and the indicated technical data.

–Install bus bar systems in accordance with

these installation instructions and drawings.

–The manufacturer's warranty will be

rendered null and void if the installation

instructions are not observed.

–Only use the devices and special tools

included in the scope of delivery for the

intended purpose and in accordance with the

stipulations of these installation instructions.

–Never climb on or walk on the bus bar

system.

–Never suspend loads from the installed bus

bar system or place objects on the bus bar

system.

–Never operate the bus bar system without

insulation or earthing.

–Refrain from performing cutting, grinding,

and welding work on or in the vicinity of bus

bar systems.

2.3 RESIDUAL RISKS

2.3.1 BASIC HAZARDS WHEN

PERFORMING INSTALLATION

Working in the construction site ………..

WARNING!

Danger arising from misuse!

Carelessness in the installation area on a

construction site can lead to hazardous situations.

–Never begin work on the construction site

without the permission of the construction

site supervisor.

–Always access construction sites with

extreme caution.

–Wear reflective clothing or a safety vest, as

necessary.

–Adhere to the national occupational safety

measures.

SAFETY

Installation Instructions for SIS Bus Bar Systems A2MS001EN revision R05

14 / 130

Improper installation / assembly ……….

WARNING!

Risk of injury due to improper installation /

assembly!

Improperly performed installation and assembly

work can cause serious or even fatal injuries and

considerable material damage.

–Make sure there is sufficient space to work

in before starting work.

–Handle exposed, sharp-edged components

with care.

–Be aware of the dead weight of the

components.

–Keep the work area clean and tidy! Parts or

tools loosely piled or lying about are a

potential source of accidents.

–Install components properly. Adhere to the

stipulated tightening torque values for

bolts.

–Secure components so they cannot fall or

topple over.

–When performing installation and assembly

work, make sure nobody is in the danger

area.

SAFETY

Installation Instructions for SIS Bus Bar Systems A2MS001EN revision R05

15 / 130

Use of load bearing and fastening

equipment …………………………………

WARNING!

Risk of injury when using lifting gear!

Improper use of load bearing equipment (ropes,

chains, belts) and fastening equipment (load

hooks, bottom hook block) can cause hazardous

situations.

–Before using lifting gear and load bearing

equipment, perform a visual inspection to

check for damage, deformation and wear.

Do not use damaged parts.

–Use lifting gear and load bearing

equipment with a sufficient load bearing

capacity for the load. Use suitable ropes,

chains and lifting belts in accordance with

the dimensions and weight of the load

being lifted. Do not overload fastening

equipment.

–Use edge protectors or a crossbeam when

lifting sharp-edged loads.

–Position the load hook above the centre of

gravity of the load.

–During the lifting procedure, observe

whether the fastening equipment takes

hold in the designated positions, whether

the transportation position remains

unchanged when lifting and make sure the

load does not become caught. In case of

any variation, immediately stop the lifting

the process.

–Protect fastening equipment from sharp-

edged parts of loads.

–During the lifting procedure, ensure

nobody is in the falling and swinging range

of the load.

–The angle of inclination must never exceed

60°.

–When guiding fastening equipment, always

take hold of it above the load.

–Wear personal safety clothing and

equipment at all times for all work.

SAFETY

Installation Instructions for SIS Bus Bar Systems A2MS001EN revision R05

16 / 130

Working at heights ……………………….

WARNING!

Risk of injury from careless work at heights!

Carelessness when working on ladders or lifting

plat- forms for installation or maintenance work can

cause injuries.

–When carrying out any work on ladders,

make sure the ladder is on a firm and even

surface.

–Adhere to the national regulations for

safety and the prevention of accidents

when performing any work with a scaffold

or lifting platform.

–If necessary, have a second person secure

the ladder.

–Wear a safety harness as necessary.

Suspended loads …………………...…….

WARNING!

Risk of fatal injury from suspended loads!

When lifting loads, the loads may swing and fall.

This can cause serious or even fatal injuries.

–Never stand under or in the swinging range

of suspended loads.

–Only move loads under supervision.

–Use only approved lifting gear and

fastening equipment with sufficient load

bearing capacity.

–Do not use torn or frayed lifting gear, such

as rope or belts.

–Do not place lifting gear, such as ropes

and belts, over sharp edges and corners.

Do not knot or twist the lifting gear.

–Before leaving the work station, set the

load down.

SAFETY

Installation Instructions for SIS Bus Bar Systems A2MS001EN revision R05

17 / 130

2.3.2 ELECTRICITY HAZARDS

DANGER!

Risk of fatal injury from arc faults and electrical

current!

There is a direct risk of fatal injury from electric

shock in case of contact with live parts. Damage to

the insulation or individual components may

represent a risk of fatal injury.

Arc faults cause high pressures and temperatures.

Heated gases or metal parts can cause burns. Flash

burns to the eyes may occur due to light from an arc.

–Have work on the electrical components

performed by qualified electricians only.

–Only allow trained installation staff to carry out

installation and assembly work. Staff must be

sufficiently informed about possible hazards

which may arise in the installation and

assembly area.

–Wear electric arc safety clothing when working

in the vicinity of electrical systems.

–In case of damage to the insulation,

immediately switch off the power supply and

make repairs.

–When performing installation and assembly

work on or in the vicinity of bus bars,

implement measures in the working position so

it is and remains isolated from the voltage.

Follow the five safety rules:

1. Isolate from the voltage.

2. Secure to prevent from being

switched back on.

3. Make sure parts are no longer live

with voltage.

4. Earth and short-circuit

5. Cover or section off neighboring

parts which are live with voltage.

–Make sure that the system is perfectly earthed

with a protective earth conductor system.

–Keep moisture away from parts which are live

with voltage, as this can cause a short circuit.

–Refrain from making any changes to the bus

bar system.

Recommendation:

After installation, perform a high voltage test in order

to check that the system has been properly installed.

Annually check the bus bar system and earthing for

mechanical damage, and use a thermal camera to

check for the generation of heat.

Arc fault and electrical current …..……

SAFETY

Installation Instructions for SIS Bus Bar Systems A2MS001EN revision R05

18 / 130

2.3.3 HAZARDS FROM SUBSTANCES

AND CONSUMABLES

Handling lubricants ……………………..…

WARNING!

Risk of health hazards from lubricants!

Contact with lubricants can provoke allergies and

skin irritation.

–Wear protective gloves when handling

lubricants.

–Do not swallow. Do not inhale vapors.

–In case of accidental contact with the eyes,

rinse out thoroughly with copious amounts

of water and consult a doctor as

necessary.

–Adhere to the lubricant manufacturer's

material safety data sheet.

–Wear protective gloves when applying and

removing liquid lubricant.

Handling acetone ………………………...

WARNING!

Health hazard from acetone!

Acetone is highly flammable, and can cause

fatigue, dizziness, and serious eye irritation.

Repeated contact can cause chapped or cracked

skin.

–Avoid contact with acetone.

–Do not eat, drink, or smoke when handling

acetone. Wash your hands before breaks

and at the end of work.

–Adhere to the acetone manufacturer's

material safety data sheet.

–When handling acetone, wear the personal

safety clothing and equipment stipulated in

the safety data sheet.

–Keep away from heat, sparks, open

flames, and hot surfaces.

–Keep the container sealed tight and in a

well ventilated place.

SAFETY

Installation Instructions for SIS Bus Bar Systems A2MS001EN revision R05

19 / 130

2.3.4 RISK OF MATERIAL DAMAGE

Improper installation / assembly …...….

NOTICE!

Risk of material damage due to improper

installation!

Improperly performed installation and assembly

work can cause considerable material damage.

–Protect connection sleeves and bus bars

from all climatic influences before and

during installation.

–It is imperative to adhere to all the

dimensions specified in the drawings in

order to prevent any insulation damage.

–Install bus bars properly. In the process,

make sure that no components fall or

topple over.

–Adhere to the stipulated tightening torque

values for bolts.

–Never stand on or load connection sleeves

and bus bars in any other way during

installation.

–Install bus bars so that they are free from

mechanical strain.

–Make sure the system is properly earthed.

–Make sure that all installation work is

carried out and completed in accordance

with the specifications and information in

these instructions and the specific project

drawings.

–In case of any doubts or problems during

installation, always consult RITZ

Instrument Transformers GmbH.

Recommendation:

After installation, perform a high voltage test to ensure

the system is properly insulated.

This does not check that the installation has been per-

formed properly! It is merely a check of the insulation!

The current load capacity is not assessed in this case!

SAFETY

Installation Instructions for SIS Bus Bar Systems A2MS001EN revision R05

20 / 130

Prohibited spacing dimensions …....…

NOTICE!

Risk of material from incorrect spacing of bus

bars!

Improper installation and incorrect spacing of

individual fixation units can lead to resonant

vibrations at certain intervals within a bus bar due

to their natural frequency. The bus bars may be

subjected to very heavy mechanical stress, and in

extreme cases the insulation may become

damaged.

–It is imperative to adhere to the spacing

dimensions between the individual sliding

bearings (Bg), fixed bearings (Bf), and the

fixation units as shown in the installation

drawing.

–If the spacing dimensions cannot be

adhered to for reasons related to the

performance of the installation or building

interferences, any change must be

coordinated with RITZ Instrument

Transformers GmbH beforehand, and

noted in the drawings.

Cutting, grinding or welding work …......

NOTICE!

Risk of material damage to the bus bar system

from cutting, grinding or welding work!

Sparks or welding spatter can cause considerable

damage to the insulation of the bus bar system.

–Welding, cutting or grinding (angle grinder)

work must never be performed in the

vicinity of the bus bar system.

–If this kind of work cannot be avoided in the

vicinity of the bus bar system being

installed, suitable safety measures (e.g.

covers) must be provided to protect the

bus bar elements.

2.4 RESPONSIBILITY OF THE

OWNER

Owner ………………………………………

The owner is the party who uses the bus bar system for

commercial or economic purposes himself or authorizes

use/operation by a third party, and bears the legal product

responsibility for the protection of the user, operating staff or

third party during operation.

Table of contents

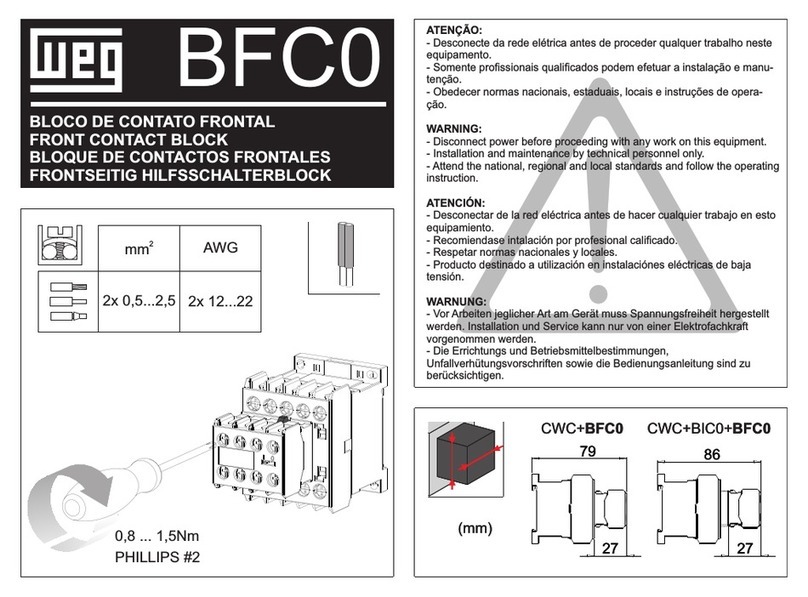

Popular Industrial Electrical manuals by other brands

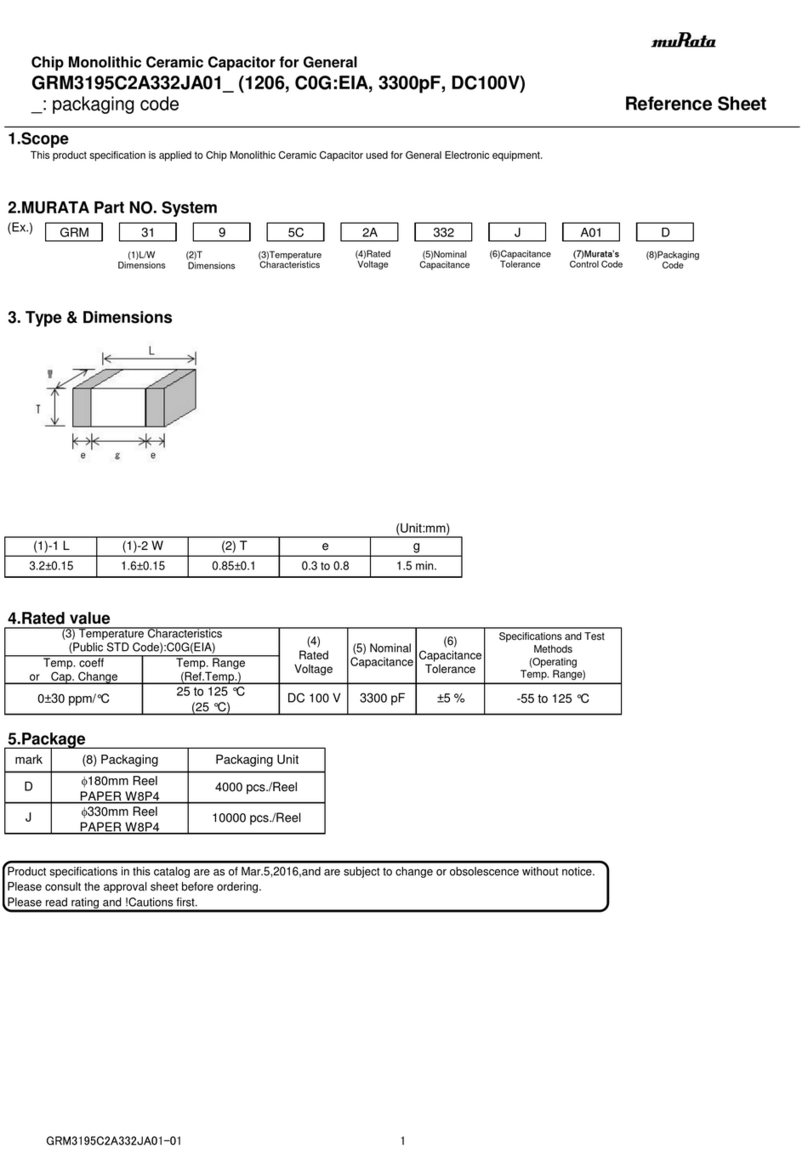

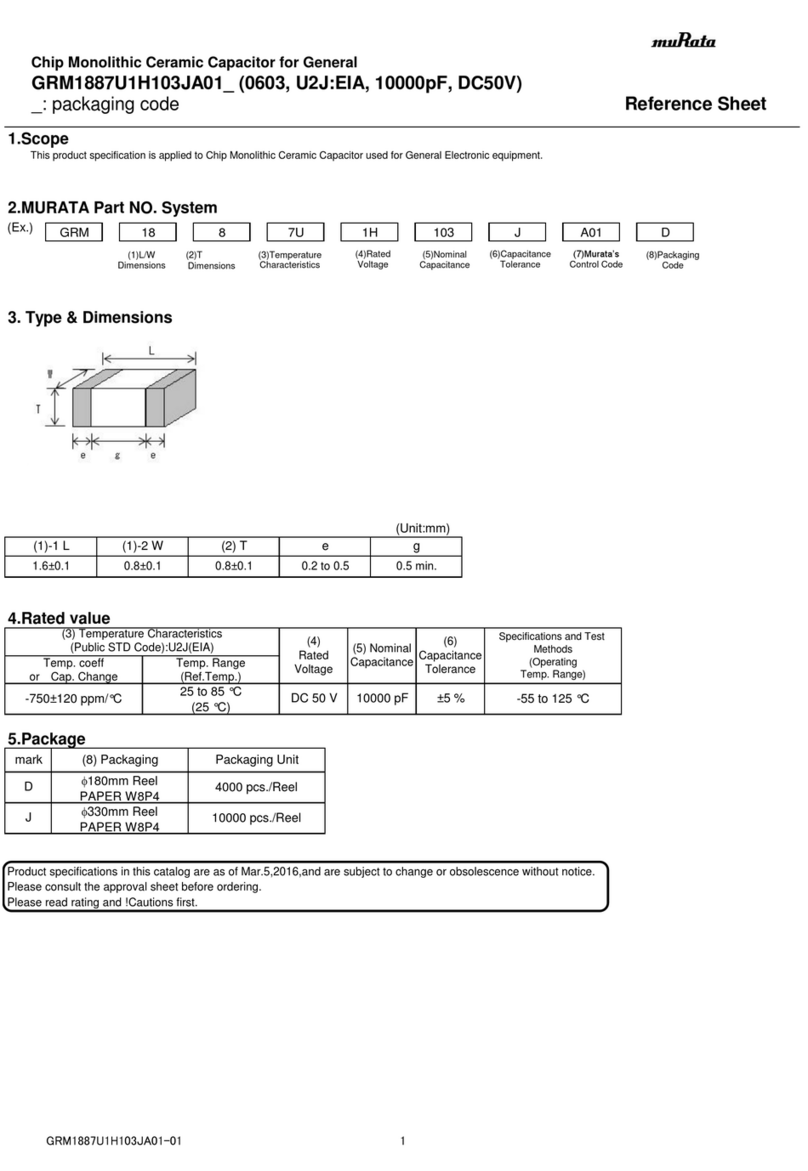

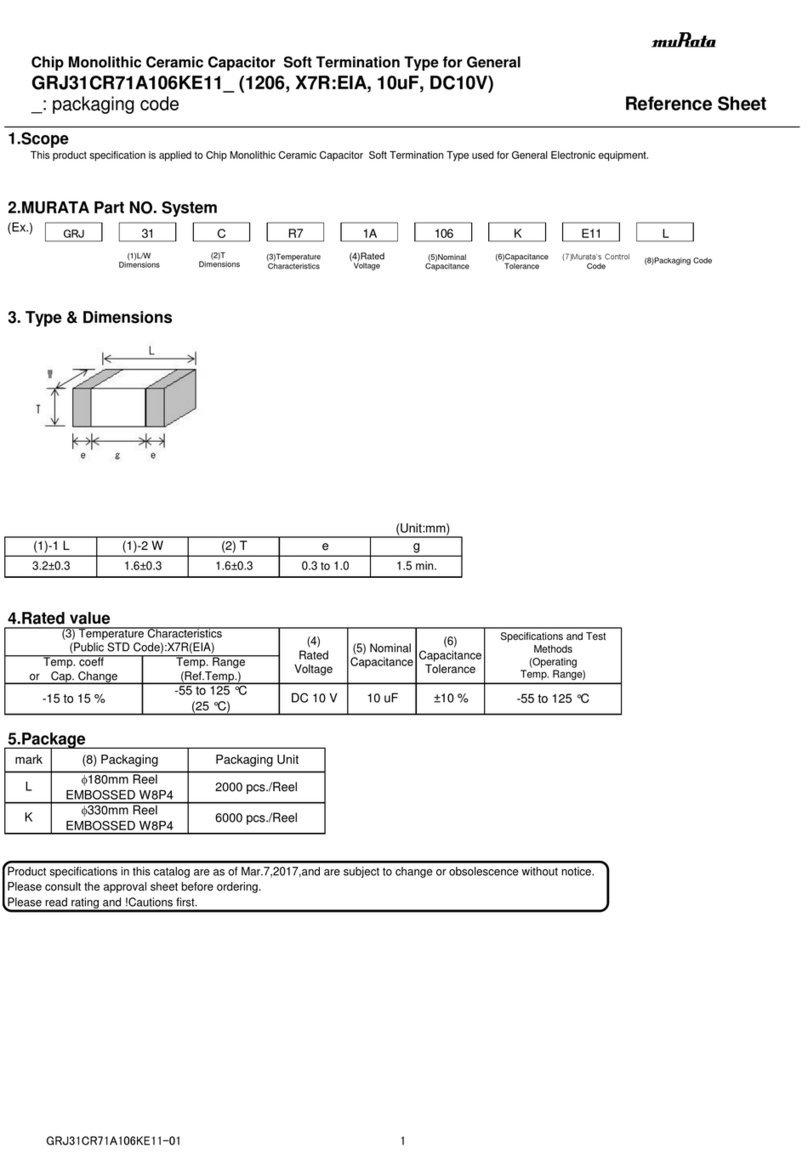

Murata

Murata GRM1887U1H103JA01 Series Reference sheet

Murata

Murata GRJ31CR71A106KE11 Series Reference sheet

Murata

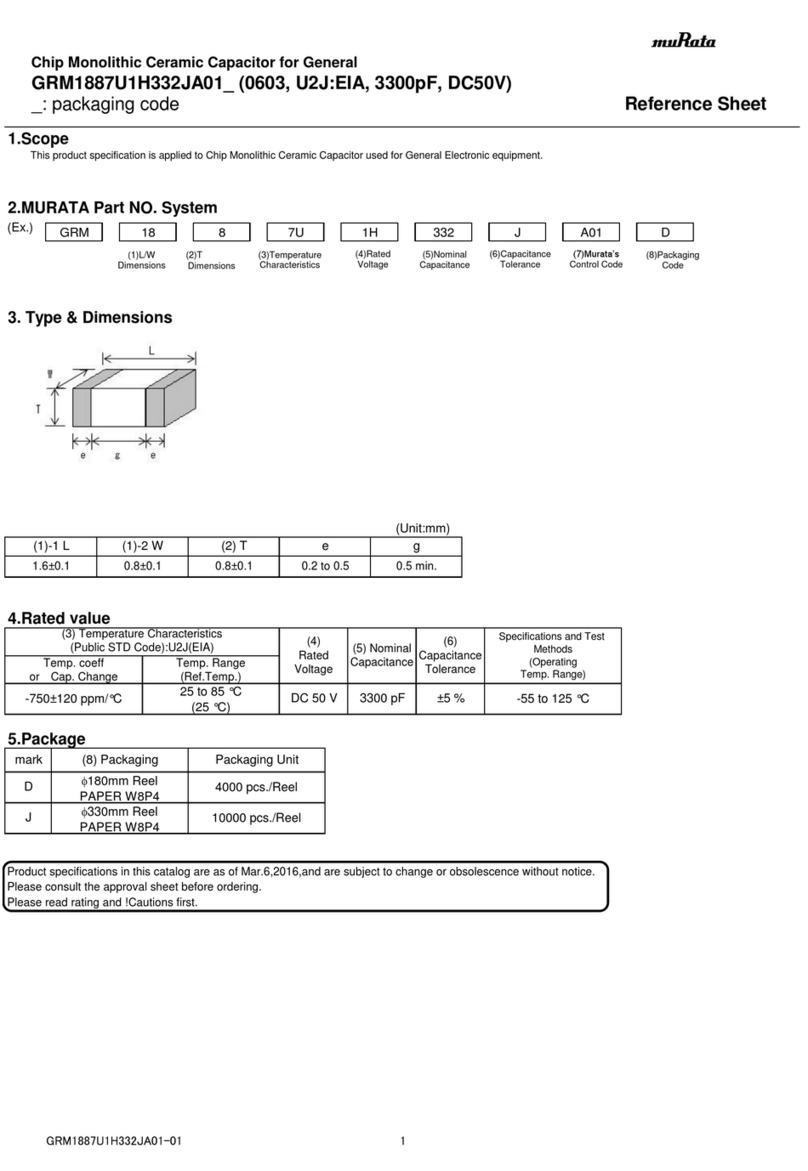

Murata GRM1887U1H332JA01 Series Reference sheet

Beckhoff

Beckhoff KL6821 Documentation

Murata

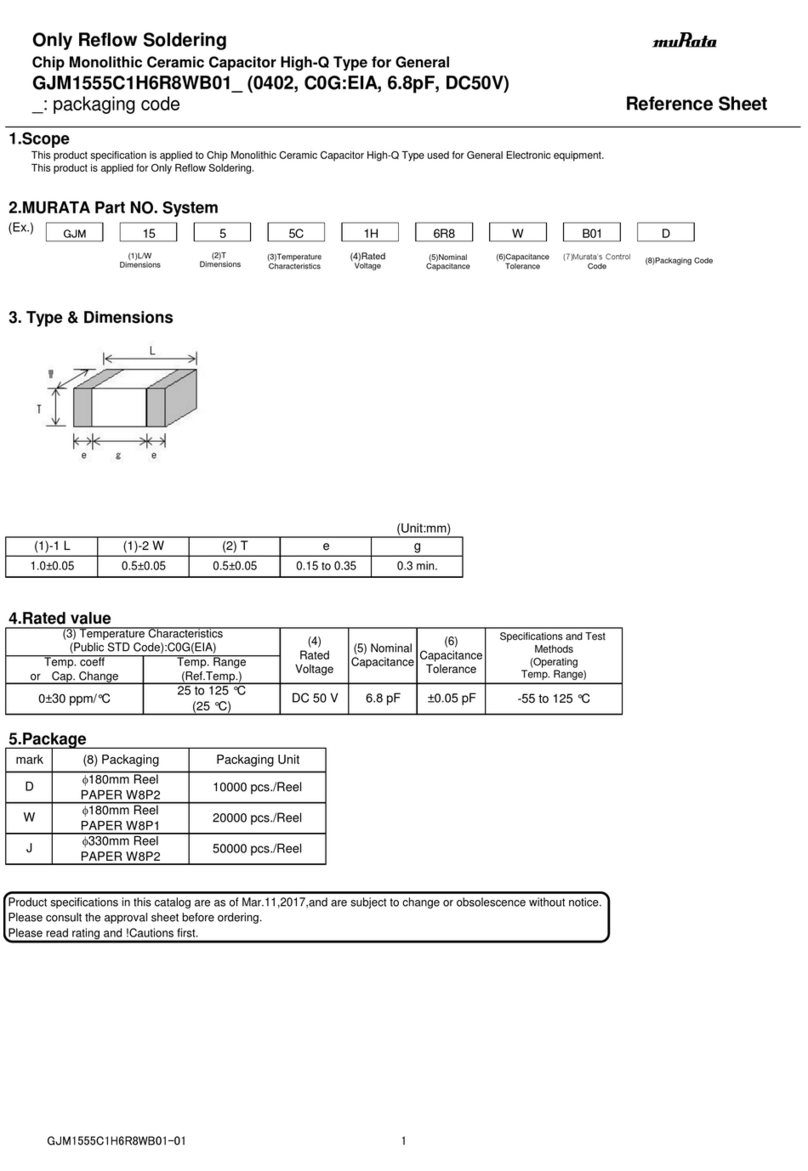

Murata GJM1555C1H6R8WB01 Series Reference sheet

Wiremold

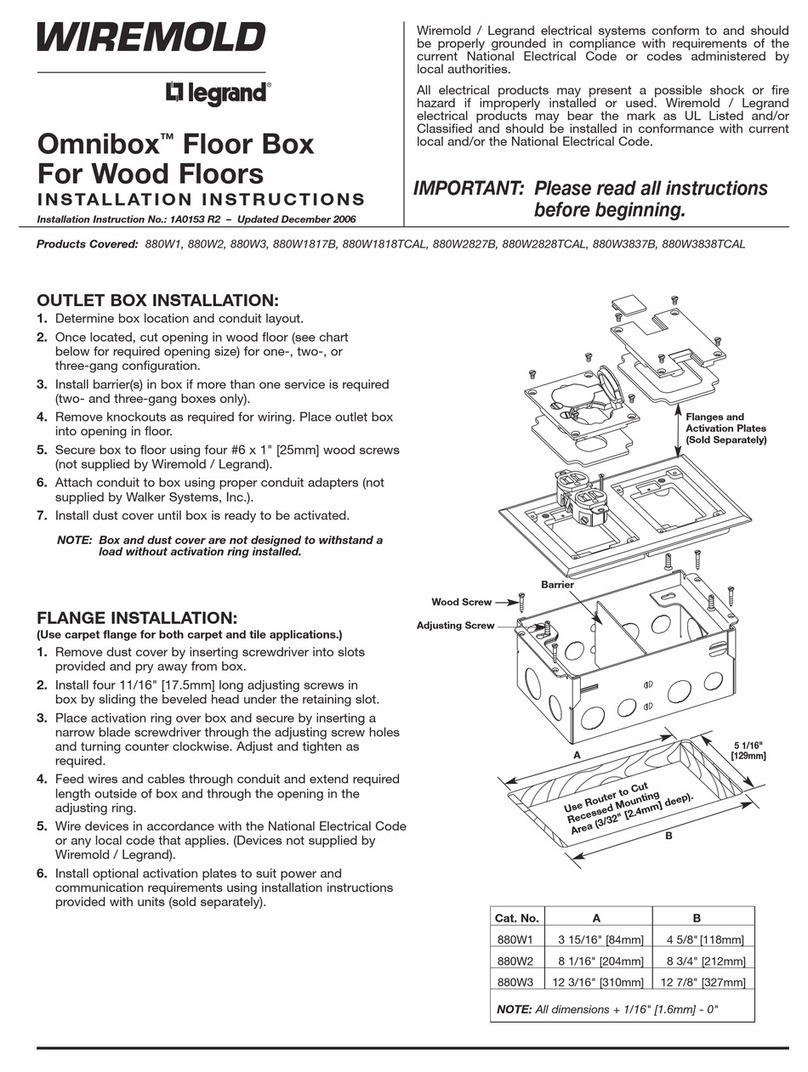

Wiremold Legrand Omnibox installation instructions