Pump Runs

Intermittently

There are small leaks in the

household plumbing

Find and x leaks

Water Temperature is too

high

Ensure the water temperature limits are

observed

Voltage is outside allowable

limits (see specications)

Check voltage level being delivered, and

correct where necessary

Not enough air ow to cool

motor

Provide adequate ventilation to motor

cooling fan

Poor

Performance

- low pressure

or ow.

Suction line is leaking Check the suction line for leaks,

especially at joints

Tank water level is too far

below the pump.

Talk to your dealer about a better pump

for your situation, or move the pump

closer to tank.

Pump is worn or damaged Ask your dealer to investigate worn

parts.

Should problems persist, contact your nearest Service Agent.

9

Pentair Water Product Warranty

Pentair Water warrants that, when this product is used for the purpose it was designed, is correctly housed and vented

against weather, vermin, dust etc., that it will be free of material and manufacturing defects at the time of the original

purchase. This warranty is limited to the cost of the product and does not cover third party costs including

the costs of electricians, plumbers, etc. unless authorised by Pentair Water.

1) YOU SHOULD CAREFULLY READ THE INSTRUCTIONS SUPPLIED PRIOR TO USING THIS PENTAIR WATER

PRODUCT.

This product is to be installed and operated in accordance with the instructions provided. This warranty will

not apply if it is used in a manner other than in accordance with the instructions.

What the warranty covers:

Pentair Water warrants its products to be free of defects in material and workmanship during the warranty

period. If a product proves to be defective in material or workmanship during the warranty period, then

Pentair Water will, at its sole option repair or replace the product with a like product. Replacement product or

parts may include re-manufactured or refurbished parts or components.

How long the warranty is effective:

1) This Pentair Water product is warranted for 12 months for all parts from the date of the rst consumer

purchase.

2) Where this Pentair Water product is sold for commercial application as dened in the relevant Trade

Practices and Consumer Protection legislation the warranty shall be for a period of six months from the

date of purchase by the end user.

Who the warranty protects: This warranty is valid only for the consumer purchaser.

What the warranty does not cover:

1) Damage, deterioration or malfunction resulting from:

a) accident, misuse, negligence, re, water, lightning, or other acts of nature, unauthorised product

modication or failure to follow instructions supplied with the product;

b) repair or attempted repair by anyone not authorised by Pentair Water;

c) any damage to the product due to shipment;

d) removal or installation of the product;

e) causes external to the product such as electric power uctuations or failure;

f) use of supplies or parts not meeting Pentair Water specications;

g) normal wear and tear;

h) water ingression or exposure to abnormal corrosive conditions or “run dry” conditions;

2

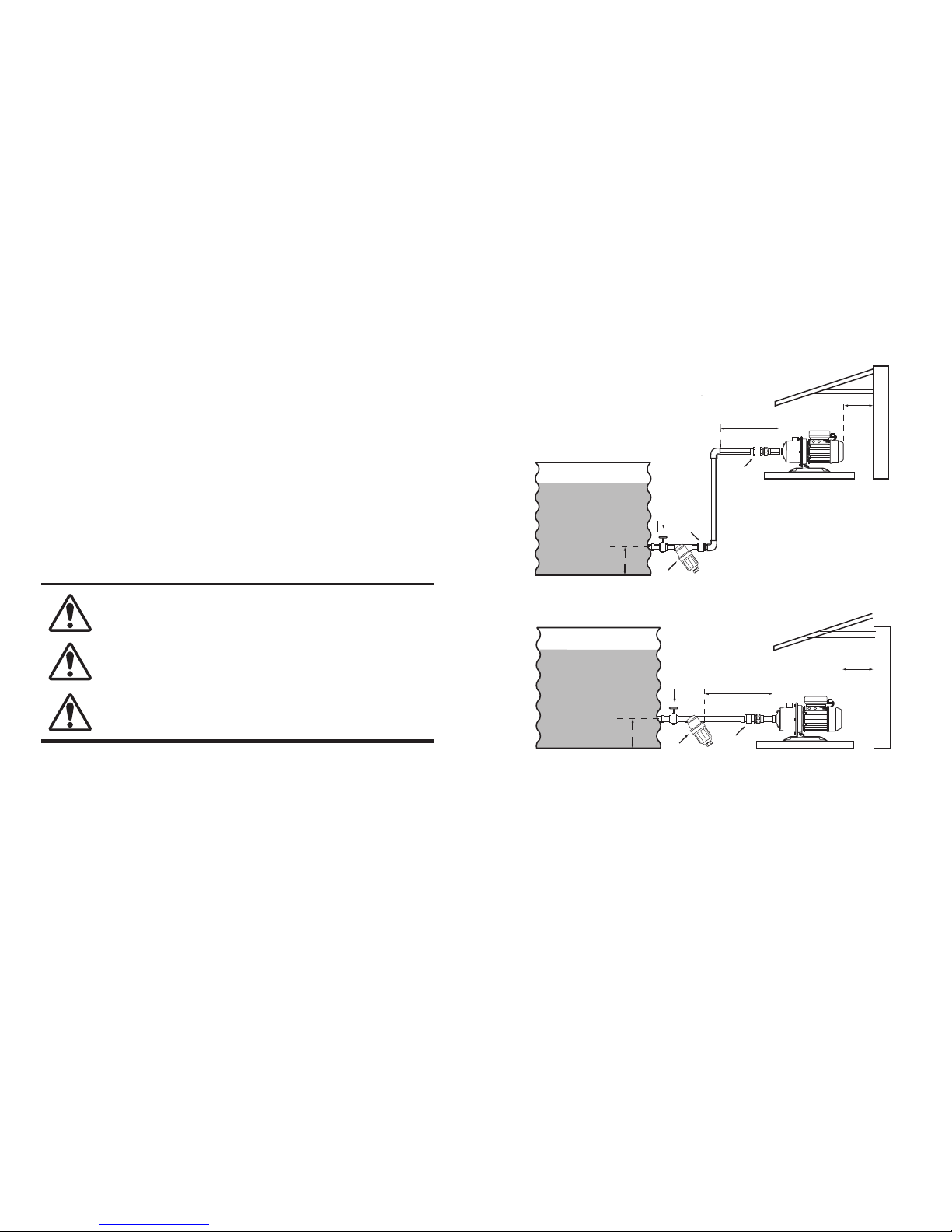

Installation

The electrical installation shall be in accordance with the national

wiring rules (AS/NZS 3000) for class 1, IP44 rated products.

These instructions are a guide only. Users not familiar with

pumping equipment should seek advice from people experienced

in pump equipment and installation.

Freezing conditions will damage the unit, because when water

freezes it expands. Ensure that the pump is located so that it is

not prone to freezing, or ensure that the product is disconnected

and dried of water during cold conditions.

The pump is electrically connected. Ensure that it is isolated

from electrical supply during installation and any subsequent

service work.

The pump is designed to be used with clean water in a residential

application. Do not use it with alternative uids, abrasive,

corrosive or explosive uids. Do not install or operate your pump

in an explosive environment or near combustible matter.

Incorrectly installed or tested equipment may fail, causing severe

injury or property damage.

Fire and burn hazard. Modern motors run at high temperatures.

To reduce risk of re, do not allow leaves, debris, or foreign

matter to collect around the pump motor. To avoid burns when

handling the motor, let it cool for at least 20 minutes before trying

to work on it. A thermal overload switch protects the motor for

heat damage during operation.

Read the following instructions in this owner’s manual when installing and

operating equipment.

1. Preparation for Installation

Inspect your pump for shipping damage. Report any damage to your Dealer. Make sure

the suction piping is free of air leaks and is laid so that there can be no airlocks.

Warranty of these pumps is void unless they are operated in accordance with this

owner’s manual.