INTRODUCTIONINTRODUCTION

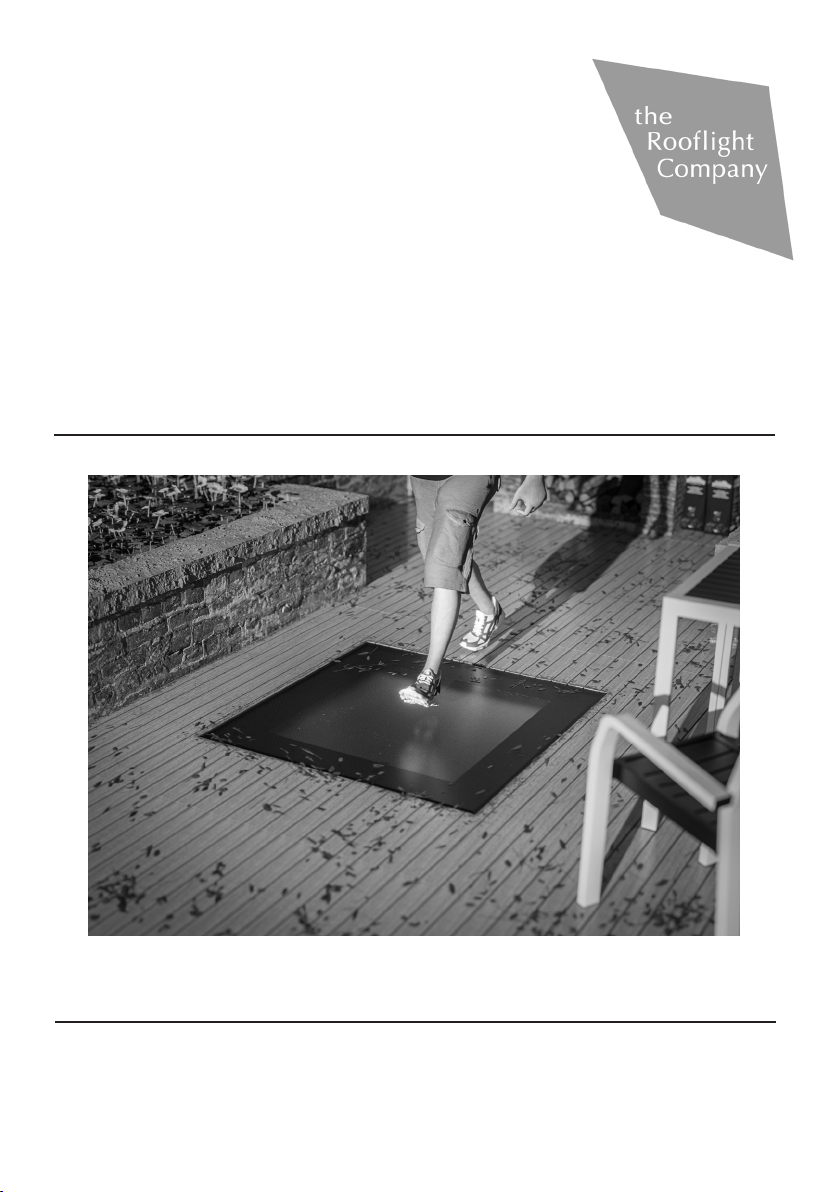

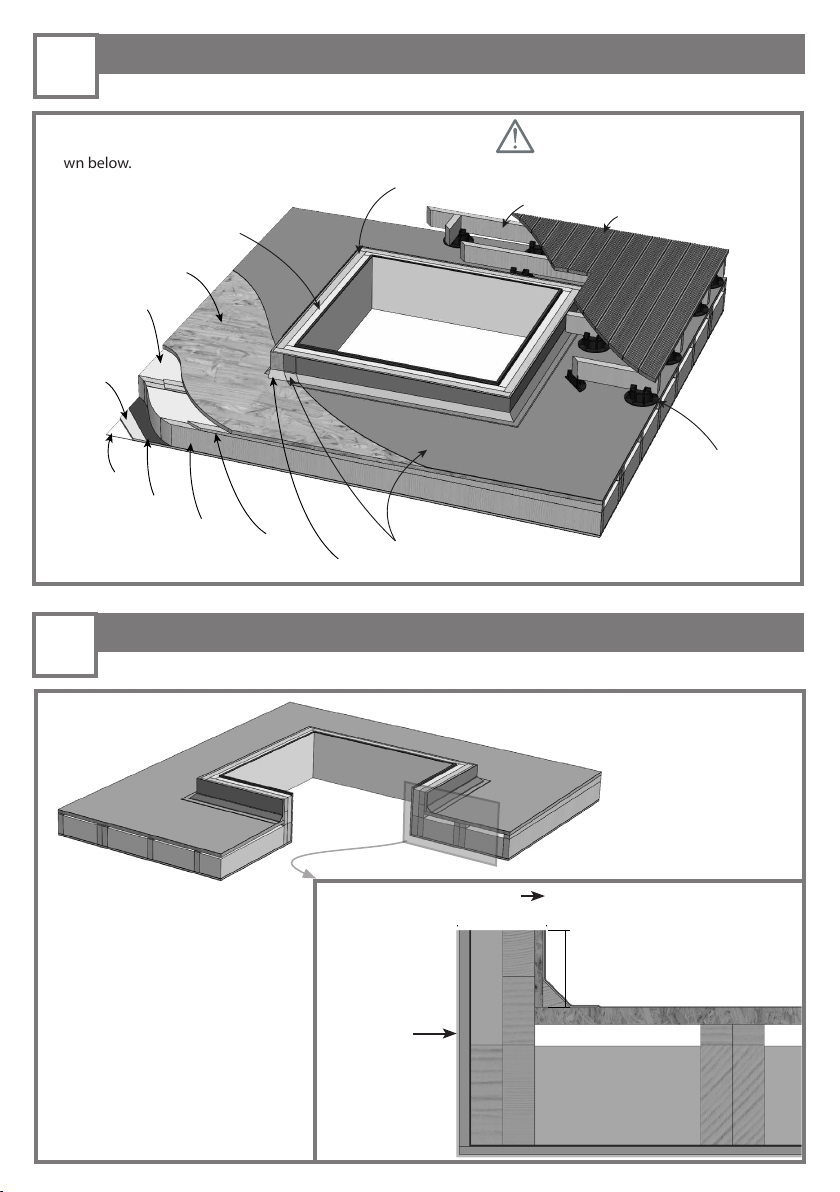

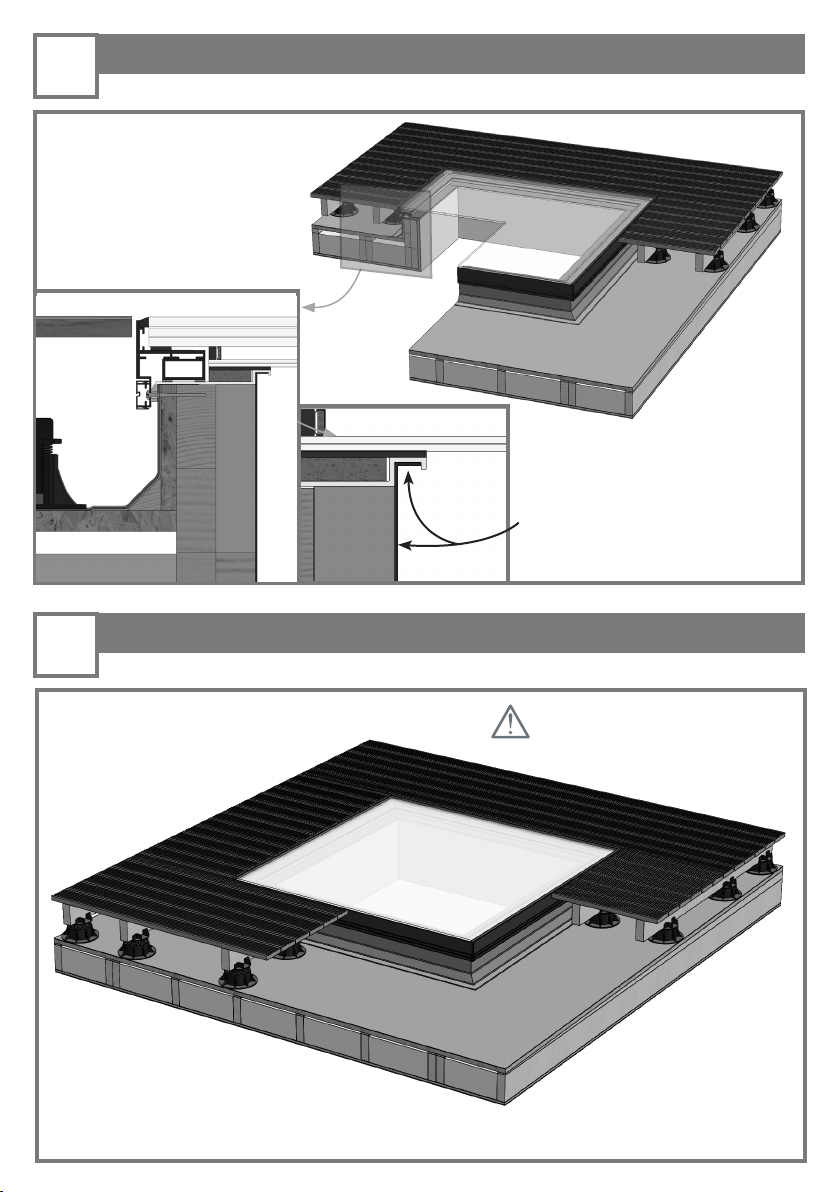

Thank you for choosing the neo Advance Skywalk™ rooflight, we are sure it will provide a high-quality

finishing touch to your project. This is a step by step guide to installing the neo Advance Skywalk™ and

neo Advance Skywalk™ + walk-on rooflights.

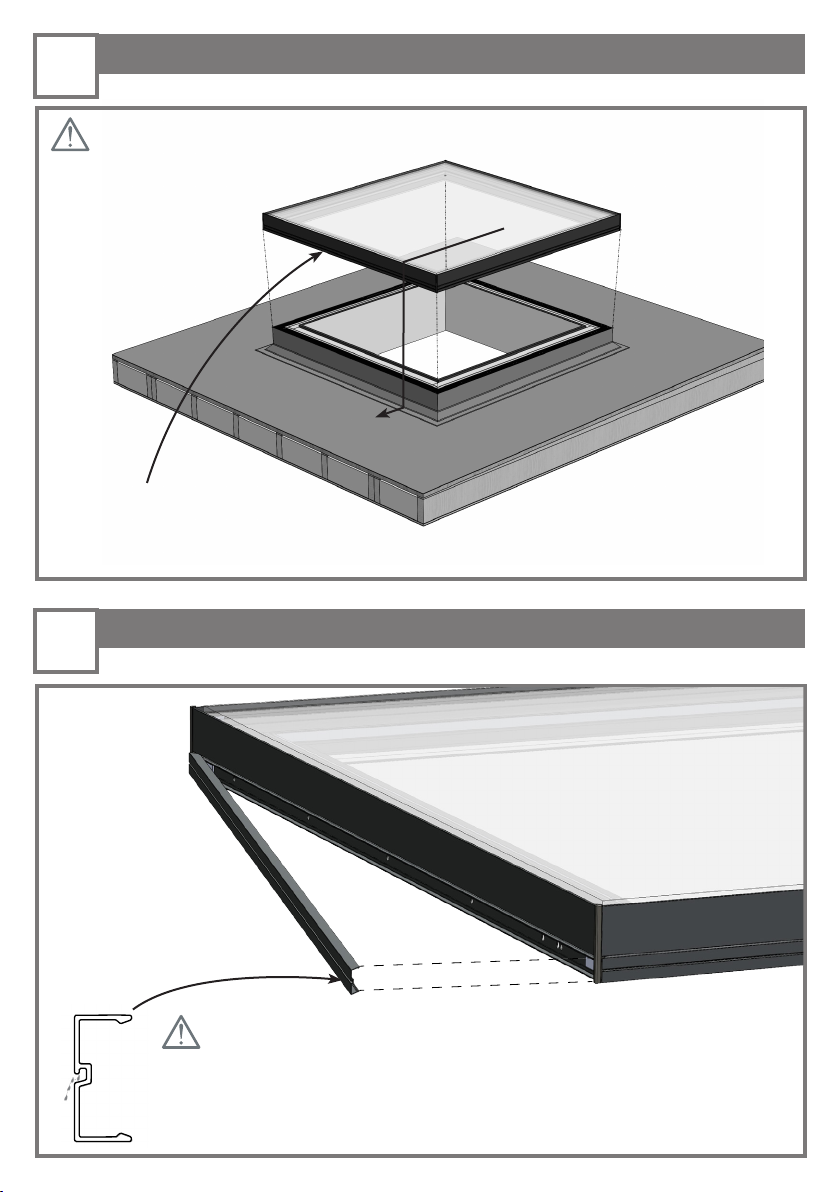

The step-by-step process must be followed in numerical order to ensure the installation is correct. Every

project is different therefore it may be necessary to adapt the installation to suit the structure.

What you need to know about theWhat you need to know about the neo Advance Skywalk™::

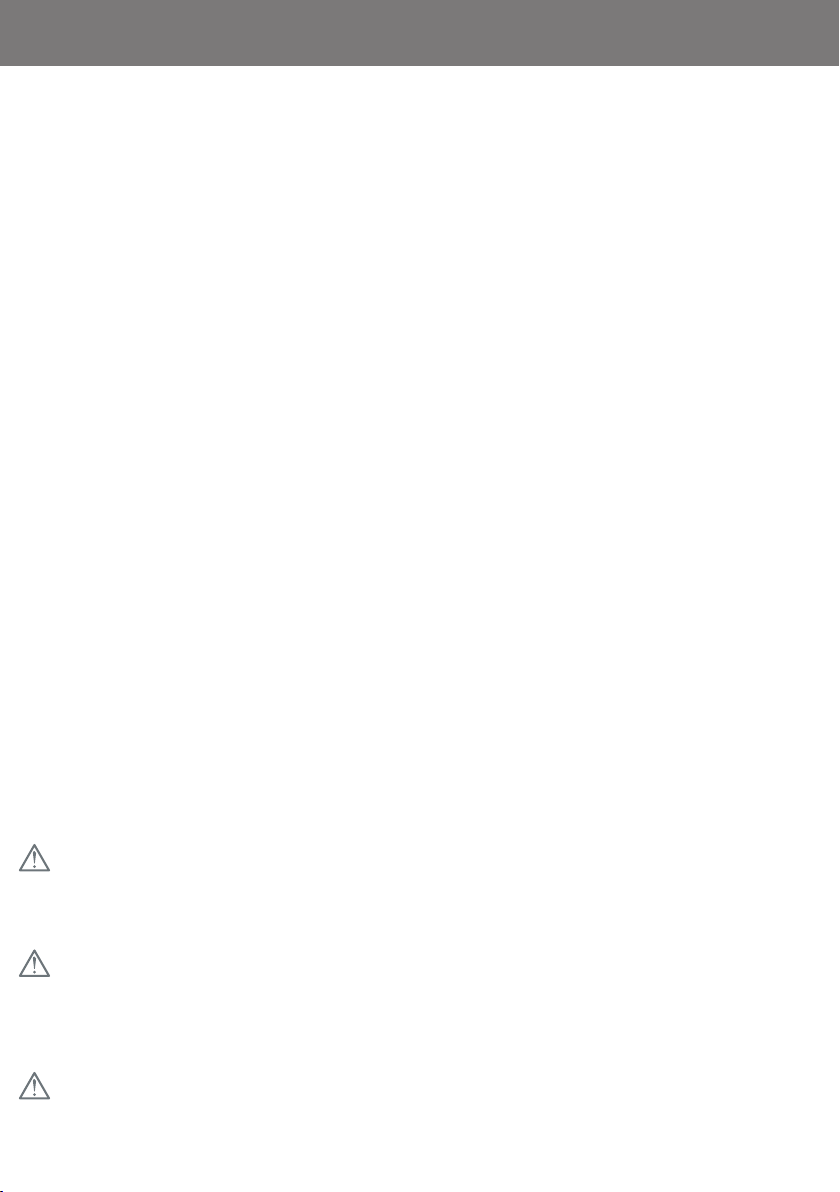

- It should be installed in plane with the finished walk-on surface ensuring there is no potential for water

pooling.

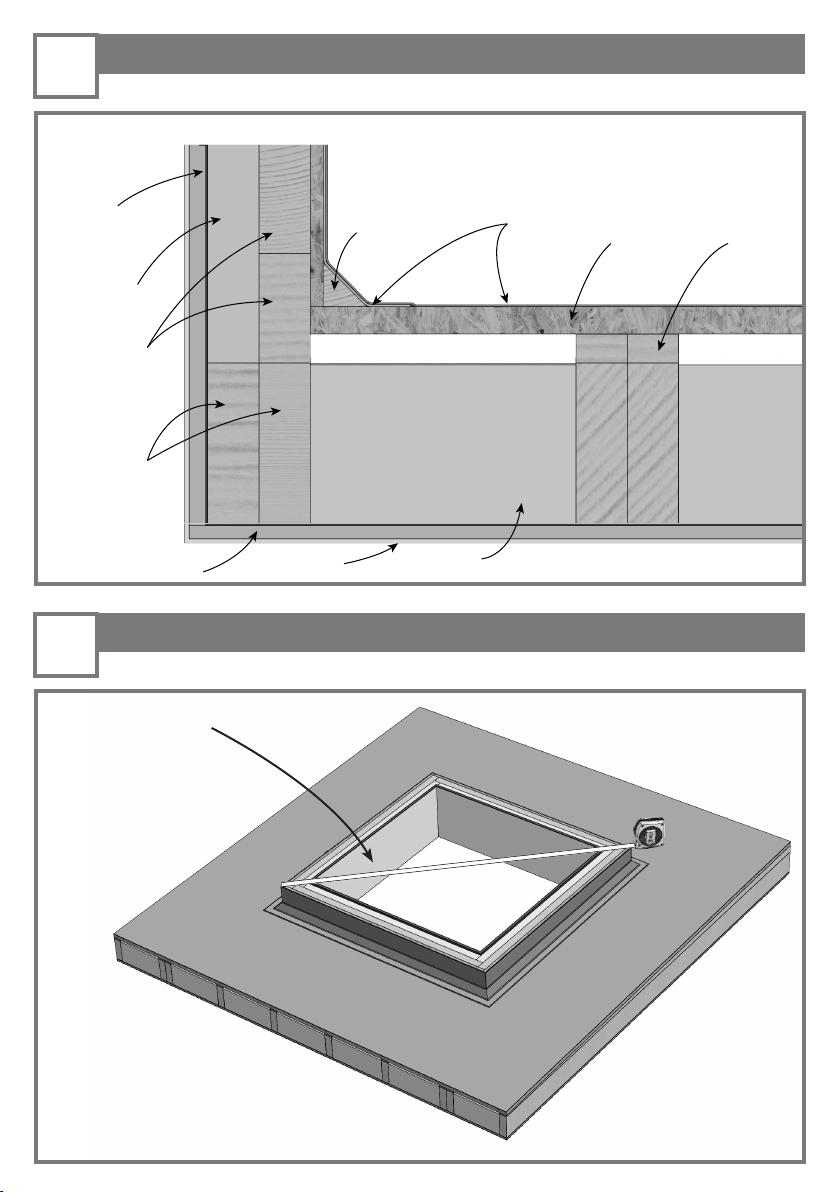

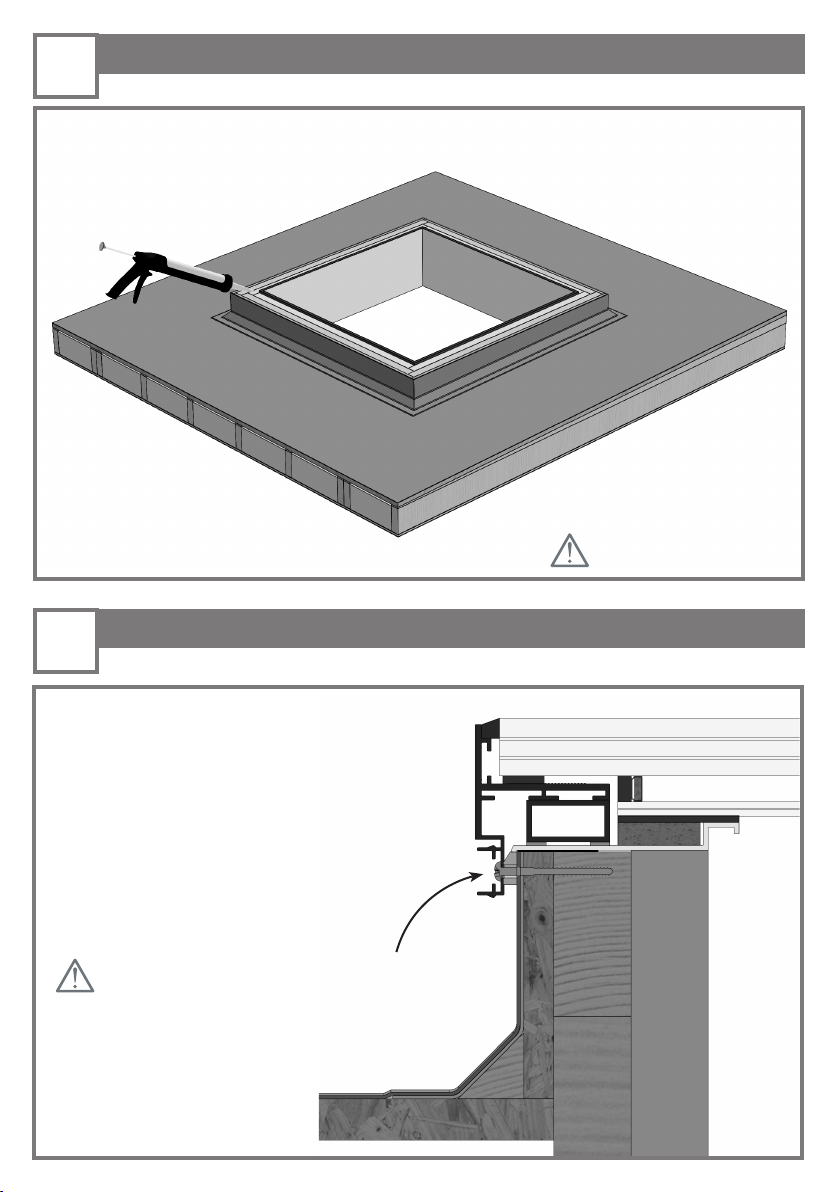

- The following installation details pertain to a timber deck over a membrane roof finish, installed on an

insulated timber kerb.

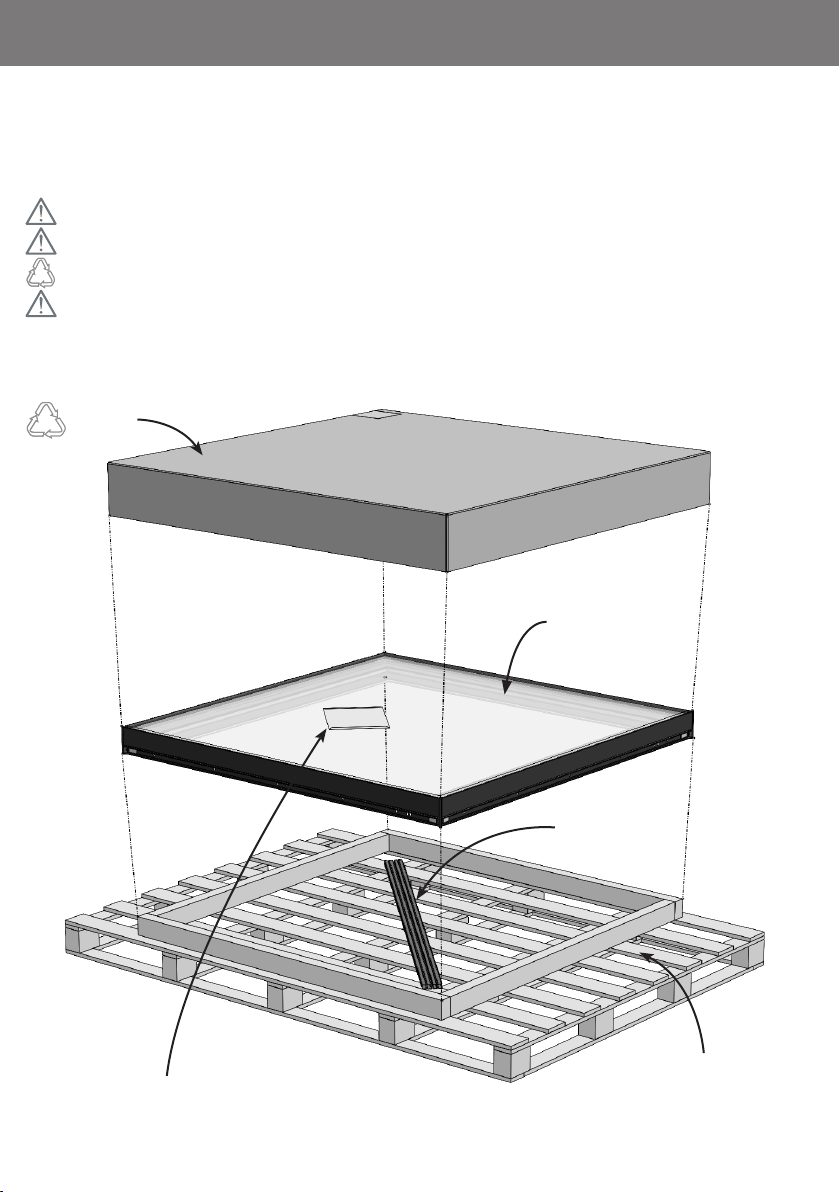

All of the images in this guide are diagrammatic (with some components omitted for clarity). They

should be used as a reference. Installation instructions are regularly reviewed and we reserve the right

to update or amend these details without alteration to this guide.

CARE AND MAINTENANCE

To achieve the maximum service life from the neo Advance Skywalk™ rooflight it is important that

scheduled care and maintenance is undertaken. Please note that the guarantee will become void if the

procedures outlined in this manual and the separately supplied maintenance manual are not adhered

to. Please refer to the Operations and Maintenance Guide for further details.

ADVISORY

Standard rooflight. All the information provided in this document refers to a standard

specification neo Advance Skywalk™ rooflight.

Install in accordance with national building regulations / codes. This manual is an installation

suggestion and installers should verify ‘fitness for purpose’ in accordance with all applicable

regulations / standards at time of installation.

Structural supports for the neo Advance Skywalk™ rooflight are to be

designed and supervised during construction by the rooflight installer or project structural

engineer. Nothing in this manual constitutes a structural proposal. Sizing / positioning of

structural supports should be determined by the projects suitably qualified structural engineer.