Contents

1-INTRODUCTION ..............................................................................................................1

1.1 OVERVIEW...........................................................................................................................1

1.2 SAFETY ...............................................................................................................................1

1.3 PRODUCT FEATURES............................................................................................................1

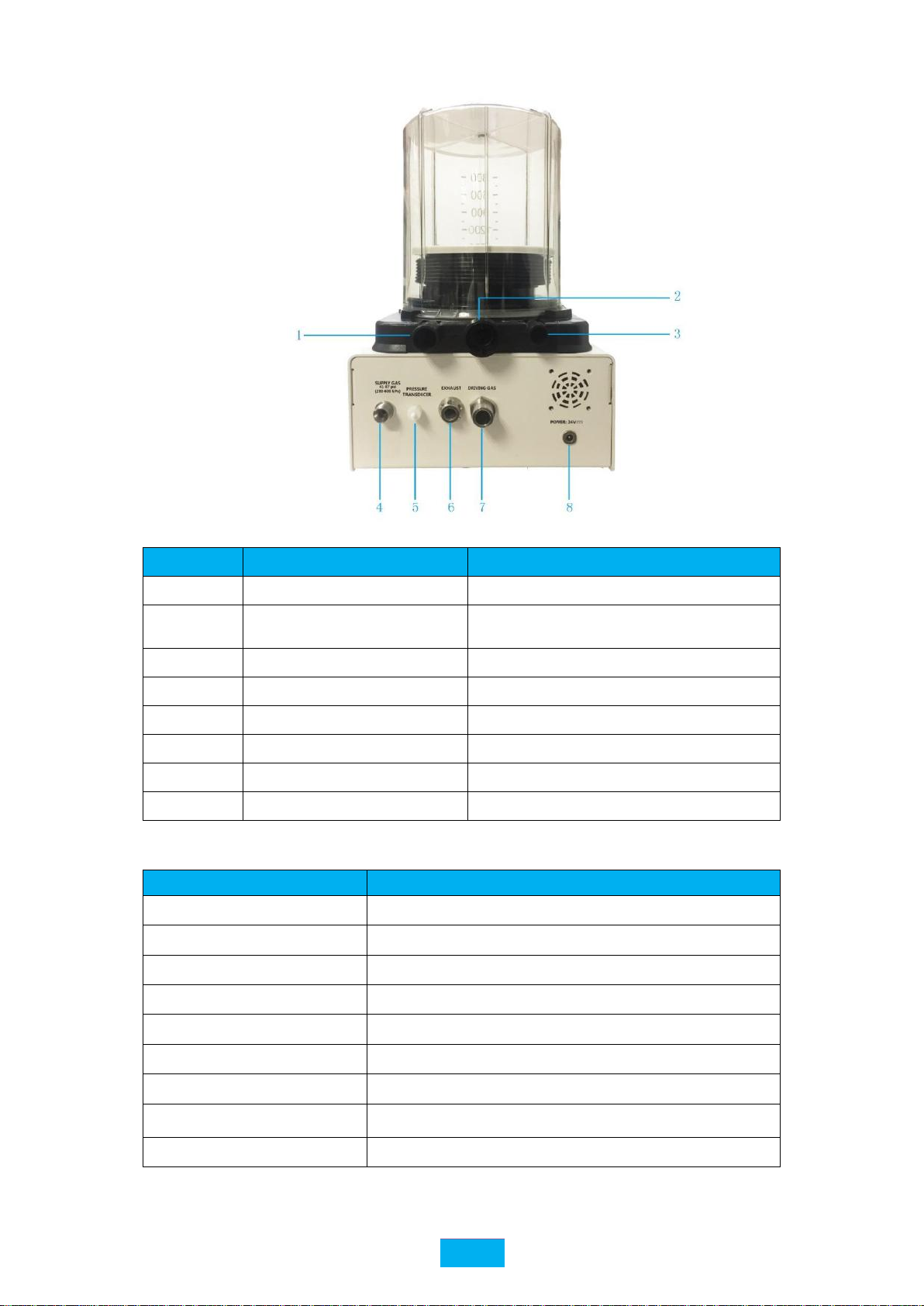

1.4 INTRODUCTION OF DEVICE’S MAIN COMPONENTS ................................................................2

1.5 SPECIFICATION ....................................................................................................................3

2-SYSTEM SAFETY .............................................................................................................4

2.1 SAFETY INSTRUCTIONS........................................................................................................4

2.2 CAUTIONS ...........................................................................................................................4

2.3 SAFETY INSTRUCTIONS........................................................................................................5

2.4 WARRANTY.........................................................................................................................5

3-UNPACKING AND ASSEMBLY ......................................................................................7

3.1 NOTICE FOR USE .................................................................................................................7

3.2 INSTALLATION .....................................................................................................................7

4-OPERATING INSTRUCTION .......................................................................................10

4.1 POWER-ON SELF-CALIBRATION/TEST ................................................................................10

4.2 LEAKAGE DETECTING .......................................................................................................11

4.3 MODE SETTING .................................................................................................................11

4.4 WEIGHT SETTING ..............................................................................................................12

4.5 SETTING OF BREATHING PARAMETERS ..............................................................................13

4.6 ADD, CALL, DELETE AND ADJUST PARAMETERS...............................................................14

4.6.1 Add Parameters.............................................................................................................14

4.6.2 Call Parameters ............................................................................................................14

4.6.3 Delete Parameters.........................................................................................................15

4.6.4 Adjust Parameters.........................................................................................................15

4.7 SYSTEM SETTING ..............................................................................................................16

4.7.1 Brightness Control ........................................................................................................16

4.7.2 Chinese-English shift ....................................................................................................16

4.7.3 Calibration ....................................................................................................................16

4.8 ALARM INFORMATION AND PROCESSING ...........................................................................17

4.8.1 Alarm Prompt of High Airway Pressure .......................................................................17

4.8.2 Alarm Prompt of “High / Low Gas Source Pressure” ..................................................18

4.8.3 Alarm Prompt of “Low Flow” ....................................................................................19

4.8.4 Alarm Prompt of Breathing Tubes Blocked...................................................................19

4.8.5 Alarm prompt of is Low Battery....................................................................................20

4.8.6 Alarm Prompt of Over-temperature ..............................................................................20

4.8.7 Alarm prompts for Circuit abnormality ........................................................................20

4.8.8 Message Prompt of “Inspiration hold” ........................................................................20

5-CLEANING AND MAINTENANCE..............................................................................22

5.1 PRODUCT CLEANING .........................................................................................................22